stop start ISUZU KB P190 2007 Workshop Service Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 2009 of 6020

ENGINE DIAGNOSIS (C24SE) 6-9

Abnormal Noise Due to Hydraulic Lash Adjuster

Should abnormal noise due to the hydraulic lash

adjuster trouble be heard immediately after the engine

is started, inspect as follows:

Condition Possible cause Correction

Abnormal noise is heard Air contaminated Bleed

HLA is spongy Check ball valve broken Repair

Safety valve in cylinder head

broken Replace

Valve clearance is not zero HLA inside stick

Replace HLA assembly

Troubleshooting Procedure

Short out each spark plug in sequence using insulated

spark plug wire removers. Locate cylinder with

defective bearing by listening for abnormal noise that

stops when spark plug is shorted out.

Condition Possible cause Correction

Noise from connecting rods or

from connecting rod bearings

(Faulty connecting rods or

connecting rod bearings usually

make an abnormal noise slightly

higher than the crank bearing

noise, which becomes more

evident when engine is

accelerated) Bearing or crankshaft pin worn Replace connecting rod bearings

and crankshaft or regrind

crankshaft and install the under

size bearing

Crankpin out of round Replace connecting rod bearings

and crankshaft or regrind

crankshaft and install the under

size bearing

Connecting rod bent Correct or replace

Connecting rod bearing seized Replace connecting rod bearings

and crankshaft or regrind

crankshaft and install the under

size bearing

Troubleshooting Procedure

Abnormal noise stops when the spark plug on the

cylinder with defective parts is shorted out.

Condition Possible cause Correction

Piston and cylinder

(Faulty piston or cylinder usually

makes a combined mechanical

thumping noise which increases

when engine is suddenly

accelerated but diminishes

gradually as the engine warms up) Piston clearance increased due to

cylinder wear Replace piston and cylinder body

Piston seized Replace piston and cylinder body

Piston ring broken Replace piston and cylinder body

Piston defective Replace pistons and others

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2013 of 6020

ENGINE DIAGNOSIS (C24SE) 6-13

Fuel Consumption Excessive

Condition Possible cause Correction

Trouble in fuel system Mixture too rich or too lean due to

trouble in fuel injection system Refer to "Abnormal Combustion"

Fuel cut function does not act Refer to "Abnormal Combustion"

Trouble in ignition system Misfiring or abnormal combustion

due to trouble in ignition system Refer to Hard Start or Abnormal

Combustion Troubleshooting

Guide

Others Engine idle speed too high Reset Idle Air Control Valve

Returning of accelerator control

sluggish Correct

Fuel system leakage Correct or replace

Clutch slipping Correct

Brake drag Correct

Selection of transmission gear

incorrect Caution operator of incorrect gear

selection

Oil Problems

Condition Possible cause Correction

Oil pressure too low Wrong oil in use Replace with correct engine oil

Relief valve sticking Replace

Oil pump not operating properly Correct or replace

Oil pump strainer clogged Clean or replace strainer

Oil pump worn Replace

Oil pressure gauge defective Correct or replace

Crankshaft bearing or connecting

rod bearing worn Replace

Oil contamination

Wrong oil in use Replace with new engine oil

Oil filter clogged Replace oil filter

Cylinder head gasket damage Replace gasket

Burned gases leaking Replace piston and piston rings or

rebore cylinders

Oil not reaching valve system Oil passage in cylinder head or cylinder body clogged Clean or correct

Engine Oil Pressure Check

1. Check for dirt, gasoline or water in the engine

oil.

a. Check the viscosity of the oil.

b. Change the oil if the viscosity is outside the specified standard.

c. Refer to the "Maintenance and Lubrication" section of this manual.

2. Check the engine oil level. The level should fall somewhere between the

"ADD" and the "FULL" marks on the oil level

dipstick.

If the oil level does not reach the "ADD" mark on

the oil level dipstick, engine oil must be added.

3. Remove the oil pressure unit.

4. Install an oil pressure gauge.

5. Start the engine and allow the engine to reach normal operating temperature (About 80 °C).

6. Measure the oil pressure.

Oil pressure should be:

150 kPa(21.8 psi) at idle speed.

7. Stop the engine.

8. Remove the oil pressure gauge

9. Install the oil pressure unit.

10. Start the engine and check for leaks.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2110 of 6020

6B-6 ENGINE COOLING

Draining and Refilling Cooling

System

Before draining the cooling system, inspect the system and

perform any necessary service to ensure that it is clean, does

not leak and is in proper working order. The engine coolant

level should be between the "MIN" and "MAX" lines of reserve

tank when the engine is cold. If low, check for leakage and add

engine coolant up to the "MAX" line. There should not be any

excessive deposit of rust or scales around the radiator cap or

radiator filler hole, and the engine coolant should also be free

from oil.

Replace the engine coolant if excessively dirty.

1. Completely drain the cooling system by opening the drain

plug at the bottom of the radiator.

2. Remove the radiator cap.

WARNING: TO AVOID THE DANGER OF BEING BURNED,

DO NOT REMOVE THE CAP WHILE THE ENGINE AND

RADIATOR ARE STILL HOT. SCALDING FLUID AND

STEAM CAN BE BLOWN OUT UNDER PRESSURE.

3. Disconnect all hoses from the engine coolant reserve tank.

Scrub and clean the inside of the reserve tank with soap and water. Flush it well with clean water, then drain it. Install

the reserve tank and hoses.

4. Refill the cooling system with the engine coolant using a solution that is at least 50 percent antifreeze.

5. Fill the radiator to the base of the filler neck.

Fill the engine coolant reserve tank to "MAX" line when the engine is cold.

6. Block the drive wheels and firmly apply the parking brake and place the shift lever in the "NEUTRAL" position.

7. Remove the radiator cap. Start the engine and warm it up at 2,500 - 3,000 rpm for about 30 minutes.

8. W hen the air comes out from the radiator filler neck and the engine coolant level has gone down, replenish with the

engine coolant. Repeat this procedure until the engine

coolant level does not go down. Then stop the engine and

install the radiator cap. Let the engine cool down.

9. After the engine has cooled, replenish with engine coolant up to the "MAX" line of the reserve tank.

10. Start the engine. W ith the engine running at 3,000 rpm, make sure there is no running water sound from the heate

r

core (behind the center console).

11. If the running water sound is heard, repeat steps 8 to 10.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2113 of 6020

ENGINE COOLING 6B-9

Thermostat

Removal

1. Disconnect battery ground cable.

2. Drain engine coolant from the radiator and engine.

3. Disconnect radiator hose from the inlet pipe.

4. Remove thermostat housing.

5. Remove thermostat from thermostat housing.

Inspection

Suspend the thermostat in a water-filled container using thin

wire. Place a thermometer next to the thermostat.

Do not directly heat the thermostat.

Gradually increase the water temperature. Stir the water so

that the entire water is same temperature.

Confirm the temperature when the valve first begins to open.

Valve opening temperature 92 °

°°

°

C (197.6 °

°°

°

F)

Confirm the temperature when the valve is fully opened.

Valve full open temperature 107 °

°°

°

C(224.6 °

°°

°

F)

Make necessary repair and parts replacement if extreme wear

or damage is found during inspection.

Installation

1. Before installing thermostat, coat sealing surface with

silicon grease.

2. Install O-ring.

3. Install thermostat housing and tighten bolts to the specified torque.

Torque: 15 N ⋅

⋅⋅

⋅

m (1.5 kgf ⋅

⋅⋅

⋅

m)

4. Installation rubber hose.

5. Replenish engine coolant (EC).

6. Start engine and check for EC leakage.

Fan Clutch with Cooling Fan

Inspection and Repair

Make necessary correction or parts replacement if wear,

damage or any other abnormal condition are found through

inspection.

Visually inspect for damage, leak (silicon grease) or other

abnormal conditions.

1. Inspection (on-vehicle)

1) Turn the fan clutch by hand when in a low temperature condition before starting the engine, and confirm that it

can be turned readily.

2) Start the engine to warm it up until the temperature at the fan clutch portion gets to around 80 °C. Then stop the

engine and confirm that the fan clutch can be turned with

considerable effort (clutch torque) when turned by hand.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2117 of 6020

ENGINE COOLING 6B-13

Installation

1. Install radiator assembly, taking care not to damage theradiator core.

2. Install the radiator assembly.

3. Connect reserve tank hose.

4. Connect radiator inlet hose and outlet hose.

5. Pour engine coolant up to filler neck of radiator, and up to MAX mark of reserve tank.

Important operation (in case of 100% engine coolant change) procedure for filling with engine coolant.

• Remove radiator cap.

• Fill with engine coolant to the radiator filler neck.

• Fill with EC to the "MAX" line on the reservoir tank.

• Start the engine with the radiator cap removed and bring to

operating temperature by running engine at 2,500 - 3,000

rpm for 30 minutes.

• By engine coolant temperature gauge reading make sure

that the thermostat is open.

• If air bubbles come up to the radiator filler neck, replenish

with engine coolant. Repeat until the EC level does not drop

any further. Install the radiator cap and stop the engine.

• Replenish engine coolant to the "MAX" line on the reservoi

r

tank and leave as it is until the engine gets cool.

•

After the engine gets cool, start the engine and make sure

there is no water running noise heard from the heater core

while the engine runs at 3000 rpm.

• Should water running noise be heard, repeat the same

procedure from the beginning.

Main Data and Specifications

General Specifications

Cooling system Engine Coolant forced circulation

Radiator Tube type corrugated (2 tube in row)

Heat radiation capacity 66.3 kcal/h

Heat radiation area 7.08 m2

Radiator front area 028 m2

Radiator dry (weight) 3.1 kg

Radiator cap valve opening pressure 93.3 – 122.7 kpa

Engine coolant capacity 3.4L

Engine coolant pump Centrifugal type

Thermostat Bypass type

Engine coolant total capacity 8lit

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2124 of 6020

6C-6 ENGINE FUEL (C24SE)

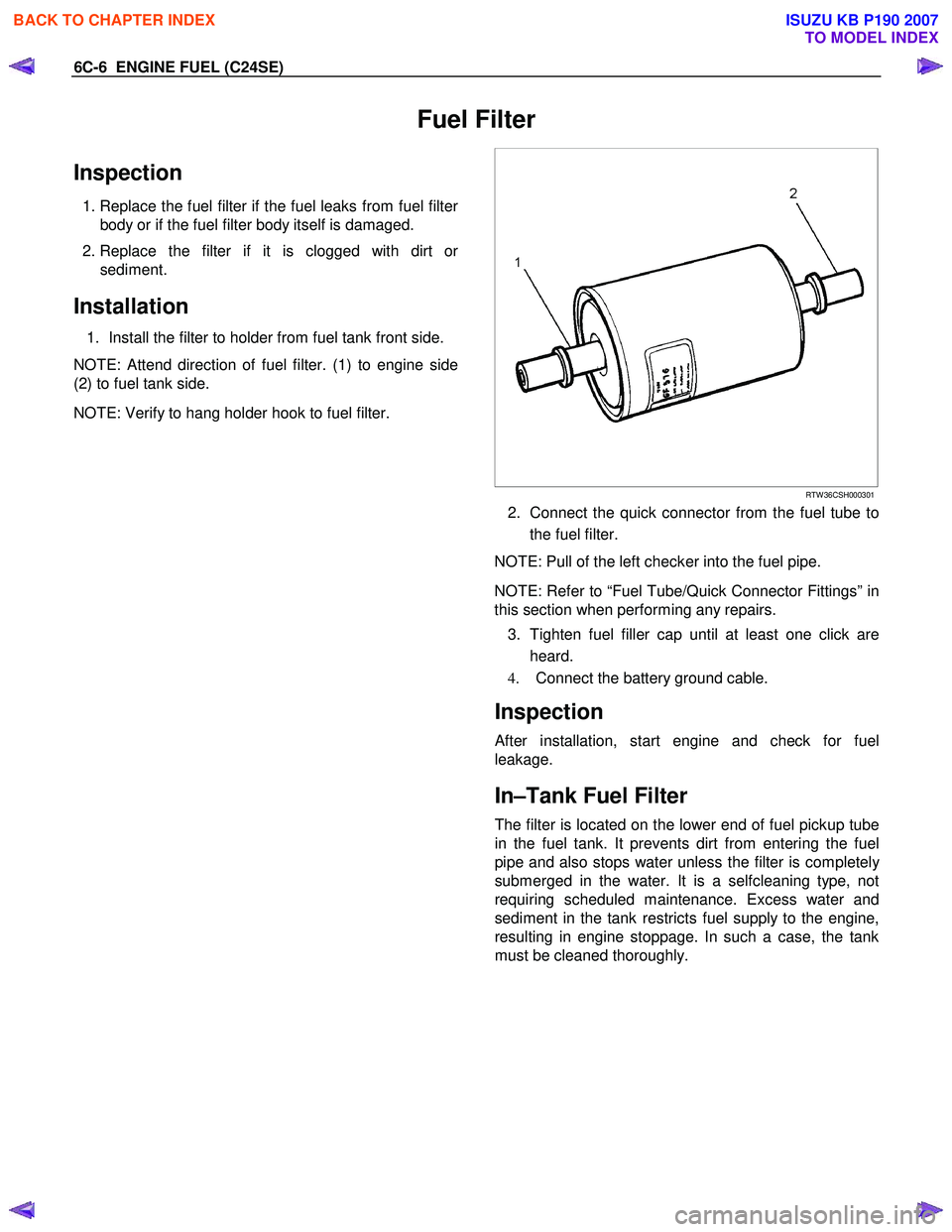

Fuel Filter

Inspection

1. Replace the fuel filter if the fuel leaks from fuel filter

body or if the fuel filter body itself is damaged.

2. Replace the filter if it is clogged with dirt o

r

sediment.

Installation

1. Install the filter to holder from fuel tank front side.

NOTE: Attend direction of fuel filter. (1) to engine side

(2) to fuel tank side.

NOTE: Verify to hang holder hook to fuel filter.

RTW 36CSH000301

2. Connect the quick connector from the fuel tube to

the fuel filter.

NOTE: Pull of the left checker into the fuel pipe.

NOTE: Refer to “Fuel Tube/Quick Connector Fittings” in

this section when performing any repairs.

3. Tighten fuel filler cap until at least one click are heard.

4. Connect the battery ground cable.

Inspection

After installation, start engine and check for fuel

leakage.

In–Tank Fuel Filter

The filter is located on the lower end of fuel pickup tube

in the fuel tank. It prevents dirt from entering the fuel

pipe and also stops water unless the filter is completel

y

submerged in the water. It is a selfcleaning type, not

requiring scheduled maintenance. Excess water and

sediment in the tank restricts fuel supply to the engine,

resulting in engine stoppage. In such a case, the tank

must be cleaned thoroughly.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2132 of 6020

6C-14 ENGINE FUEL (C24SE)

Removal

CAUTION: When repair to the fuel system has been

completed, start engine and check the fuel system

for loose connection or leakage. For the fuel system

diagnosis, see Section “Driveability and Emission".

1. Disconnect battery ground cable.

2. Loosen slowly the fuel filler cap.

NOTE: To prevent spouting out fuel to change the

pressure in the fuel tank.

NOTE: Cover opening of the filler neck to prevent an

y

dust entering.

3. Jack up the vehicle.

4. Support underneath of the fuel tank with a lifter.

5. Remove the inner liner of the wheel house on rea

r

left side.

6. Remove fasten bolt to the filler neck from the body.

7. Disconnect the quick connector (8) into the fuel

tube from the fuel pipe and the evapo tube from

evapo joint connector.

NOTE: Cover the quick connector to prevent any dust

entering and fuel leaking.

NOTE: Refer to “Fuel Tube/Quick Connector Fittings” in

this section when performing any repairs.

8. Remove fasten bolt (1) to the tank band and the tank band (2).

9. Disconnect the pump and sender connector on the

fuel pump and remove the harness from weld clip

on the fuel tank.

10. Lower the fuel tank (6).

NOTE: W hen the fuel tank is lowered from the vehicle,

don’t scratch each hose and tube by around other pars.

Installation

1. Rise the fuel tank into position.

NOTE: Ensure hoses and tubes do not foul on othe

r

component. 2. Connect the pump and sender connector to the

fuel pump and install harness to into the plastic clip

welded to the top of the fuel tank..

NOTE: The connector must be certainly connected

against stopper.

Ensure tank band anchor mates with guide hole on

frame.

3. Install the tank band to fasten bolt.

Torque: 68 N ⋅

⋅⋅

⋅

m (6.9kg ⋅

⋅⋅

⋅

m/50 lb ft)

NOTE: The anchor of the tank band must be certainl

y

installed to guide hole on frame. 4. Connect the quick connector from the fuel tube to

the fuel pipe and the evapo tube from evapo joint

connector.

NOTE: Pull off the left checker into the fuel pipe.

NOTE: Refer to “Fuel Tube/Quick Connector Fittings” in

this section when performing any repairs.

5. Install the filler neck to the body by bolt.

6. Install the inner liner of the wheel house on rea

r

side.

7. Remove lifter to support underneath of the fuel tank.

8. Put back the vehicle.

9. Tigten the filler cap until at least three clicks are

heard.

10. Connect the battery ground cable.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2150 of 6020

6D3-2 STARTING AND CHARGING SYSTEM

Starting System

General Description

Cranking Circuit

The cranking system consists of a battery, starter, starter

switch, starter relay, etc. These main components are

connected.

Starter

The cranking system employs a magnetic type reduction

starter in which the motor shaft is also used as a pinion shaft.

W hen the starter switch is turned on, the contacts of magnetic

switch are closed, and the armature rotates. At the same time,

the plunger is attracted, and the pinion is pushed forward by

the shift lever to mesh with the ring gear.

Then, the ring gear runs to start the engine. W hen the engine

starts and the starter switch is turned off, the plunger returns,

the pinion is disengaged from the ring gear, and the armature

stops rotation. W hen the engine speed is higher than the

pinion, the pinion idles, so that the armature is not driven.

Service Precaution

CAUTION:

Always use the correct fastener in the proper location.

When you replace a fastener, use ONLY the exact part

number for that application. ISUZU will call out those

fasteners that require a replacement after removal. ISUZU

will also call out the fasteners that require thread lockers

or thread sealant. UNLESS OTHERWISE SPECIFIED, do

not use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or fastener

joint interfaces. Generally, such coatings adversely affect

the fastener torque and the joint clamping force, and may

damage the fastener. When you install fasteners, use the

correct tightening sequence and specifications. Following

these instructions can help you avoid damage to parts

and systems.

Diagnosis

Condition Possible cause Correction

Starter does not run Charging failure Repair charging system

Battery Failure Replace Battery

Terminal connection failure Repair or replace terminal connector

and/or wiring harness

Starter switch failure Repair or replace starter switch

Starter failure Repair or replace starter

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2156 of 6020

6D3-8 STARTING AND CHARGING SYSTEM

General On-Vehicle Inspection

The operating condition of charging system is indicated by the

charge warning lamp. The warning lamp comes on when the

starter switch is turned to "ON" position. The charging system

operates normally if the lamp goes off when the engine starts.

If the warning lamp shows abnormality or if undercharged or

overcharged battery condition is suspected, perform diagnosis

by checking the charging system as follows:

1. Check visually the belt and wiring connector.

2. W ith the engine stopped, turn the stator switch to "ON" position and observe the warning lamp.

If lamp does not come on:

Disconnect wiring connector from generator, and ground the terminal "L" on connector side.

If lamp comes on:

Repair or replace the generator.

Generator

Removal

1. Disconnect battery ground cable.

2. Move drive belt tensioner to loose side using wrench then remove drive belt.

3. Disconnect terminal "B" wiring connector and connector.

4. Remove generator assembly.

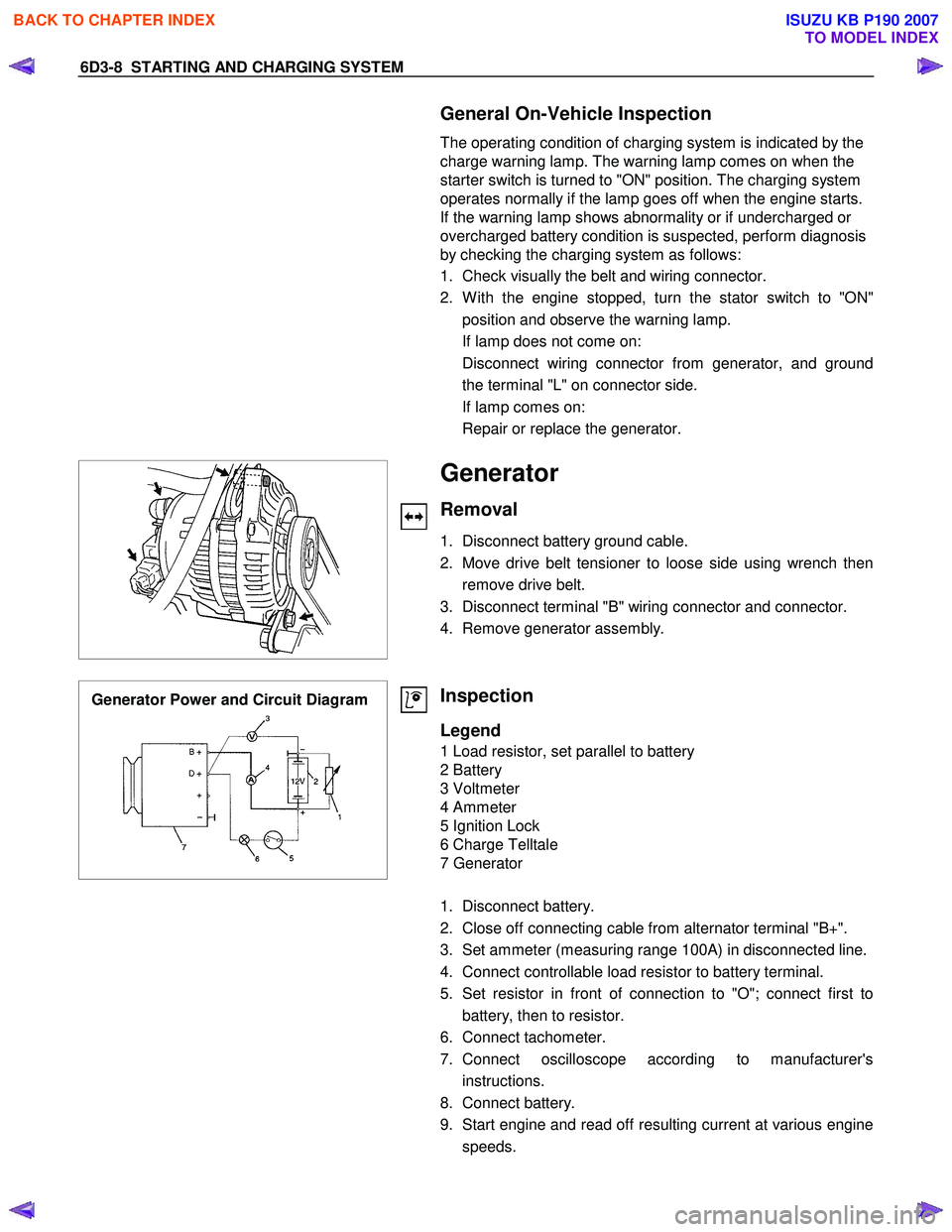

Generator Power and Circuit Diagram

Inspection

Legend

1 Load resistor, set parallel to battery

2 Battery

3 Voltmeter

4 Ammeter

5 Ignition Lock

6 Charge Telltale

7 Generator

1. Disconnect battery.

2. Close off connecting cable from alternator terminal "B+".

3. Set ammeter (measuring range 100A) in disconnected line.

4. Connect controllable load resistor to battery terminal.

5. Set resistor in front of connection to "O"; connect first to battery, then to resistor.

6. Connect tachometer.

7. Connect oscilloscope according to manufacturer's instructions.

8. Connect battery.

9. Start engine and read off resulting current at various engine speeds.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2161 of 6020

STARTING AND CHARGING SYSTEM 6D3-13

5. During current output tests please make sure that the

ammeter is securely connceted into the charge circuit.

6. Some battery powered timing lights can produce high transient voltages when connected or disconnected. Onl

y

disconnect or connect timing lights when the engine is

switched off.

7. Make sure the warning lamp circuit is functioning normall

y

before commencing tests.

8. Battery isolation switches must only be operated when the engine is stopped.

9. To protect the charging system when using 240 volt chargers it is recommeneded that the battery is

disconnected whilst charging.

10. Due to the very low resistance value of the stator winding it may not be possible to obtain accurate readings without

special equipment.

11. 12 volts must never be connected to the "L" terminal of the regulator as this will damage the lamp driver circuit.

12. No loads apart from the warning lamp can be connected to the "L" termainal. The "W " terminal is provided for this

purpose.

Disassembly

1. Mark the relative positions of the end housings in relation to the stator assembly to aid reassembly. Use a permanent

marking pen do not use centre punched as this can cause

misalignmnet of the housings.

2. Remove the EP regulator from the slipring end housing b

y

removing the two screws. Tilt the regulator slightly from the

plug connection until the regulator clears the housing, then

lift clear.

3. Remove the four through bolts.

4. Carefully remove the stator assembly along with the slipring end housing taking care not to put strain on the stator wires.

5. To disconnect the stator from the rectifier assembly, grasp the stator wires close to the wire loop with a pair of long

nosed pliers, heat the joint with a soldering iron, when the

point becomes plastic apply a slight twisting motion to the

wires, then pull upwards to release the wires. Remove the

stator.

This procedure opens the wire loop to release the stato

r

connections easily.

6. To remove the rectifier remove the three retaining scre

w

and the B+ terminal nut and washers.

Note: the B+ bolt and the positive heatsink retaining screw are

fitted with mica insulating washers.

These must be discarded and replaced with new washers and

heatsink compound.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007