torque ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 2670 of 6020

Engine Mechanical – V6 Page 6A1–191

Figure 6A1 – 332

Figure 6A1 – 333 Figure 6A1 – 334

42 Fit the engine lifting brackets (1), (EN–46114) and attach the engine hoist, raise the engine to take the weight off the engine mounts.

Engine Lift Bracket Attaching Bolt

torque specification

.............................................................58.0 – 72.0.0 Nm

43 Remove the left-hand side knock sensor (1).

Figure 6A1 – 335

NOTE

Removal or the starter motor is only required for

vehicles with an Automatic Transmission.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2677 of 6020

Engine Mechanical – V6 Page 6A1–198

k Timing chains, tensioners, shoes, guides & sprockets, refer to 3.16 Timing Chains, Tensioners, Shoes and

Guides.

l Cylinder head assemblies, refer to 3.22 Cylinder Head Assembly.

m Oil pan assembly, refer to 4.2 Oil Pan and Oil Pump Suction Pipe Assembly.

n Piston and connecting rod assemblies, refer to 4.5 Pistons, Pins, Rings, Connecting Rods and Big-end Bearings.

o Crankshaft assembly, refer to 4.6 Crankshaft and Main Bearings.

p Piston oil nozzles, refer 4.5 Pistons, Pins, Rings, Connecting Rods and Big-end Bearings.

Reassemble

Reassembly of the engine assembly is the reverse of the disassembly procedure.

Reinstall

Reinstallation of the engine assembly is the reverse to the removal procedure, noting the following:

NOTE

Refer to 6 Torque Wrench Specifications

for the correct torque specifications.

1 Tighten the fasteners to the correct torque specification.

Engine ground connector bolt

torque specification ............................................10.0 Nm

Power steering high pressure line

attaching bolt torque specification .............8.0 – 12.0 Nm

Power steering high pressure line

flare nut torque specification ...................25.0 – 35.0 Nm

Engine mount to frame attaching bolt

torque specification .................................44.0 – 60.0 Nm

Knock Sensor Attaching Nut

torque specification ............................................23.0 Nm

2 Use only the specified engine lubricant type and quantity. It is recommended that a fluorescent oil dye, such as that contained in J 28481-B, be added to assist in any future oil leak diagnosis.

3 Fill the cooling system with the correct quantity and grade of coolant, refer to 6B1 Engine Cooling – V6.

4 Check transmission fluid level, replenishing as required, using the specified lubricant for the transmission fitted, refer to 7C1 Automatic – 4L60E – General Information.

5 Disable the ignition system, refer to 6C1-3 Engine Management – V6 – Service Operations.

6 Crank the engine several times. Listen for any unusual noises or evidence that parts are binding.

7 Enable the ignition system. Start the engine and listen for any unusual noises.

8 Check the vehicle oil pressure gauge or warning indicator and confirm the engine has acceptable oil pressure. If required, install an oil pressure gauge and measure the engine oil pressure, refer to 2.19 Engine Oil Pressure

Diagnosis.

9 Run the engine at about 1,000 r.p.m. until the engine has reached normal operating temperature.

10 Listen for any unusual noises.

11 Check for oil, fuel, coolant and exhaust leaks while the engine is running, correcting as required.

12 Perform a final inspection for correct engine oil and coolant levels.

4.2 Oil Pan and Oil Pump Suction Pipe Assembly

Remove

1 Remove the engine assembly from the vehicle, refer to 4.1 Engine .

2 Separate the engine and transmission assemblies, refer to 7C1 Automatic – 4L60E – General Information.

3 Mount the engine assembly on a suitable engine stand.

4 Remove the engine front cover, refer to 3.15 Front Cover Assembly.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2681 of 6020

Engine Mechanical – V6 Page 6A1–202

1 Install a new oil suction tube seal onto the oil suction

tube.

2 Install the oil suction pipe and tighten the attaching bolts to the correct torque specification.

Oil suction pipe attaching

bolt torque specification .....................................10.0 Nm

3 Install the crankshaft oil deflector into the oil pan assembly and tighten the attaching bolts to the

correct torque specification.

Crankshaft oil deflector

attaching bolt torque specification ......................10.0 Nm

4 Install the oil level sensor into the oil pan assembly and tighten to the correct torque specification.

Oil level sensor torque specification...................20.0 Nm

Figure 6A1 – 358

5 Install the oil pan drain plug into the oil pan assembly and tighten to the correct torque specification. Oil pan drain plug

torque specification ............................................25.0 Nm

Reinstall

1 Install the guide pins, Tool No. EN-46109 (1) into the oil pan rail bolt hole on each side of the engine block.

Figure 6A1 – 359

2 Place a 3mm bead (1) of RTV sealant on the cylinder block pan rail and crankshaft rear oil seal housing to

oil pan mating surfaces.

3 Position the oil pan onto the cylinder block.

4 Remove the guide pins, Tool No. EN-46109 from the cylinder block.

Figure 6A1 – 360

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2682 of 6020

Engine Mechanical – V6 Page 6A1–203

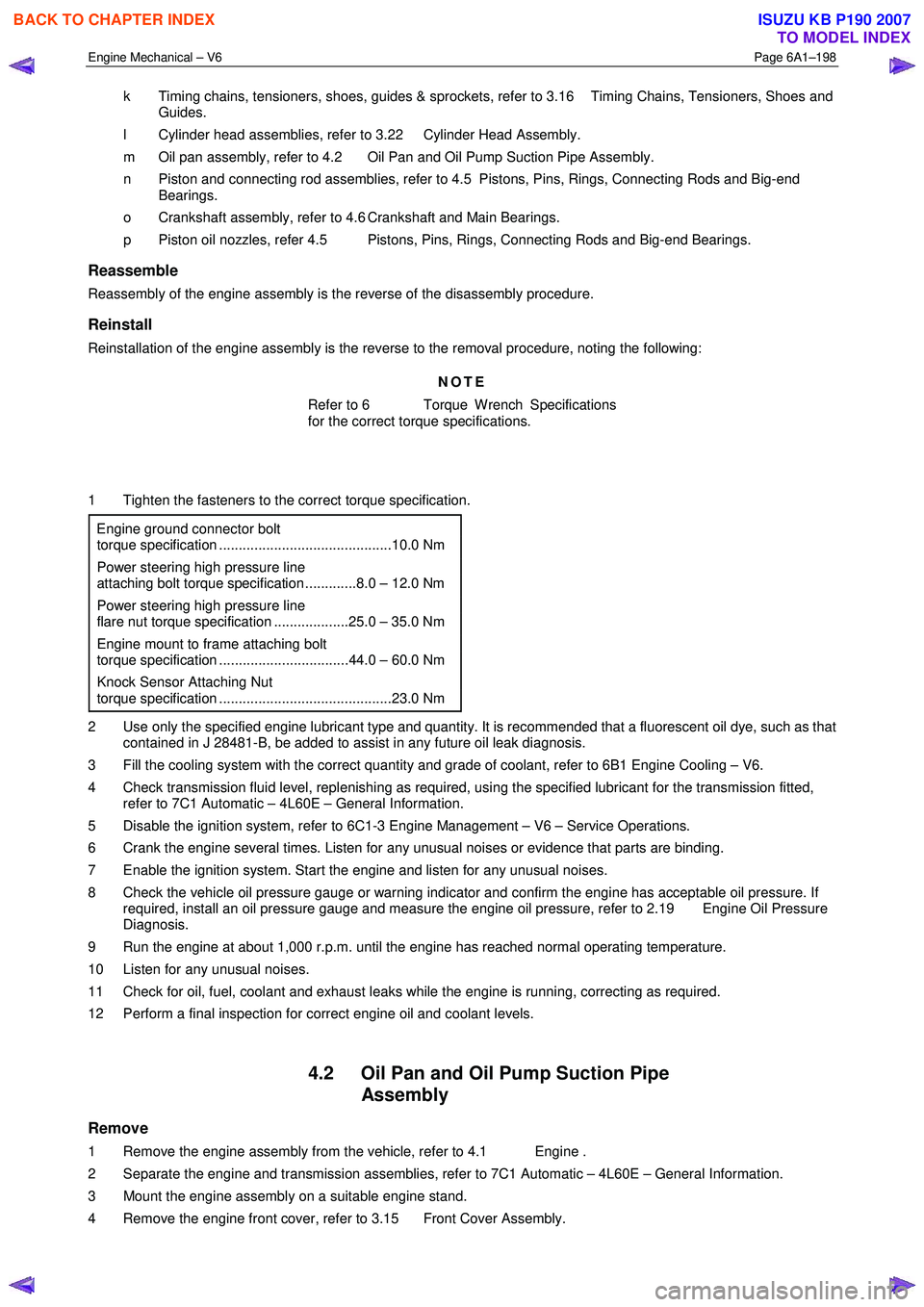

5 Loosely install the oil pan bolts.

6 Tighten the oil pan attaching bolts to the correct torque specification and in the sequence shown.

Oil pan to cylinder block attaching

bolt (1 – 11) torque specification .............20.0 – 26.0 Nm

Oil pan to crankshaft rear oil

seal housing attaching bolt (12 – 13)

torque specification ...................................8.0 – 12.0 Nm

Figure 6A1 – 361

4.3 Flexplate Assembly

Remove

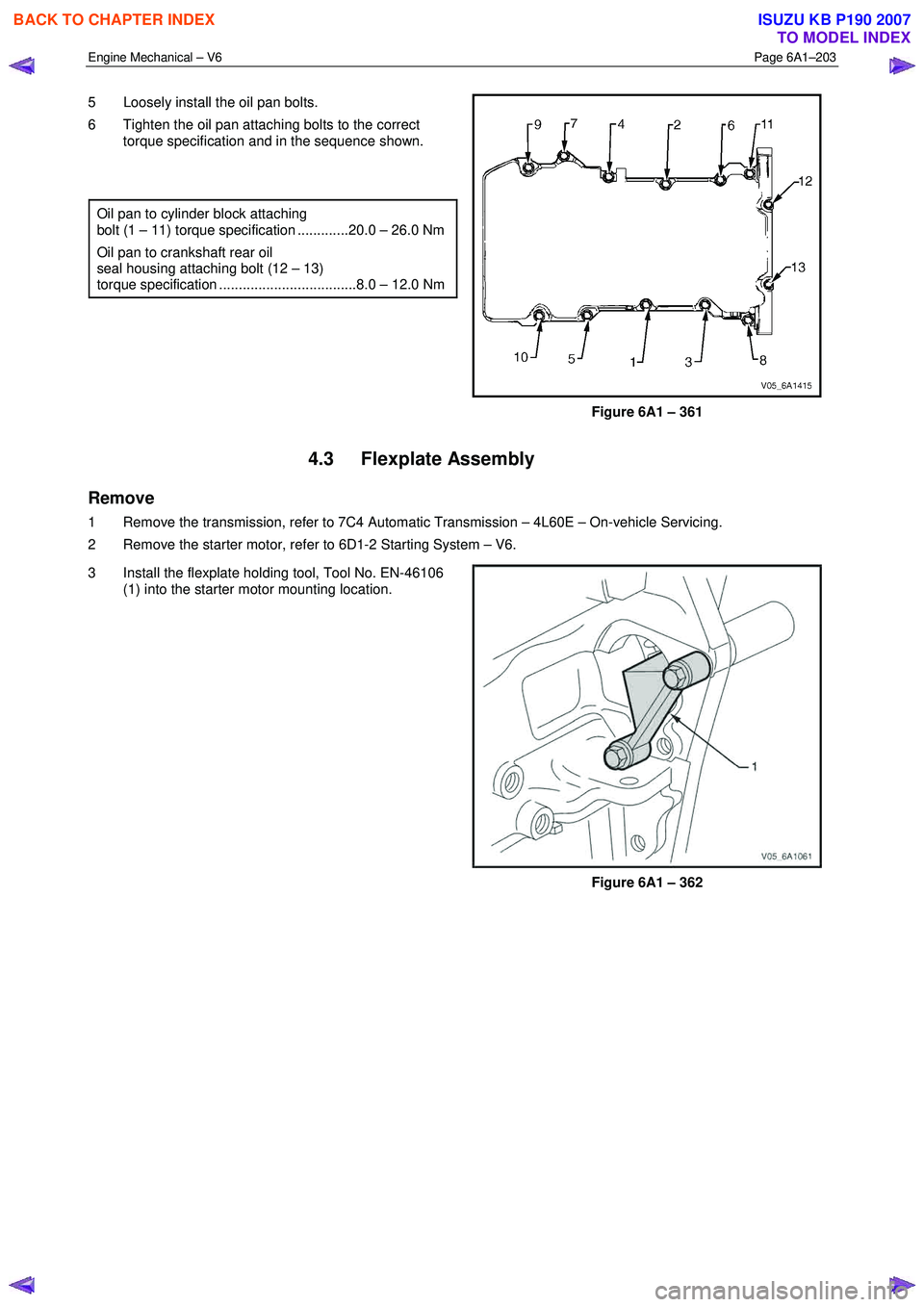

1 Remove the transmission, refer to 7C4 Automatic Transmission – 4L60E – On-vehicle Servicing.

2 Remove the starter motor, refer to 6D1-2 Starting System – V6.

3 Install the flexplate holding tool, Tool No. EN-46106 (1) into the starter motor mounting location.

Figure 6A1 – 362

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2683 of 6020

Engine Mechanical – V6 Page 6A1–204

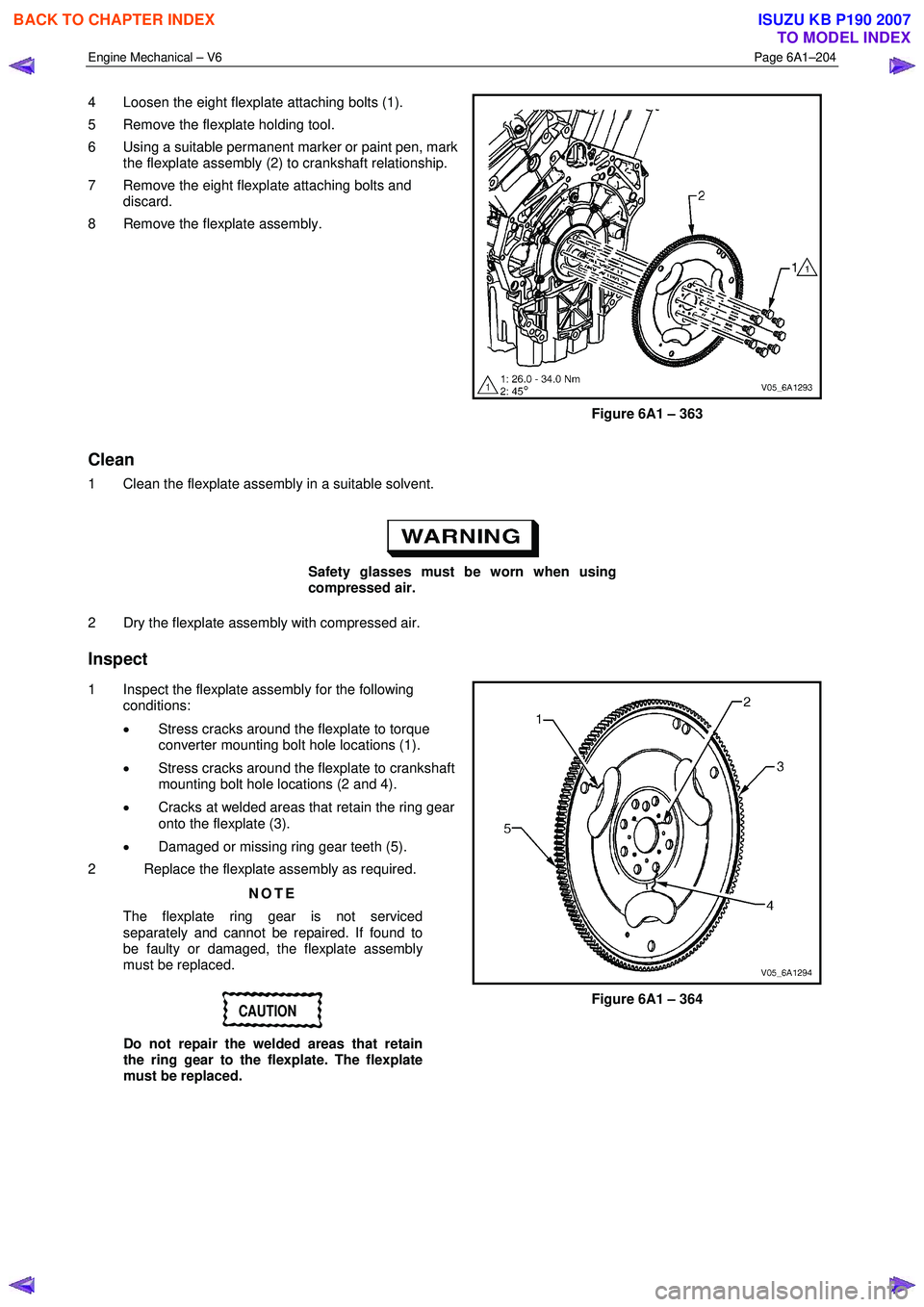

4 Loosen the eight flexplate attaching bolts (1).

5 Remove the flexplate holding tool.

6 Using a suitable permanent marker or paint pen, mark the flexplate assembly (2) to crankshaft relationship.

7 Remove the eight flexplate attaching bolts and discard.

8 Remove the flexplate assembly.

Figure 6A1 – 363

Clean

1 Clean the flexplate assembly in a suitable solvent.

Safety glasses must be worn when using

compressed air.

2 Dry the flexplate assembly with compressed air.

Inspect

1 Inspect the flexplate assembly for the following conditions:

• Stress cracks around the flexplate to torque

converter mounting bolt hole locations (1).

• Stress cracks around the flexplate to crankshaft

mounting bolt hole locations (2 and 4).

• Cracks at welded areas that retain the ring gear

onto the flexplate (3).

• Damaged or missing ring gear teeth (5).

2 Replace the flexplate assembly as required.

NOTE

The flexplate ring gear is not serviced

separately and cannot be repaired. If found to

be faulty or damaged, the flexplate assembly

must be replaced.

CAUTION

Do not repair the welded areas that retain

the ring gear to the flexplate. The flexplate

must be replaced.

Figure 6A1 – 364

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2684 of 6020

Engine Mechanical – V6 Page 6A1–205

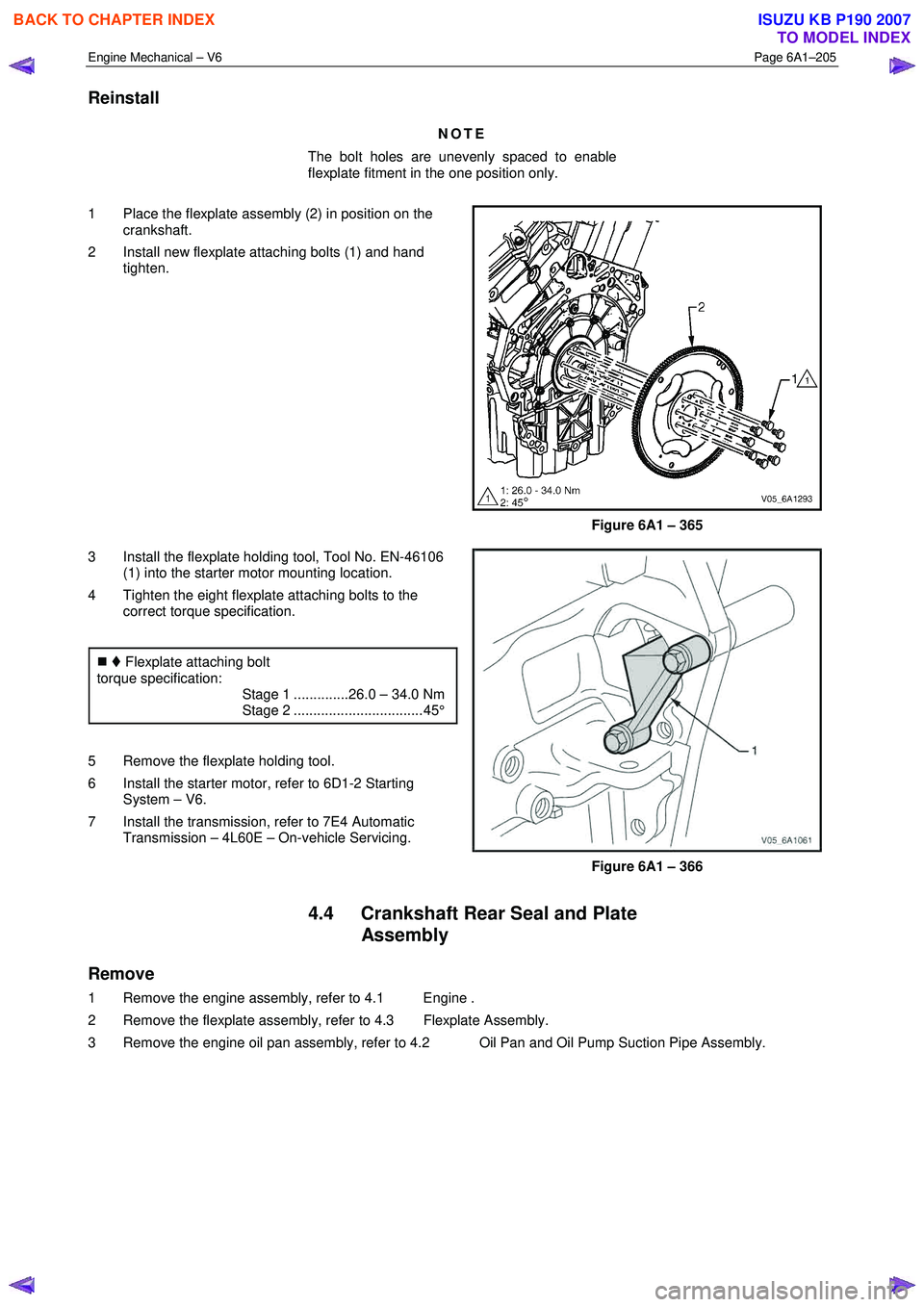

Reinstall

NOTE

The bolt holes are unevenly spaced to enable

flexplate fitment in the one position only.

1 Place the flexplate assembly (2) in position on the crankshaft.

2 Install new flexplate attaching bolts (1) and hand tighten.

Figure 6A1 – 365

3 Install the flexplate holding tool, Tool No. EN-46106 (1) into the starter motor mounting location.

4 Tighten the eight flexplate attaching bolts to the correct torque specification.

�„ Flexplate attaching bolt

torque specification:

Stage 1 ..............26.0 – 34.0 Nm

Stage 2 ................................. 45°

5 Remove the flexplate holding tool.

6 Install the starter motor, refer to 6D1-2 Starting System – V6.

7 Install the transmission, refer to 7E4 Automatic Transmission – 4L60E – On-vehicle Servicing.

Figure 6A1 – 366

4.4 Crankshaft Rear Seal and Plate Assembly

Remove

1 Remove the engine assembly, refer to 4.1 Engine .

2 Remove the flexplate assembly, refer to 4.3 Flexplate Assembly.

3 Remove the engine oil pan assembly, refer to 4.2 Oil Pan and Oil Pump Suction Pipe Assembly.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2687 of 6020

Engine Mechanical – V6 Page 6A1–208

5 Install the crankshaft rear oil seal housing attaching

bolts (1) to the cylinder block (2) and tighten to the

correct torque specification.

Crankshaft rear oil seal housing

attaching bolt torque specification .............8.0 – 12.0 Nm

Figure 6A1 – 373

4.5 Pistons, Pins, Rings, Connecting Rods and Big-end Bearings

Remove

1 Remove the engine assembly, refer to 4.1 Engine .

2 Remove both cylinder head assemblies, refer to 3.22 Cylinder Head Assembly.

3 Remove the oil pan assembly, refer to 4.2 Oil Pan and Oil Pump Suction Pipe Assembly.

4 Mark the top of the piston being removed to identify its specific bore.

5 Install Tool No. EN-46111 (1) onto the crankshaft (2).

6 Rotate the crankshaft until the piston being removed is at the bottom of its stroke; bottom dead centre

(BDC).

Figure 6A1 – 374

CAUTION

If the connecting rod bearings have been

used in a running engine, they must be

replaced with new connecting rod bearings

for reassembly.

7 Before removing the connecting rods, check the connecting rod side clearance using the following procedure: a Tap the connecting rod to one end of the crankshaft journal with a dead blow or wooden hammer.

b Using feeler gauges, measure the clearance between the crankshaft counterweight and the connecting rod.

c The connecting rod side clearance should not exceed specifications, refer to 5 Specifications.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2688 of 6020

Engine Mechanical – V6 Page 6A1–209

d If the endplay exceeds the specified limits, measure the width of the crankpin end of the connecting rod, refer

to 5 Specifications.

e If the connecting rod width is significantly smaller than specified and severe wear is present on the side of the connecting rod, replace the connecting rod.

f If the connecting rod width is within specification and excessive scoring is present on the crankshaft journals, replace the crankshaft.

CAUTION

Do not use a stamp, punch or any other

method that may distort or stress the

connecting rod and cap. Extensive engine

damage may result from a connecting rod that

is distorted or stressed.

8 Mark the cylinder number on the connecting rod and the connecting rod cap with a paint stick or permanent marker.

CAUTION

Powdered metal connecting rods have rod

bolts which yield when tighten to the

specified torque. If the bolts are loosened or

removed they must be replaced. Rod bolts

that are not replaced will not torque to the

correct clamp load and can lead to serious

engine damage.

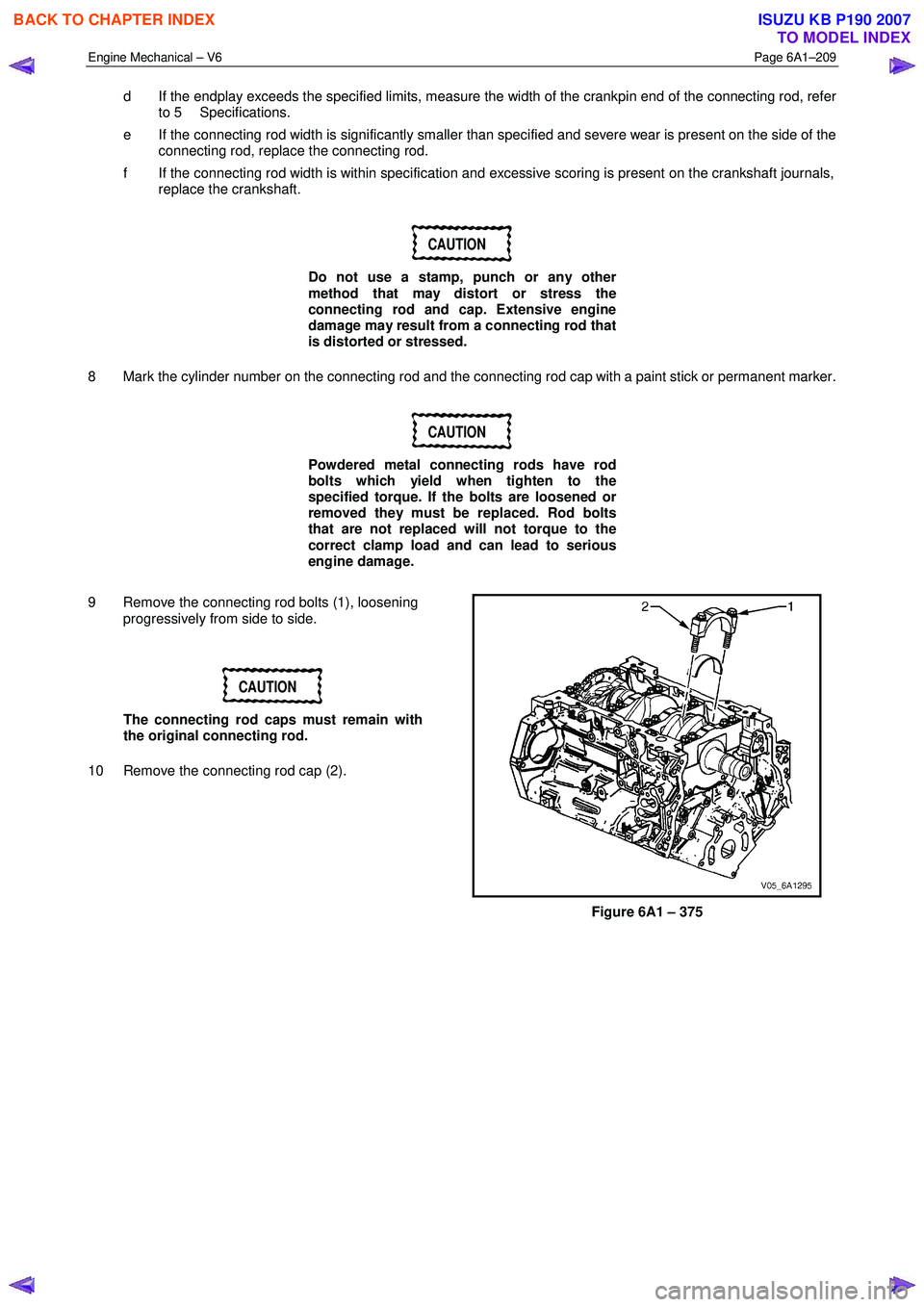

9 Remove the connecting rod bolts (1), loosening progressively from side to side.

CAUTION

The connecting rod caps must remain with

the original connecting rod.

10 Remove the connecting rod cap (2).

Figure 6A1 – 375

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2700 of 6020

Engine Mechanical – V6 Page 6A1–221

7 Remove connecting rod guide pin set, Tool No.

EN-46121 (1) from the connecting rod bolt holes.

Figure 6A1 – 406

Connecting Rod Bearing Clearance Measurement Procedure

NOTE

Before final assembly, check the clearance of the

new connecting rod bearings.

1 Place a length of fresh, room temperature plastic gauging material all the way across the connecting

rod bearing journal.

2 Install the connecting rod bearing into the connecting rod cap.

3 Install the connecting rod end cap (1) on its original connecting rod and ensure the bearing lock tangs are

aligned on the same side of the rod.

Figure 6A1 – 407

NOTE

Reuse the old connecting rod bolts only for

measuring the connecting rod bearing clearance.

4 Install the connecting rod cap bolts into the connecting rod cap and tighten to the correct torque specification using torque angle wrench, Tool No. EN-7115.

Connecting rod cap attaching

bolt torque specification:

Stage 1 .........................30.0 Nm

Stage 2 ........ Loosen completely

Stage 3 .........................25.0 Nm

Stage 4 .................. 110 degrees

5 Allow the assembly to sit for at least 2 minutes.

6 Remove the connecting rod cap bolts and discard.

7 Remove the connecting rod cap.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2701 of 6020

Engine Mechanical – V6 Page 6A1–222

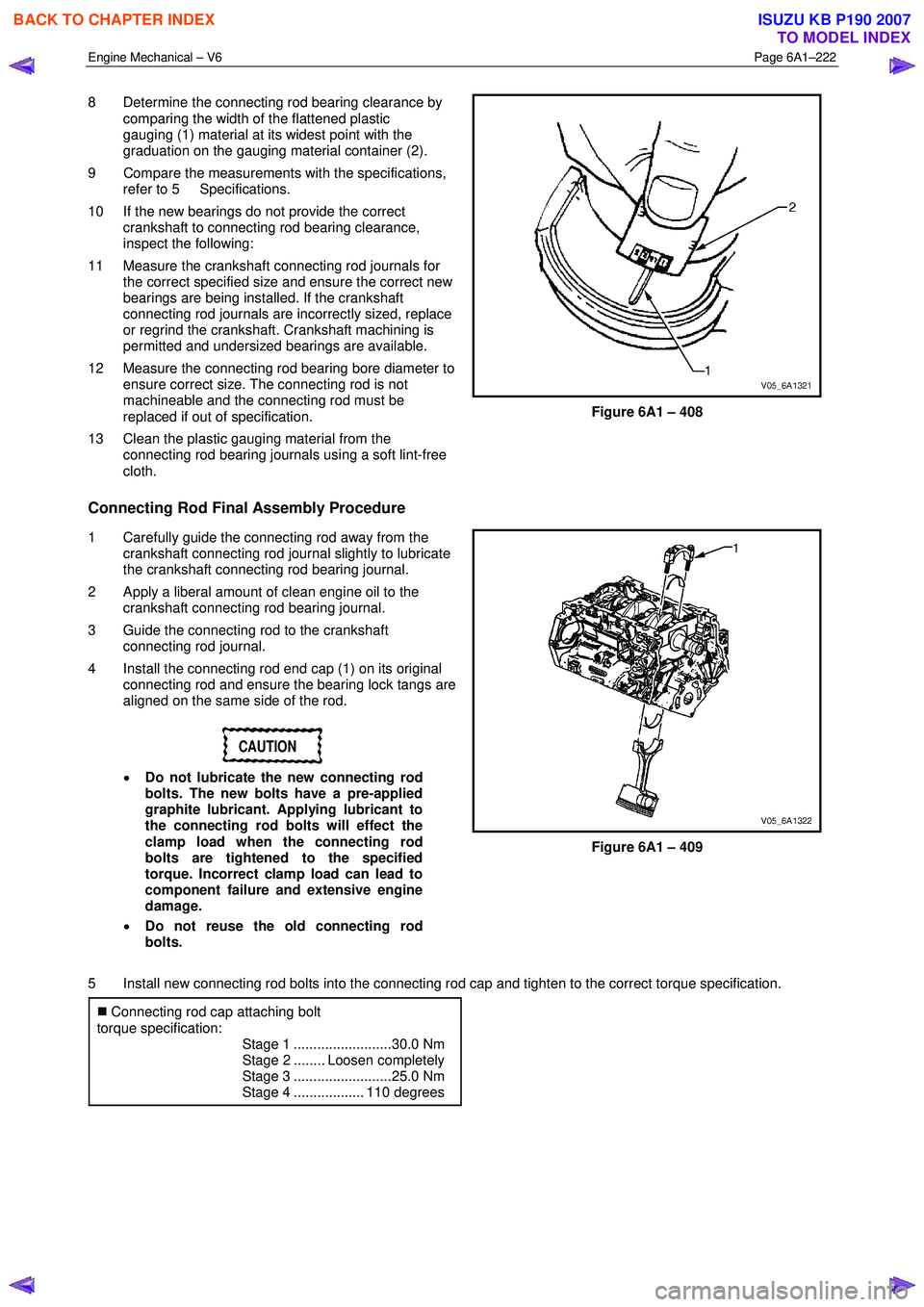

8 Determine the connecting rod bearing clearance by

comparing the width of the flattened plastic

gauging (1) material at its widest point with the

graduation on the gauging material container (2).

9 Compare the measurements with the specifications, refer to 5 Specifications.

10 If the new bearings do not provide the correct crankshaft to connecting rod bearing clearance,

inspect the following:

11 Measure the crankshaft connecting rod journals for the correct specified size and ensure the correct new

bearings are being installed. If the crankshaft

connecting rod journals are incorrectly sized, replace

or regrind the crankshaft. Crankshaft machining is

permitted and undersized bearings are available.

12 Measure the connecting rod bearing bore diameter to ensure correct size. The connecting rod is not

machineable and the connecting rod must be

replaced if out of specification.

13 Clean the plastic gauging material from the connecting rod bearing journals using a soft lint-free

cloth.

Figure 6A1 – 408

Connecting Rod Final Assembly Procedure

1 Carefully guide the connecting rod away from the crankshaft connecting rod journal slightly to lubricate

the crankshaft connecting rod bearing journal.

2 Apply a liberal amount of clean engine oil to the crankshaft connecting rod bearing journal.

3 Guide the connecting rod to the crankshaft connecting rod journal.

4 Install the connecting rod end cap (1) on its original connecting rod and ensure the bearing lock tangs are

aligned on the same side of the rod.

CAUTION

• Do not lubricate the new connecting rod

bolts. The new bolts have a pre-applied

graphite lubricant. Applying lubricant to

the connecting rod bolts will effect the

clamp load when the connecting rod

bolts are tightened to the specified

torque. Incorrect clamp load can lead to

component failure and extensive engine

damage.

• Do not reuse the old connecting rod

bolts.

Figure 6A1 – 409

5 Install new connecting rod bolts into the connecting rod cap and tighten to the correct torque specification. �„ Connecting rod cap attaching bolt

torque specification:

Stage 1 .........................30.0 Nm

Stage 2 ........ Loosen completely

Stage 3 .........................25.0 Nm

Stage 4 .................. 110 degrees

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007