bulb ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 36 of 6020

1-2 HEATER AND AIR CONDITIONING

PAGE

Evaporator (With A/C) ..................................................................................................... 1- 6 5

Removal and Installation............................................................................................ 1- 65

Disassembly and Reassembly................................................................................... 1- 66

Duct (Without A/C) ........................................................................................................... 1 - 68

Removal and Installation............................................................................................ 1- 68

Disassembly and Reassembly................................................................................... 1- 69

Blower Unit Assembly..................................................................................................... 1- 70

Removal and Installation............................................................................................ 1- 70

Disassembly and Reassembly................................................................................... 1- 72

Defroster Nozzle and Vent Duct ..................................................................................... 1- 73 Removal and Installation............................................................................................ 1- 73

Rear Heater Duct ............................................................................................................. 1 - 74

Removal and Installation............................................................................................ 1- 74

Control Lever Assembly ................................................................................................. 1- 75 Removal and Installation............................................................................................ 1- 75

Control Panel Illumination Bulb ..................................................................................... 1- 79 Removal and Installation............................................................................................ 1- 79

Inspection and Repair ................................................................................................ 1- 81

Troubleshooting .............................................................................................................. 1 - 85

Special Service Tool........................................................................................................ 1- 119

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 113 of 6020

HEATER AND AIR CONDITIONING 1-79

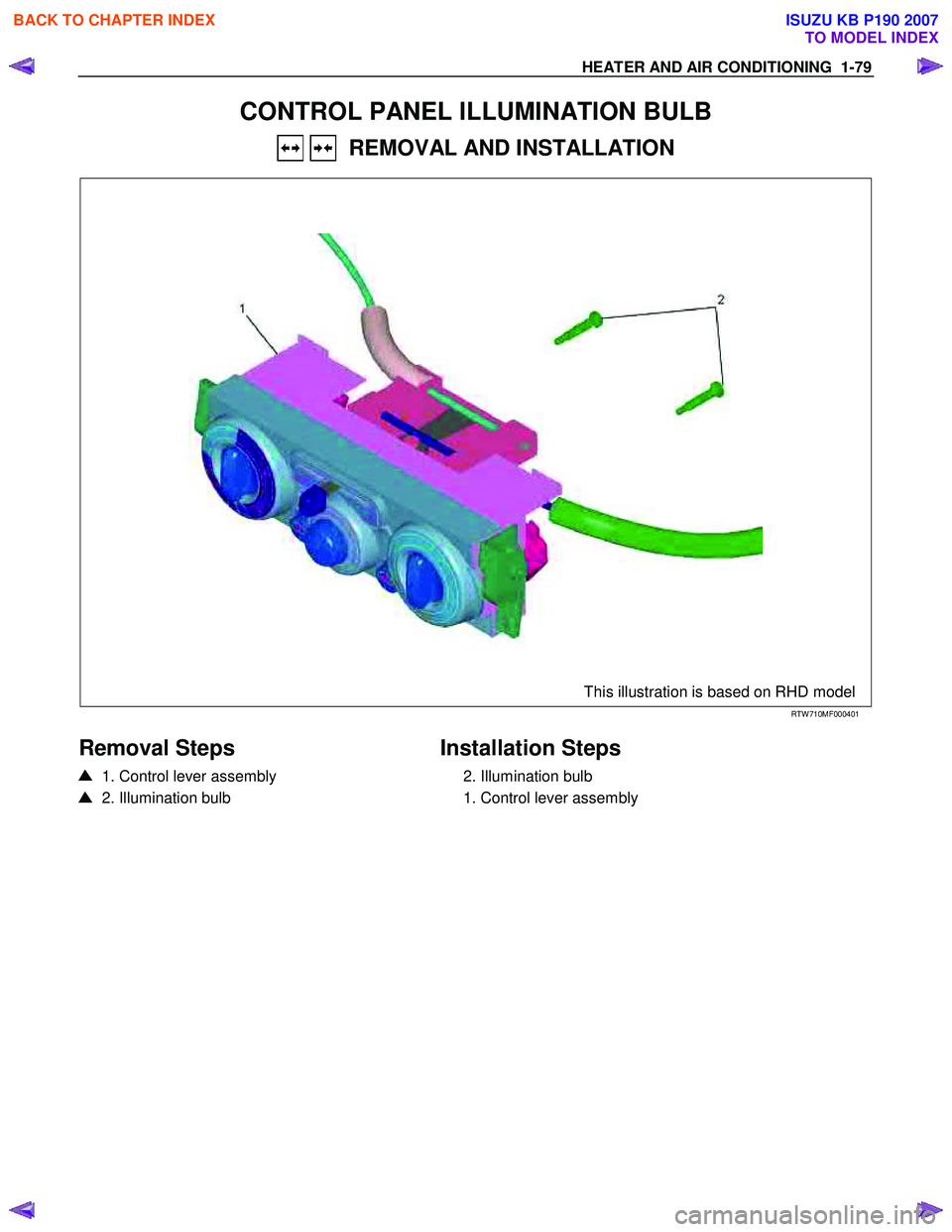

CONTROL PANEL ILLUMINATION BULB

REMOVAL AND INSTALLATION

This illustration is based on RHD model

RTW 710MF000401

Removal Steps

1. Control lever assembly

2. Illumination bulb

Installation Steps

2. Illumination bulb

1. Control lever assembly

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 114 of 6020

1-80 HEATER AND AIR CONDITIONING

RTW 710MH000101

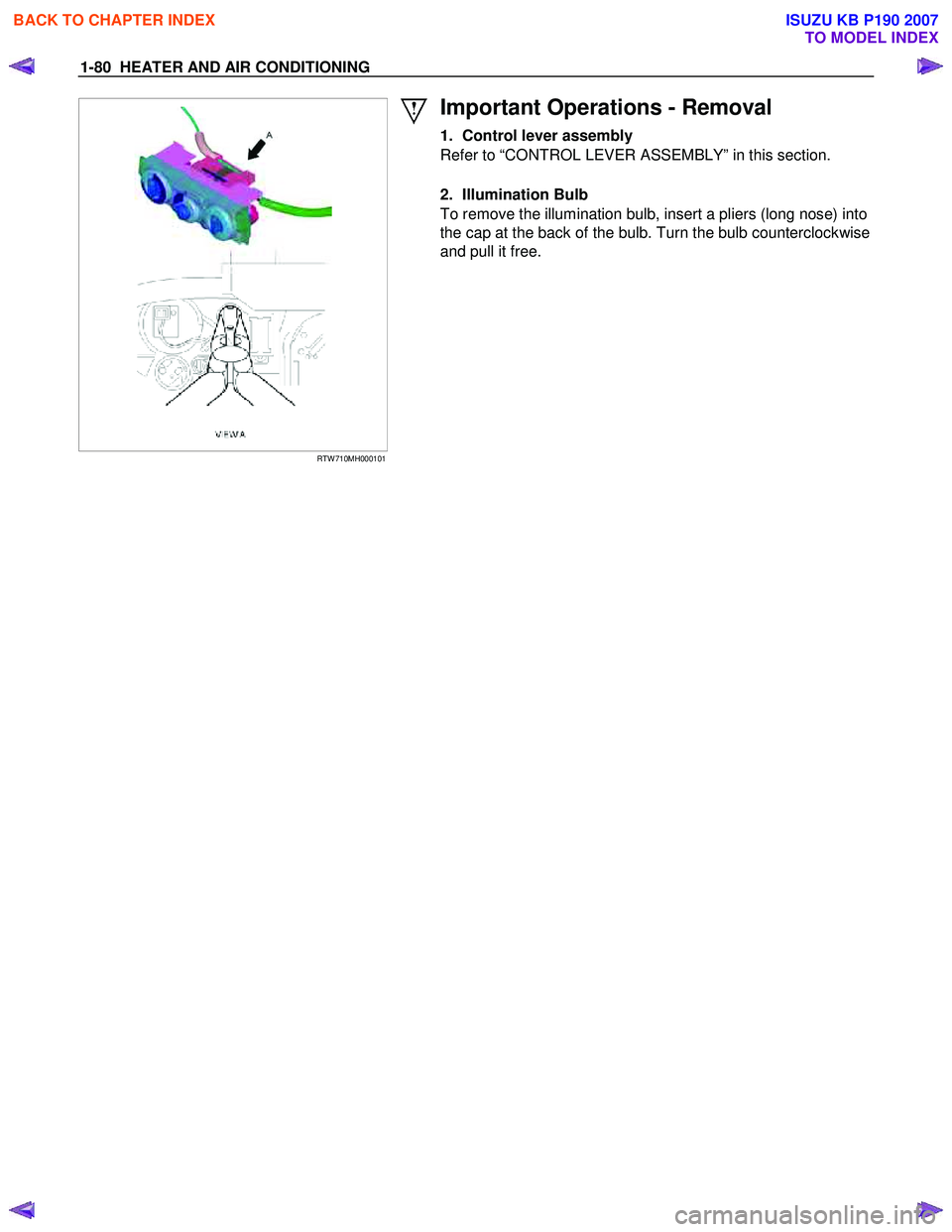

Important Operations - Removal

1. Control lever assembly

Refer to “CONTROL LEVER ASSEMBLY” in this section.

2. Illumination Bulb

To remove the illumination bulb, insert a pliers (long nose) into

the cap at the back of the bulb. Turn the bulb counterclockwise

and pull it free.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1073 of 6020

Engine Control System (4JH1) 6E-39

Brake Pedal 2 Switch

This parameter displays the state of the brake pedal 2

switch as determined by the ECM terminal (pin 65). The

scan tool will display Released or Applied. Released

indicates the brake pedal is not being pushed down.

Applied indicates the brake switch is being depressed.

Clutch Pedal Switch (M/T Only)

This parameter displays the state of the clutch pedal as

determined by the ECM terminal (pin 31) based on an

input from the clutch pedal switch. The scan tool will

display Release or Applied. Release indicates the clutch

pedal is not being push down. Applied indicates the

clutch switch is being depressed.

Vehicle Speed

This parameter displays the vehicle speed calculated b

y

the ECM based on an input from the vehicle speed

sensor (VSS). The scan tool will display a high value at

higher vehicle speeds, and low value at lower vehicle

speeds.

Glow Relay Command

This parameter displays the commanded state of the

glow plug relay control circuit (pin 94). The scan tool will

display On or Off. On indicates the glow plug rela

y

control circuit is being grounded by the ECM, allowing

voltage to the glow plugs. Off indicates the glow plug

relay is not being commanded On by the ECM.

Glow Indicator Lamp Command

This parameter displays the commanded state of the

glow indicator lamp control circuit (pin 43). The glo

w

indicator lamp should be On when the scan tool

indicates On. The glow indicator should be Off when the

scan tool indicates Off.

Malfunction Indicator Lamp (MIL) Command

This parameter displays the commanded state of the

malfunction indicator lamp (MIL) control circuit (pin 42).

The MIL should be On when the scan tool indicates On.

The MIL should be Off when the scan tool indicates Off.

The ECM will command the MIL On for a certain length

of time when the ignition is On with the engine Off in

order to perform a bulb check.

A/C Request Signal

This parameter displays the state of the air conditioning

(A/C) request input to the ECM terminal (pin 33) from

the heating, ventilation, and air conditioning (HVAC)

controls. The scan tool will display On or Off. On

indicates the ECM is receiving a request from the HVAC

system to ground the A/C compressor relay control

circuit, engaging the

A/C compressor clutch. Off

indicates the ECM is not receiving a request from the

HVAC system.

A/C Relay Command

This parameter displays the commanded state of the

A/C compressor relay control circuit (pin 41). The scan

tool will display On or Off. On indicates the

A/C

compressor relay control circuit is being grounded b

y

the ECM, allowing voltage to the A/C compressor

clutch. Off indicates the A/C compressor relay is not

being commanded On by the ECM.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1074 of 6020

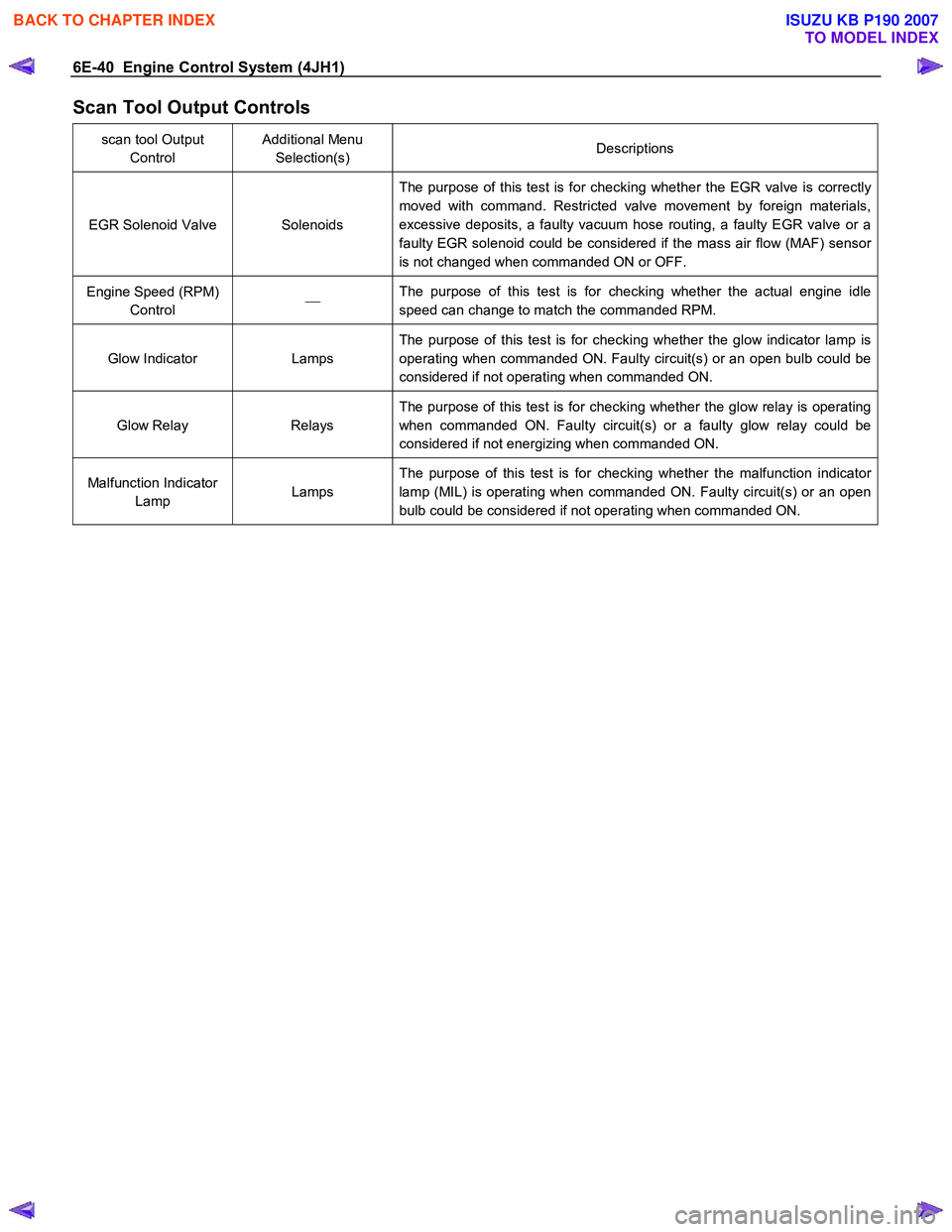

6E-40 Engine Control System (4JH1)

Scan Tool Output Controls

scan tool Output Control Additional Menu

Selection(s) Descriptions

EGR Solenoid Valve Solenoids The purpose of this test is for checking whether the EGR valve is correctly

moved with command. Restricted valve movement by foreign materials,

excessive deposits, a faulty vacuum hose routing, a faulty EGR valve or a

faulty EGR solenoid could be considered if the mass air flow (MAF) sensor

is not changed when commanded ON or OFF.

Engine Speed (RPM) Control

The purpose of this test is for checking whether the actual engine idle

speed can change to match the commanded RPM.

Glow Indicator Lamps The purpose of this test is for checking whether the glow indicator lamp is

operating when commanded ON. Faulty circuit(s) or an open bulb could be

considered if not operating when commanded ON.

Glow Relay Relays The purpose of this test is for checking whether the glow relay is operating

when commanded ON. Faulty circuit(s) or a faulty glow relay could be

considered if not energizing when commanded ON.

Malfunction Indicator Lamp Lamps The purpose of this test is for checking whether the malfunction indicator

lamp (MIL) is operating when commanded ON. Faulty circuit(s) or an open

bulb could be considered if not operating when commanded ON.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1090 of 6020

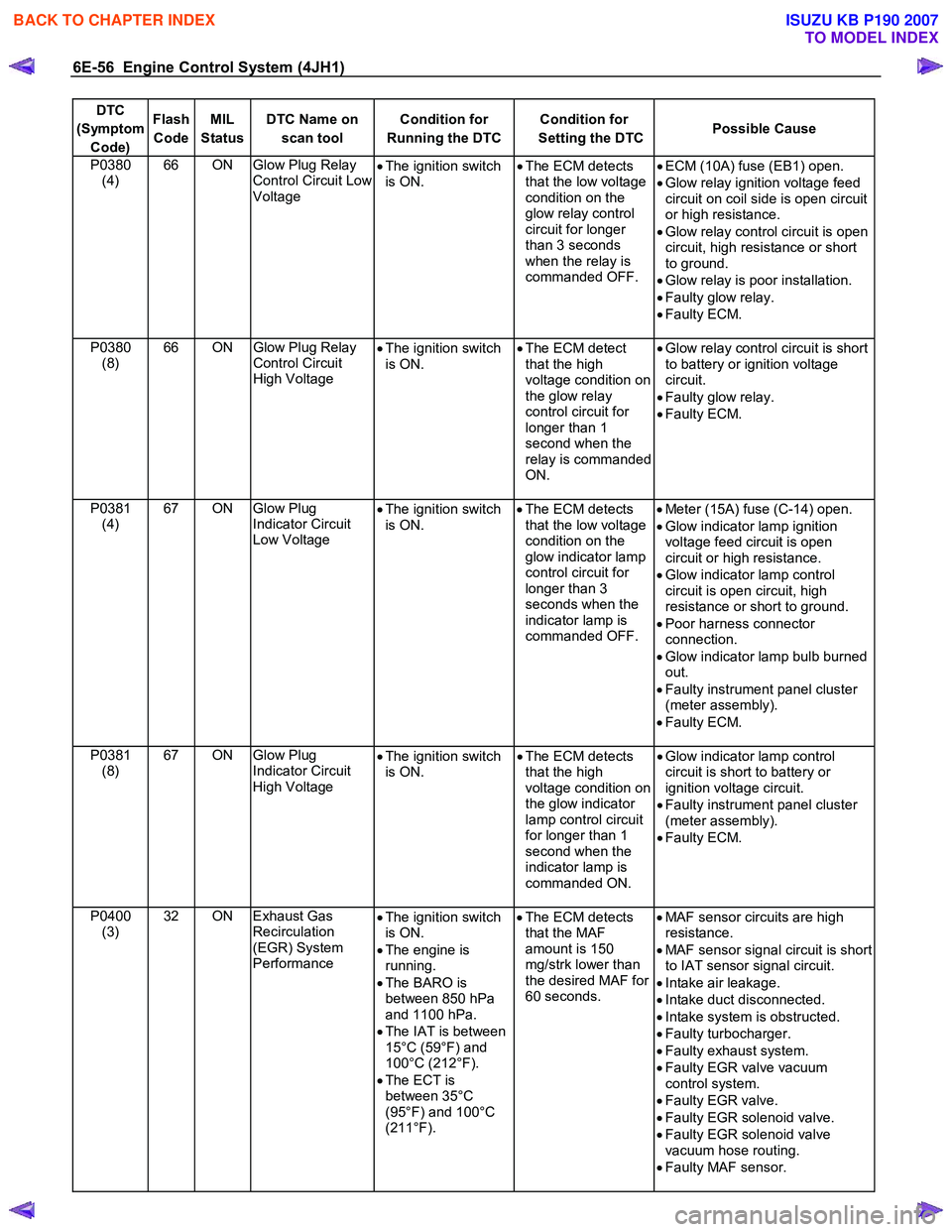

6E-56 Engine Control System (4JH1)

DTC

(Symptom Code) Flash

Code MIL

Status DTC Name on

scan tool Condition for

Running the DTC Condition for

Setting the DTC Possible Cause

P0380

(4) 66 ON Glow Plug Relay

Control Circuit Low

Voltage •

The ignition switch

is ON. •

The ECM detects

that the low voltage

condition on the

glow relay control

circuit for longer

than 3 seconds

when the relay is

commanded OFF.

•

ECM (10A) fuse (EB1) open.

• Glow relay ignition voltage feed

circuit on coil side is open circuit

or high resistance.

• Glow relay control circuit is open

circuit, high resistance or short

to ground.

• Glow relay is poor installation.

• Faulty glow relay.

• Faulty ECM.

P0380 (8) 66 ON

Glow Plug Relay

Control Circuit

High Voltage •

The ignition switch

is ON. •

The ECM detect

that the high

voltage condition on

the glow relay

control circuit for

longer than 1

second when the

relay is commanded

ON.

•

Glow relay control circuit is short

to battery or ignition voltage

circuit.

• Faulty glow relay.

• Faulty ECM.

P0381 (4) 67 ON Glow Plug

Indicator Circuit

Low Voltage •

The ignition switch

is ON.

•

The ECM detects

that the low voltage

condition on the

glow indicator lamp

control circuit for

longer than 3

seconds when the

indicator lamp is

commanded OFF.

•

Meter (15A) fuse (C-14) open.

• Glow indicator lamp ignition

voltage feed circuit is open

circuit or high resistance.

• Glow indicator lamp control

circuit is open circuit, high

resistance or short to ground.

• Poor harness connector

connection.

• Glow indicator lamp bulb burned

out.

• Faulty instrument panel cluster

(meter assembly).

• Faulty ECM.

P0381 (8) 67 ON Glow Plug

Indicator Circuit

High Voltage •

The ignition switch

is ON. •

The ECM detects

that the high

voltage condition on

the glow indicator

lamp control circuit

for longer than 1

second when the

indicator lamp is

commanded ON.

•

Glow indicator lamp control

circuit is short to battery or

ignition voltage circuit.

• Faulty instrument panel cluster

(meter assembly).

• Faulty ECM.

P0400 (3) 32 ON Exhaust Gas

Recirculation

(EGR) System

Performance •

The ignition switch

is ON.

• The engine is

running.

• The BARO is

between 850 hPa

and 1100 hPa.

• The IAT is between

15°C (59°F) and

100°C (212°F).

• The ECT is

between 35°C

(95°F) and 100°C

(211°F).

•

The ECM detects

that the MAF

amount is 150

mg/strk lower than

the desired MAF for

60 seconds.

•

MAF sensor circuits are high

resistance.

• MAF sensor signal circuit is short

to IAT sensor signal circuit.

• Intake air leakage.

• Intake duct disconnected.

• Intake system is obstructed.

• Faulty turbocharger.

• Faulty exhaust system.

• Faulty EGR valve vacuum

control system.

• Faulty EGR valve.

• Faulty EGR solenoid valve.

• Faulty EGR solenoid valve

vacuum hose routing.

• Faulty MAF sensor.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1099 of 6020

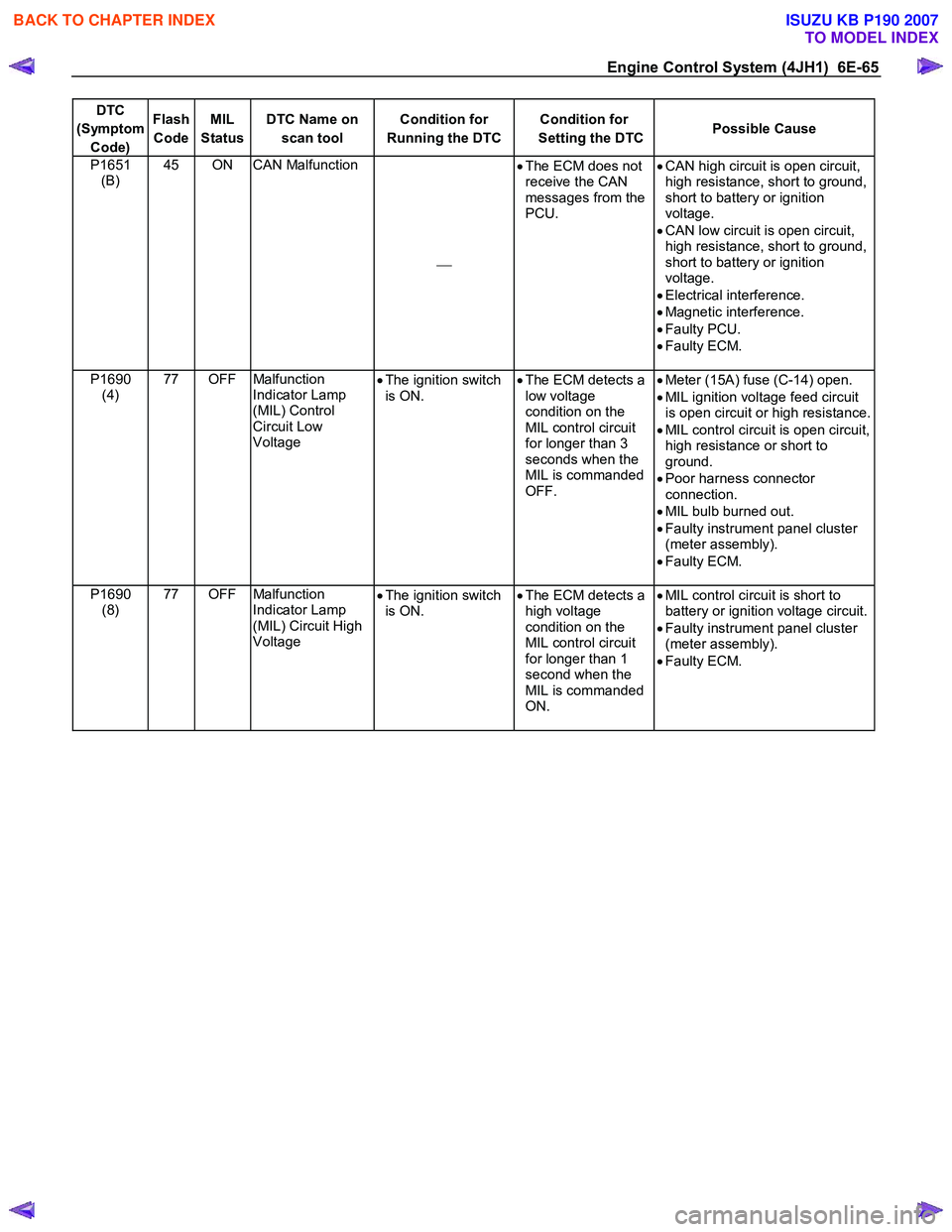

Engine Control System (4JH1) 6E-65

DTC

(Symptom Code) Flash

Code MIL

Status DTC Name on

scan tool Condition for

Running the DTC Condition for

Setting the DTC Possible Cause

P1651

(B) 45 ON CAN Malfunction

•

The ECM does not

receive the CAN

messages from the

PCU.

•

CAN high circuit is open circuit,

high resistance, short to ground,

short to battery or ignition

voltage.

• CAN low circuit is open circuit,

high resistance, short to ground,

short to battery or ignition

voltage.

• Electrical interference.

• Magnetic interference.

• Faulty PCU.

• Faulty ECM.

P1690 (4) 77 OFF Malfunction

Indicator Lamp

(MIL) Control

Circuit Low

Voltage •

The ignition switch

is ON. •

The ECM detects a

low voltage

condition on the

MIL control circuit

for longer than 3

seconds when the

MIL is commanded

OFF.

•

Meter (15A) fuse (C-14) open.

• MIL ignition voltage feed circuit

is open circuit or high resistance.

• MIL control circuit is open circuit,

high resistance or short to

ground.

• Poor harness connector

connection.

• MIL bulb burned out.

• Faulty instrument panel cluster

(meter assembly).

• Faulty ECM.

P1690 (8) 77 OFF Malfunction

Indicator Lamp

(MIL) Circuit High

Voltage •

The ignition switch

is ON. •

The ECM detects a

high voltage

condition on the

MIL control circuit

for longer than 1

second when the

MIL is commanded

ON.

•

MIL control circuit is short to

battery or ignition voltage circuit.

• Faulty instrument panel cluster

(meter assembly).

• Faulty ECM.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1176 of 6020

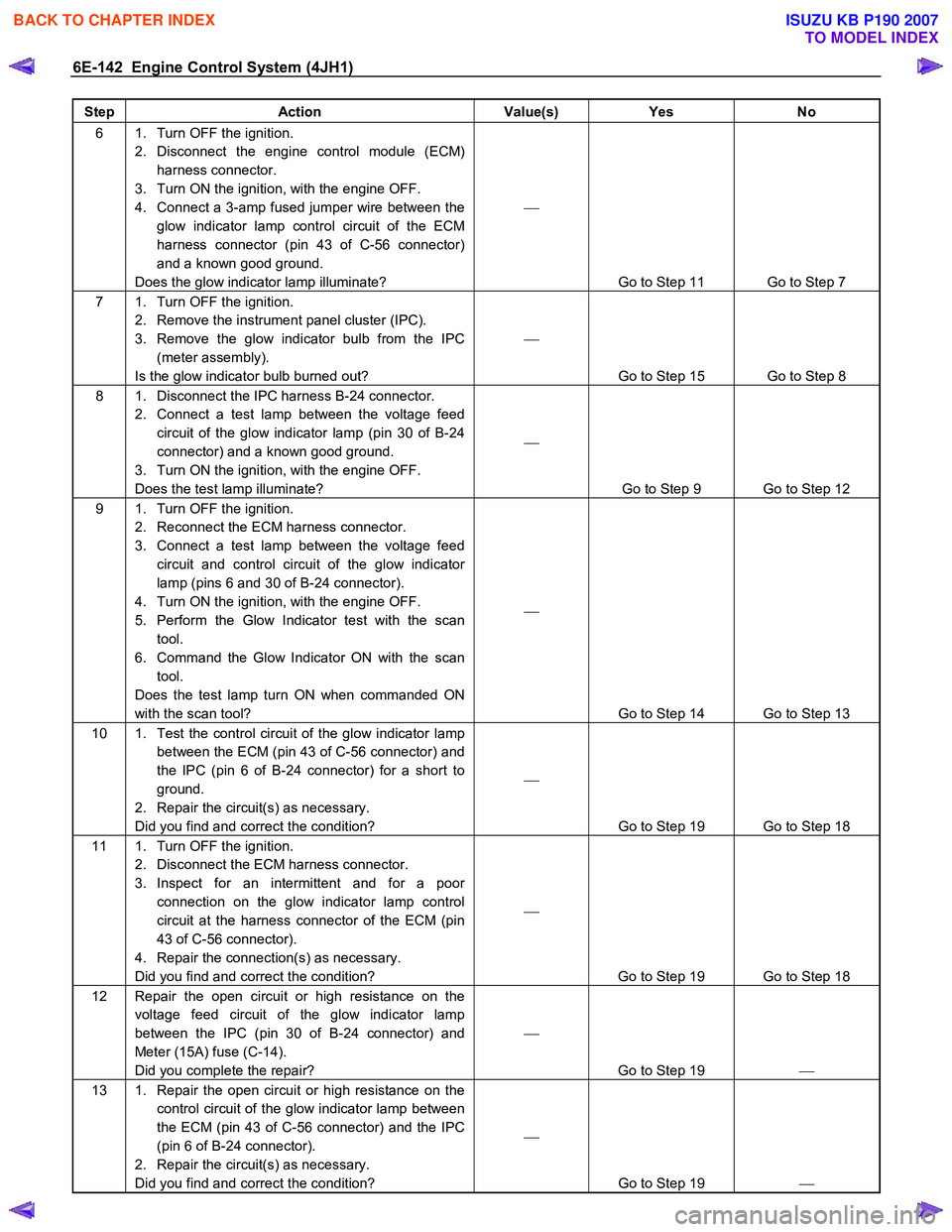

6E-142 Engine Control System (4JH1)

Step Action Value(s) Yes No

6 1. Turn OFF the ignition.

2. Disconnect the engine control module (ECM) harness connector.

3. Turn ON the ignition, with the engine OFF.

4. Connect a 3-amp fused jumper wire between the glow indicator lamp control circuit of the ECM

harness connector (pin 43 of C-56 connector)

and a known good ground.

Does the glow indicator lamp illuminate?

Go to Step 11 Go to Step 7

7 1. Turn OFF the ignition. 2. Remove the instrument panel cluster (IPC).

3. Remove the glow indicator bulb from the IPC (meter assembly).

Is the glow indicator bulb burned out?

Go to Step 15 Go to Step 8

8 1. Disconnect the IPC harness B-24 connector. 2. Connect a test lamp between the voltage feed circuit of the glow indicator lamp (pin 30 of B-24

connector) and a known good ground.

3. Turn ON the ignition, with the engine OFF.

Does the test lamp illuminate?

Go to Step 9 Go to Step 12

9 1. Turn OFF the ignition. 2. Reconnect the ECM harness connector.

3. Connect a test lamp between the voltage feed circuit and control circuit of the glow indicator

lamp (pins 6 and 30 of B-24 connector).

4. Turn ON the ignition, with the engine OFF.

5. Perform the Glow Indicator test with the scan tool.

6. Command the Glow Indicator ON with the scan tool.

Does the test lamp turn ON when commanded ON

with the scan tool?

Go to Step 14 Go to Step 13

10 1. Test the control circuit of the glow indicator lamp between the ECM (pin 43 of C-56 connector) and

the IPC (pin 6 of B-24 connector) for a short to

ground.

2. Repair the circuit(s) as necessary.

Did you find and correct the condition?

Go to Step 19 Go to Step 18

11 1. Turn OFF the ignition. 2. Disconnect the ECM harness connector.

3. Inspect for an intermittent and for a poor connection on the glow indicator lamp control

circuit at the harness connector of the ECM (pin

43 of C-56 connector).

4. Repair the connection(s) as necessary.

Did you find and correct the condition?

Go to Step 19 Go to Step 18

12 Repair the open circuit or high resistance on the voltage feed circuit of the glow indicator lamp

between the IPC (pin 30 of B-24 connector) and

Meter (15A) fuse (C-14).

Did you complete the repair?

Go to Step 19

13 1. Repair the open circuit or high resistance on the

control circuit of the glow indicator lamp between

the ECM (pin 43 of C-56 connector) and the IPC

(pin 6 of B-24 connector).

2. Repair the circuit(s) as necessary.

Did you find and correct the condition?

Go to Step 19

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1177 of 6020

Engine Control System (4JH1) 6E-143

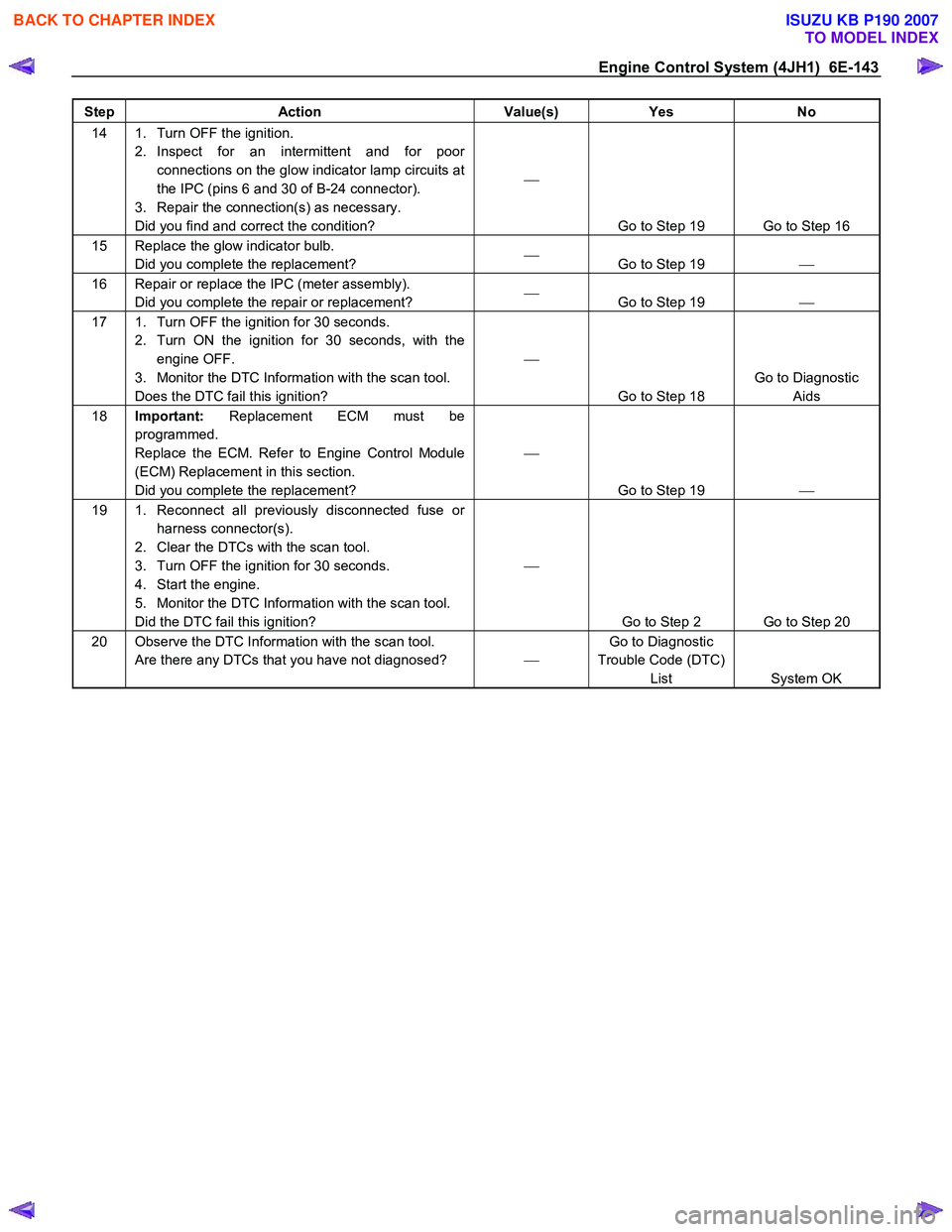

Step Action Value(s) Yes No

14 1. Turn OFF the ignition.

2. Inspect for an intermittent and for poor connections on the glow indicator lamp circuits at

the IPC (pins 6 and 30 of B-24 connector).

3. Repair the connection(s) as necessary.

Did you find and correct the condition?

Go to Step 19 Go to Step 16

15 Replace the glow indicator bulb. Did you complete the replacement?

Go to Step 19

16 Repair or replace the IPC (meter assembly).

Did you complete the repair or replacement?

Go to Step 19

17 1. Turn OFF the ignition for 30 seconds.

2. Turn ON the ignition for 30 seconds, with the engine OFF.

3. Monitor the DTC Information with the scan tool.

Does the DTC fail this ignition?

Go to Step 18 Go to Diagnostic

Aids

18 Important: Replacement ECM must be

programmed.

Replace the ECM. Refer to Engine Control Module

(ECM) Replacement in this section.

Did you complete the replacement?

Go to Step 19

19 1. Reconnect all previously disconnected fuse or

harness connector(s).

2. Clear the DTCs with the scan tool.

3. Turn OFF the ignition for 30 seconds.

4. Start the engine.

5. Monitor the DTC Information with the scan tool.

Did the DTC fail this ignition?

Go to Step 2 Go to Step 20

20 Observe the DTC Information with the scan tool. Are there any DTCs that you have not diagnosed? Go to Diagnostic

Trouble Code (DTC) List System OK

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1268 of 6020

6E-234 Engine Control System (4JH1)

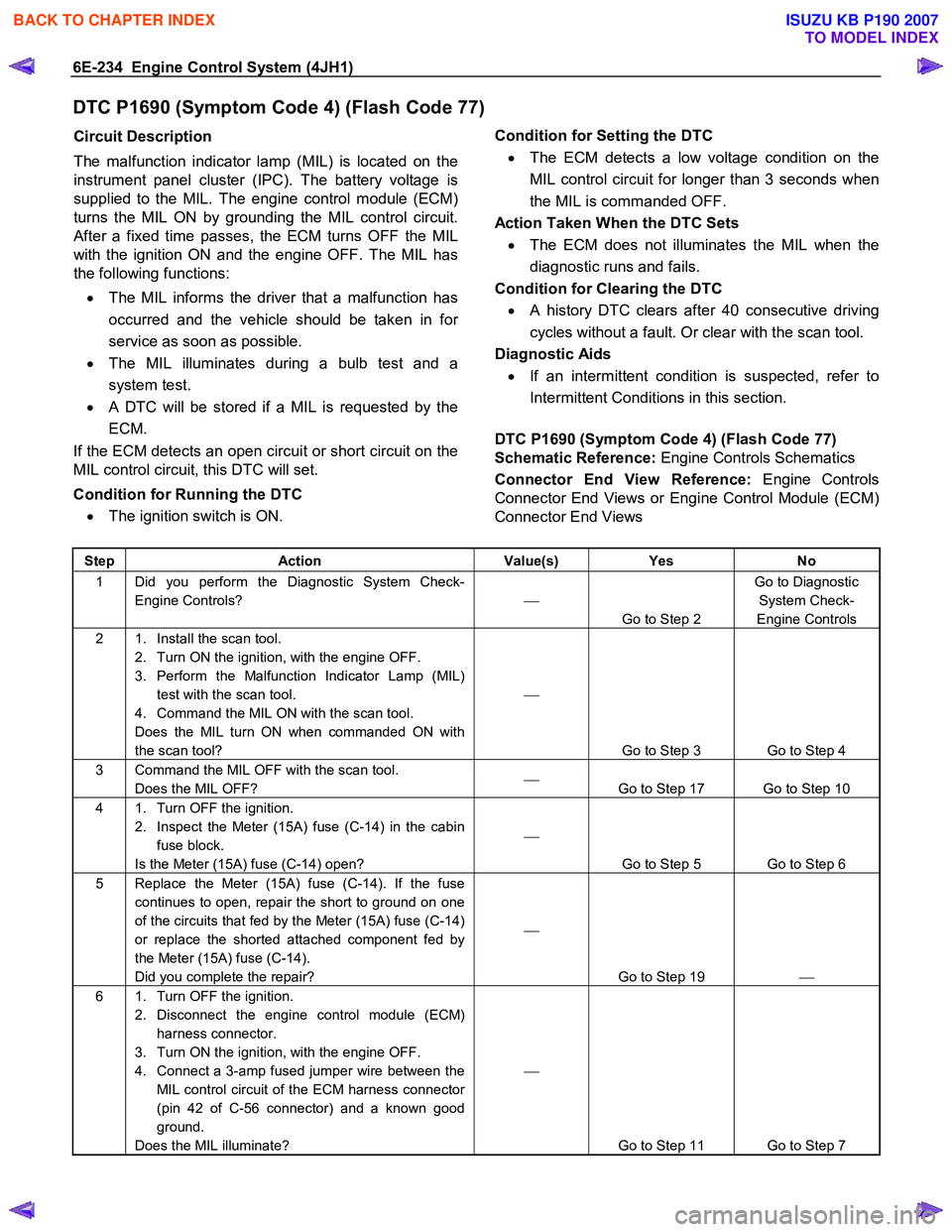

DTC P1690 (Symptom Code 4) (Flash Code 77)

Circuit Description

The malfunction indicator lamp (MIL) is located on the

instrument panel cluster (IPC). The battery voltage is

supplied to the MIL. The engine control module (ECM)

turns the MIL ON by grounding the MIL control circuit.

After a fixed time passes, the ECM turns OFF the MIL

with the ignition ON and the engine OFF. The MIL has

the following functions:

• The MIL informs the driver that a malfunction has

occurred and the vehicle should be taken in fo

r

service as soon as possible.

• The MIL illuminates during a bulb test and a

system test.

•

A DTC will be stored if a MIL is requested by the

ECM.

If the ECM detects an open circuit or short circuit on the

MIL control circuit, this DTC will set.

Condition for Running the DTC • The ignition switch is ON.

Condition for Setting the DTC

• The ECM detects a low voltage condition on the

MIL control circuit for longer than 3 seconds when

the MIL is commanded OFF.

Action Taken When the DTC Sets • The ECM does not illuminates the MIL when the

diagnostic runs and fails.

Condition for Clearing the DTC • A history DTC clears after 40 consecutive driving

cycles without a fault. Or clear with the scan tool.

Diagnostic Aids

• If an intermittent condition is suspected, refer to

Intermittent Conditions in this section.

DTC P1690 (Symptom Code 4) (Flash Code 77)

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or Engine Control Module (ECM)

Connector End Views

Step Action Value(s) Yes No

1 Did you perform the Diagnostic System Check-

Engine Controls?

Go to Step 2 Go to Diagnostic

System Check-

Engine Controls

2 1. Install the scan tool. 2. Turn ON the ignition, with the engine OFF.

3. Perform the Malfunction Indicator Lamp (MIL) test with the scan tool.

4. Command the MIL ON with the scan tool.

Does the MIL turn ON when commanded ON with

the scan tool?

Go to Step 3 Go to Step 4

3 Command the MIL OFF with the scan tool. Does the MIL OFF?

Go to Step 17 Go to Step 10

4 1. Turn OFF the ignition.

2. Inspect the Meter (15A) fuse (C-14) in the cabin fuse block.

Is the Meter (15A) fuse (C-14) open?

Go to Step 5 Go to Step 6

5 Replace the Meter (15A) fuse (C-14). If the fuse continues to open, repair the short to ground on one

of the circuits that fed by the Meter (15A) fuse (C-14)

or replace the shorted attached component fed by

the Meter (15A) fuse (C-14).

Did you complete the repair?

Go to Step 19

6 1. Turn OFF the ignition.

2. Disconnect the engine control module (ECM) harness connector.

3. Turn ON the ignition, with the engine OFF.

4. Connect a 3-amp fused jumper wire between the MIL control circuit of the ECM harness connector

(pin 42 of C-56 connector) and a known good

ground.

Does the MIL illuminate?

Go to Step 11 Go to Step 7

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007