stop start ISUZU KB P190 2007 Workshop Owner's Guide

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 1754 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-137

DTC P0219 (Flash Code 543)

Circuit Description

The crankshaft position (CKP) sensor is located on the

left-hand of the cylinder block rear and it is behind the

starter motor. The ECM calculates the engine speed

and exact position of the crankshaft based on the

signal pulse from the CKP sensor. If the ECM detects

an engine overrun condition, this DTC will set.

Condition for Setting the DTC • The ECM detects that the engine speed is more than 4900 RPM (4JK1 standard output) or 4700

RPM (4JK1 high output and 4JJ1).

Action Taken When the DTC Sets • The ECM illuminates the SVS lamp when the diagnostic runs and fails. Refer to DTC Type

Definitions for Action Taken When the DTC Sets -

Type C. (Euro 4 Specification)

• The ECM illuminates the MIL when the diagnostic runs and fails. Refer to DTC Type Definitions for

Action Taken When the DTC Sets - Type A.

(Except Euro 4 Specification)

• The ECM limits fuel injection quantity.

• The ECM inhibits pilot injection.

• The ECM inhibits cruise control. • The ECM stops engine running when the vehicle

speed is lower than 5 km/h (3 MPH) for 5 seconds.

The engine will run after the key is cycled when the

ignition has been tuned OFF for longer than 10

seconds.

Condition for Clearing the DTC • Refer to DTC Type Definitions for Condition for Clearing the SVS Lamp/ DTC - Type C. (Euro 4

Specification)

• Refer to DTC Type Definitions for Condition for Clearing the MIL/ DTC - Type A. (Except Euro 4

Specification)

Diagnostic Aids • Make sure the CKP sensor is tight and the teeth are not damaged.

• Electromagnetic interference in the CKP sensor circuits may set this DTC.

• The Total Engine Overspeed Events parameter on scan tool indicates number of overrun events.

Notice: • This DTC is caused by an engine overspeed condition, which was most likely caused by driver

error (i.e. downshifting a manual transmission on a

steep grade). Excessive engine overspeed may

damage internal engine components.

Circuit/ System Testing DTC P0219

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 Important:

If DTC P0335 or P0336 is set, diagnose

that DTC first.

1. Install a scan tool.

2. Start the engine.

3. Observe the Engine Speed parameter with a scan tool.

4. Accelerate the engine as necessary.

Does the Engine Speed parameter ever exceed the

specified value? 5000 RPM

Go to Step 4 Go to Step 3

3 Ask the driver if overrun is caused by gear slip-out,

shift error, down-slope driving, etc. If engine

overrun has experienced, the engine must be

inspected and repaired as necessary.

Did you complete the action? —

Go to Step 6

—

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1765 of 6020

6E-148 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

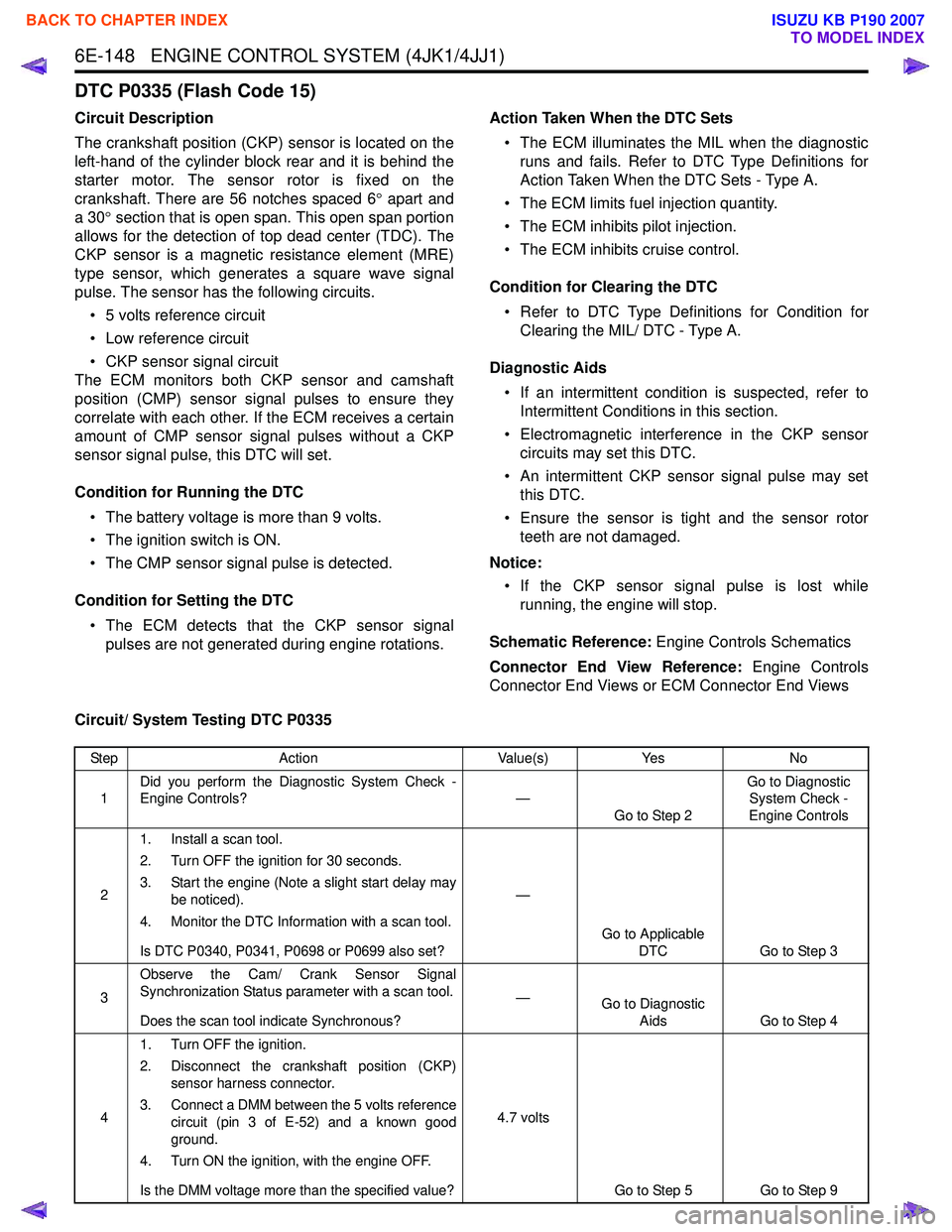

DTC P0335 (Flash Code 15)

Circuit Description

The crankshaft position (CKP) sensor is located on the

left-hand of the cylinder block rear and it is behind the

starter motor. The sensor rotor is fixed on the

crankshaft. There are 56 notches spaced 6 ° apart and

a 30 ° section that is open span. This open span portion

allows for the detection of top dead center (TDC). The

CKP sensor is a magnetic resistance element (MRE)

type sensor, which generates a square wave signal

pulse. The sensor has the following circuits.

• 5 volts reference circuit

• Low reference circuit

• CKP sensor signal circuit

The ECM monitors both CKP sensor and camshaft

position (CMP) sensor signal pulses to ensure they

correlate with each other. If the ECM receives a certain

amount of CMP sensor signal pulses without a CKP

sensor signal pulse, this DTC will set.

Condition for Running the DTC • The battery voltage is more than 9 volts.

• The ignition switch is ON.

• The CMP sensor signal pulse is detected.

Condition for Setting the DTC • The ECM detects that the CKP sensor signal pulses are not generated during engine rotations. Action Taken When the DTC Sets

• The ECM illuminates the MIL when the diagnostic runs and fails. Refer to DTC Type Definitions for

Action Taken When the DTC Sets - Type A.

• The ECM limits fuel injection quantity.

• The ECM inhibits pilot injection.

• The ECM inhibits cruise control.

Condition for Clearing the DTC • Refer to DTC Type Definitions for Condition for Clearing the MIL/ DTC - Type A.

Diagnostic Aids • If an intermittent condition is suspected, refer to Intermittent Conditions in this section.

• Electromagnetic interference in the CKP sensor circuits may set this DTC.

• An intermittent CKP sensor signal pulse may set this DTC.

• Ensure the sensor is tight and the sensor rotor teeth are not damaged.

Notice: • If the CKP sensor signal pulse is lost while running, the engine will stop.

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or ECM Connector End Views

Circuit/ System Testing DTC P0335

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine (Note a slight start delay may be noticed).

4. Monitor the DTC Information with a scan tool.

Is DTC P0340, P0341, P0698 or P0699 also set? —

Go to Applicable DTC Go to Step 3

3 Observe the Cam/ Crank Sensor Signal

Synchronization Status parameter with a scan tool.

Does the scan tool indicate Synchronous? —

Go to Diagnostic

Aids Go to Step 4

4 1. Turn OFF the ignition.

2. Disconnect the crankshaft position (CKP) sensor harness connector.

3. Connect a DMM between the 5 volts reference circuit (pin 3 of E-52) and a known good

ground.

4. Turn ON the ignition, with the engine OFF.

Is the DMM voltage more than the specified value? 4.7 volts

Go to Step 5 Go to Step 9

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1811 of 6020

6E-194 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

DTC P0601 (Flash Code 53)

Circuit Description

This diagnostic applies to internal microprocessor

integrity conditions within the ECM.

Condition for Setting the DTC • The ECM detects that the calculated checksum does not agree with the ECM internal registered

checksum.

Action Taken When the DTC Sets • The ECM illuminates the SVS lamp when the diagnostic runs and fails. Refer to DTC Type

Definitions for Action Taken When the DTC Sets -

Type C. (Euro 4 Specification)

• The ECM illuminates the MIL when the diagnostic runs and fails. Refer to DTC Type Definitions for

Action Taken When the DTC Sets - Type A.

(Except Euro 4 Specification) • The ECM limits fuel injection quantity.

• The ECM inhibits pilot injection.

• The ECM inhibits cruise control.

• The ECM stops engine running when the vehicle speed is lower than 5 km/h (3 MPH) for 5 seconds.

The engine will run after the key is cycled when the

ignition has been tuned OFF for longer than 10

seconds.

Condition for Clearing the DTC • Refer to DTC Type Definitions for Condition for Clearing the SVS Lamp/ DTC - Type C. (Euro 4

Specification)

• Refer to DTC Type Definitions for Condition for Clearing the MIL/ DTC - Type A. (Except Euro 4

Specification)

Circuit/ System Testing DTC P0601

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Turn ON the ignition, with the engine OFF.

4. Monitor the DTC Information with a scan tool.

Does the DTC fail this ignition? —

Go to Step 3 Go to Step 4

3 Important:

Replacement ECM must be

programmed and learned.

Replace the ECM. Refer to ECM Replacement.

Did you complete the replacement? —

Go to Step 4

—

41. Clear the DTCs with a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Operate the vehicle within the Conditions for Running the DTC. You may also operate the

vehicle within the conditions that you

observed from the Freeze Frame/ Failure

Records.

Did the DTC fail this ignition? —

Go to Step 3 Go to Step 5

5 Observe the DTC Information with a scan tool.

Are there any DTCs that you have not diagnosed? —

Go to DTC List System OK

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1814 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-197

DTC P0604 or P0606 (Flash Code 153 or 51)

Circuit Description

This diagnostic applies to internal microprocessor

integrity conditions within the ECM.

Condition for Setting the DTC • The ECM detects a malfunction in its internal random access memory (RAM). (DTC P0604)

• The ECM detects a malfunction in its internal main central processing unit (CPU) or sub integrated

circuit (IC). (DTC P0606)

Action Taken When the DTC Sets • The ECM illuminates the SVS lamp when the diagnostic runs and fails. Refer to DTC Type

Definitions for Action Taken When the DTC Sets -

Type C. (Euro 4 Specification)

• The ECM illuminates the MIL when the diagnostic runs and fails. Refer to DTC Type Definitions for

Action Taken When the DTC Sets - Type A.

(Except Euro 4 Specification) • The ECM limits fuel injection quantity. (DTC

P0604)

• The ECM inhibits pilot injection. (DTC P0604)

• The ECM inhibits cruise control. (DTC P0604)

• The ECM stops engine running when the vehicle speed is lower than 5 km/h (3 MPH) for 5 seconds.

The engine will run after the key is cycled when the

ignition has been tuned OFF for longer than 10

seconds. (DTC P0604)

Condition for Clearing the DTC • Refer to DTC Type Definitions for Condition for Clearing the SVS Lamp/ DTC - Type C. (Euro 4

Specification)

• Refer to DTC Type Definitions for Condition for Clearing the MIL/ DTC - Type A. (Except Euro 4

Specification)

Circuit/ System Testing DTC P0604 or P0606

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Turn ON the ignition, with the engine OFF.

4. Monitor the DTC Information with a scan tool.

Does the DTC fail this ignition? —

Go to Step 3 Go to Step 4

3 Important:

Replacement ECM must be

programmed and learned.

Replace the ECM. Refer to ECM Replacement.

Did you complete the replacement? —

Go to Step 4

—

41. Clear the DTCs with a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Operate the vehicle within the Conditions for Running the DTC. You may also operate the

vehicle within the conditions that you

observed from the Freeze Frame/ Failure

Records.

Did the DTC fail this ignition? —

Go to Step 3 Go to Step 5

5 Observe the DTC Information with a scan tool.

Are there any DTCs that you have not diagnosed? —

Go to DTC List System OK

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1815 of 6020

6E-198 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

DTC P0615 (Flash Code 19)

Circuit Description

The ECM controls the starter cut relay, which de-

energizes the starter relay based on engine speed

inputs or immobilizer command signal. The starter cut

relay uses normally close type relay. During engine

stopping, the starter cut relay is closed to allow

grounding the starter relay. Once engine run, the ECM

energizes the starter cut relay to open the starter relay

circuit and starter motor is disengaged even the ignition

is positioned at START. If the ECM detects an improper

voltage on the starter cut relay control circuit, this DTC

will set.

Condition for Running the DTC • The ignition switch is ON.

Condition for Setting the DTC

Either of following condition is met: • The ECM detects a short to ground circuit condition on the starter cut relay control circuit for

longer than 3 seconds when the relay is

commanded OFF. • The ECM detects a short to voltage circuit

condition on the starter cut relay control circuit for

longer than 3 seconds when the relay is

commanded ON.

Action Taken When the DTC Sets • The ECM illuminates the SVS lamp when the diagnostic runs and fails. Refer to DTC Type

Definitions for Action Taken When the DTC Sets -

Typ e C.

Condition for Clearing the DTC • Refer to DTC Type Definitions for Condition for Clearing the SVS Lamp/ DTC - Type C.

Diagnostic Aids • If an intermittent condition is suspected, refer to Intermittent Conditions in this section.

Notice: • If the starter cut relay control circuit is short to ground, engine does not crank.

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or ECM Connector End Views

Circuit/ System Testing DTC P0615

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Turn ON the ignition, with the engine OFF. DO NOT start the engine.

4. Monitor the DTC Information with a scan tool.

Does the DTC fail this ignition? —

Go to Step 4 Go to Step 3

3 1. Start the engine.

2. Monitor the DTC Information with a scan tool.

Does the DTC fail this ignition? —

Go to Step 6 Go to Diagnostic

Aids

4 1. Turn OFF the ignition.

2. Replace the starter cut relay with the head light dimmer relay or replace with a known

good relay.

3. Turn ON the ignition, with the engine OFF. DO NOT start the engine.

4. Monitor the DTC Information with a scan tool.

Does the DTC fail this ignition? —

Go to Step 5 Go to Step 7

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1843 of 6020

6E-226 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

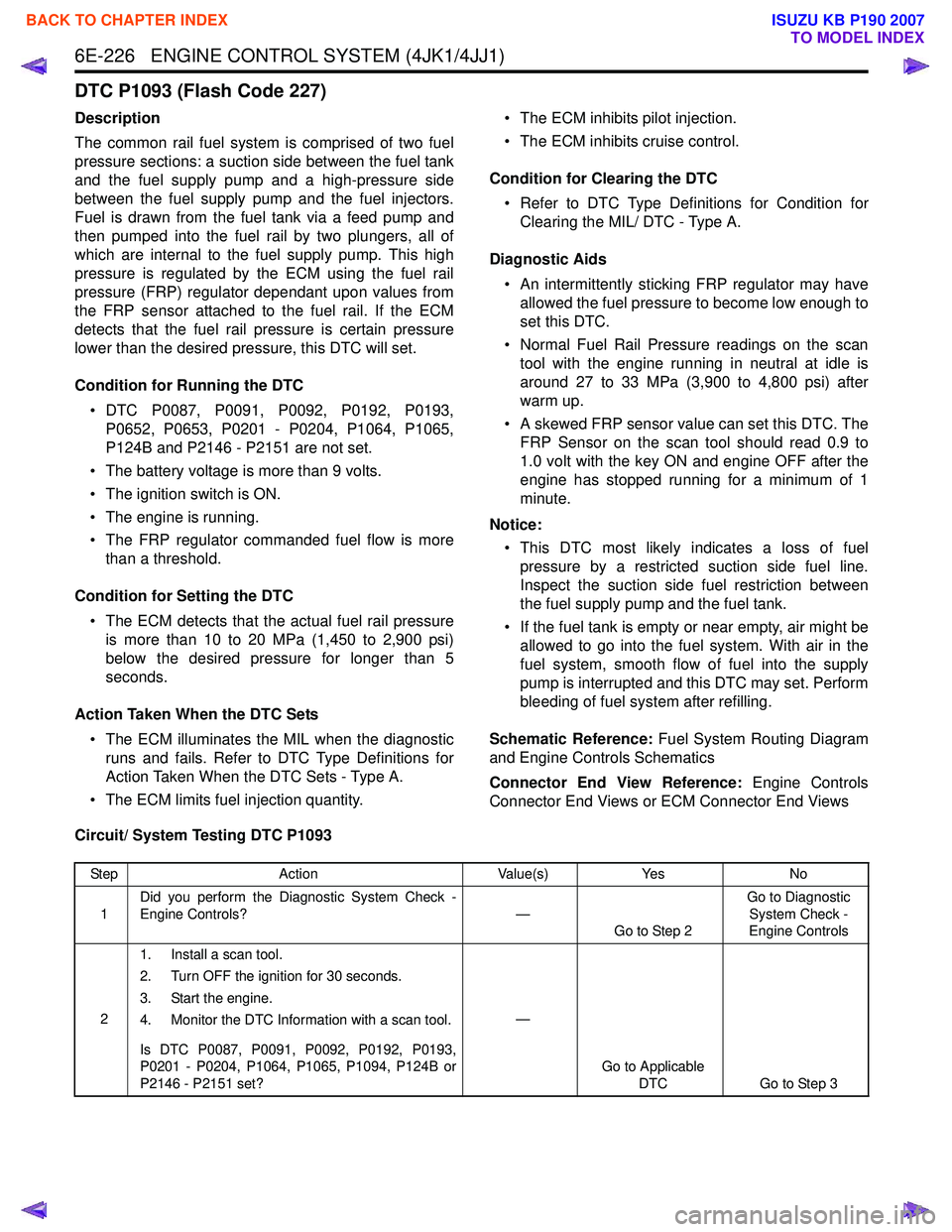

DTC P1093 (Flash Code 227)

Description

The common rail fuel system is comprised of two fuel

pressure sections: a suction side between the fuel tank

and the fuel supply pump and a high-pressure side

between the fuel supply pump and the fuel injectors.

Fuel is drawn from the fuel tank via a feed pump and

then pumped into the fuel rail by two plungers, all of

which are internal to the fuel supply pump. This high

pressure is regulated by the ECM using the fuel rail

pressure (FRP) regulator dependant upon values from

the FRP sensor attached to the fuel rail. If the ECM

detects that the fuel rail pressure is certain pressure

lower than the desired pressure, this DTC will set.

Condition for Running the DTC • DTC P0087, P0091, P0092, P0192, P0193, P0652, P0653, P0201 - P0204, P1064, P1065,

P124B and P2146 - P2151 are not set.

• The battery voltage is more than 9 volts.

• The ignition switch is ON.

• The engine is running.

• The FRP regulator commanded fuel flow is more than a threshold.

Condition for Setting the DTC • The ECM detects that the actual fuel rail pressure is more than 10 to 20 MPa (1,450 to 2,900 psi)

below the desired pressure for longer than 5

seconds.

Action Taken When the DTC Sets • The ECM illuminates the MIL when the diagnostic runs and fails. Refer to DTC Type Definitions for

Action Taken When the DTC Sets - Type A.

• The ECM limits fuel injection quantity. • The ECM inhibits pilot injection.

• The ECM inhibits cruise control.

Condition for Clearing the DTC • Refer to DTC Type Definitions for Condition for Clearing the MIL/ DTC - Type A.

Diagnostic Aids • An intermittently sticking FRP regulator may have allowed the fuel pressure to become low enough to

set this DTC.

• Normal Fuel Rail Pressure readings on the scan tool with the engine running in neutral at idle is

around 27 to 33 MPa (3,900 to 4,800 psi) after

warm up.

• A skewed FRP sensor value can set this DTC. The FRP Sensor on the scan tool should read 0.9 to

1.0 volt with the key ON and engine OFF after the

engine has stopped running for a minimum of 1

minute.

Notice: • This DTC most likely indicates a loss of fuel pressure by a restricted suction side fuel line.

Inspect the suction side fuel restriction between

the fuel supply pump and the fuel tank.

• If the fuel tank is empty or near empty, air might be allowed to go into the fuel system. With air in the

fuel system, smooth flow of fuel into the supply

pump is interrupted and this DTC may set. Perform

bleeding of fuel system after refilling.

Schematic Reference: Fuel System Routing Diagram

and Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or ECM Connector End Views

Circuit/ System Testing DTC P1093

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Monitor the DTC Information with a scan tool.

Is DTC P0087, P0091, P0092, P0192, P0193,

P0201 - P0204, P1064, P1065, P1094, P124B or

P2146 - P2151 set? —

Go to Applicable DTC Go to Step 3

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1928 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-311

In-Tank Fuel Pump System Check

Description

The ECM controls the fuel pump relay, which supplies

power to the fuel pump in the fuel tank. The ECM

commands the fuel pump relay ON for a certain length

of time at ignition switch is ON with the engine OFF.

During the engine is running it is continuity commanded

ON.

In-tank Fuel Pump Control Operation • The battery voltage is more than 9 volts. • The ignition switch is ON.

• The fuel pump is commanded ON for 12 seconds at ignition switch is ON with the engine OFF.

• The fuel pump is continuously ON while engine is running.

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or ECM Connector End Views

Circuit/ System Testing In-Tank Fuel Pump System Check

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Turn ON the ignition for 20 seconds, then start the engine.

4. Monitor the DTC Information with a scan tool.

Is DTC P0231 or P0232 set? —

Refer to Applicable DTC Go to Step 3

3 1. Turn OFF the ignition for 30 seconds.

2. Remove the fuel filler cap.

3. Turn ON the ignition, with the engine OFF.

Is the fuel pump operating sound heard from the

fuel filler? —

Go to Step 4 Go to Step 7

4 Does the fuel pump operating sound stop after

approximately 12 seconds passed? —

Go to Step 21 Go to Step 5

5 1. Turn OFF the ignition for 30 seconds.

2. Replace the fuel pump relay with the head light relay or replace with a known good relay.

3. Turn ON the ignition, with the engine OFF.

Does the fuel pump operating sound stop after

approximately 12 seconds passed? —

Go to Step 20 Go to Step 6

6 Repair the short to battery or ignition voltage

between the fuel pump relay (pin 2 of X-13) and the

fuel pump (pin 1 of F-2).

Did you complete the repair? —

Go to Step 25

—

71. Turn OFF the ignition for 30 seconds.

2. Replace the fuel pump relay with the head light relay or replace with a known good relay.

3. Turn ON the ignition, with the engine OFF.

Is the fuel pump operating sound heard from the

fuel filler? —

Go to Step 17 Go to Step 8

8 Inspect the Fuel Pump (10A) fuse in the engine

room fuse block.

Is the Fuel Pump (10A) fuse open? —

Go to Step 9 Go to Step 10

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1945 of 6020

6E-328 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

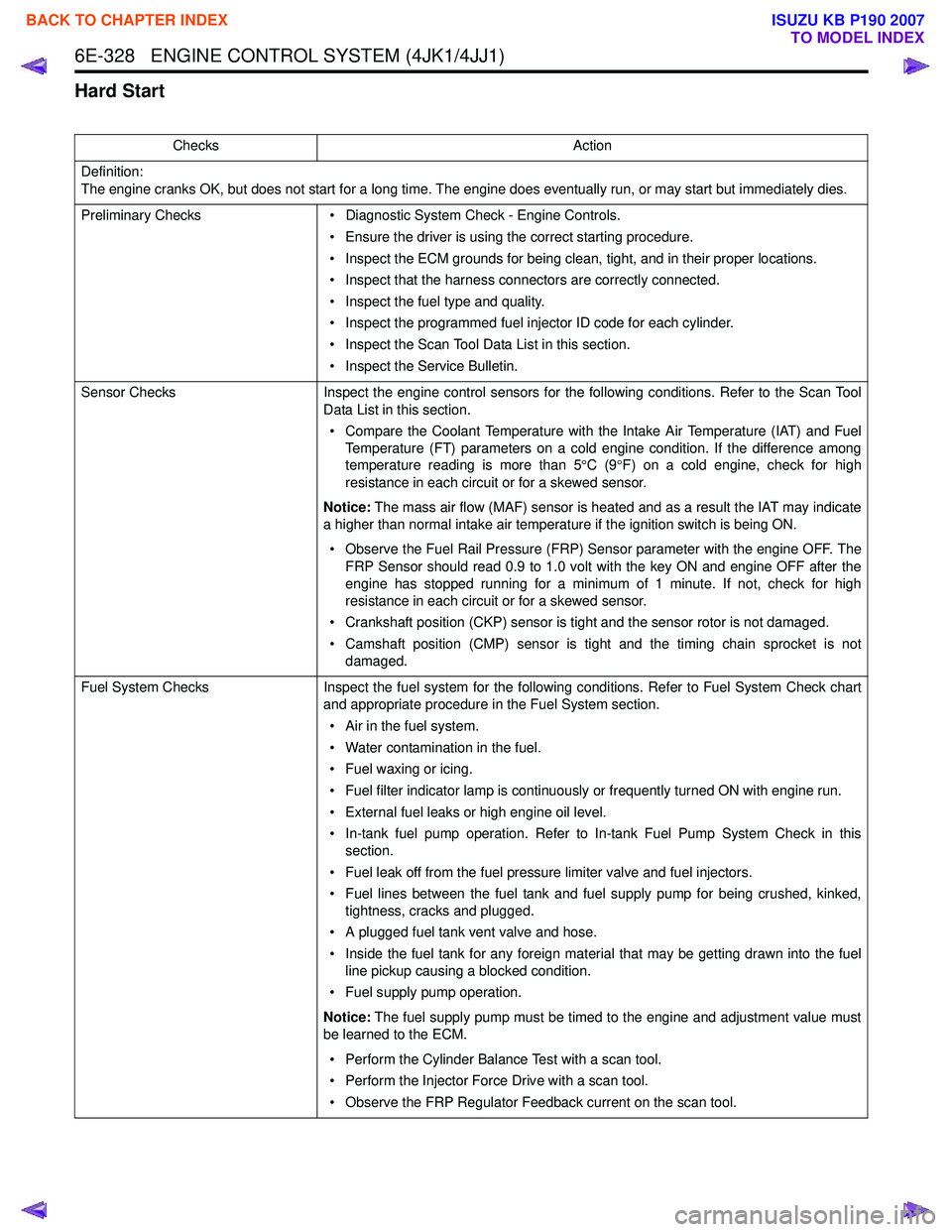

Hard Start

ChecksAction

Definition:

The engine cranks OK, but does not start for a long time. The engine does eventually run, or may start but immediately dies.

Preliminary Checks • Diagnostic System Check - Engine Controls.

• Ensure the driver is using the correct starting procedure.

• Inspect the ECM grounds for being clean, tight, and in their proper locations.

• Inspect that the harness connectors are correctly connected.

• Inspect the fuel type and quality.

• Inspect the programmed fuel injector ID code for each cylinder.

• Inspect the Scan Tool Data List in this section.

• Inspect the Service Bulletin.

Sensor Checks Inspect the engine control sensors for the following conditions. Refer to the Scan Tool

Data List in this section.

• Compare the Coolant Temperature with the Intake Air Temperature (IAT) and Fuel Temperature (FT) parameters on a cold engine condition. If the difference among

temperature reading is more than 5 °C (9 °F) on a cold engine, check for high

resistance in each circuit or for a skewed sensor.

Notice: The mass air flow (MAF) sensor is heated and as a result the IAT may indicate

a higher than normal intake air temperature if the ignition switch is being ON.

• Observe the Fuel Rail Pressure (FRP) Sensor parameter with the engine OFF. The FRP Sensor should read 0.9 to 1.0 volt with the key ON and engine OFF after the

engine has stopped running for a minimum of 1 minute. If not, check for high

resistance in each circuit or for a skewed sensor.

• Crankshaft position (CKP) sensor is tight and the sensor rotor is not damaged.

• Camshaft position (CMP) sensor is tight and the timing chain sprocket is not damaged.

Fuel System Checks Inspect the fuel system for the following conditions. Refer to Fuel System Check chart

and appropriate procedure in the Fuel System section.

• Air in the fuel system.

• Water contamination in the fuel.

• Fuel waxing or icing.

• Fuel filter indicator lamp is continuously or frequently turned ON with engine run.

• External fuel leaks or high engine oil level.

• In-tank fuel pump operation. Refer to In-tank Fuel Pump System Check in this section.

• Fuel leak off from the fuel pressure limiter valve and fuel injectors.

• Fuel lines between the fuel tank and fuel supply pump for being crushed, kinked, tightness, cracks and plugged.

• A plugged fuel tank vent valve and hose.

• Inside the fuel tank for any foreign material that may be getting drawn into the fuel line pickup causing a blocked condition.

• Fuel supply pump operation.

Notice: The fuel supply pump must be timed to the engine and adjustment value must

be learned to the ECM.

• Perform the Cylinder Balance Test with a scan tool.

• Perform the Injector Force Drive with a scan tool.

• Observe the FRP Regulator Feedback current on the scan tool.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1960 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-343

Excessive Smoke (Black Smoke)

ChecksAction

Definition:

Black smoke under load, idle or start up hot or cold.

Preliminary Check • Ensure the vehicle has an actual problem.

• Inspect the ECM grounds for being clean, tight, and in their proper locations.

• Remove the air cleaner and check for dirt, or for air ducts being plugged or restricted. Replace as necessary.

• Inspect the fuel quality (cetane index).

• Inspect the engine oil level and quality.

• Inspect the programmed fuel injector ID code for each cylinder.

• Inspect the Scan Tool Data List in this section.

• Inspect the Service Bulletin.

Sensor Checks Inspect the engine control sensors for the following conditions. Refer to the Scan Tool

Data List in this section.

• Compare the Coolant Temperature with the Intake Air Temperature (IAT) and Fuel Temperature (FT) parameters on a cold engine condition. If the difference among

temperature reading is more than 5 °C (9 °F) on a cold engine, check for high

resistance in each circuit or for a skewed sensor.

Notice: The mass air flow (MAF) sensor is heated and as a result the IAT may indicate

a higher than normal intake air temperature if the ignition switch is being ON.

• Observe the MAF parameter for a skewed or slow MAF sensor.

• Observe the Fuel Rail Pressure (FRP) Sensor parameter with the engine OFF. The FRP Sensor should read 0.9 to 1.0 volt with the key ON and engine OFF after the

engine has stopped running for a minimum of 1 minute. If not, check for high

resistance in each circuit or for a skewed sensor.

• Observe the Fuel Rail Pressure and Desired Fuel Rail Pressure parameter between idle and W.O.T. (accelerator pedal full travel) in Neutral. Fuel Rail Pressure

parameter should follow within ±5 MPa ( ±725 psi) quick enough.

• Observe the Barometric Pressure (BARO) parameter. The BARO parameter should indicate near surrounding barometric pressure. Refer to Altitude vs. Barometric

Pressure. (Standard output)

• Observe the Boost Pressure and BARO with ignition ON and engine OFF. Both parameters should be within the 7.0 kPa (1.0 psi) each other. (High output)

Fuel System Checks Inspect the fuel system for the following conditions. Refer to the Fuel System section.

• Fuel injectors. Remove the injectors and visually inspect.

• Perform the Cylinder Balance Test with a scan tool.

• Perform the Pilot Injection Control with a scan tool.

• Observe the Fuel Compensation for each cylinder at idle on the scan tool.

Air Intake System Checks Inspect the air intake system for the following conditions.

• Air cleaner, air intake ducts and charge air cooler for a restriction, holes, or leaks.

• A restriction in the turbocharger inlet duct.

• Intake throttle valve for a stuck condition.

• A restriction or leak in the intake manifold.

• A restriction or damaged at MAF sensor.

• A worn or damaged turbocharger turbine wheel, shaft or compressor wheel. Refer to turbocharger inspection in the Engine Mechanical section.

Exhaust System Checks Inspect the exhaust system for a possible restriction. Refer to the Exhaust System

section.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1962 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-345

Excessive Smoke (White Smoke)

ChecksAction

Difinition:

White smoke under load, idle or start up hot or cold.

Preliminary Check • Ensure the vehicle has an actual problem.

• Inspect the ECM grounds for being clean, tight, and in their proper locations.

• Inspect the fuel quality (cetane index).

• Inspect the programmed fuel injector ID code for each cylinder.

• Inspect the Scan Tool Data List in this section.

• Inspect the Service Bulletin.

Sensor Checks Inspect the engine control sensors for the following conditions. Refer to the Scan Tool

Data List in this section.

• Compare the Coolant Temperature with the Intake Air Temperature (IAT) and Fuel Temperature (FT) parameters on a cold engine condition. If the difference among

temperature reading is more than 5 °C (9 °F) on a cold engine, check for high

resistance in each circuit or for a skewed sensor.

Notice: The mass air flow (MAF) sensor is heated and as a result the IAT may indicate

a higher than normal intake air temperature if the ignition switch is being ON.

• Observe the Fuel Rail Pressure (FRP) Sensor parameter with the engine OFF. The FRP Sensor should read 0.9 to 1.0 volt with the key ON and engine OFF after the

engine has stopped running for a minimum of 1 minute. If not, check for high

resistance in each circuit or for a skewed sensor.

• Observe the Fuel Rail Pressure and Desired Fuel Rail Pressure parameter between idle and W.O.T. (accelerator pedal full travel) in Neutral. Fuel Rail Pressure

parameter should follow within ± 5 MPa ( ± 725 psi) quick enough.

• Observe the Accelerator Pedal Position (APP). APP parameter should change linearly from 0 to 100% according to the accelerator pedal operation.

• Observe the Boost Pressure and Barometric Pressure (BARO) with ignition ON and engine OFF. Both parameters should be within the 7.0 kPa (1.0 psi) each other.

• Crankshaft position (CKP) sensor is tight and the sensor rotor is not damaged.

Fuel System Checks • If excessive smoke is present, check for a stuck open fuel injector. Inspect for fuel

leakage into the combustion chamber.

• Fuel injectors. Remove the injectors and visually inspect.

• Perform the Cylinder Balance Test with a scan tool.

• Perform the Pilot Injection Control with a scan tool.

• Observe the Fuel Compensation for each cylinder at idle on the scan tool.

Air Intake System Checks Inspect the air intake system for the following conditions.

• Air cleaner, air intake ducts and charge air cooler for a restriction, holes, or leaks.

• A restriction in the turbocharger inlet duct.

• Intake throttle valve for a stuck condition.

• A restriction or leak in the intake manifold.

• A restriction or damaged at MAF sensor.

• Perform the Swirl Control Solenoid Test with a scan tool. Inspect the diaphragm valve operation when it commanded ON/ OFF.

• A worn or damaged turbocharger turbine wheel, shaft or compressor wheel. Oil leak from turbocharger. Refer to turbocharger inspection in the Engine Mechanical

section.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007