diagram ISUZU KB P190 2007 Workshop Owner's Guide

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 1938 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-321

31. Inspect the following conditions:

• Air leakage around the boost pressuresensor objects that block the sensor hole.

• Air leaking around any of the air induction tubing between the turbocharger and

intake manifold. Check for damaged

components and for loose clamps.

• Misrouted, disconnected or kinked turbocharger nozzle control actuator

vacuum hoses. Refer to Vacuum Hose

Routing Diagram in this section for

correct routing.

• Turbine shaft binding causing lower turbocharger spinning speeds. Refer to

the Turbocharger in engine mechanical

section for diagnosis.

• Turbocharger nozzle control actuator for a stuck condition or slow movement.

Refer to Turbocharger in engine

mechanical section for testing.

• Intake throttle valve sticking. Perform the Intake Throttle Solenoid Control with a

scan tool.

• Restricted air cleaner element, restricted or collapsed air tubing between the air

cleaner and the boost pressure sensor.

• Oil in the air induction tubing causing an incorrect boost pressure sensor signal.

When there is adhesion of oil inside of

tubing, intercooler or turbocharger it

needs to be wiped off.

2. Repair the condition as necessary.

Did you find and correct the condition? —

Go to Step 8 Go to Step 4

4 1. Place the transmission in Neutral and set the

parking brake.

2. Accelerate the engine between idle and W.O.T. (accelerator pedal full travel) many

times while observing the Desired Boost

Pressure and Boost Pressure parameter with

a scan tool.

3. Drive the vehicle that the engine speed is more than 2000 RPM and the Calculated

Engine Load parameter reaches at least 50%

for longer than 10 seconds (such as

acceleration on ramp) while comparing the

Boost Pressure to the Desired Boost

Pressure.

Does the Boost Pressure parameter follow within

the specified value? ±

20 kPa ( ±3

psi)

System OK Go to Step 5

Step

Action Value(s)Yes No

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2156 of 6020

6D3-8 STARTING AND CHARGING SYSTEM

General On-Vehicle Inspection

The operating condition of charging system is indicated by the

charge warning lamp. The warning lamp comes on when the

starter switch is turned to "ON" position. The charging system

operates normally if the lamp goes off when the engine starts.

If the warning lamp shows abnormality or if undercharged or

overcharged battery condition is suspected, perform diagnosis

by checking the charging system as follows:

1. Check visually the belt and wiring connector.

2. W ith the engine stopped, turn the stator switch to "ON" position and observe the warning lamp.

If lamp does not come on:

Disconnect wiring connector from generator, and ground the terminal "L" on connector side.

If lamp comes on:

Repair or replace the generator.

Generator

Removal

1. Disconnect battery ground cable.

2. Move drive belt tensioner to loose side using wrench then remove drive belt.

3. Disconnect terminal "B" wiring connector and connector.

4. Remove generator assembly.

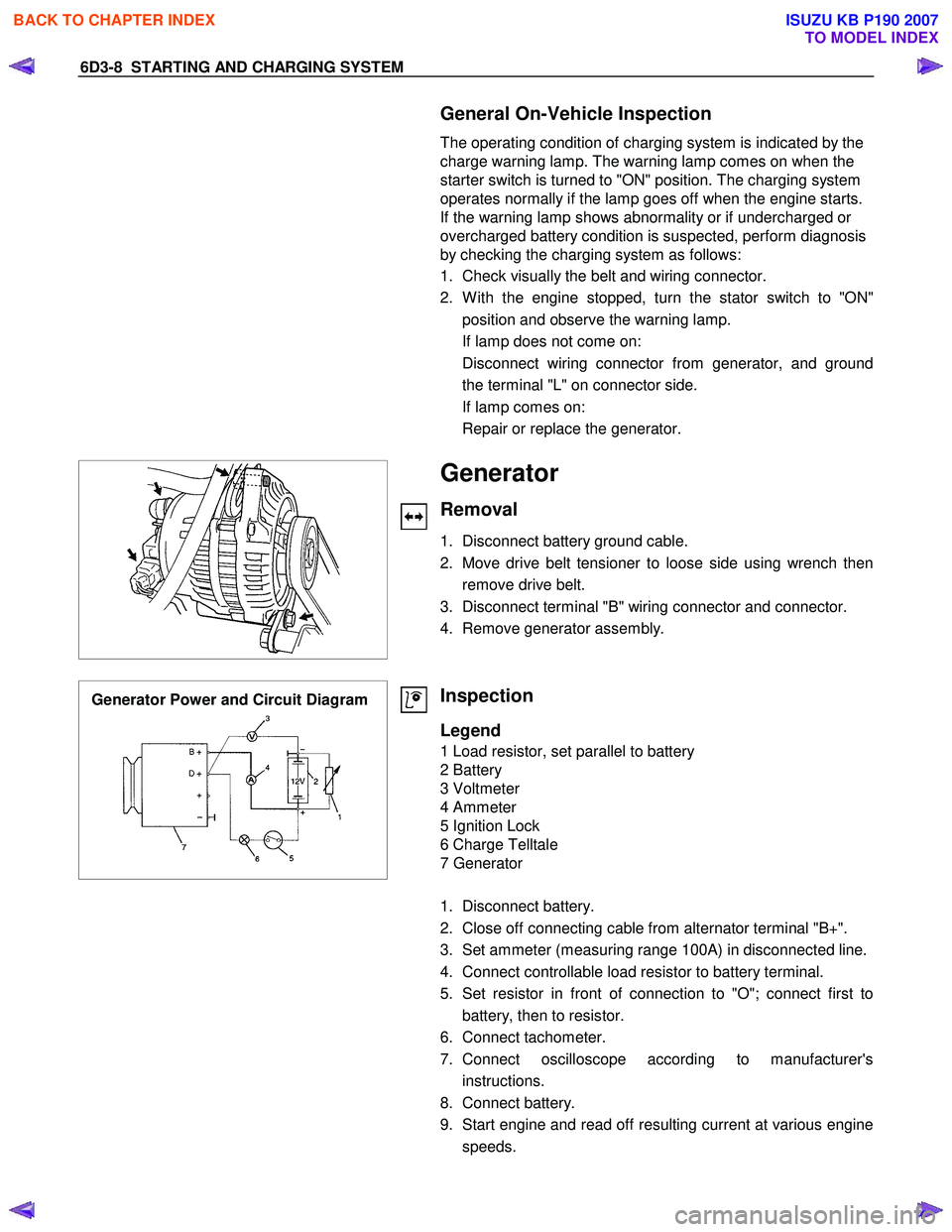

Generator Power and Circuit Diagram

Inspection

Legend

1 Load resistor, set parallel to battery

2 Battery

3 Voltmeter

4 Ammeter

5 Ignition Lock

6 Charge Telltale

7 Generator

1. Disconnect battery.

2. Close off connecting cable from alternator terminal "B+".

3. Set ammeter (measuring range 100A) in disconnected line.

4. Connect controllable load resistor to battery terminal.

5. Set resistor in front of connection to "O"; connect first to battery, then to resistor.

6. Connect tachometer.

7. Connect oscilloscope according to manufacturer's instructions.

8. Connect battery.

9. Start engine and read off resulting current at various engine speeds.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2157 of 6020

STARTING AND CHARGING SYSTEM 6D3-9

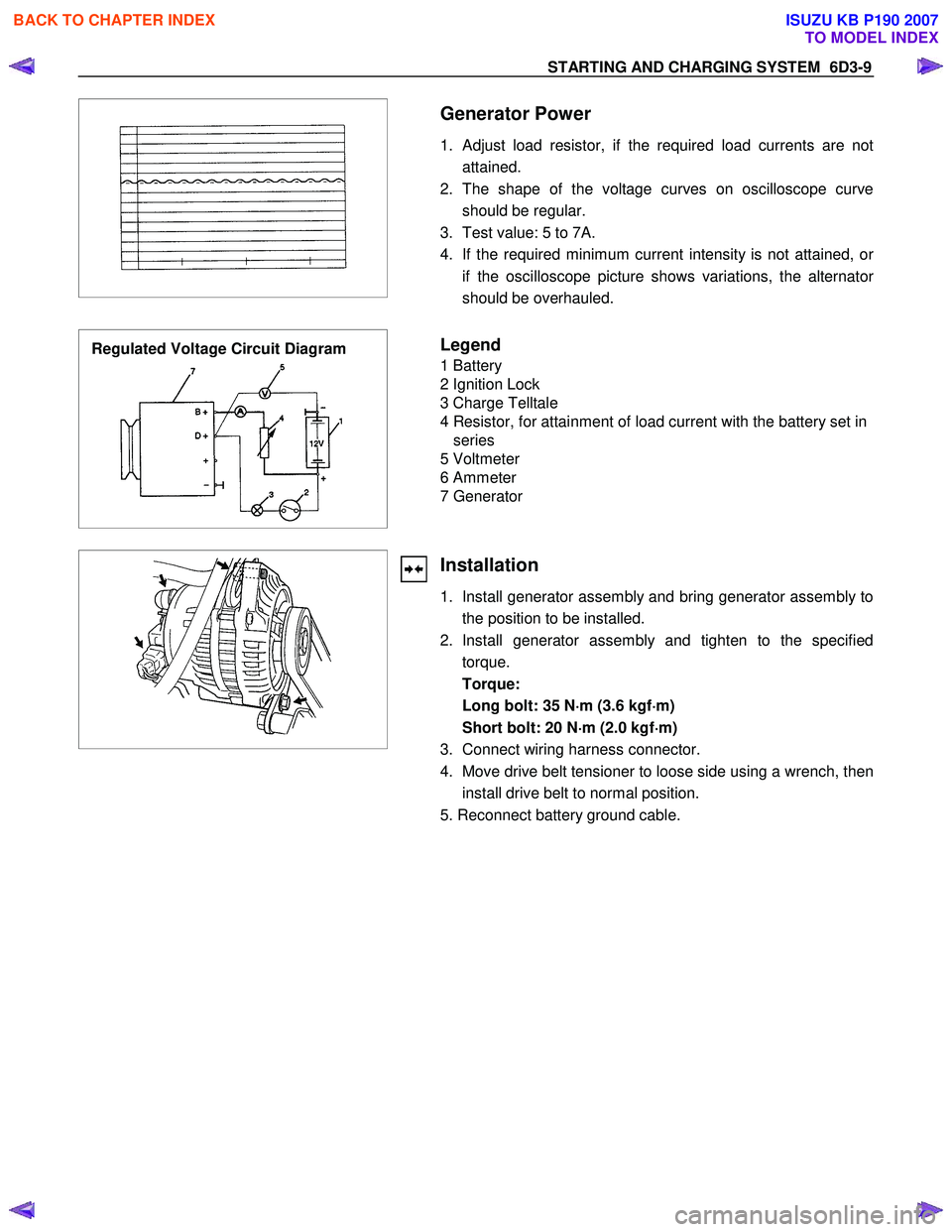

Generator Power

1. Adjust load resistor, if the required load currents are not attained.

2. The shape of the voltage curves on oscilloscope curve should be regular.

3. Test value: 5 to 7A.

4. If the required minimum current intensity is not attained, o

r

if the oscilloscope picture shows variations, the alternator

should be overhauled.

Regulated Voltage Circuit Diagram

Legend

1 Battery

2 Ignition Lock

3 Charge Telltale

4 Resistor, for attainment of load current with the battery set in series

5 Voltmeter

6 Ammeter

7 Generator

Installation

1. Install generator assembly and bring generator assembly to the position to be installed.

2. Install generator assembly and tighten to the specified torque.

Torque:

Long bolt: 35 N ⋅

⋅⋅

⋅

m (3.6 kgf ⋅

⋅⋅

⋅

m)

Short bolt: 20 N ⋅

⋅⋅

⋅

m (2.0 kgf ⋅

⋅⋅

⋅

m)

3. Connect wiring harness connector.

4. Move drive belt tensioner to loose side using a wrench, then install drive belt to normal position.

5. Reconnect battery ground cable.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2171 of 6020

SECTION 6E

TABLE OF CONTENTS

C24SE ENGINE DRIVEABILITY AND EMISSIONS

ABBREVIATIONS CHARTS ......................... 6E-6

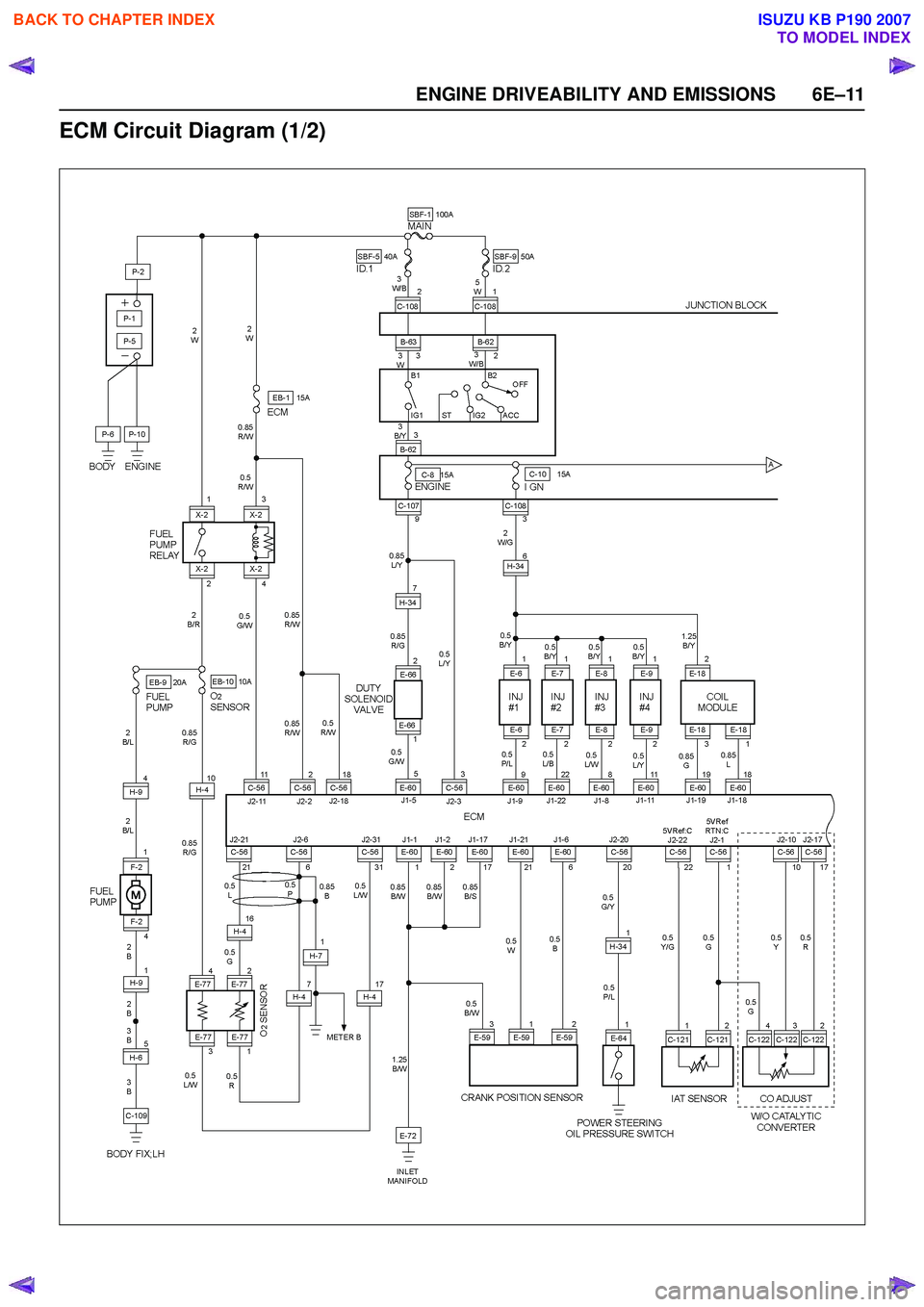

ECM Circuit Diagram (1/2) ............................ 6E-11

ECM Circuit Diagram (2/2) ............................ 6E-12

GROUND POINT CHART - LHD G.EXP (1/4) 6E-13

GROUND POINT CHART - RHD G.EXP (1/4) 6E-17

LOCATION ................................................... 6E-21

CABLE HARNESS & CONNECTOR LOCATION .............................................. 6E-23

CABLE HARNESS & CONNECTOR LOCATION - LHD ................................... 6E-24

CABLE HARNESS & CONNECTOR LOCATION - RHD ................................... 6E-25

CONNECTOR LIST ...................................... 6E-28

RELAY AND FUSE ....................................... 6E-30

RELAY AND FUSE BOX LOCATION (LHD & RHD) ........................................... 6E-30

FUSE AND RELAY LOCATION (LHD & RHD) 6E-32

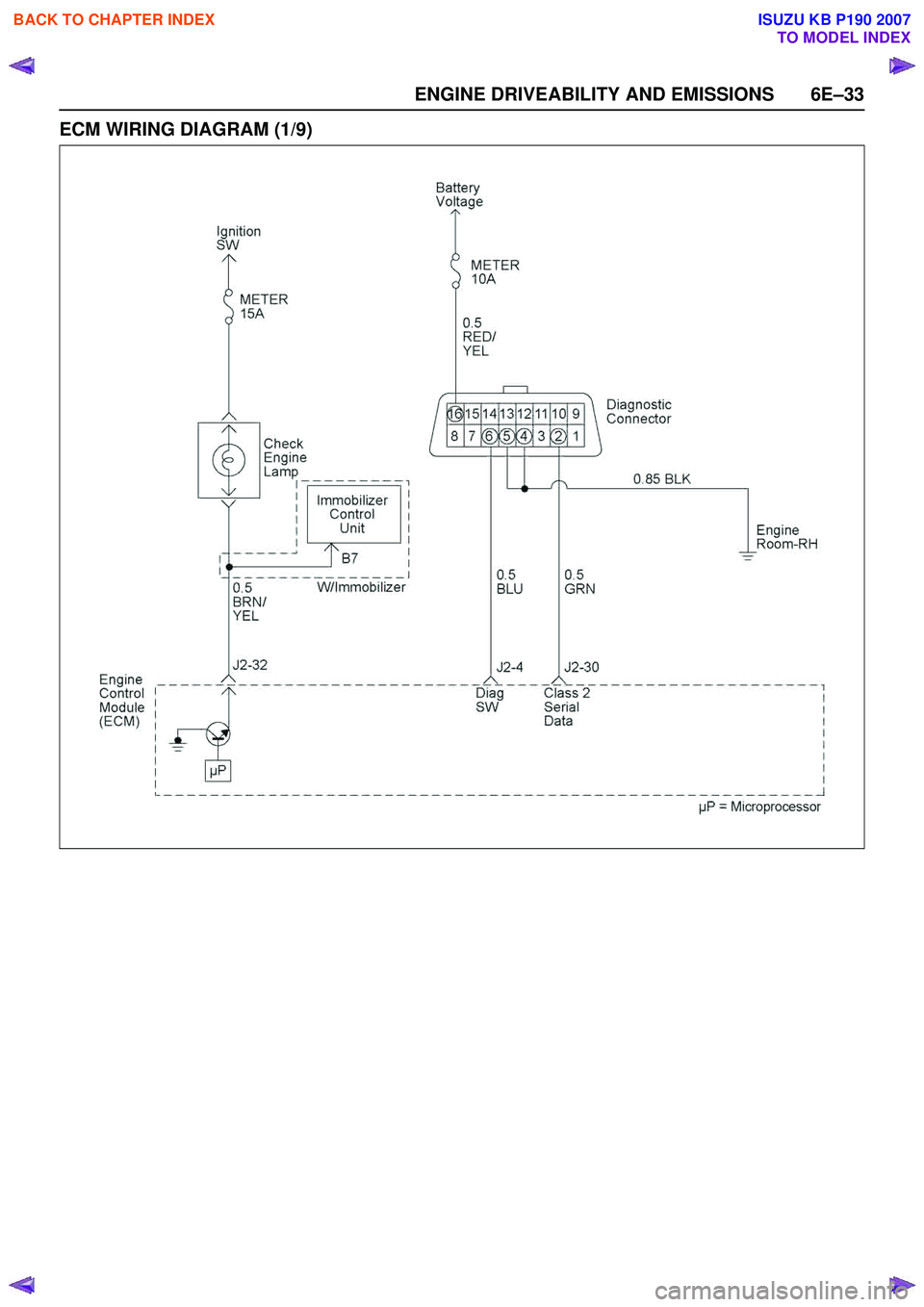

ECM WIRING DIAGRAM (1/9) ..................... 6E-33

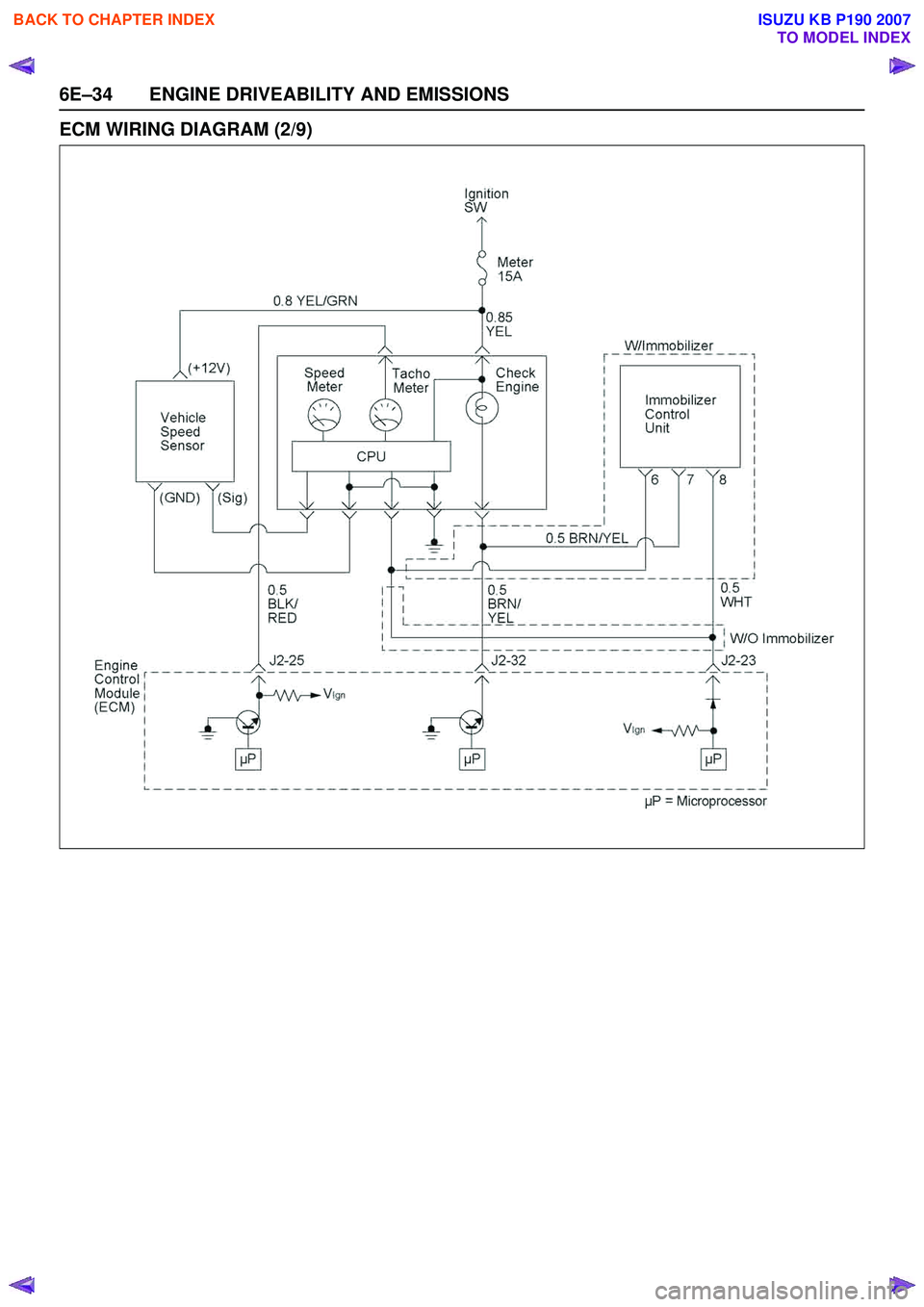

ECM WIRING DIAGRAM (2/9) ..................... 6E-34

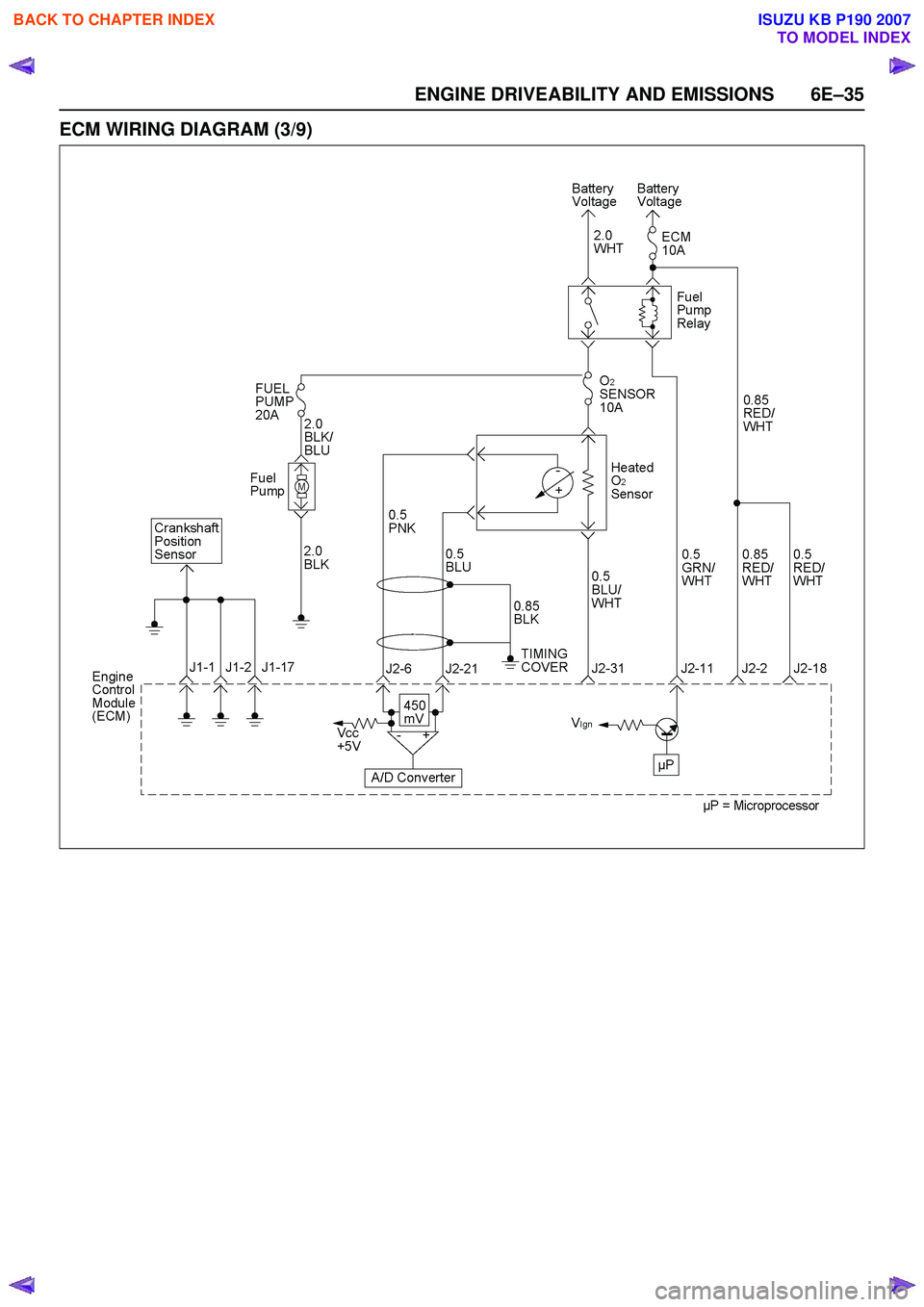

ECM WIRING DIAGRAM (3/9) ..................... 6E-35

ECM WIRING DIAGRAM (4/9) ..................... 6E-36

ECM WIRING DIAGRAM (5/9) ..................... 6E-37

ECM WIRING DIAGRAM (6/9) ..................... 6E-38

ECM WIRING DIAGRAM (7/9) ..................... 6E-39

ECM WIRING DIAGRAM (8/9) ..................... 6E-40

ECM WIRING DIAGRAM (9/9) ..................... 6E-41

ECM CONNECTOR PIN ASSIGNMENT & OUTPUT SIGNAL .................................... 6E-42

GENERAL DESCRIPTION FOR ECM AND SENSORS ............................................... 6E-48

Engine Control Module (ECM) ................... 6E-48

Manifold Absolute Pressure (MAP) Sensor 6E-48

Throttle Position Sensor (TPS) .................. 6E-49

Idle Air Control (IAC) Valve ....................... 6E-49

Crankshaft Position (CKP) Sensor ............ 6E-50

Knock Sensor (KS) .................................... 6E-50

Engine Coolant Temperature (ECT) Sensor 6E-50

Intake Air Temperature (IAT) Sensor ........ 6E-51

Vehicle Speed Sensor (VSS) .................... 6E-51

Heated Oxygen (O

2) Sensor ..................... 6E-51

GENERAL DESCRIPTION FOR FUEL METERING .............................................. 6E-52 Battery Voltage Correction Mode ............... 6E-52

Clear Flood Mode ...................................... 6E-52

Deceleration Fuel Cutoff (DFCO) Mode .... 6E-52

Engine Speed/ Vehicle Speed/ Fuel Disable Mode ........................................................ 6E-52

Acceleration Mode ..................................... 6E-52

Fuel Cutoff Mode ....................................... 6E-52

Starting Mode ............................................ 6E-52

Run Mode .................................................. 6E-52

Fuel Metering System Components .......... 6E-53

Fuel Injector ............................................... 6E-53

Fuel Pressure Regulator ............................ 6E-53

Fuel Rail ..................................................... 6E-53

Fuel Pump Electrical Circuit ....................... 6E-53

Thottle Body Unit ....................................... 6E-53

GENERAL DESCRIPTION FOR ELECTRIC IGNITION SYSTEM ................................. 6E-54

Spark Plug ................................................. 6E-54

GENERAL DESCRIPTION FOR EVAPORATIVE EMISSION SYSTEM ............................... 6E-57

EVAP Emission Control System Purpose .. 6E-57

EVAP Emission Control System Operation 6E-57

System Fault Detection .............................. 6E-57

POSITIVE CRANKCASE VENTILATION (PCV) SYSTEM .................................................. 6E-59

Crankcase Ventilation System Purpose .... 6E-59

A/C CLUTCH DIAGNOSIS ........................ 6E-60

A/C Clutch Circuit Operation ...................... 6E-60

A/C Clutch Circuit Purpose ........................ 6E-60

A/C Request Signal ................................... 6E-60

ISUZU STRATEGY BASED DIAGNOSTICS 6E-61

Overview .................................................... 6E-61

STRATEGY BASED DIAGNOSTICS CHART 6E-61 Diagnostic Thought Process ...................... 6E-62

1. Verify the Complaint .............................. 6E-62

2. Perform Preliminary Checks .................. 6E-62

3. Check Bulletins and Troubleshooting Hints 6E-63

4. Perform Service Manual Diagnostic Checks 6E-63

5a and 5b. Perform Service Manual Diagnostic Procedures .............................................. 6E-63

5c. Technician Self Diagnoses .................. 6E-63

5d. Intermittent Diagnosis .......................... 6E-64

6 E –1

E N GINE DRIV EABILITY AND E M IS SIONS

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2181 of 6020

ENGINE DRIVEABILITY AND EMISSIONS 6E–11

ECM Circuit Diagram (1/2)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2182 of 6020

6E–12 ENGINE DRIVEABILITY AND EMISSIONS

ECM Circuit Diagram (2/2)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2203 of 6020

ENGINE DRIVEABILITY AND EMISSIONS 6E–33

ECM WIRING DIAGRAM (1/9)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2204 of 6020

6E–34 ENGINE DRIVEABILITY AND EMISSIONS

ECM WIRING DIAGRAM (2/9)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2205 of 6020

ENGINE DRIVEABILITY AND EMISSIONS 6E–35

ECM WIRING DIAGRAM (3/9)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2206 of 6020

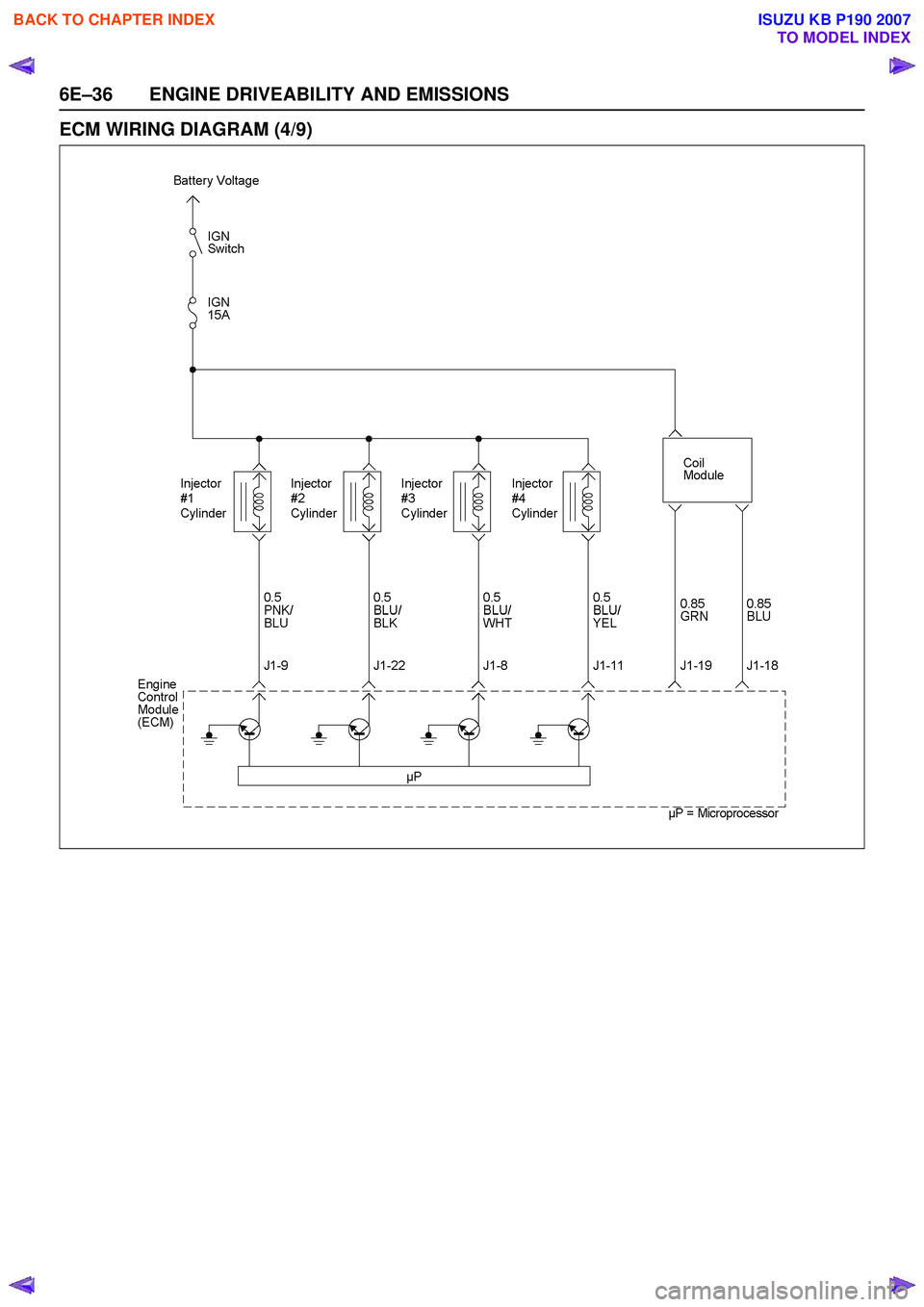

6E–36 ENGINE DRIVEABILITY AND EMISSIONS

ECM WIRING DIAGRAM (4/9)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007