transfer case ISUZU KB P190 2007 Workshop Owner's Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 3937 of 6020

Automatic Transmission – 4L60E – On-vehicle Servicing Page 7C4–24

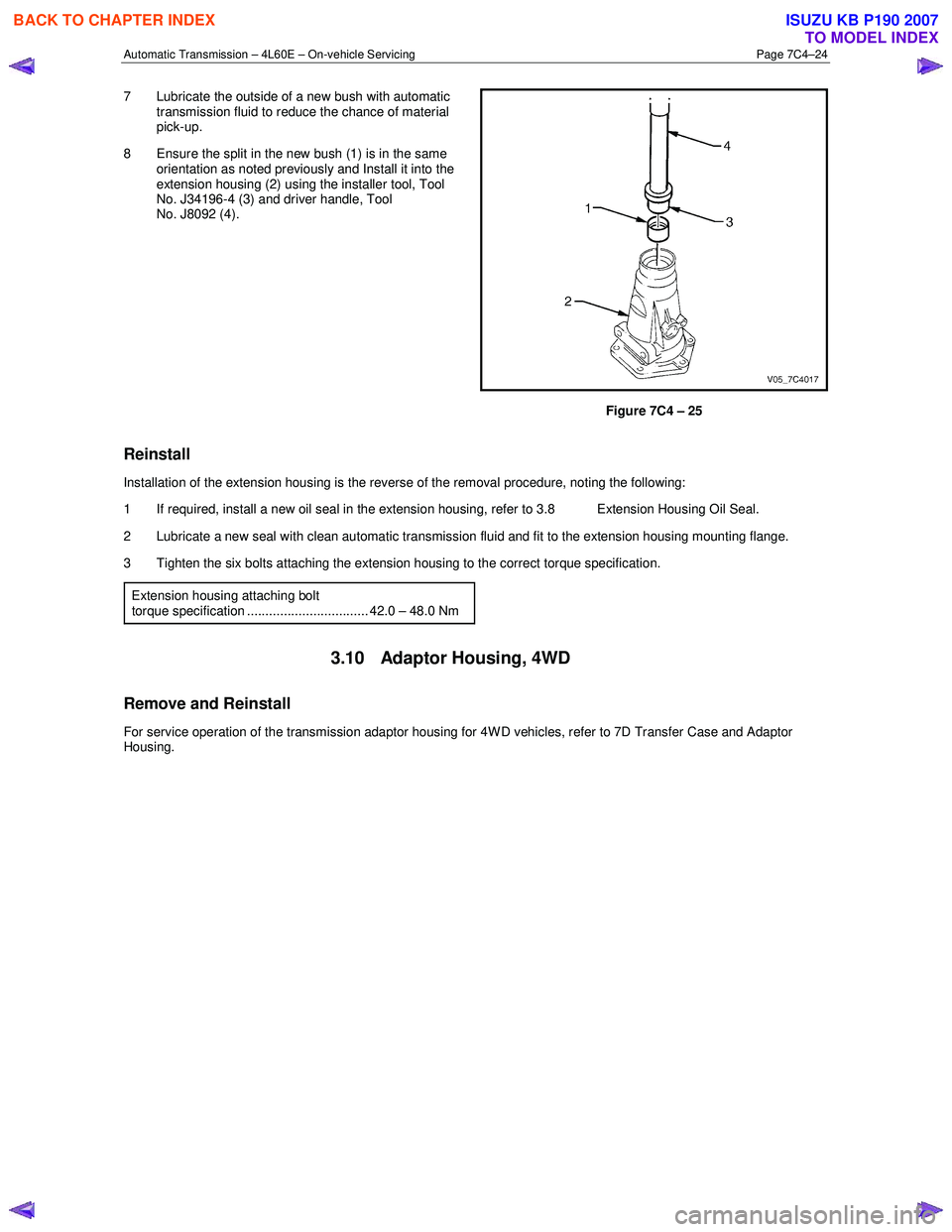

7 Lubricate the outside of a new bush with automatic

transmission fluid to reduce the chance of material

pick-up.

8 Ensure the split in the new bush (1) is in the same orientation as noted previously and Install it into the

extension housing (2) using the installer tool, Tool

No. J34196-4 (3) and driver handle, Tool

No. J8092 (4).

Figure 7C4 – 25

Reinstall

Installation of the extension housing is the reverse of the removal procedure, noting the following:

1 If required, install a new oil seal in the extension housing, refer to 3.8 Extension Housing Oil Seal.

2 Lubricate a new seal with clean automatic transmission fluid and fit to the extension housing mounting flange.

3 Tighten the six bolts attaching the extension housing to the correct torque specification.

Extension housing attaching bolt

torque specification ................................. 42.0 – 48.0 Nm

3.10 Adaptor Housing, 4WD

Remove and Reinstall

For service operation of the transmission adaptor housing for 4W D vehicles, refer to 7D Transfer Case and Adaptor

Housing.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3956 of 6020

Automatic Transmission – 4L60E – On-vehicle Servicing Page 7C4–43

If the verifier disc does not clip into place, the

quick-connect fitting is not engaged, rectify

as required.

10 As a security check, push and clip each verification disc into place over the quick-connect fittings. If difficulty is experienced, repeat the installation process until the verification disc can be clipped into place over the radiator

quick-connect fitting.

11 Snap the outlet cooler line (4) in the clip (5) of the radiator fan shroud.

12 Ensure the routeing of the cooler lines is correct and there is no fouling of the lines.

13 Tighten the screw attaching the cooler lines bracket to the correct torque specifications.

Transmission cooler lines bracket

attaching screw torque specification .................. 23.0 Nm

14 If required, top up the transmission fluid level (cold).

15 Start the engine and check for any fluid leak at the fittings. If a leak is found, stop the engine and rectify the leak.

16 Check and top up the transmission fluid to the correct level as required, refer to 2.1 Transmission Fluid.

3.18 Transmission Assembly

Remove

Disconnection of the battery affects certain

vehicle electronic systems. Refer to 6D1-3

Battery, before disconnecting the battery.

1 Disconnect the battery ground lead.

2 Raise the vehicle and support in a safe manner, refer to 0A General Information for the location of support points.

3 Remove the heat shield from the neutral start and back-up lamp switch, gently prise the selector cable from the transmission external manual shaft linkage and remove the selector cable from the bracket, refer to

3.3 Selector Cable Assembly.

4 Disconnect the harness connectors from the following:

a Vehicle speed sensor, refer to 3.5 Vehicle Speed Sensor.

b Neutral start and back-up switch, refer to 3.4 Neutral Start and Back-up Lamp Switch.

c For the following on four wheel drive vehicles (4W D), refer to 7D Transfer Case and Adaptor Housing:

• neutral switch,

• 2WD – 4WD shift actuator switch,

• speed sensor.

NOTE

If the battery is connected, avoid turning the

ignition switch to the ON position, as the transfer

case control module (TTCM) must first be

removed (memory to be cleared as Check 4W D

Indicator will light).

5 Remove the following components: a Front and centre exhaust assemblies, refer to 6F Exhaust System.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3957 of 6020

Automatic Transmission – 4L60E – On-vehicle Servicing Page 7C4–44

b Starter motor, refer to 6D1-2 Starting System.

b Rear propeller shaft and for 4WD front propeller shaft, refer to 4A Propeller Shaft.

6 On 4WD vehicle, disconnect the harness two clips from the upper side of the transfer case.

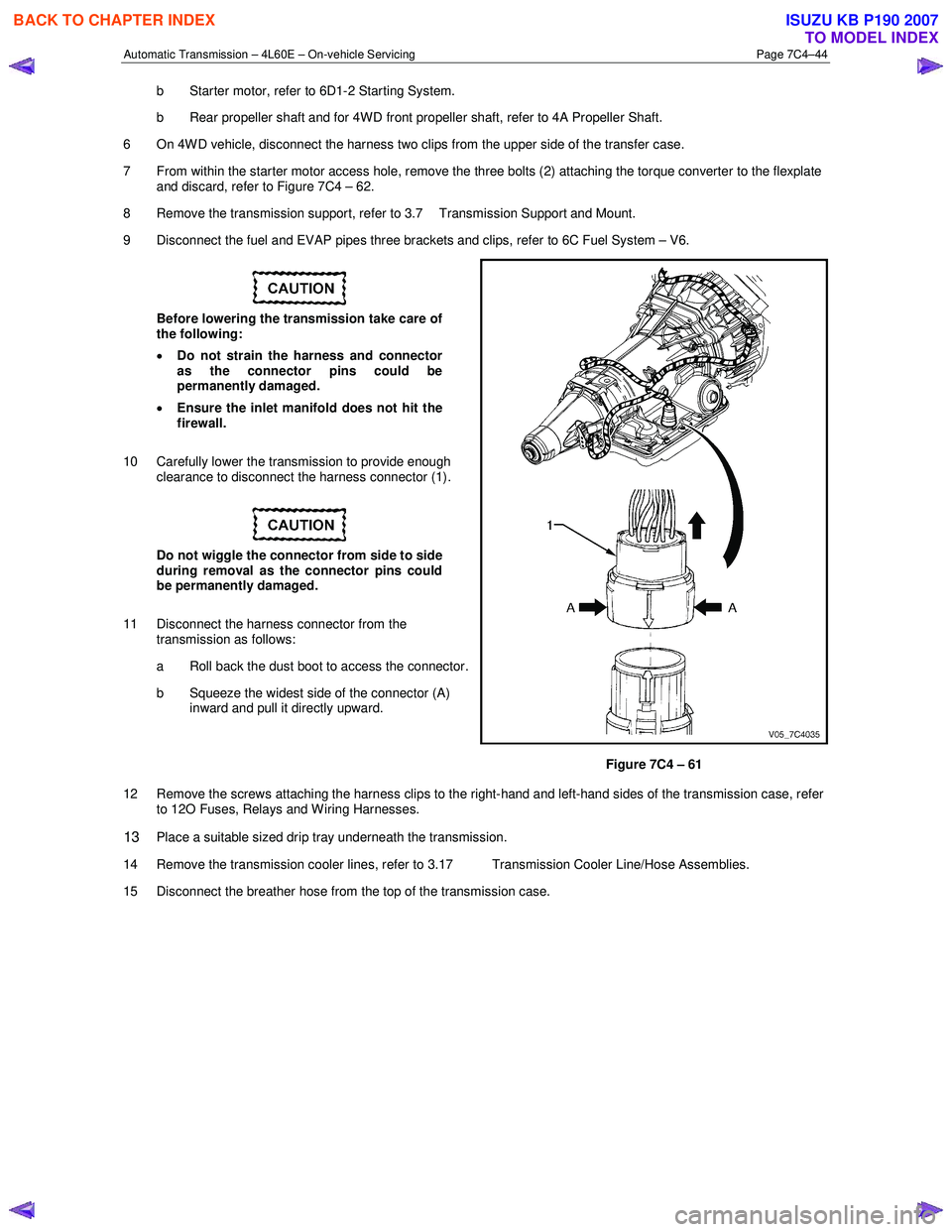

7 From within the starter motor access hole, remove the three bolts (2) attaching the torque converter to the flexplate and discard, refer to Figure 7C4 – 62.

8 Remove the transmission support, refer to 3.7 Transmission Support and Mount.

9 Disconnect the fuel and EVAP pipes three brackets and clips, refer to 6C Fuel System – V6.

Before lowering the transmission take care of

the following:

• Do not strain the harness and connector

as the connector pins could be

permanently damaged.

• Ensure the inlet manifold does not hit the

firewall.

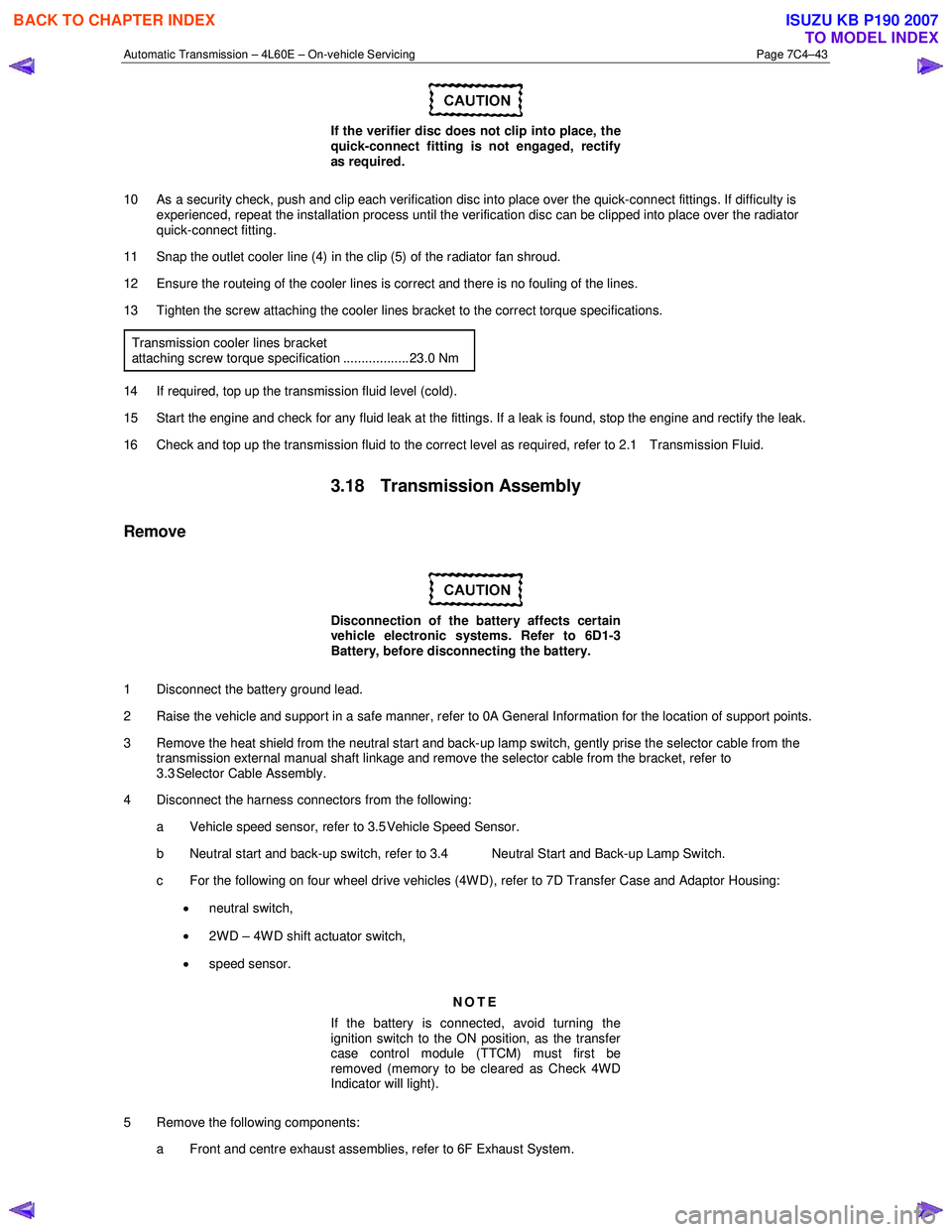

10 Carefully lower the transmission to provide enough clearance to disconnect the harness connector (1).

Do not wiggle the connector from side to side

during removal as the connector pins could

be permanently damaged.

11 Disconnect the harness connector from the transmission as follows:

a Roll back the dust boot to access the connector.

b Squeeze the widest side of the connector (A) inward and pull it directly upward.

Figure 7C4 – 61

12 Remove the screws attaching the harness clips to the right-hand and left-hand sides of the transmission case, refer to 12O Fuses, Relays and W iring Harnesses.

13 Place a suitable sized drip tray underneath the transmission.

14 Remove the transmission cooler lines, refer to 3.17 Transmission Cooler Line/Hose Assemblies.

15 Disconnect the breather hose from the top of the transmission case.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3958 of 6020

Automatic Transmission – 4L60E – On-vehicle Servicing Page 7C4–45

Support the transmission when removing the

attaching bolts to avoid damage to the torque

converter and flexplate. Do not have the

transmission hanging.

NOTE

The bolts attaching the torque converter housing

are facing forward except for the bolt in position ℑ

which is facing rearward.

16 W ith the transmission supported, using a long socket extension, universal joint and suitable size socket, remove the bolt (1), nine places, attaching the torque converter housing to the engine, in the reverse order of the torque

sequence shown in

within Figure 7C4 – 62.

The transmission assembly must not be

allowed to rest on its oil pan.

17 Support the transmission assembly on a suitable cradle and secure it. Place a suitable support under the engine oil pan rail to support the engine after the transmission has been removed.

18 Remove the transmission assembly, disengaging the filler tube attached to the engine.

19 Remove the bolt (3) and torque converter cover (4) on the transmission right-hand side, remove the bolt (5) and torque converter cover (6) on the transmission left-hand side.

20 Install a suitable holding tool to prevent the torque converter from becoming dislodged.

21 If required on 4W D vehicle, remove the transfer case, refer to 7D Transfer Case and Adaptor Housing.

Figure 7C4 – 62

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3959 of 6020

Automatic Transmission – 4L60E – On-vehicle Servicing Page 7C4–46

Reinstall

1 If required on 4W D vehicle, reinstall the transfer case, refer to 7D Transfer Case and Adaptor Housing.

2 Ensure the transmission and the engine mating surfaces are clean and free of burrs.

3 Lubricate the torque converter spigot (7) with a small amount of high temperature wheel bearing grease, refer to Figure 7C4 – 62.

4 Install a new filler tube seal into the transmission case.

Support the transmission while installing the

attaching bolts to avoid damage to the torque

converter and flexplate. Do not have the

transmission hanging.

5 Bring the transmission up to the engine, inserting the filler tube and ensuring the locating dowels completely enter the torque converter housing.

6 Reconnect the breather hose to the top of the transmission case.

NOTE

The bolts attaching the torque converter housing

are facing forward except for the bolt in position ℑ

which is facing rearward.

7 With the transmission supported, install the bolt (1), nine places, attaching the torque converter housing to the engine and tighten to the correct torque specification following the sequence shown in

within Figure 7C4 – 62.

Torque converter housing attaching

bolt torque specification .......................... 52.0 – 66.0 Nm

8 Remove the access hole cover plate from the lower surface of the housing and push the torque converter forward to meet the flexplate, then hand start three new bolts (2) before tightening to the correct torque specification.

Reinstall the access hole cover plate.

Torque converter to flexplate attaching

bolt torque specification .......................... 60.0 – 70.0 Nm

9 Reinstall the bolt (3) and torque converter cover (4) on the transmission right-hand side and the bolt (5) and torque converter cover (6) on the transmission left-hand side, tighten the bolts to the correct torque specification.

Torque converter cover attaching

bolt torque specification .......................... 12.0 – 16.0 Nm

10 Reinstall the transmission fluid lines, refer to 3.17 Transmission Cooler Line/Hose Assemblies.

Prior to connecting the harness connector to

the transmission, check that all pins and

seals are in sound condition and the dust

boot is not torn or damaged.

11 Reconnect the transmission harness connector to the transmission as follows: a Push straight down on the connector body until a click is heard.

b Reinstall the dust boot ensuring it is correctly located.

12 Attach the harness clips to the right-hand and left-hand sides of the transmission case, refer to 12O Fuses, Relays and Wiring Harnesses.

13 On 4WD vehicle, connect the harness two clips from the upper side of the transfer case.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3960 of 6020

Automatic Transmission – 4L60E – On-vehicle Servicing Page 7C4–47

14 Reconnect the fuel and EVAP pipes three brackets and clips, refer to 6C Fuel System – V6.

15 Reinstall the following components:

a Starter motor, refer to 6D1-2 Starting System.

b Transmission support, refer to 3.7 Transmission Support and Mount.

c Front and centre exhaust assemblies, refer to 6F Exhaust System.

d Rear propeller shaft and for 4WD front propeller shaft, refer to 4A Propeller Shaft.

16 Reconnect the harness connectors to the following: a Vehicle speed sensor, refer to 3.5 Vehicle Speed Sensor.

b Neutral start and back-up switch, refer to 3.4 Neutral Start and Back-up Lamp Switch.

c For the following on 4W D vehicles, refer to 7D Transfer Case and Adaptor Housing:

• neutral switch,

• 2WD – 4WD shift actuator switch,

• speed sensor.

17 Reinstall the selector cable to the transmission external manual shaft linkage, secure the selector cable to the bracket and attach the heat shield to the neutral start and back-up lamp switch, refer to 3.3 Selector Cable

Assembly.

18 Perform a reverse flush of the cooler lines and a flow rate test, refer to 2.2 Reverse Flush and Flow Rate, if either of the following applies:

• the transmission fluid is contaminated,

• the transmission has been replaced,

• the torque converter has been replaced, or

• the transmission oil pump has been replaced.

19 Lower the vehicle to the ground.

20 If required, top up the transmission fluid level (cold).

21 Reconnect the battery ground lead.

22 Start the engine and check for any fluid leaking at the fittings. If a leak is found, stop the engine and rectify the leak.

23 Road test until the transmission has reached operating temperature. Re-check the fluid level and for any fluid leaks, refer to 2.1 Transmission Fluid.

3.19 Transmission Control Module

Remove

1 Ensure the ignition switch is in the OFF position.

2 Disconnect the connector (1) from the transmission control module (TCM) (2) as follows, refer to Figure 7C4 – 63: a remove the securing pin (3),

b press the locking tab and swing the lever (4) to free the connector,

c remove the connector.

3 Remove the four bolts (5) and nuts (6), then the TCM from the mounting bracket (7).

4 If required, remove the two nuts (8) and the mounting bracket from the firewall.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4117 of 6020

7A3-32 ON-VEHICLE SERVICE (AW30–40LE)

Shift Solenoid and Lock-Up Solenoid

Removal

Preparation:

• Disconnect negative (–) battery cable.

• Drain the fluid.

Refer to ATF REPLACEMENT in this section.

1. Remove oil lever gage and oil filler tube.

2. Support transfer case (4

×4) or rear cover (4×2)

with a transmission jack.

3. Remove engine rear mounting nuts.

F07RW 008

4. Remove fule pipe heat protector on tansmission

corssmenber.

5. Remove fuel pipe from the crossmenber.

6. Remove transmission crossmenber.

7. Remove the nineteen bolts.

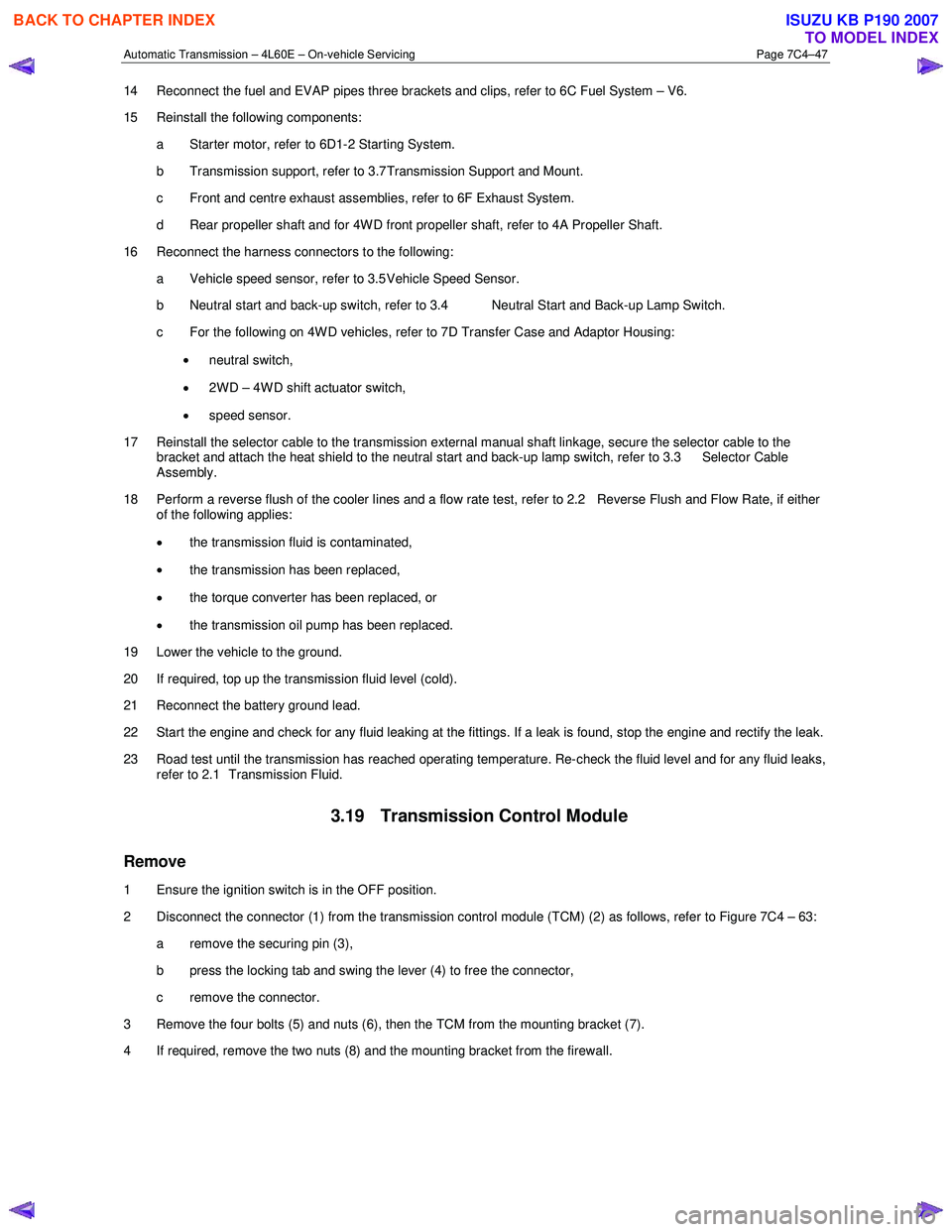

8. Remove oil pan, using seal cutter 5-8840-2153-0.

RUW 37ASH002901

NOTE: Do not turn over the transmission as this will

contaminate the valve body with foreign materials in the

bottom of the oil pan.

Remove oil pan by lifting the transmission case.

Oil pan seal cutter: 5-8840-2153-0

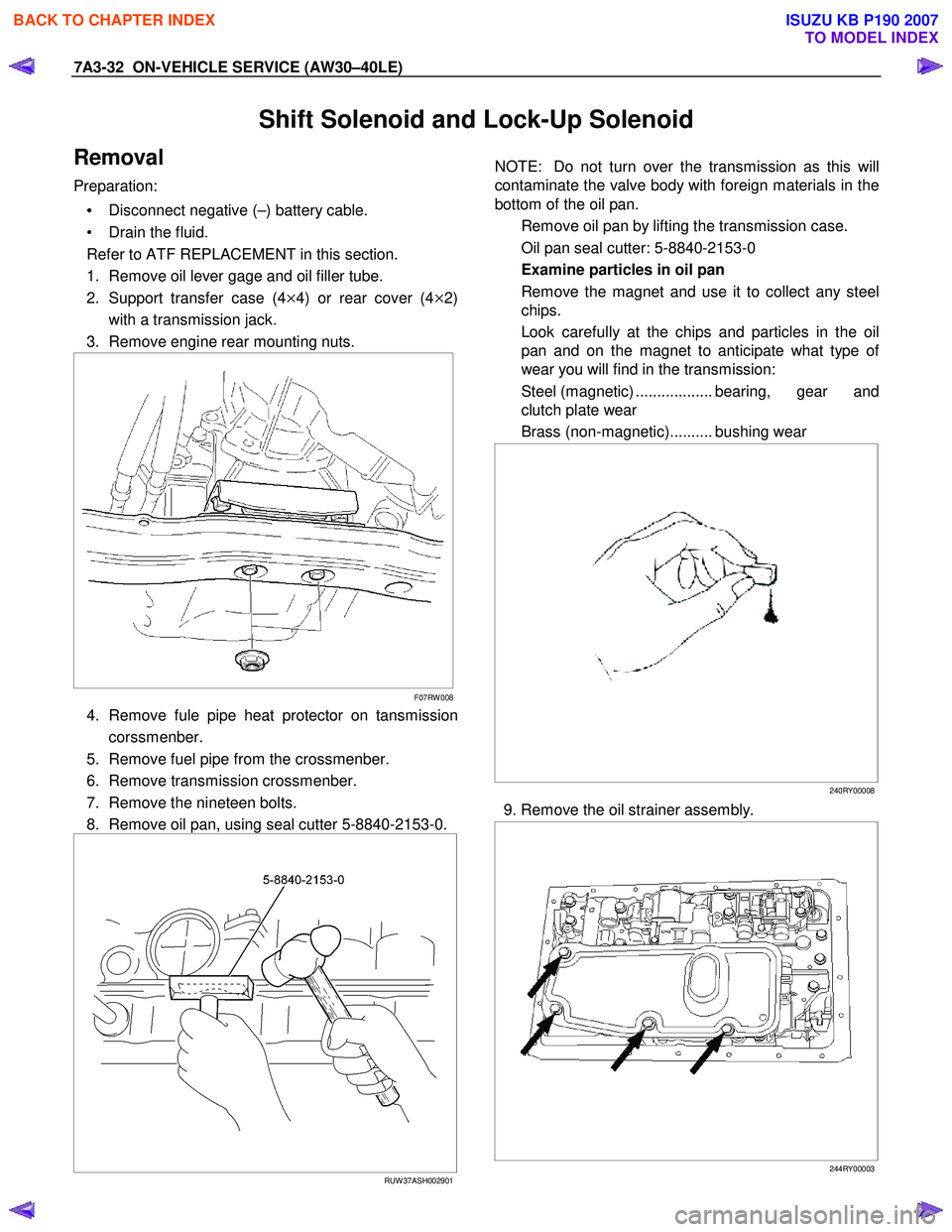

Examine particles in oil pan

Remove the magnet and use it to collect any steel

chips.

Look carefully at the chips and particles in the oil

pan and on the magnet to anticipate what type o

f

wear you will find in the transmission:

Steel (magnetic) .................. bearing, gear and

clutch plate wear

Brass (non-magnetic).......... bushing wear

240RY00008

9. Remove the oil strainer assembly.

244RY00003

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4122 of 6020

ON-VEHICLE SERVICE (AW30–40LE) 7A3-37

Rear Oil Seal (Adapter Housing, 4×

××

×4)

Removal

1. Remove the front and rear propeller shaft assembly

from the transfer case.

2. Remove the transfer case assembly from the transmission case.

Refer to Section 7D TRANSFER.

3. Using a screwdriver, remove the rear oil seal.

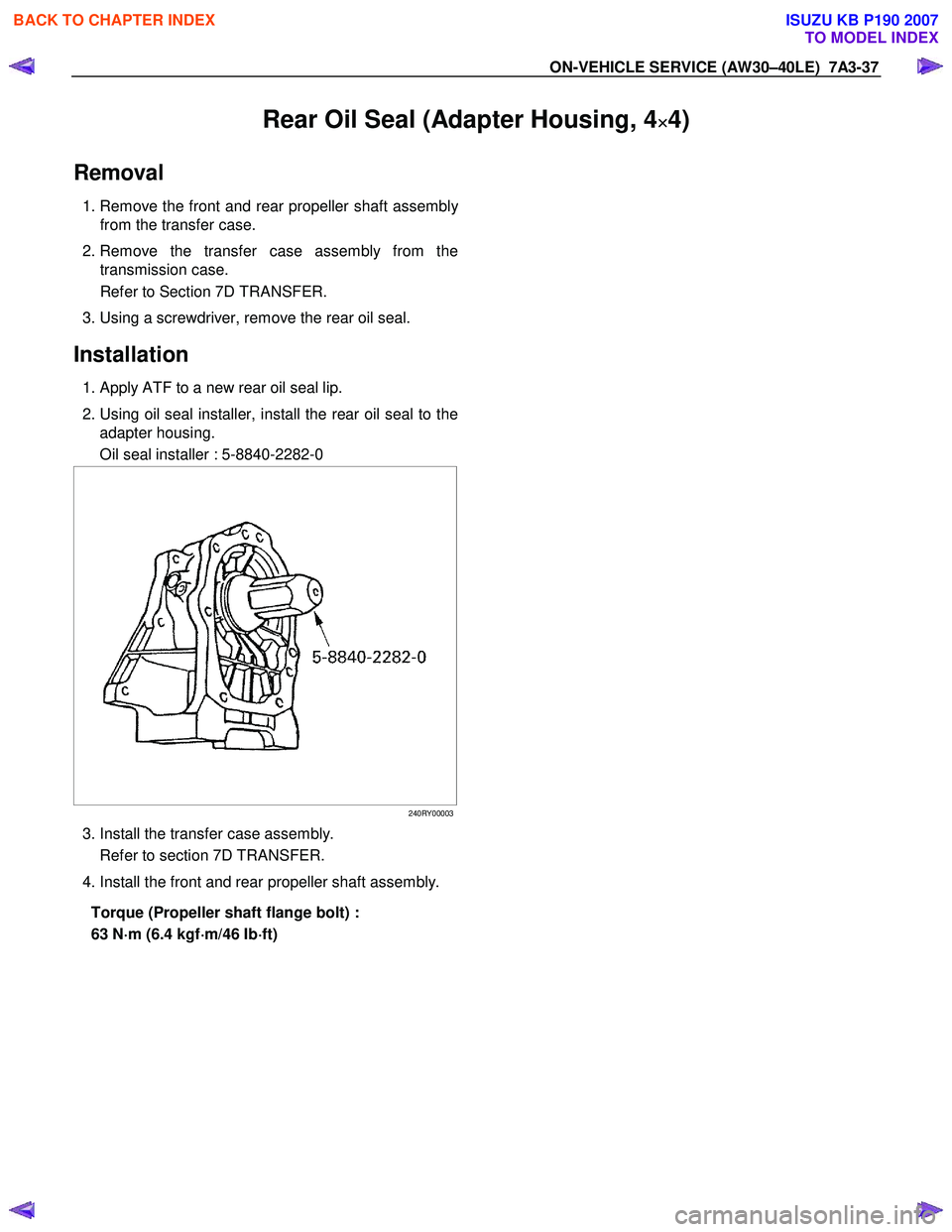

Installation

1. Apply ATF to a new rear oil seal lip.

2. Using oil seal installer, install the rear oil seal to the adapter housing.

Oil seal installer : 5-8840-2282-0

240RY00003

3. Install the transfer case assembly.

Refer to section 7D TRANSFER.

4. Install the front and rear propeller shaft assembly.

Torque (Propeller shaft flange bolt) :

63 N ⋅

⋅⋅

⋅

m (6.4 kgf ⋅

⋅⋅

⋅

m/46 Ib ⋅

⋅⋅

⋅

ft)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4273 of 6020

7A1-34 CONSTRUCTION AND FUNCTION

MAJOR INPUT/OUTPUT COMPONENT AND THEIR FUNCTIONS

Speed sensor Detects output shaft revolution and sends rpm signal to TCM.

Turbine sensor Detects input shaft revolution and sends rpm signal to TCM.

Engine speed sensor Inputs engine revolution from engine control computer.

Brake switch Detects brake pedal operation by the driver and sends signal

to TCM.

Inhibitor switch Detects select lever position and sends signal to TCM.

Mode select switch Detects "Power Drive" or "3rd Start" selected by the driver and

sends signal to TCM.

4L switch (4W D Only) Inputs 4L mode from transfer control computer.

ATF thermo sensor Detects ATF temperature and sends signal to TCM.

High clutch oil pressure switch Detects high clutch supply oil pressure and sends signal to

TCM.

2-4 brake oil pressure switch Detects 2-4 brake supply oil pressure and sends signal to

TCM.

Low & Reverse brake oil pressure switch Detects low & reverse brake supply oil pressure and sends signal to TCM.

Accelerator Pedal position sensor Inputs throttle opening angle from engine control computer.

Input

TCM Judges necessary line pressure, gear shifting point and lock-up

operation based on electrical signals from switches and

sensors and sends appropriate signals to solenoids.

Line pressure solenoid Regulates oil pump delivery pressure to the appropriate line

pressure for current driving conditions based on a signal from

TCM.

Low clutch solenoid Selects appropriate gear shifting position for current driving

conditions and regulates low clutch supply oil pressure based

on a signal from TCM.

High clutch solenoid Selects appropriate gear shifting position for current driving

conditions and regulates high clutch supply oil pressure based

on a signal from TCM.

2-4 brake solenoid Selects appropriate gear shifting position for current driving

conditions and regulates 2-4 brake supply oil pressure based

on a signal from TCM.

Low & Reverse brake solenoid Selects appropriate gear shifting position for current driving

conditions and regulates low & reverse brake supply oil

pressure based on a signal from TCM.

Lock-up solenoid Regulates lock-up pressure to appropriate level for current

driving conditions based on a signal from TCM.

Mode indicator lamp Indicates POW ER DRIVE or 3rd START switch position.

Speed meter signal (2W D Only) Outputs vehicle speed to the speed meter.

A/T OIL TEMP indicator lamp Indicates A/T OIL TEMP indicator lamp in case of high

temperature.

Output

CHECK TRANS indicator lamp Indicates CHECK TRANS indicator lamp in case of

malfunction.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4308 of 6020

7A2-24 TRANSMISSION CONTROL SYSTEM (JR405E)

Scan Tool Data List

The Transmission Scan Tool Data List contains all

transmission related parameters that are available on

the scan tool. Use the Transmission Scan Tool Data

List only after the following is determined:

• The Transmission Controls - Diagnostic System Check is completed. • On-board diagnostics are functioning properly.

Scan tool values from a properly running engine may

be used for comparison with the transmission you are

diagnosing. The Transmission Scan Tool Data List

represents values that would be seen on a normal

running engine. Only the parameters listed below are

referenced in this service manual for use in diagnosis.

Scan Tool Parameter Units DisplayedTypical Data

Operating Conditions: Engine idle/ Engine coolant temperature is between 75 to 85 °C (167 to 185 °F)/ Accelerator pedal is not

pressed/ Park range/ Transfer case is 2H position/ Accessories OFF

Accelerator Pedal Position %0%

Engine Speed RPMNearly 700 RPM

AT Input Speed (Automatic Transmission) RPM600 to 700 RPM

TCC Slip Speed (Torque Converter Clutch) RPMLess than 100 RPM

AT Output Speed (Automatic Transmission) RPM0 RPM

Vehicle Speed km/h/ MPH0 km/h / MPH

Current Gear 1st/ 2nd/ 2nd L-Up/ 3rd/ 3rd

L-Up/ 4th/ 4th L-Up 1st

Estimated Gear Ratio : 132.77:1

Transmission Range (TR) Park/ Neutral/ Reverse/

Drive/ Drive 3/ Drive 2/ Drive 1 Park

TR Switch P (Transmission Range) On/ OffOn

TR Switch R (Transmission Range) On/ OffOff

TR Switch N (Transmission Range) On/ OffOff

TR Switch D (Transmission Range) On/ OffOff

TR Switch 3 (Transmission Range) On/ OffOff

TR Switch 2 (Transmission Range) On/ OffOff

TR Switch L (Transmission Range) On/ OffOff

PCS Command (Pressure Control Solenoid) On/ OffOn

Low & Reverse Brake Solenoid Command %100%

Low & Reverse Brake Pressure Switch On/ OffOff

2-4 Brake Solenoid Command %100%

2-4 Brake Pressure Switch On/ OffOff

High Clutch Solenoid Command %100%

High Clutch Pressure Switch On/ OffOff

Low Clutch Solenoid Command %0%

TCC Solenoid (Torque Converter Clutch) %5%

Transmission Fluid Temperature °C/ °F V arie s

Transmission Oil Temperature Lamp On/ OffOff

TCM Status Temp. (Temperature Transmission Control Module) Low/ HighLow

4 Wheel Drive Low On/ OffOff

TCM Status Transfer (Transmission Control Module) Low/ HighHigh

TCM Status Down Slope (Transmission Control Module) On/ OffOff

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007