DTC CHECK ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 2254 of 6020

6E–84 ENGINE DRIVEABILITY AND EMISSIONS

SERVICE PROGRAMMING SYSTEM (SPS)

The procedure to program the control unit by using the

Service Programming System (SPS) software contained

in TIS2000 is explained below.

NOTE:

• If the Engine Control Module (ECM) was programmed, the Immobilizer System must be

linked to the ECM: Refer to section 11

“Immobilizer System-ECM replacement” for the

ECM/Immobilizer linking procedure.

• Should Tech2 display "SPS Procedure was not successful", engine will not start, but no DTCs

are present, low battery voltage or poor electrical

connections should be the primary suspects.

Perform the SPS procedure again after rectifying

the fault/s. IMPORTANT:

Perform the following checks before attempting to

program the control unit:

• The Tech2 PCMCIA card is programmed with The latest software release.

• The latest release of TIS2000 is loaded on the PC.

• The vehicle battery is fully charged.

• The control unit to be programmed is connected to the vehicle.

1. Preparations of TIS 2000 1. Connect Tech 2 to P/C.

2. Check to see if Hardware Key is plugged into Port.

3. Activate TIS 2000 by P/C.

4. On the activating screen of TIS2000, choose “Service Programming System”

5. On the screen of “Diagnostic Tester and Processing Program Selection”, choose the one that will comply

with the following.

• Tech-2 in use

• New programming by the existing module or new programming by the replaced/new module.

• Fixing position of the control unit. 6. Upon completion of the selection, push the button of

“Next”.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2261 of 6020

ENGINE DRIVEABILITY AND EMISSIONS 6E–91

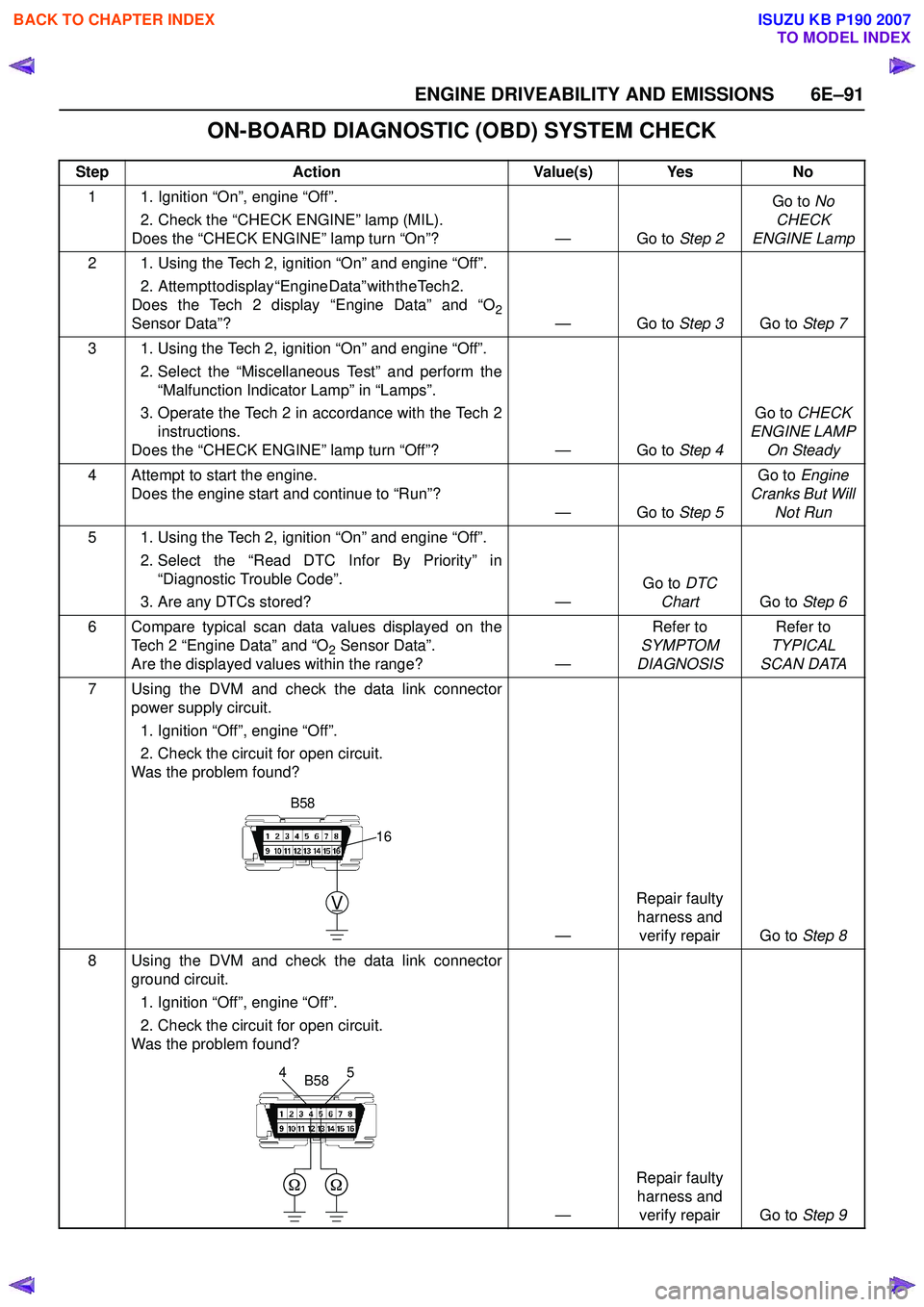

ON-BOARD DIAGNOSTIC (OBD) SYSTEM CHECK

StepAction Value(s) Yes No

1 1. Ignition “On”, engine “Off”. 2. Check the “CHECK ENGINE” lamp (MIL).

Does the “CHECK ENGINE” lamp turn “On”? — Go to Step 2Go to

No

CHECK

ENGINE Lamp

2 1. Using the Tech 2, ignition “On” and engine “Off”. 2 . A t t e m p t t o d i s p l a y “ E n g i n e D a t a ” w i t h t h e T e c h 2 .

Does the Tech 2 display “Engine Data” and “O

2Sensor Data”? — Go to Step 3Go to Step 7

3 1. Using the Tech 2, ignition “On” and engine “Off”. 2. Select the “Miscellaneous Test” and perform the“Malfunction Indicator Lamp” in “Lamps”.

3. Operate the Tech 2 in accordance with the Tech 2 instructions.

Does the “CHECK ENGINE” lamp turn “Off”? — Go to Step 4Go to

CHECK

ENGINE LAMP On Steady

4 Attempt to start the engine. Does the engine start and continue to “Run”? —Go to Step 5Go to

Engine

Cranks But Will Not Run

5 1. Using the Tech 2, ignition “On” and engine “Off”. 2. Select the “Read DTC Infor By Priority” in“Diagnostic Trouble Code”.

3. Are any DTCs stored? —Go to

DTC

Chart Go to Step 6

6 Compare typical scan data values displayed on the Tech 2 “Engine Data” and “O

2 Sensor Data”.

Are the displayed values within the range? —Refer to

SYMPTOM

DIAGNOSIS Refer to

TYPICAL

SCAN DATA

7 Using the DVM and check the data link connector power supply circuit.

1. Ignition “Off”, engine “Off”.

2. Check the circuit for open circuit.

Was the problem found?

—Repair faulty

harness and verify repair Go to Step 8

8 Using the DVM and check the data link connector ground circuit.

1. Ignition “Off”, engine “Off”.

2. Check the circuit for open circuit.

Was the problem found?

—Repair faulty

harness and verify repair Go to Step 9

V

16

B58

5

4B58

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2266 of 6020

6E–96 ENGINE DRIVEABILITY AND EMISSIONS

CHECK ENGINE LAMP (MIL) “ON” STEADY

Circuit description

The check engine lamp should always be illuminated

and steady for about five seconds with ignition “ON” and

the engine stopped. Ignition feed voltage is supplied

directly to the check engine lamp indicator. The Engine

Control Module (ECM) turns the check engine lamp

“ON” by grounding the check engine lamp driver circuit.

The check engine lamp should not remain “ON” with the

engine running and no DTC(s) set. A steady check

engine lamp with the engine running and no DTC(s)

suggests a short to ground in the check engine lamp

driver circuit.

Diagnostic Aids

An intermittent may be caused by a poor connection,

rubbed-through wire insulation, or a wire broken inside

the insulation. Check for the following items:

• Poor connection or damaged harness - Inspect the ECM harness and connectors for improper mating,

broken locks, improperly formed or damaged

terminals, poor terminal-to-wire connection, and

damaged harness.

Check Engine Lamp (MIL) “ON” Steady

Step Action Value(s) Yes No

1 1. Ignition “Off”, engine “Off”. 2. Disconnect the ECM connector.

3. Ignition “On”.

Was the “CHECK ENGINE” lamp turned on? — Go to Step 2Go to Step 4

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2268 of 6020

6E–98 ENGINE DRIVEABILITY AND EMISSIONS

FUEL METERING SYSTEM CHECK

Some failures of the fuel metering system will result in

an “Engine Cranks But Will Not Run” symptom. If this

condition exists, refer to the Cranks But Will Not Run

chart. This chart will determine if the problem is caused

by the ignition system, the ECM, or the fuel pump

electrical circuit.

Refer to Fuel System Electrical Test for the fuel system

wiring schematic.

If there is a fuel delivery problem, refer to Fuel System

Diagnosis , which diagnoses the fuel injectors, the fuel

pressure regulator, and the fuel pump.

Followings are applicable to the vehicles with

closed Loop System:

If a malfunction occurs in the fuel metering system, it

usually results in either a rich HO2S signal or a lean

HO2S signal. This condition is indicated by the HO2S

voltage, which causes the ECM to change the fuel

calculation (fuel injector pulse width) based on the

HO2S reading. Changes made to the fuel calculation

will be indicated by a change in the long term fuel trim

values which can be monitored with a Scan Tool. Ideal

long term fuel trim values are around 0%; for a lean

HO2S signal, the ECM will add fuel, resulting in a fuel

trim value above 0%. Some variations in fuel trim values

are normal because all engines are not exactly the

same. If the evaporative emission canister purge is 02

status may be rich condition. 02 status indicates the

lean condition, refer to DTC P1171 for items which can

cause a lean HO2S signal.

FUEL INJECTOR COIL TEST PROCEDURE

AND FUEL INJECTOR BALANCE TEST

PROCEDURE

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart:

2. Relieve the fuel pressure by connecting 5-8840- 0378-0 T-Joint to the fuel pressure connection on the

fuel rail.

Caution: In order to reduce the risk of fire and

personal injury, wrap a shop towel around the

fuel pressure connection. The towel will absorb

any fuel leakage that occurs during the

connection of the fuel pressure gauge. Place the

towel in an approved container when the

connection of the fuel pressure gauge is

complete.

Place the fuel pressure gauge bleed hose in an

approved gasoline container.

With the ignition switch OFF open the valve on the

fuel pressure gauge.

3. Record the lowest voltage displayed by the DVM after the first second of the test. (During the first

second, voltage displayed by the DVM may be

inaccurate due to the initial current surge.)

Injector Specifications:

• The voltage displayed by the DVM should be within the specified range.

• The voltage displayed by the DVM may increase throughout the test as the fuel injector windings

warm and the resistance of the fuel injector

windings changes. Resistance Ohms

Voltage Specification at

10°C-35°C (50°F-95°F)

11.8-12.6 5.7-6.6

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2283 of 6020

ENGINE DRIVEABILITY AND EMISSIONS 6E–113

ECM DIAGNOSTIC TROUBLE CODES (DTC)Ty p e A

•Emission related.

• Requests illumination of the MIL (Malfunction Indicator Lamp = Check Engine Lamp) of the first trip with a fail.

• Stores a history DTC on the first trip.

• Stores a freeze frame (If empty).

• Stores a fail record.

• Updates the fail record each time the diagnostic test fails.

Ty p e B

•Emission related.

• “Armed” after one trip with fail.

• “Disarmed” after one trip with a pass.

• Requests illumination of the MIL on the second consecutive trip with a fail.

• Store a history DTC on the second consecutive trip with a fail. (The DTC will be armed after the first fail.)

• Stores a freeze frame on the second consecutive trip with a fail (If empty).

• Stores a fail record when the first test fails (not dependent on consecutive trip).

• Updates the fail record each time the diagnostic test fails.

Ty p e D

• Non emission related.

• Does not request illumination of any lamp.

• Stores a history DTC on the first trip.

• Does not store a freeze frame.

• Stores fail record when test fails.

• Updates the fail record each time the diagnostic test fails.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2287 of 6020

ENGINE DRIVEABILITY AND EMISSIONS 6E–11 7

P0351 A Ignition 1 Control Circuit #1 or #4cylinder ignition signals are not

detected consecutively. No fail-safe function.

Consecutive ignition signals are detected. 1. Ignition coil module 1 harness open

circuit, short to ground or short to voltage

circuit.

2. Ignition coil module malfunction.

3. ECM malfunction. J1-19

P0352 A Ignition 2 Control Circuit #2 or #3 cylinder ignition signals are not

detected consecutively. 1. Ignition coil module 2 harness open circuit,

short to ground or short to voltage circuit.

2. Ignition coil module malfunction.

3. ECM malfunction. J1-18

P0443 B EVAP Emission Control System Purge Control Circuit EVAP purge solenoid circuit open, short to

ground or short to voltage circuit. No fail-safe function.

EVAP purge solenoid circuit is correct

condition. 1. Solenoid harness open circuit, short to

ground or short to voltage circuit.

2. Solenoid malfunction.

3. ECM malfunction. J1-5

P0502 B Vehicle Speed Sensor Circuit Low Input 1. No DTC relating to MAP sensor, TPS, ECT sensor, injector control circuit and

ignition control circuit.

2. Engine is running.

3. Vehicle speed is below 3km/h in power condition or 2km/h in deceleration

condition. ECM uses 0km/h condition as

substitute. VSS circuit correct condition.

1. Sensor harness open circuit, short to

ground circuit or short to voltage circuit.

2. Poor connector connection.

3. VSS malfunction.

4. ECM malfunction. J2-23

P0562 D System Voltage Low Battery voltage is below 11V.No fail-safe function.Battery voltage is between 11V and 16V. 1. Battery power feed harness open circuit

or short to ground circuit.

2. ECM ground harness open or poor connection.

3. Poor connector connection.

4. Battery malfunction.

5. Charge system malfunction.

6. ECM malfunction. -

P0563 A System Voltage High Battery voltage is above 16V. 1. Charge system malfunction.

2. Battery jump start cable misconnect.

3. ECM malfunction. -

P0601 A ECM Memory Checksum ECM memory area error.Engine control disabled.Memory are is OK. ECM malfunction. -

P0602 - ECU Programming Error ECM memory area error.Engine control disabled.Memory are is OK. ECM is not programmed. -

P0650 A Malfunction Indicator Lamp (MIL) Control Circuit Malfunction Check engine lamp circuit open, short to

ground or short to voltage circuit. No fail-safe function.

Check engine lamp circuit is correct

condition. 1. Solenoid harness open circuit, short to

ground or short to voltage circuit.

2. Solenoid malfunction.

3. ECM malfunction. J2-32

Code Type

DTC Name DTC Setting Condition Fail-Safe (Back Up)Recovery Condition Related Failure PartsRelated

ECM

Pin No.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2288 of 6020

6E–118 ENGINE DRIVEABILITY AND EMISSIONSP1167 D Fuel Supply System Rich During

Deceleration Fuel Cutoff 1. No DTC relating to MAP sensor, TPS,

EVAP purge, ECT sensor, CKP sensor,

VSS, injector control circuit and ignition

control circuit.

2. O

2 sensor bank 1 output voltage is more

than 550mV in deceleration fuel cutoff

mode. No fail-safe function.

O

2 sensor output voltage is below 550mV. 1. Sensor harness open or short to ground

circuit.

2. O

2 sensor malfunction.

3. MAF sensor output is incorrect.

4. Air intake line malfunction.

5. IAC valve malfunction.

6. Low fuel pressure.

7. Injector malfunction.

8. EVAP purge solenoid valve malfunction.

9. Ignition system malfunction.

10. Spark plug malfunction. 11. ECM malfunction. J2-6/

J2-21

P1171 D Fuel Supply System Lean During Power Enrichment 1. No DTC relating to MAP sensor, TPS,

EVAP purge, ECT sensor, CKP sensor,

VSS, injector control circuit and ignition

control circuit.

2. Engine coolant temperature is more than 60deg. C.

3. Mass air flow is below 13.5m/s.

4. O

2 sensor bank 1 output voltage is below

350mV in power enrichment mode. No fail-safe function.

O

2 sensor output voltage is more than

350mV. 1. Sensor harness open or short to ground

circuit.

2. O

2 sensor malfunction.

3. MAF sensor output is incorrect.

4. Air intake line malfunction.

5. IAC valve malfunction.

6. Low fuel pressure.

7. Injector malfunction.

8. ECM malfunction. J2-6/

J2-21

P1625 B ECM System Reset ECM reset has occurred other than “On ”. Engine control disabled. Memory are is OK. 1. Electrical interference.

2. Magnetic interference.

3. ECM malfunction. -

P1626 - Immobilizer No Signal No response from immobilizer control unit. 1. Engine does not start.

2. Check engine lamp flash.No recovery.

1. ECM and immobilizer control unit

communication circuit open circuit, short to

ground circuit or short to voltage circuit.

2. ECM malfunction.

3. Immobilizer control unit malfunction.

4. Transponder key malfunction. J2-23/

J2-32

P1631 - Immobilizer Wrong Signal Received response is not correct. 1. ECM malfunction.

2. Immobilizer control unit malfunction.

3. Transponder key malfunction. -

P1648 - Wrong Security Code Entered Received incorrect security code. 1. ECM malfunction.

2. Immobilizer control unit malfunction.

3. Transponder key malfunction. -

P1649 - Immobilizer Function Not Programmed Immobilizer function is not programmed in the ECM. ECM malfunction.

-

P1693 B Tachometer Output Low Voltage Tacho output circuit short to ground circuit. No fail-safe function. Tacho output circuit is correct condition. 1. Tacho output circuit short to ground circuit.

2. Poor connector connection.

3. ECM malfunction. J2-25

Code Type

DTC Name DTC Setting Condition Fail-Safe (Back Up)Recovery Condition Related Failure PartsRelated

ECM

Pin No.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2289 of 6020

ENGINE DRIVEABILITY AND EMISSIONS 6E–119

DIAGNOSTIC TROUBLE CODE (DTC) P0107 MANIFOLD ABSOLUTE PRESSURE CIRCUIT LOW INPUT

Condition for setting the DTC and action taken when the DTC sets

Circuit Description

The manifold absolute pressure (MAP) sensor responds

to changes in intake manifold pressure. The MAP

sensor signal voltage to the engine control module

(ECM) varies from below 2 volts at idle (low manifold

pressure) to above 4 volts with the ignition ON, engine

not running or at wide-open throttle (high manifold

pressure).

A “speed density” method of determining engine load is

used on the 2.4L engine. This is calculated using inputs

from the MAP sensor, the CKP Sensor, and the Intake Air Temperature (IAT) sensor. The MAP sensor is the

main sensor used in this calculation, and measuring

engine load is its main function.

The ECM monitors the MAP signals for voltages outside

the normal range (10-104 kPa) of the MAP sensor. If the

ECM detects a MAP signal voltage that is excessively

low, Diagnostic Trouble Code P0107 will be set.

Diagnostic Aids

Check for the following conditions:

• Poor connection at ECM - Inspect harness

Code Type DTC Name DTC Setting Condition Fail-Safe (Back Up)

P0107 A Manifold Absolute Pressure Circuit Low Input 1. No DTC relating to TPS.

2. Throttle position is more than 0% if engine speed is below 1000rpm, or throttle posi-

tion more than 5% if engine speed is more

than 1000rpm.

3. MAP sensor output is below 12kPa. The ECM uses default manifold absolute

pressure value based on engine speed

and throttle position.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2290 of 6020

6E–120 ENGINE DRIVEABILITY AND EMISSIONS

connectors for backed-out terminals, improper

mating, broken locks, improperly formed or damaged

terminals, and poor terminal-to-wire connection.

• If these codes are also set, it could indicate a problem with the 5 Volt reference circuit.

• Damaged harness - Inspect the wiring harness for damage, short to ground, short to battery positive,

and open circuit. If the harness appears to be OK,

observe the MAP display on the Tech 2 while moving

connectors and wiring harnesses related to the

sensor. A change in the display will indicate the

location of the fault.

Diagnostic Trouble Code (DTC) P0107

Manifold Absolute Pressure Circuit Low Input

Step Action Value(s) Yes No

1 Was the “On-Board Diagnostic (OBD) System Check” performed?

—Go to Step 2Go to

On Board

Diagnostic

(OBD) System Check

2 1. Connect the Tech 2. 2. Review and record the failure information.

3. Select “F0: Read DTC Infor By Priority” in “F0: Diagnostic Trouble Code”.

Is the DTC P0107 stored as “Present Failure”? — Go to Step 3Refer to

Diagnostic Aids and Go to Step

3

3 1. Using the Tech2, ignition “On” and engine “Off”. 2. Select “Clear DTC Information” with the Tech2 andclear the DTC information.

3. Operate the vehicle and monitor the “F5: Failed This Ignition” in “F2: DTC Information”.

Was the DTC P0107 stored in this ignition cycle? — Go to Step 4Refer to

Diagnostic Aids and Go to Step

4

4 Check for poor/faulty connection at the MAP sensor or ECM connector. If a poor/faulty connection is found,

repair as necessary.

Was the problem found?

— Verify repair Go to Step 5

5 Visually check the MAP. Was the problem found? — Go to Step 9 Go to Step 6

6 Using the DVM and check the MAP sensor power supply circuit.

1. Ignition “On”, engine “Off”.

2. Disconnect the MAP sensor connector.

3. Check the circuit for open or short to ground circuit.

Was the DVM indicated specified value?

Approximately 5.0V Go to Step 8Go to Step 7

16

31 24E85

E60(J1)

V

E85

3

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2294 of 6020

6E–124 ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Aids

Check for the following conditions:

• Poor connection at ECM - Inspect harness connectors for backed-out terminals, improper

mating, broken locks, improperly formed or damaged

terminals, and poor terminal-to-wire connection.

• If these codes are also set, it could indicate a problem with the 5 Volt reference circuit.

• Damaged harness - Inspect the wiring harness for damage; an open circuit, a short to ground, or a short

to voltage. If the harness appears to be OK, observe

the MAP display on the Tech 2 while moving

connectors and wiring harnesses related to the

sensor. A change in the display will indicate the

location of the fault.

Diagnostic Trouble Code (DTC) P0108

Manifold Absolute Pressure Circuit High Input

Step Action Value(s) Yes No

1 Was the “On-Board Diagnostic (OBD) System Check” performed?

—Go to Step 2Go to

On Board

Diagnostic

(OBD) System Check

2 1. Connect the Tech 2. 2. Review and record the failure information.

3. Select “F0: Read DTC Infor By Priority” in “F0: Diagnostic Trouble Code”.

Is the DTC P0108 stored as “Present Failure”? — Go to Step 3Refer to

Diagnostic Aids and Go to Step

3

3 1. Using the Tech2, ignition “On” and engine “Off”. 2. Select “Clear DTC Information” with the Tech2 andclear the DTC information.

3. Operate the vehicle and monitor the “F5: Failed This Ignition” in “F2: DTC Information”.

Was the DTC P0108 stored in this ignition cycle? — Go to Step 4Refer to

Diagnostic Aids and Go to Step

4

4 Check for poor/faulty connection at the MAP sensor or ECM connector. If a poor/faulty connection is found,

repair as necessary.

Was the problem found?

— Verify repair Go to Step 5

5 Visually check the MAP sensor. Was the problem found? — Go to Step 11Go to Step 6

16

31 24E85

E60(J1)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007