Circuit ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 1912 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-295

Circuit/ System Testing DTC P2229

13Observe the DTC Information with a scan tool.

Are there any DTCs that you have not diagnosed? —

Go to DTC List System OK

Step Action Value(s) Yes No

Step

Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Observe the Barometric Pressure (BARO) Sensor parameter with a scan tool.

Is the BARO Sensor parameter more than the

specified value? 4.3 volts

Go to Step 3 Go to Diagnostic

Aids

3 Monitor the DTC Information with a scan tool.

Is DTC P0653 also set? —

Go to Step 4 Go to Step 5

4 1. Turn OFF the ignition.

2. Disconnect the BARO sensor harness connector.

3. Turn ON the ignition, with the engine OFF.

Is the BARO Sensor parameter less than the

specified value? 0.1 volts

Go to DTC P0653 Go to Step 7

5 1. Turn OFF the ignition.

2. Disconnect the BARO sensor harness connector.

3. Turn ON the ignition, with the engine OFF.

Is the BARO Sensor parameter less than the

specified value? 0.1 volts

Go to Step 6 Go to Step 7

6 Connect a test lamp between the low reference

circuit (pin 1 of E-40) and battery voltage.

Does the test lamp illuminate? —

Go to Step 9 Go to Step 8

7 Important:

The BARO sensor may be damaged if

the sensor signal circuit is shorted to a voltage

source.

1. Test the signal circuit between the ECM (pin 18 of E-90) and the BARO sensor (pin 2 of E-

40) for the following conditions:

• A short to battery or ignition voltage

• A short to any 5 volts reference

2. Repair the circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 13 Go to Step 12

8 1. Test the low reference circuit between the

ECM (pin 17 of E-90) and the BARO sensor

(pin 1 of E-40) for an open circuit or high

resistance.

2. Repair the circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 13 Go to Step 10

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1914 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-297

DTC P2621 or P2622 (Flash Code 94)

Circuit Description

The accelerator pedal position (APP) sensor is

mounted on the accelerator pedal control assembly.

The analogue APP signals are converted by the ECM

into a pulse width modulation (PWM) signal. This

converted signal is sent from the ECM to the TCM to

determine appropriate shift points depending on the

accelerator pedal pressing amount. If the ECM detects

an improper voltage level on the APP PWM signal

circuit, DTC P2621 or P2622 will set.

Condition for Running the DTC • The battery voltage is more than 9 volts.

• The ignition switch is ON.

Condition for Setting the DTC • The ECM detects a low voltage condition on the APP PWM signal circuit for longer than 3 seconds.

(DTC P2621) • The ECM detects a high voltage condition on the

APP PWM signal circuit for longer than 3 seconds.

(DTC P2622)

Action Taken When the DTC Sets • The ECM illuminates the MIL when the diagnostic runs and fails. Refer to DTC Type Definitions for

Action Taken When the DTC Sets - Type A.

Condition for Clearing the DTC • Refer to DTC Type Definitions for Condition for Clearing the MIL/ DTC - Type A.

Diagnostic Aids • If an intermittent condition is suspected, refer to Intermittent Conditions in this section.

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or ECM Connector End Views

Circuit/ System Testing DTC P2621

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Monitor the DTC Information with a scan tool.

Does the DTC fail this ignition? —

Go to Step 3 Go to Diagnostic

Aids

3 1. Turn OFF the ignition.

2. Back probe a DMM between the accelerator pedal position (APP) signal circuit of the TCM

harness connector (pin 16 of C-94) and a

known good ground.

3. Turn ON the ignition, with the engine OFF.

Is the DMM voltage more than the specified value? 10.0 volts

Go to Step 6 Go to Step 4

4 Is the DMM voltage more than the specified value

at Step 3? 2.0 volts

Go to Step 7 Go to Step 5

5 Repair the short to ground between the ECM (pin

56 of C-58) and the TCM (pin 16 of C-94).

Did you complete the repair? —

Go to Step 11

—

61. Test the signal circuit between the ECM (pin

56 of C-58) and the TCM (pin 16 of C-94) for

an open circuit or high resistance.

2. Repair the circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 11 Go to Step 8

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1915 of 6020

6E-298 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

Circuit/ System Testing DTC P2622

71. Turn OFF the ignition.

2. Disconnect the TCM harness connector.

3. Inspect for an intermittent and for a poor connection at the harness connector of the

TCM (pin 16 of C-94).

4. Repair the connection(s) as necessary.

Did you find and correct the condition? —

Go to Step 11 Go to Step 9

8 1. Turn OFF the ignition.

2. Disconnect the ECM harness connector.

3. Inspect for an intermittent and for a poor connection at the harness connector of the

ECM (pin 56 of C-58).

4. Repair the connection(s) as necessary.

Did you find and correct the condition? —

Go to Step 11 Go to Step 10

9 Important:

Replacement TCM must be

programmed.

Replace the TCM. Refer to TCM Replacement.

Did you complete the replacement? —

Go to Step 11

—

10Important:

Replacement ECM must be

programmed and learned.

Replace the ECM. Refer to ECM Replacement.

Did you complete the replacement? —

Go to Step 11

—

111. Reconnect all previously disconnected

harness connector(s).

2. Clear the DTCs with a scan tool.

3. Turn OFF the ignition for 30 seconds.

4. Start the engine.

5. Operate the vehicle within the Conditions for Running the DTC. You may also operate the

vehicle within the conditions that you

observed from the Freeze Frame/ Failure

Records.

Did the DTC fail this ignition? —

Go to Step 3 Go to Step 12

12 Observe the DTC Information with a scan tool.

Are there any DTCs that you have not diagnosed? —

Go to DTC List System OK

Step

Action Value(s)Yes No

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Monitor the DTC Information with a scan tool.

Does the DTC fail this ignition? —

Go to Step 3 Go to Diagnostic

Aids

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1916 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-299

31. Turn OFF the ignition.

2. Disconnect the TCM harness connector.

3. Connect a test lamp between the accelerator pedal position (APP) signal circuit of the TCM

harness connector (pin 16 of C-94) and a

known good ground.

4. Turn ON the ignition, with the engine OFF.

Does the test lamp illuminate? —

Go to Step 4 Go to Step 5

4 1. Test the signal circuit between the ECM (pin

56 of C-58) and the TCM (pin 16 of C-94) for a

short to battery or ignition voltage.

2. Repair the circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 7 Go to Step 6

5 Important:

Replacement TCM must be

programmed.

Replace the TCM. Refer to TCM Replacement.

Did you complete the replacement? —

Go to Step 7

—

6Important:

Replacement ECM must be

programmed and learned.

Replace the ECM. Refer to ECM Replacement.

Did you complete the replacement? —

Go to Step 7

—

71. Reconnect all previously disconnected

harness connector(s).

2. Clear the DTCs with a scan tool.

3. Turn OFF the ignition for 30 seconds.

4. Start the engine.

5. Operate the vehicle within the Conditions for Running the DTC. You may also operate the

vehicle within the conditions that you

observed from the Freeze Frame/ Failure

Records.

Did the DTC fail this ignition? —

Go to Step 3 Go to Step 8

8 Observe the DTC Information with a scan tool.

Are there any DTCs that you have not diagnosed? —

Go to DTC List System OK

Step

Action Value(s)Yes No

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1917 of 6020

6E-300 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

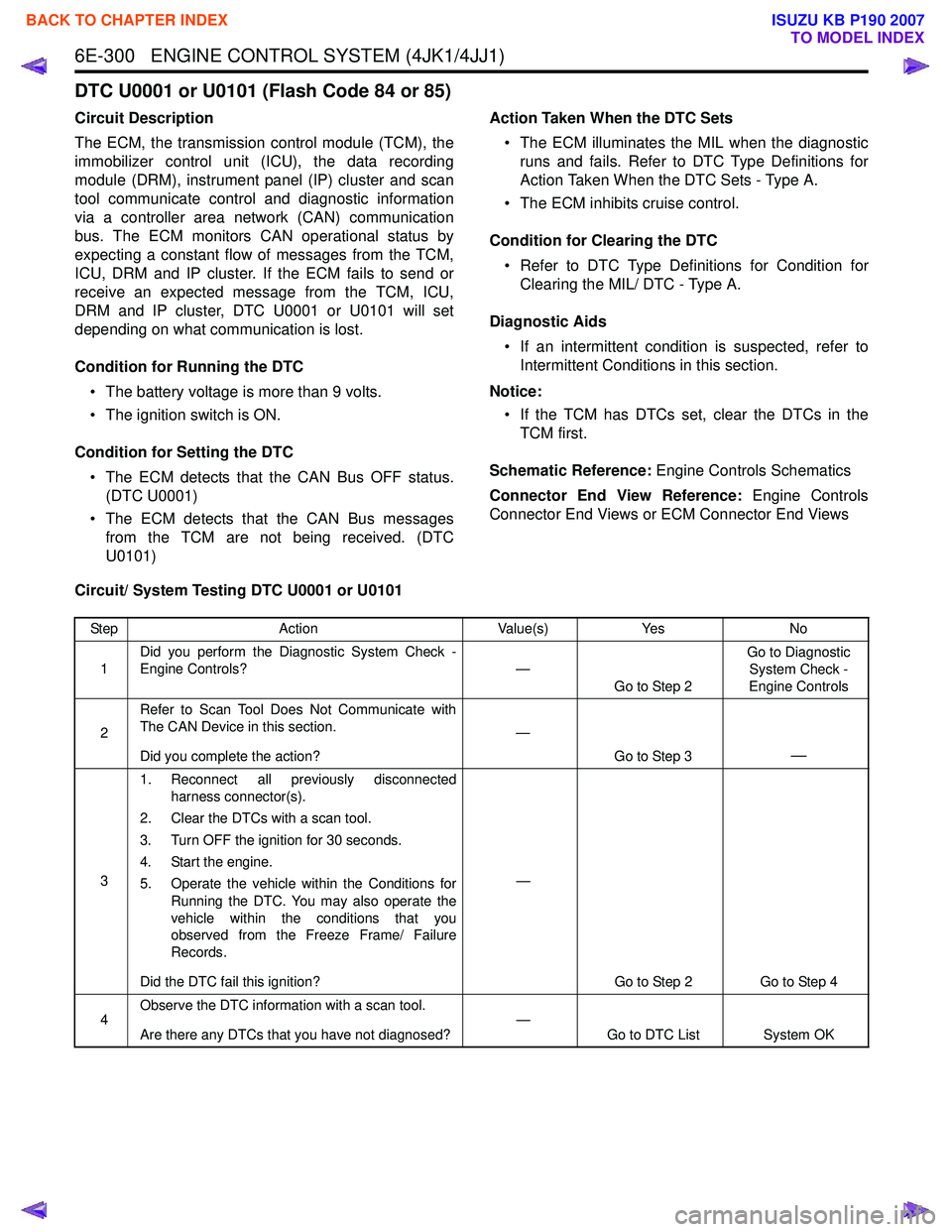

DTC U0001 or U0101 (Flash Code 84 or 85)

Circuit Description

The ECM, the transmission control module (TCM), the

immobilizer control unit (ICU), the data recording

module (DRM), instrument panel (IP) cluster and scan

tool communicate control and diagnostic information

via a controller area network (CAN) communication

bus. The ECM monitors CAN operational status by

expecting a constant flow of messages from the TCM,

ICU, DRM and IP cluster. If the ECM fails to send or

receive an expected message from the TCM, ICU,

DRM and IP cluster, DTC U0001 or U0101 will set

depending on what communication is lost.

Condition for Running the DTC • The battery voltage is more than 9 volts.

• The ignition switch is ON.

Condition for Setting the DTC • The ECM detects that the CAN Bus OFF status. (DTC U0001)

• The ECM detects that the CAN Bus messages from the TCM are not being received. (DTC

U0101) Action Taken When the DTC Sets

• The ECM illuminates the MIL when the diagnostic runs and fails. Refer to DTC Type Definitions for

Action Taken When the DTC Sets - Type A.

• The ECM inhibits cruise control.

Condition for Clearing the DTC • Refer to DTC Type Definitions for Condition for Clearing the MIL/ DTC - Type A.

Diagnostic Aids • If an intermittent condition is suspected, refer to Intermittent Conditions in this section.

Notice: • If the TCM has DTCs set, clear the DTCs in the TCM first.

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or ECM Connector End Views

Circuit/ System Testing DTC U0001 or U0101

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 Refer to Scan Tool Does Not Communicate with

The CAN Device in this section.

Did you complete the action? —

Go to Step 3

—

31. Reconnect all previously disconnected

harness connector(s).

2. Clear the DTCs with a scan tool.

3. Turn OFF the ignition for 30 seconds.

4. Start the engine.

5. Operate the vehicle within the Conditions for Running the DTC. You may also operate the

vehicle within the conditions that you

observed from the Freeze Frame/ Failure

Records.

Did the DTC fail this ignition? —

Go to Step 2 Go to Step 4

4 Observe the DTC information with a scan tool.

Are there any DTCs that you have not diagnosed? —

Go to DTC List System OK

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1918 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-301

DTC U0167 (Flash Code 177)

Circuit Description

The ECM communicates with the immobilizer control

unit (ICU) to execute immobilizer function. The ECM

sends request signal to the ICU. The ECM receives

response signal from the ICU. Both communication

signals are carried out via a controller area network

(CAN) communication bus. If the ECM does not detect

a response signal from the ICU, this DTC will set.

Condition for Setting the DTC • The ECM does not receive an immobilizer response signal from the ICU.

Action Taken When the DTC Sets • The ECM illuminates the SVS lamp when the diagnostic runs and fails. Refer to DTC Type

Definitions for Action Taken When the DTC Sets -

Type C. (Euro 4 Specification) • The ECM illuminates the MIL when the diagnostic

runs and fails. Refer to DTC Type Definitions for

Action Taken When the DTC Sets - Type A.

(Except Euro 4 Specification)

Condition for Clearing the DTC • Refer to DTC Type Definitions for Condition for Clearing the SVS Lamp/ DTC - Type C. (Euro 4

Specification)

• Refer to DTC Type Definitions for Condition for Clearing the MIL/ DTC - Type A. (Except Euro 4

Specification)

Diagnostic Aids • If an intermittent condition is suspected, refer to Intermittent Conditions in this section.

• Electromagnetic interference may affect intermittent condition.

• Any communication fault with the ICU may set this DTC.

Circuit/ System Testing DTC U0167

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Turn ON the ignition, with the engine OFF.

4. Monitor the DTC Information with a scan tool.

Is DTC U0001 also set? —

Go to DTC U0001 Go to Step 3

3 Attempt to communicate with the immobilizer

control unit (ICU) via the Immobilizer Data table.

Does the scan tool communicate with the ICU? —

Go to Step 4 Go to Diagnostic

System Check - Immobilizer Controls

4 Monitor the immobilizer DTC Information with a

scan tool.

Does the immobilizer DTCs fail this ignition which

begin with B or U? —

Go to Applicable

DTC in Immobilizer

Section Go to Step 5

5 Important:

Replacement ECM must be

programmed and learned.

Replace the ECM. Refer to ECM Replacement.

Did you complete the replacement? —

Go to Step 6

—

61. Clear the DTCs with a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Turn ON the ignition, with the engine OFF.

Did the DTC fail this ignition? —

Go to Step 2 Go to Step 7

7 Observe the DTC Information with a scan tool.

Are there any DTCs that you have not diagnosed? —

Go to DTC List System OK

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1919 of 6020

6E-302 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

EGR Control System Check

Description

The EGR system recirculates a part of exhaust gas

back into the intake manifold, which results in reducing

NOx emissions. The EGR control system uses an

electronic control system to ensure both driveability

and low emission. A control current from the ECM

operates a solenoid to control the lift amount of EGR

valve. Also, an EGR position sensor is provided at the

rear of the solenoid to feed actual valve lift amount

back to the ECM for more precision control.

The EGR control starts when the conditions for engine

speed, engine coolant temperature, intake air

temperature and barometric pressure are satisfied.

Then, the valve opening is calculated according to the

engine speed, and target fuel injection quantity. Based

on this valve opening, the drive duty of the solenoid is

determined and the valve is driven accordingly. The

intake throttle valve is provided to adequate intake

manifold depression to ensure EGR gas flow. EGR Control Operation

• The engine coolant temperature (ECT) is between 5°C (41 °F) and 100 °C (212 °F).

• The intake air temperature (IAT) is more than 5 °C

(41 °F).

• The barometric pressure (BARO) is more than 90kPa (13psi).

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or ECM Connector End Views

Circuit/ System Testing EGR Control System Check

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Turn ON the ignition, with the engine OFF.

4. Monitor the DTC Information with a scan tool.

Are any DTCs set in which the “Action Taken When

the DTC Sets” under that particular code states,

“The ECM inhibits EGR control”? —

Refer to Applicable DTC Go to Step 3

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1921 of 6020

6E-304 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

6Notice:

If the intake throttle solenoid is

commanded OFF, Intake Throttle Position

parameter indicates over 100%.

Observe the Desired Intake Throttle Position and

Intake Throttle Position parameter with a scan tool.

Does the Intake Throttle Position parameter follow

within the specified value? ±

5%

Go to Step 7 Go to Step 10

7 1. Perform the Intake Throttle Solenoid Control

with a scan tool several times.

2. Command the Desired Intake Throttle Position Increase and Decrease while observing the

Intake Throttle Position.

Does the Intake Throttle Position parameter follow

within the specified value quick enough? ±

5%

System OK Go to Step 10

8 1. Remove the EGR valve assembly from the

engine.

2. Inspect the EGR valve for the following conditions:

• Restricted EGR valve by foreign materials

• Excessive deposits at valve

• Bent valve shaft

3. Repair or replace as necessary.

Did you find and correct the condition? —

Go to Step 14 Go to Step 9

9 1. Turn OFF the ignition.

2. Disconnect the EGR valve harness connector.

3. Inspect for an intermittent, for poor connections and corrosion at the harness

connector of the EGR valve (pins 1, 2, 3, 4

and 6 of E-71).

4. Disconnect the ECM harness connector.

5. Inspect for an intermittent, for poor connections and corrosion at the harness

connector of the ECM (pins 30, 31, 32, 62 and

63 of E-90).

6. Test for high resistance on each circuit.

7. Repair the connection(s) or circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 14 Go to Step 12

10 1. Remove the intake duct that is connected to

the intake throttle valve.

2. Inspect the intake throttle valve for the following conditions:

• Restricted intake throttle valve by foreign materials

• Excessive deposits at throttle bore

• Bent butterfly valve

Notice: Replace the intake throttle valve is there is

any sticking

3. Repair or replace as necessary.

Did you find and correct the condition? —

Go to Step 14 Go to Step 11

Step

Action Value(s)Yes No

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1922 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-305

111. Turn OFF the ignition.

2. Disconnect the intake throttle valve harness connector.

3. Inspect for an intermittent, for poor connections and corrosion at the harness

connector of the intake throttle valve (pins 1,

2, 3, 5 and 6 of E-38).

4. Disconnect the ECM harness connector.

5. Inspect for an intermittent, for poor connections and corrosion at the harness

connector of the ECM (pins 35, 36, 55, 56 and

57 of E-90).

6. Test for high resistance on each circuit.

7. Repair the connection(s) or circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 14 Go to Step 13

12 Replace the EGR valve. Refer to EGR valve

Replacement.

Did you complete the replacement? —

Go to Step 14

—

13Replace the intake throttle valve. Refer to Intake

Throttle Valve Replacement.

Did you complete the replacement? —

Go to Step 14

—

14Reconnect all previously disconnected components

or harness connector(s).

Did you complete the action? —

Go to Step 2

—

Step Action Value(s)Yes No

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1923 of 6020

6E-306 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

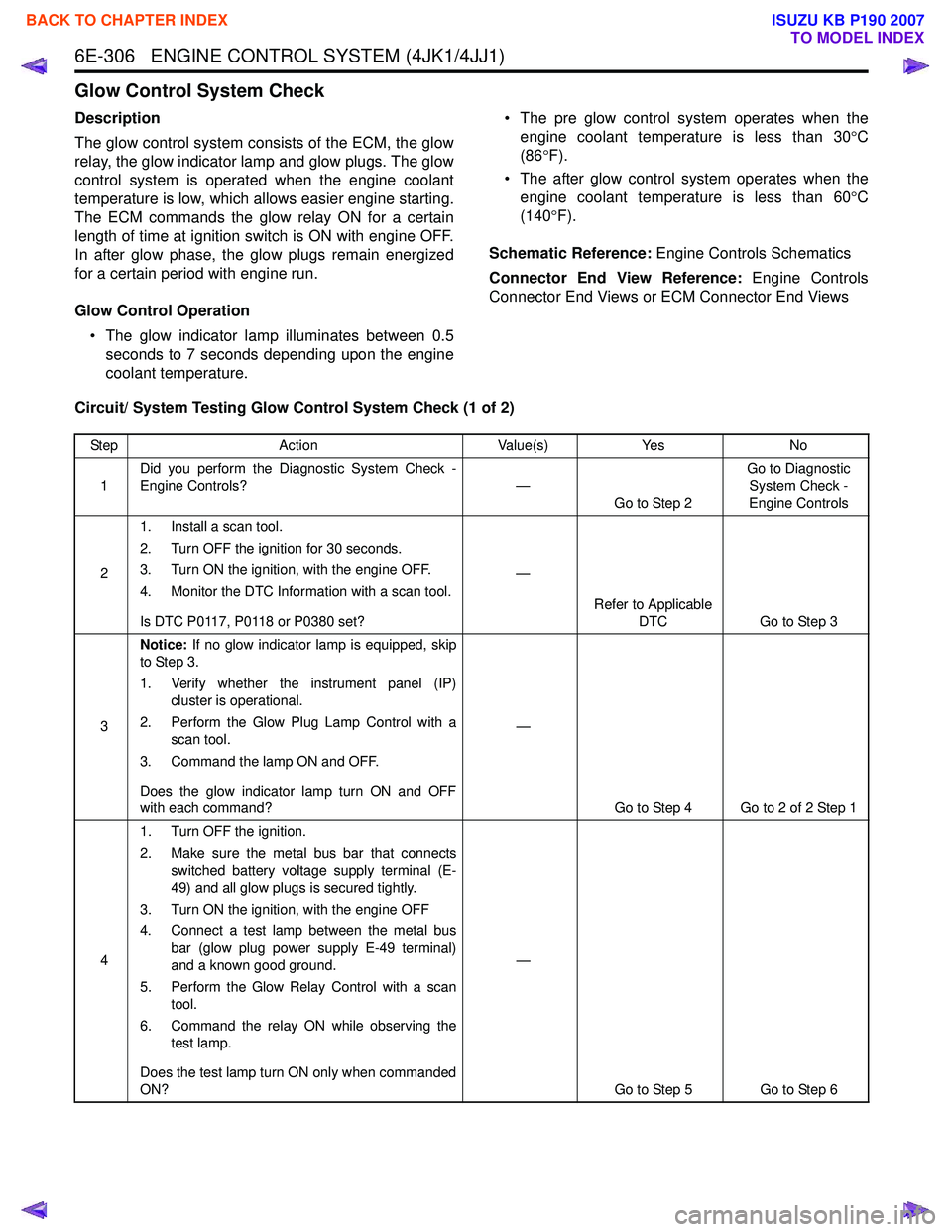

Glow Control System Check

Description

The glow control system consists of the ECM, the glow

relay, the glow indicator lamp and glow plugs. The glow

control system is operated when the engine coolant

temperature is low, which allows easier engine starting.

The ECM commands the glow relay ON for a certain

length of time at ignition switch is ON with engine OFF.

In after glow phase, the glow plugs remain energized

for a certain period with engine run.

Glow Control Operation • The glow indicator lamp illuminates between 0.5 seconds to 7 seconds depending upon the engine

coolant temperature. • The pre glow control system operates when the

engine coolant temperature is less than 30 °C

(86 °F).

• The after glow control system operates when the engine coolant temperature is less than 60 °C

(140 °F).

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or ECM Connector End Views

Circuit/ System Testing Glow Control System Check (1 of 2)

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Turn ON the ignition, with the engine OFF.

4. Monitor the DTC Information with a scan tool.

Is DTC P0117, P0118 or P0380 set? —

Refer to Applicable DTC Go to Step 3

3 Notice:

If no glow indicator lamp is equipped, skip

to Step 3.

1. Verify whether the instrument panel (IP) cluster is operational.

2. Perform the Glow Plug Lamp Control with a scan tool.

3. Command the lamp ON and OFF.

Does the glow indicator lamp turn ON and OFF

with each command? —

Go to Step 4 Go to 2 of 2 Step 1

4 1. Turn OFF the ignition.

2. Make sure the metal bus bar that connects switched battery voltage supply terminal (E-

49) and all glow plugs is secured tightly.

3. Turn ON the ignition, with the engine OFF

4. Connect a test lamp between the metal bus bar (glow plug power supply E-49 terminal)

and a known good ground.

5. Perform the Glow Relay Control with a scan tool.

6. Command the relay ON while observing the test lamp.

Does the test lamp turn ON only when commanded

ON? —

Go to Step 5 Go to Step 6

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007