transfer case ISUZU KB P190 2007 Workshop Owner's Guide

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 4310 of 6020

7A2-26 TRANSMISSION CONTROL SYSTEM (JR405E)

Low & Reverse Brake Pressure Switch

This parameter displays the input state of the low &

reverse brake transmission fluid pressure (TFP) switch

to the TCM. When the low & reverse brake fluid

pressure is generated, the scan tool displays On.

2-4 Brake Solenoid Command

This parameter displays the 2-4 brake solenoid valve

control duty ratio based on the command from the

TCM. The scan tool will display a lower percentage

when the 2-4 brake is controlled to engage (fluid

pressure is applied to the 2-4 brake hydraulic circuits).

The scan tool will display higher percentage when the

2-4 brake is controlled to disengage (fluid pressure is

drained from the 2-4 brake hydraulic circuits).

2-4 Brake Pressure Switch

This parameter displays the input state of the 2-4 brake

transmission fluid pressure (TFP) switch to the TCM.

When the 2-4 brake fluid pressure is generated, the

scan tool displays On.

High Clutch Solenoid Command

This parameter displays the high clutch solenoid valve

control duty ratio based on the command from the

TCM. The scan tool will display a lower percentage

when the high clutch is controlled to engage (fluid

pressure is applied to the high clutch hydraulic circuits).

The scan tool will display higher percentage when the

high clutch is controlled to disengage (fluid pressure is

drained from the high clutch hydraulic circuits).

High Clutch Pressure Switch

This parameter displays the input state of the high

clutch transmission fluid pressure (TFP) switch to the

TCM. When the high clutch fluid pressure is generated,

the scan tool displays On.

Low Clutch Solenoid Command

This parameter displays the low clutch solenoid valve

control duty ratio based on the command from the

TCM. The scan tool will display a lower percentage

when the low clutch is controlled to engage (fluid

pressure is applied to the low clutch hydraulic circuits).

The scan tool will display higher percentage when the

low clutch is controlled to disengage (fluid pressure is

drained from the low clutch hydraulic circuits).

TCC Solenoid (Torque Converter Clutch)

This parameter displays the torque converter clutch

(TCC) control duty ratio based on the command from

the TCM. The scan tool will display a lower percentage

when the TCC is controlled to disengage (fluid

pressure is drained from the TCC release hydraulic

circuits). The scan tool will display higher percentage

when the TCC is controlled to engage (fluid pressure is

applied to the TCC apply hydraulic circuits). Transmission Fluid Temperature

This parameter displays the temperature of the

automatic transmission fluid (ATF) temperature as

calculated by the TCM using the signal from the

transmission fluid temperature (TFT) sensor. The scan

tool will display a low temperature when the signal

voltage is high, and a high temperature when the signal

voltage is low.

Transmission Oil Temperature Lamp

This parameter displays the commanded state of the

transmission oil temperature lamp control circuit. The

lamp should be On when the scan tool indicates

command On.

TCM Status Temp. (Temperature Transmission

Control Module)

This parameter displays the commanded state of the

high temperature mode shift map. On indicates the

transmission fluid temperature is high and the high

temperature mode is selected to prevent an

overheating.

4 Wheel Drive Low

This parameter displays the input state of the 4WD low

gear signal from the transfer case control module

(TCCM). When the 4L mode is selected, the scan tool

displays On.

TCM Status Transfer (Transmission Control

Module)

This parameter displays the commanded state of the

shift map that is based on the transfer case position.

High indicates the high mode (2H or 4H) is inputted

from the transfer case control module (TCCM). Low

indicates the low mode (4L) is inputted from the TCCM.

TCM Status Down Slope (Transmission Control

Module)

This parameter displays the commanded state of the

down slope mode shift map. On indicates the down

slope mode is selected under certain driving conditions.

TCM Status Up Slope (Transmission Control

Module)

This parameter displays the commanded state of the

up slope mode shift map. On indicates the up slope

mode is selected under certin driving conditions.

3rd Start Switch

This parameter displays the input state of the 3rd start

switch to the TCM. When the switch is pressed, the

scan tool displays On.

3rd Start Lamp

This parameter displays the commanded state of the

3rd start lamp control circuit. The lamp should be On

when the scan tool indicates command On.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4830 of 6020

Section 7D Transfer House ............................................................................................ 4879 PAGE

Section 7D1 Transfer Control System.......................................................................... 4923

SECTION 7

TRANSFER CASE

TA BLE OF CONTENTS

TRANSMISSION

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4831 of 6020

TRANSFER CASE 7D-1

SECTION 7D

TRANSFER CASE

TABLE OF CONTENTS

PAGE

Service Precaution ......................................................................................................... 7D – 2

General Description ........................................................................................................ 7D – 3

On-Vehicle Service ......................................................................................................... 7D – 4

Transfer Case Oil Level ............................................................................................... 7D – 4

Transfer Case Oil Change ........................................................................................... 7D – 5

Transfer Case Front Oil Seal ...................................................................................... 7D – 6

Transfer Case Rear Oil Seal ........................................................................................ 7D – 9

Transfer Case Assembly ................................................................................................ 7D – 11

Transfer Case Assembly and Associated Parts ........................................................ 7D – 11

Removal ....................................................................................................................... . 7D – 12

Installation .................................................................................................................. .. 7D – 12

Transfer Control Unit ...................................................................................................... 7D – 16

Removal ....................................................................................................................... . 7D – 17

Installation .................................................................................................................. .. 7D – 17

Transfer Disassembly .................................................................................................... 7D – 18

Removal ....................................................................................................................... . 7D – 18

Inspection and Repair ................................................................................................. 7D – 27

Inspection and Repair (Transfer Case Assembly) .................................................... 7D – 27

Reassembly .................................................................................................................. 7 D – 31

Main Data and Specifications ........................................................................................ 7D – 41

Special Tools ................................................................................................................ 7D – 44

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4832 of 6020

7D-2 TRANSFER CASE

Service Precaution

WARNING: THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING, REFER TO

THE SRS SERVICE INFORMATION. FAILURE TO

FOLLOW WARNINGS COULD RESULT IN POSSIBLE

AIR BAG DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNECESSARY SRS SYSTEM

REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU/GM will call out those fasteners that require a

replacement after removal. ISUZU/GM will also call

out the fasteners that require thread lockers or

thread sealant. UNLESS OTHERWISE SPECIFIED,

do not use supplemental coatings (Paints, greases,

or other corrosion inhibitors) on threaded fasteners

or fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4833 of 6020

TRANSFER CASE 7D-3

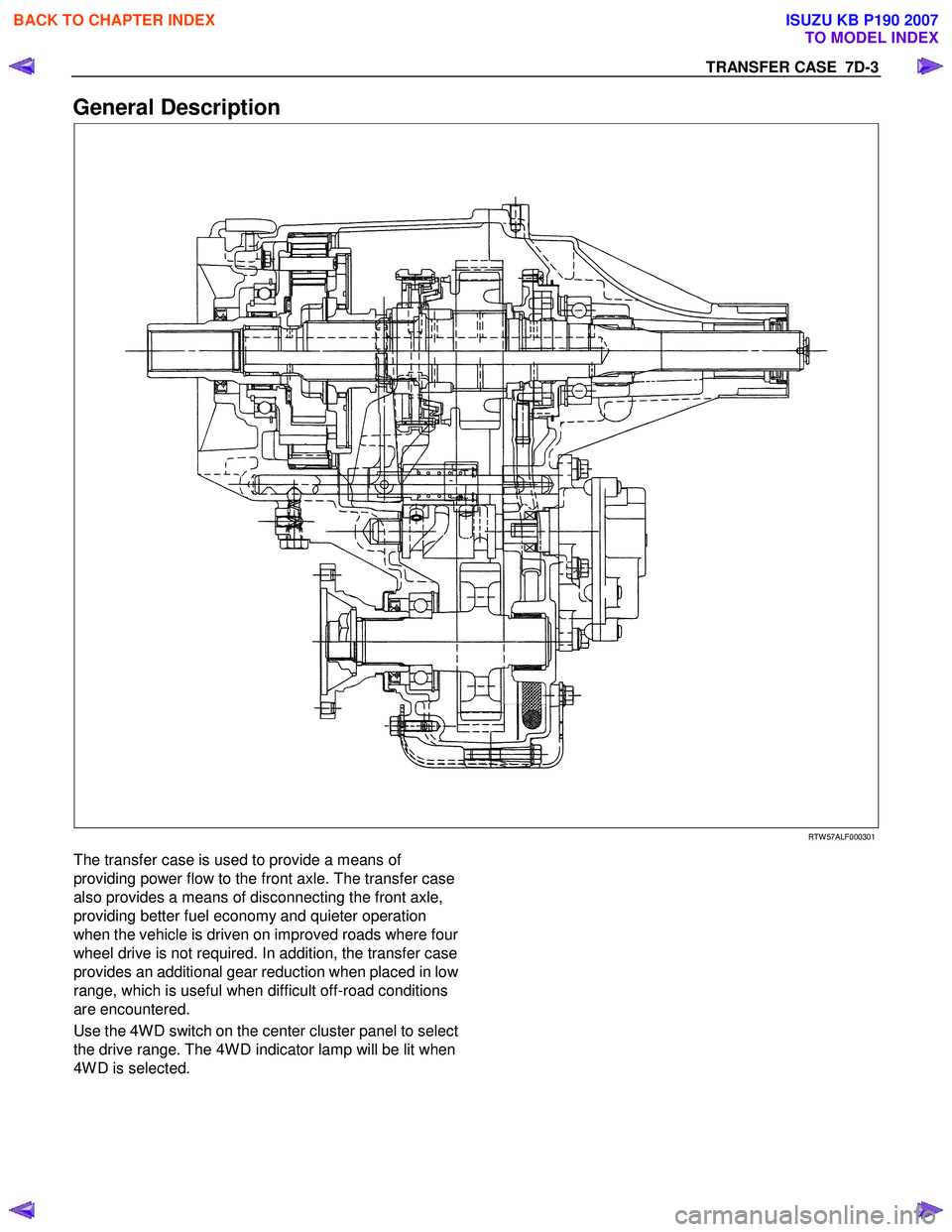

General Description

RTW 57ALF000301

The transfer case is used to provide a means of

providing power flow to the front axle. The transfer case

also provides a means of disconnecting the front axle,

providing better fuel economy and quieter operation

when the vehicle is driven on improved roads where fou

r

wheel drive is not required. In addition, the transfer case

provides an additional gear reduction when placed in lo

w

range, which is useful when difficult off-road conditions

are encountered.

Use the 4W D switch on the center cluster panel to select

the drive range. The 4W D indicator lamp will be lit when

4W D is selected.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4834 of 6020

7D-4 TRANSFER CASE

On-Vehicle Service

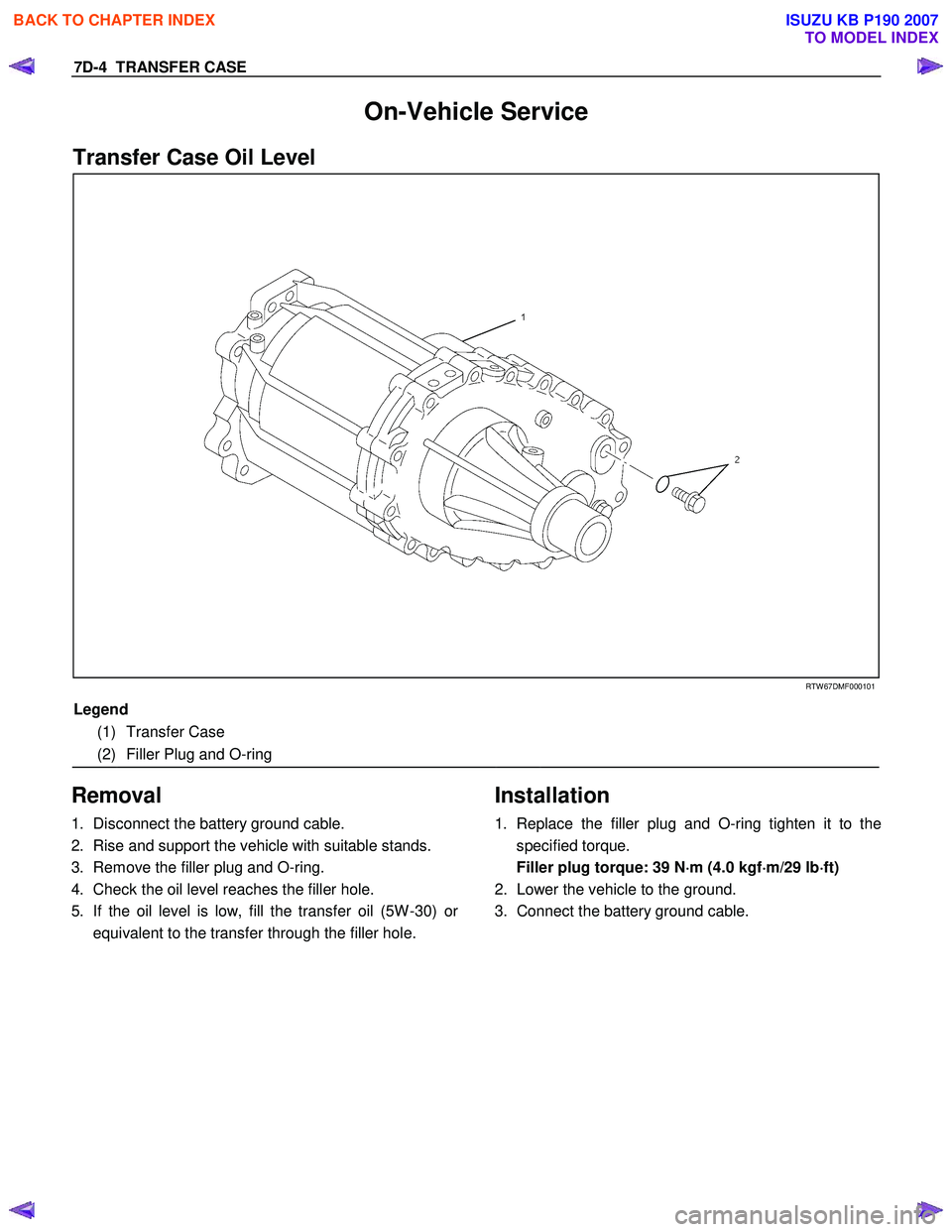

Transfer Case Oil Level

RTW 67DMF000101

Legend

(1) Transfer Case

(2) Filler Plug and O-ring

Removal

1. Disconnect the battery ground cable.

2. Rise and support the vehicle with suitable stands.

3. Remove the filler plug and O-ring.

4. Check the oil level reaches the filler hole.

5. If the oil level is low, fill the transfer oil (5W -30) o

r

equivalent to the transfer through the filler hole.

Installation

1. Replace the filler plug and O-ring tighten it to the

specified torque.

Filler plug torque: 39 N ⋅

⋅⋅

⋅

m (4.0 kgf ⋅

⋅⋅

⋅

m/29 lb ⋅

⋅⋅

⋅

ft)

2. Lower the vehicle to the ground.

3. Connect the battery ground cable.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4835 of 6020

TRANSFER CASE 7D-5

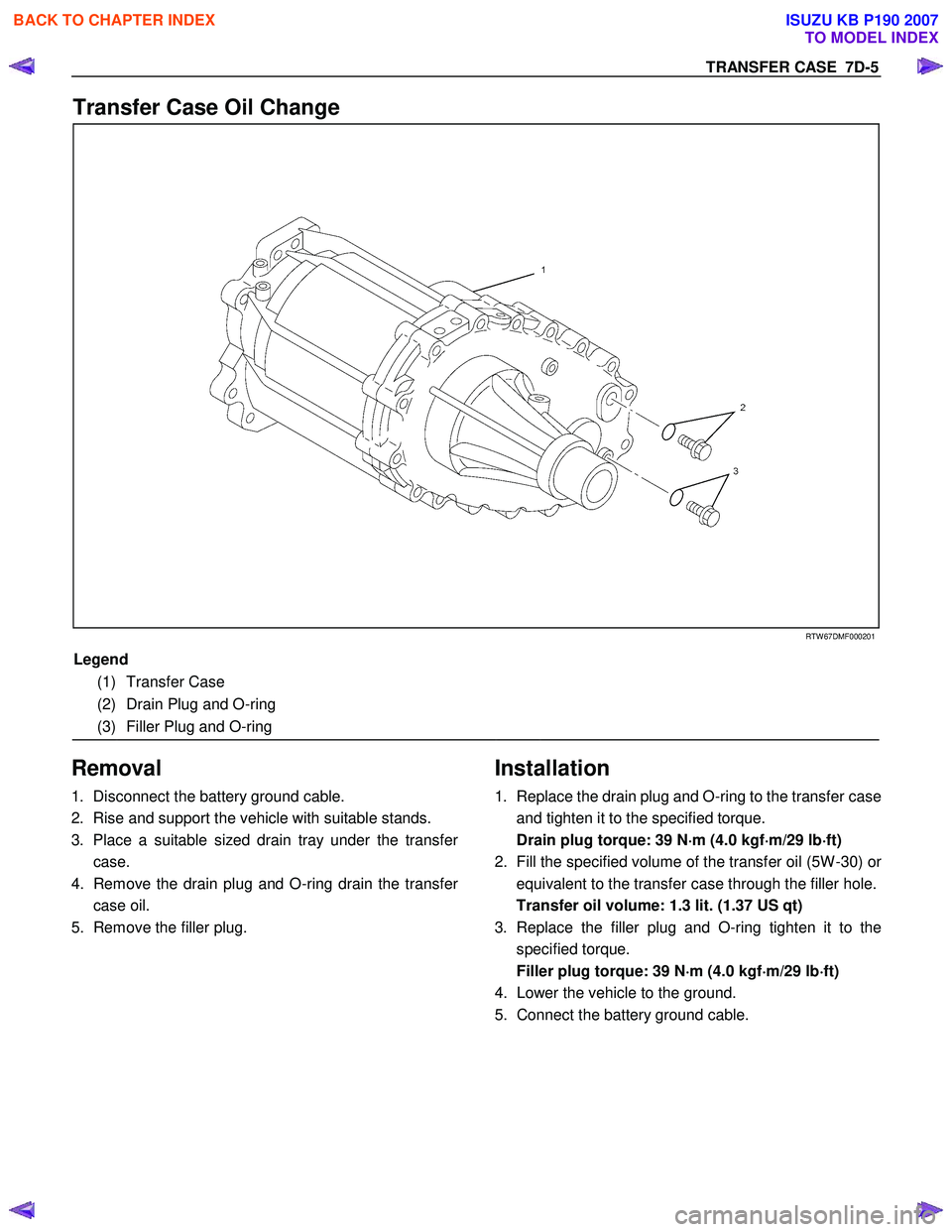

Transfer Case Oil Change

RTW 67DMF000201

Legend

(1) Transfer Case

(2) Drain Plug and O-ring

(3) Filler Plug and O-ring

Removal

1. Disconnect the battery ground cable.

2. Rise and support the vehicle with suitable stands.

3. Place a suitable sized drain tray under the transfe

r

case.

4. Remove the drain plug and O-ring drain the transfe

r

case oil.

5. Remove the filler plug.

Installation

1. Replace the drain plug and O-ring to the transfer case

and tighten it to the specified torque.

Drain plug torque: 39 N ⋅

⋅⋅

⋅

m (4.0 kgf ⋅

⋅⋅

⋅

m/29 lb ⋅

⋅⋅

⋅

ft)

2. Fill the specified volume of the transfer oil (5W -30) o

r

equivalent to the transfer case through the filler hole.

Transfer oil volume: 1.3 lit. (1.37 US qt)

3. Replace the filler plug and O-ring tighten it to the specified torque.

Filler plug torque: 39 N ⋅

⋅⋅

⋅

m (4.0 kgf ⋅

⋅⋅

⋅

m/29 lb ⋅

⋅⋅

⋅

ft)

4. Lower the vehicle to the ground.

5. Connect the battery ground cable.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4836 of 6020

7D-6 TRANSFER CASE

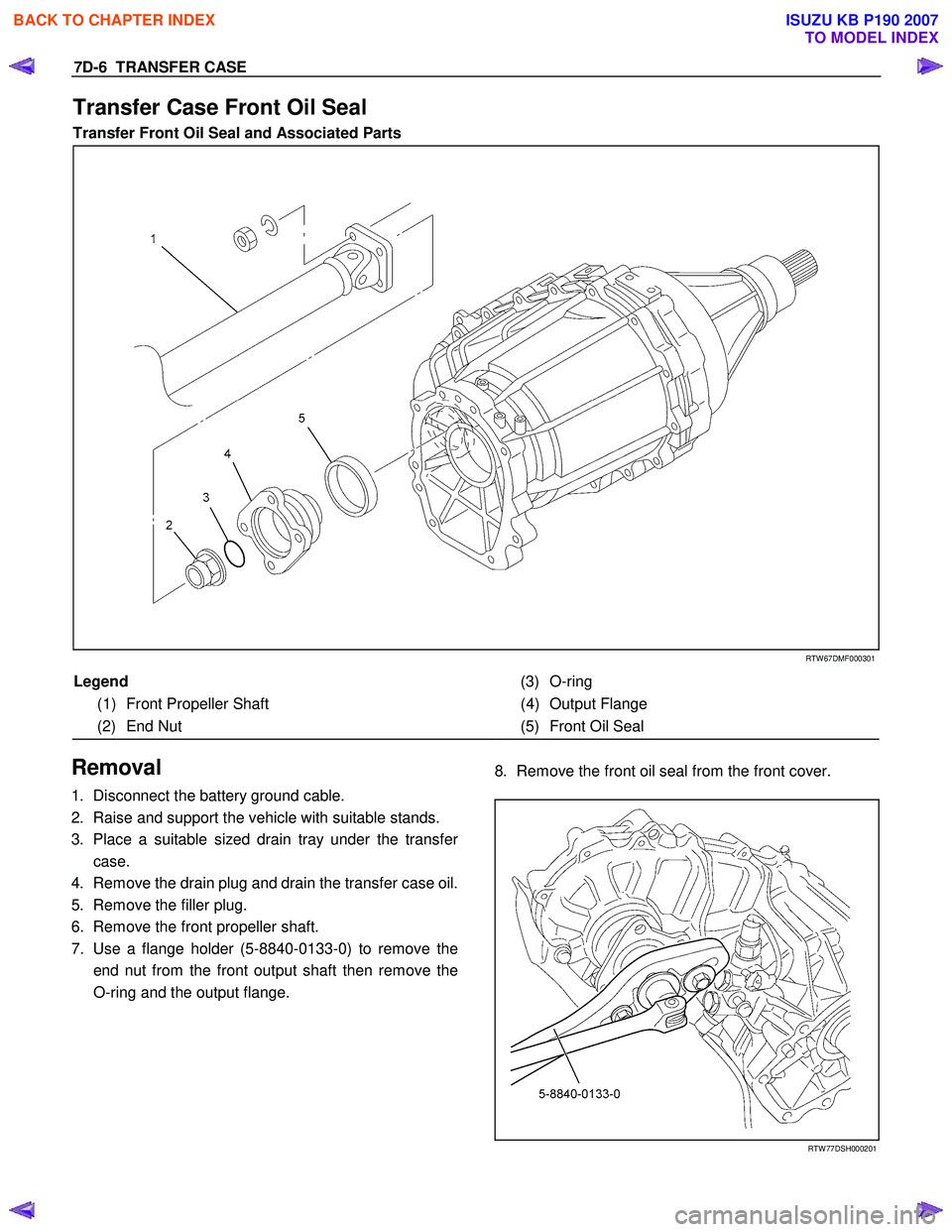

Transfer Case Front Oil Seal

Transfer Front Oil Seal and Associated Parts

RTW 67DMF000301

Legend

(3) O-ring

(1) Front Propeller Shaft (4) Output Flange

(2) End Nut (5) Front Oil Seal

Removal

1. Disconnect the battery ground cable.

2. Raise and support the vehicle with suitable stands.

3. Place a suitable sized drain tray under the transfe

r

case.

4. Remove the drain plug and drain the transfer case oil.

5. Remove the filler plug.

6. Remove the front propeller shaft.

7. Use a flange holder (5-8840-0133-0) to remove the end nut from the front output shaft then remove the

O-ring and the output flange.

8. Remove the front oil seal from the front cover.

RTW 77DSH000201

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4837 of 6020

TRANSFER CASE 7D-7

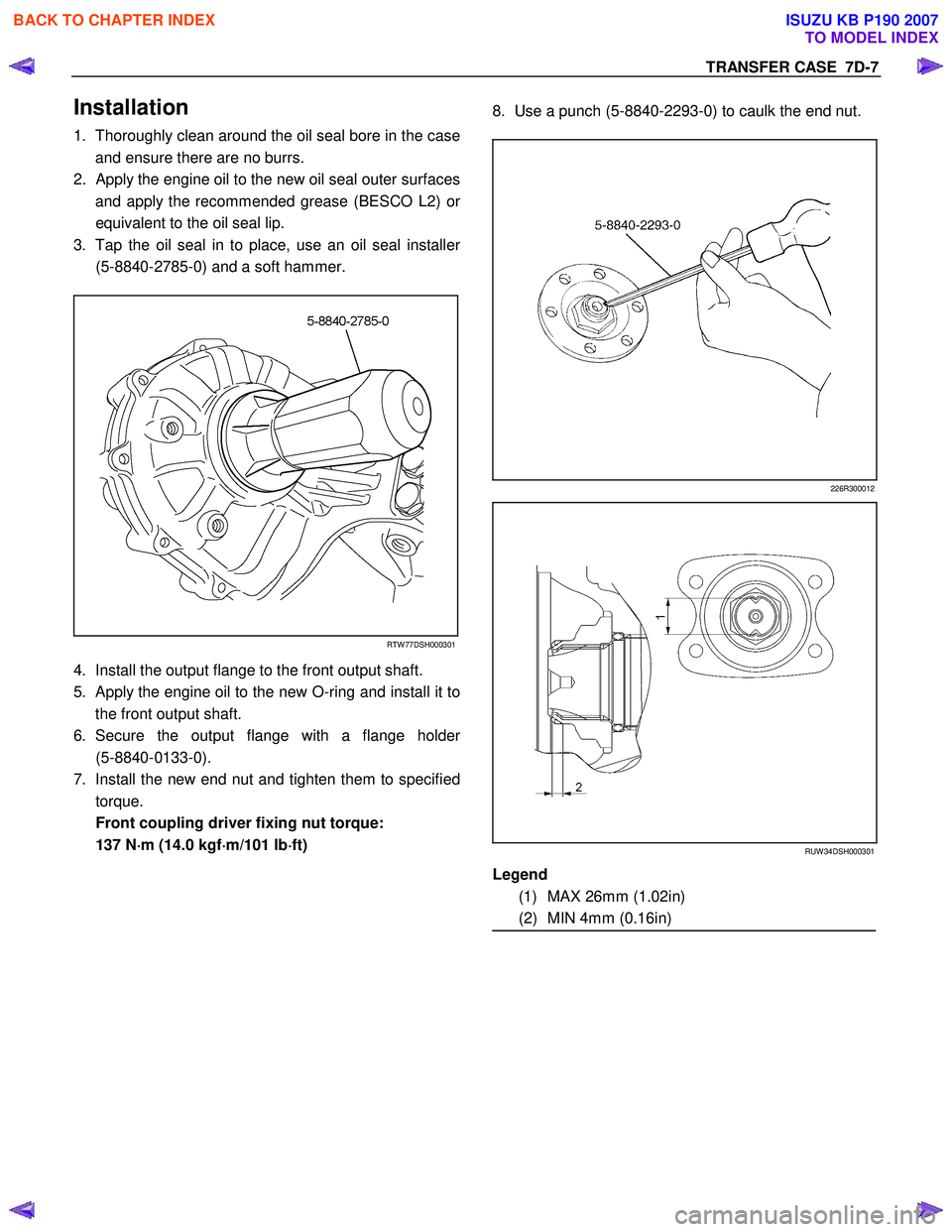

Installation

1. Thoroughly clean around the oil seal bore in the case

and ensure there are no burrs.

2.

Apply the engine oil to the new oil seal outer surfaces

and apply the recommended grease (BESCO L2) o

r

equivalent to the oil seal lip.

3. Tap the oil seal in to place, use an oil seal installe

r

(5-8840-2785-0) and a soft hammer.

RTW 77DSH000301

4. Install the output flange to the front output shaft.

5. Apply the engine oil to the new O-ring and install it to the front output shaft.

6. Secure the output flange with a flange holde

r

(5-8840-0133-0).

7. Install the new end nut and tighten them to specified torque.

Front coupling driver fixing nut torque: 137 N ⋅

⋅⋅

⋅

m (14.0 kgf ⋅

⋅⋅

⋅

m/101 lb ⋅

⋅⋅

⋅

ft)

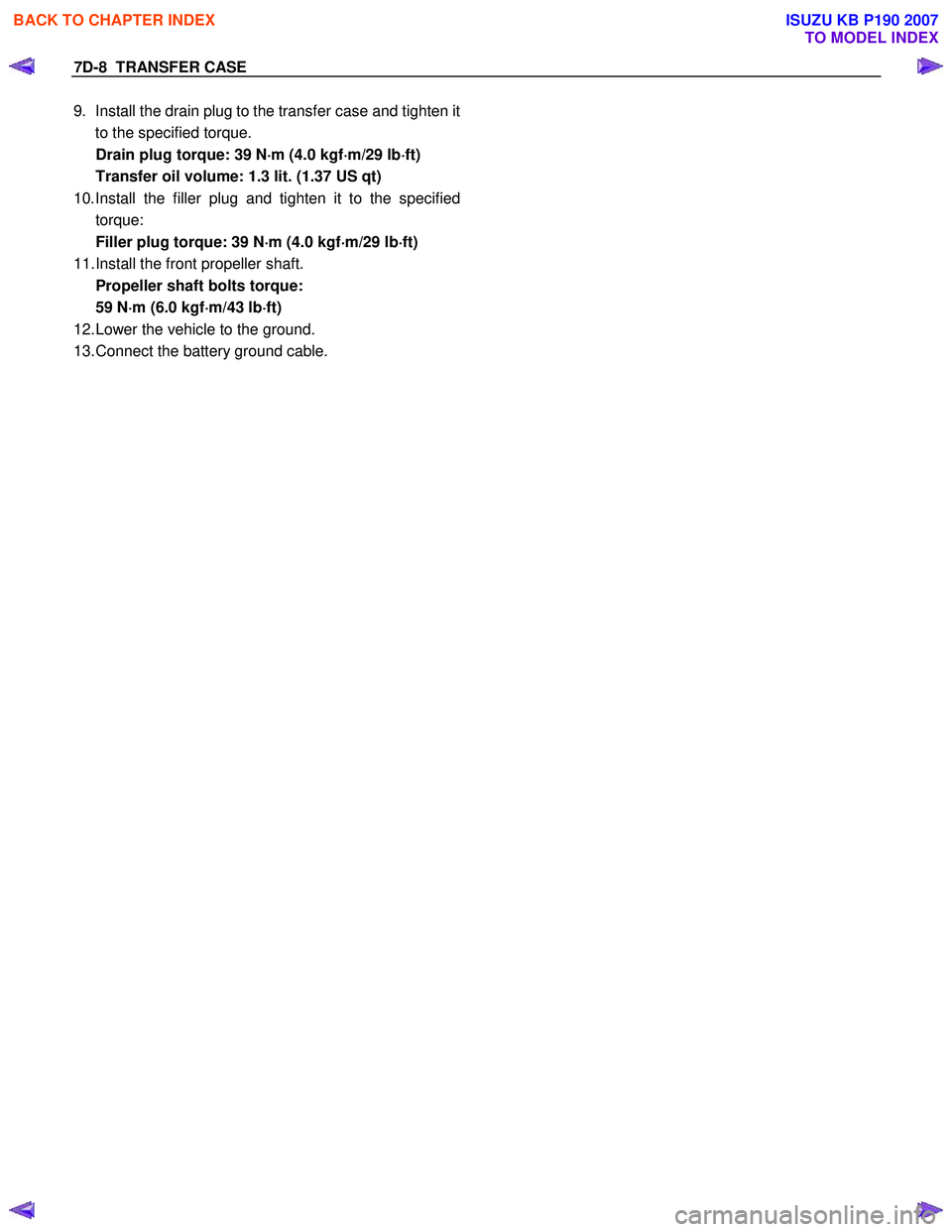

8. Use a punch (5-8840-2293-0) to caulk the end nut.

226R300012

RUW 34DSH000301

Legend

(1) MAX 26mm (1.02in)

(2) MIN 4mm (0.16in)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4838 of 6020

7D-8 TRANSFER CASE

9. Install the drain plug to the transfer case and tighten it

to the specified torque.

Drain plug torque: 39 N ⋅

⋅⋅

⋅

m (4.0 kgf ⋅

⋅⋅

⋅

m/29 lb ⋅

⋅⋅

⋅

ft)

Transfer oil volume: 1.3 lit. (1.37 US qt)

10. Install the filler plug and tighten it to the specified torque:

Filler plug torque: 39 N ⋅

⋅⋅

⋅

m (4.0 kgf ⋅

⋅⋅

⋅

m/29 lb ⋅

⋅⋅

⋅

ft)

11. Install the front propeller shaft.

Propeller shaft bolts torque: 59 N ⋅

⋅⋅

⋅

m (6.0 kgf ⋅

⋅⋅

⋅

m/43 lb ⋅

⋅⋅

⋅

ft)

12. Lower the vehicle to the ground.

13. Connect the battery ground cable.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007