torque ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 2547 of 6020

Engine Mechanical – V6 Page 6A1–68

CAUTION

Tighten the intake manifold bolts in a circular

pattern starting at the centre bolt and moving

outward.

2 Ensure that all fasteners are tightened to the correct torque specification. Upper intake manifold to lower

intake manifold attaching bolt

torque specification ............................................23.0 Nm

Upper intake manifold to

cylinder head attaching bolt

torque specification ............................................23.0 Nm

Incorrect wiring connector installation may

cause component malfunction or component

damage.

3 Ensure all wiring connectors are fully engaged and if applicable, locked in place.

4 Ensure all wiring harnesses are correctly routed and attached securely in their retaining clips.

5 Ensure that all hoses and pipes are routed correctly and that any retaining clips are correctly installed.

6 Start and run the engine to check for correct operation.

3.10 Intake Manifold Assembly – Complete

The intake manifold comprises of an upper and lower section. Some service procedures only require the removal of the

upper intake manifold (e.g. fuel injector/spark plug servicing), while other service procedures require the removal of both

the upper and lower manifold as a complete assembly (e.g. cylinder head/s). If only the upper intake manifold needs to

be removed, refer to 3.9 Upper Intake Manifold.

Remove

Disconnection of the battery affects certain

vehicle electronic systems. Refer to 1.1

WARNING, CAUTION and NOTES before

disconnecting the battery.

1 Depressurise the fuel system.

2 Disconnect the battery negative terminal.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2554 of 6020

Engine Mechanical – V6 Page 6A1–75

CAUTION

Tighten the intake manifold bolts in a circular

pattern starting at the centre bolt and moving

outward.

4 Ensure that all fasteners are tightened to the correct torque specification. Upper intake manifold to lower intake

manifold attaching bolt torque specification .......23.0 Nm

Upper intake manifold to cylinder

head attaching bolt torque specification .............23.0 Nm

Lower intake manifold to cylinder

head attaching bolt torque specification .............23.0 Nm

Fuel injector wiring harness bracket

attaching bolt torque specification ........................9.0 Nm

Incorrect wiring connector installation may

cause component malfunction or component

damage.

5 Ensure all wiring connectors are fully engaged and if applicable, locked in place.

6 Ensure all wiring harnesses are correctly routed and attached securely in their retaining clips.

7 Ensure that all hoses and pipes are routed correctly and that any retaining clips are correctly installed.

8 After installation pull on any quick connect fittings to check that each is correctly installed.

9 Start and run the engine to check for correct operation.

3.11 Exhaust Manifold Assembly

Remove

Allow the engine to cool before commencing.

Disconnection of the battery affects certain

vehicle electronic systems, refer to 1.1

WARNING, CAUTION and NOTES before

disconnecting the battery.

1 Disconnect the battery negative terminal.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2557 of 6020

Engine Mechanical – V6 Page 6A1–78

2 Position a new exhaust manifold gasket onto the exhaust manifold.

3 Apply a 5 mm bead of Loctite 272 thread sealant (or equivalent) to the threads of the exhaust manifold attaching bolts.

4 Install the bolts into the exhaust manifold. This will prevent the gasket from falling off the manifold.

5 Manoeuvre the exhaust manifold into position and install the exhaust manifold attaching bolts.

6 From underneath the vehicle install the exhaust manifold to exhaust pipe flange nuts.

7 Tighten the exhaust manifold attaching bolts to the correct torque specification.

NOTE

When tightening the exhaust manifold to cylinder

head attaching bolts, begin with the centre bolts,

then alternate from side to side to the outer bolts.

Exhaust manifold to cylinder head

attaching bolt torque specification ...........17.0 – 23.0 Nm

8 Apply an anti seize compound such as Caltex Kopr-Kote (or equivalent) to the cleaned heat shield bolt threads. Install the heat shield attaching bolts and tighten to the correct torque specification.

Exhaust manifold heat shield attaching

bolt torque specification ............................8.0 – 12.0 Nm

9 For the right-hand side, install the battery harness ground cable attaching nut through the ground terminal and lower coolant tube mounting lug, and tighten to the correct torque specification.

Battery harness ground terminal

attaching nut torque specification.......................13.0 Nm

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2562 of 6020

Engine Mechanical – V6 Page 6A1–83

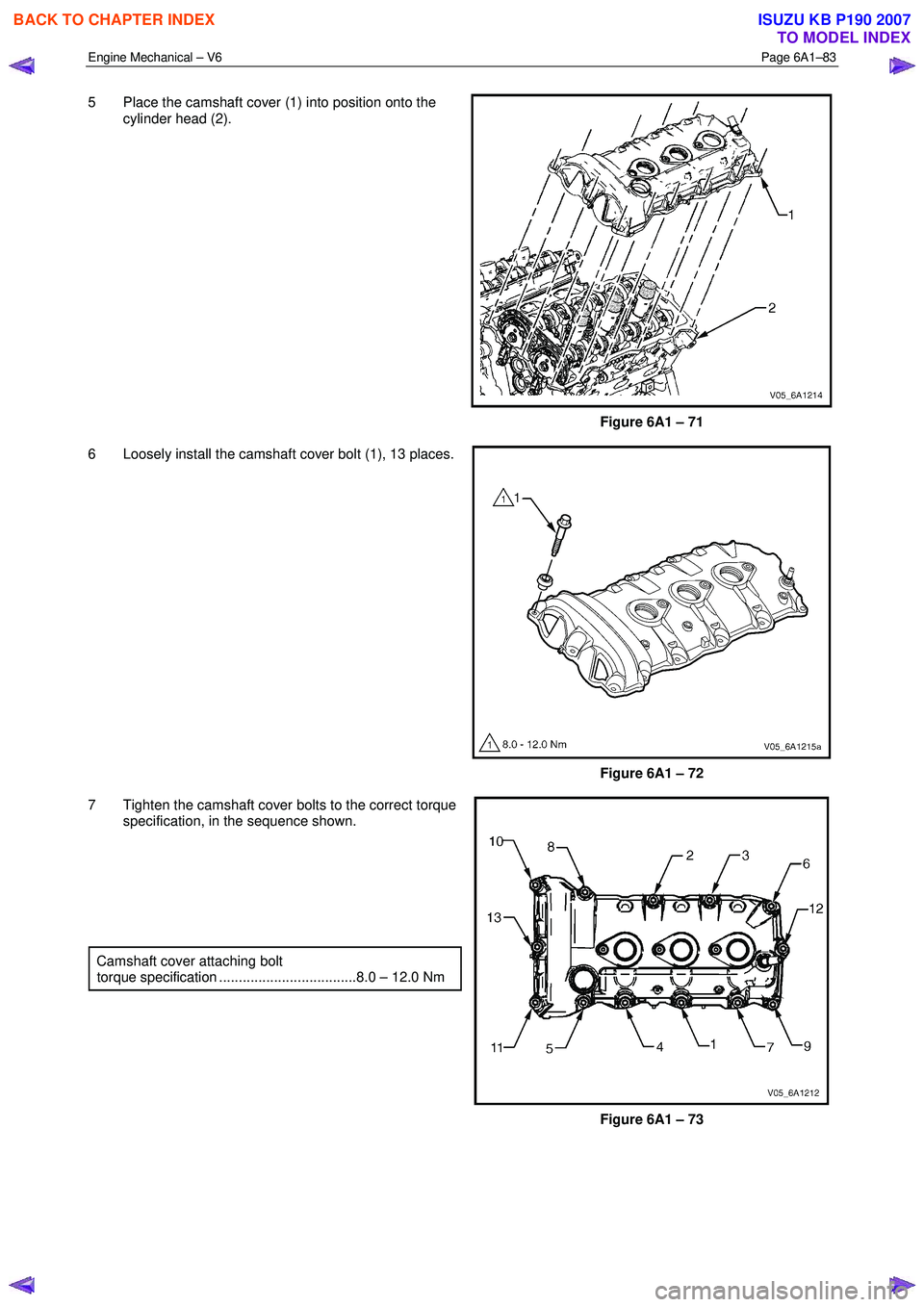

5 Place the camshaft cover (1) into position onto the

cylinder head (2).

Figure 6A1 – 71

6 Loosely install the camshaft cover bolt (1), 13 places.

Figure 6A1 – 72

7 Tighten the camshaft cover bolts to the correct torque specification, in the sequence shown.

Camshaft cover attaching bolt

torque specification ...................................8.0 – 12.0 Nm

Figure 6A1 – 73

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2563 of 6020

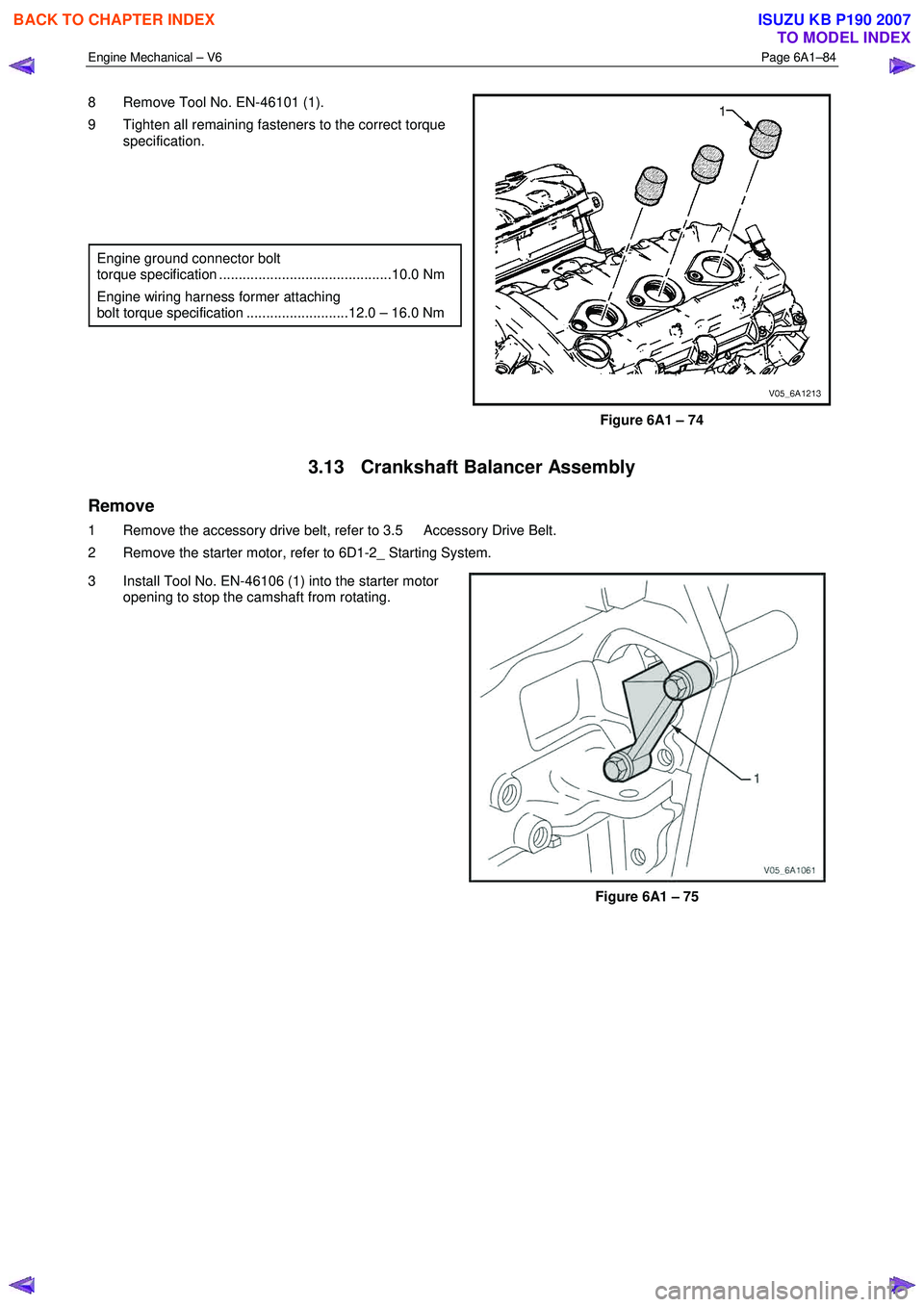

Engine Mechanical – V6 Page 6A1–84

8 Remove Tool No. EN-46101 (1).

9 Tighten all remaining fasteners to the correct torque specification.

Engine ground connector bolt

torque specification ............................................10.0 Nm

Engine wiring harness former attaching

bolt torque specification ..........................12.0 – 16.0 Nm

Figure 6A1 – 74

3.13 Crankshaft Balancer Assembly

Remove

1 Remove the accessory drive belt, refer to 3.5 Accessory Drive Belt.

2 Remove the starter motor, refer to 6D1-2_ Starting System.

3 Install Tool No. EN-46106 (1) into the starter motor opening to stop the camshaft from rotating.

Figure 6A1 – 75

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2565 of 6020

Engine Mechanical – V6 Page 6A1–86

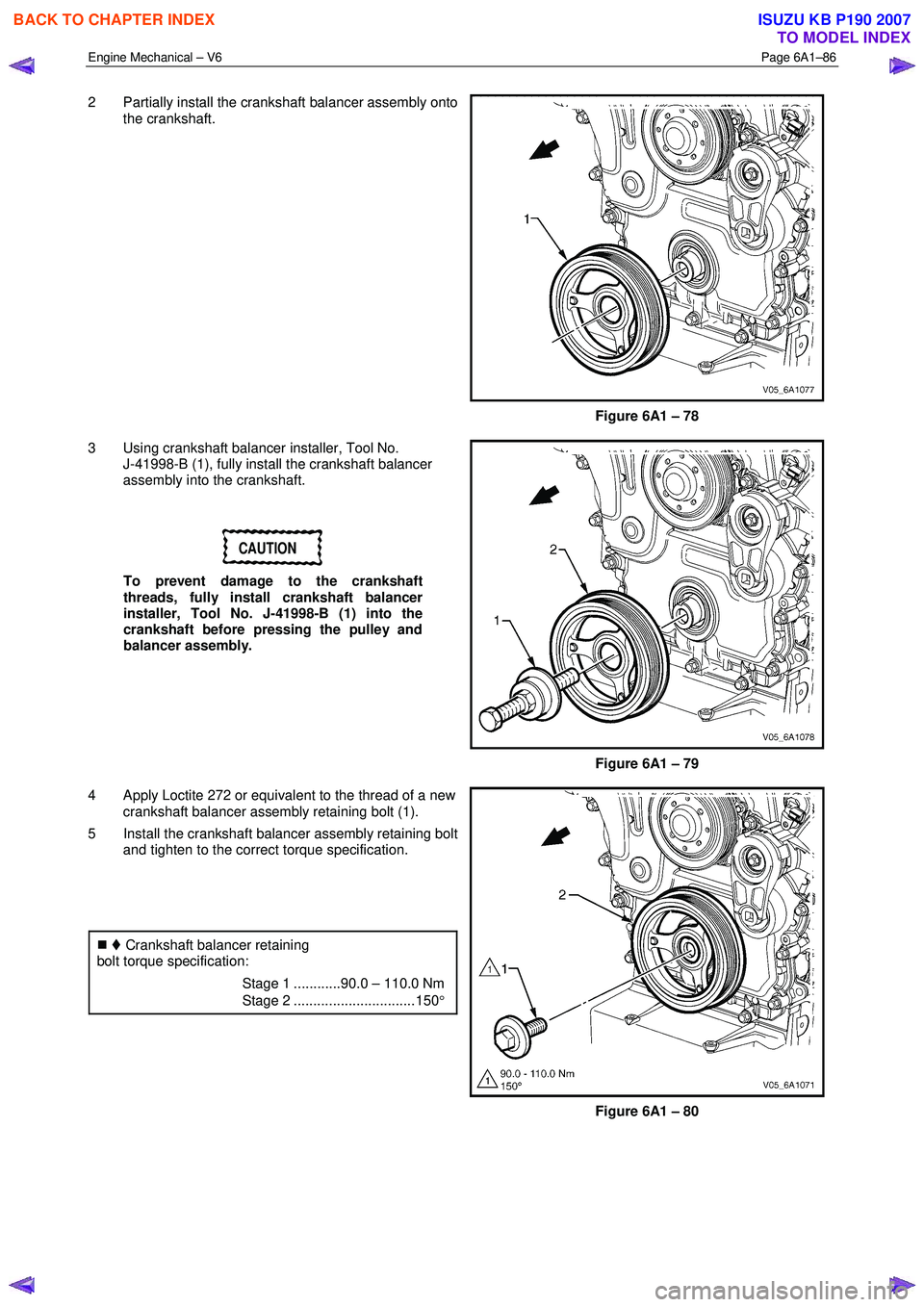

2 Partially install the crankshaft balancer assembly onto

the crankshaft.

Figure 6A1 – 78

3 Using crankshaft balancer installer, Tool No. J-41998-B (1), fully install the crankshaft balancer

assembly into the crankshaft.

CAUTION

To prevent damage to the crankshaft

threads, fully install crankshaft balancer

installer, Tool No. J-41998-B (1) into the

crankshaft before pressing the pulley and

balancer assembly.

Figure 6A1 – 79

4 Apply Loctite 272 or equivalent to the thread of a new crankshaft balancer assembly retaining bolt (1).

5 Install the crankshaft balancer assembly retaining bolt and tighten to the correct torque specification.

�„ Crankshaft balancer retaining

bolt torque specification:

Stage 1 ............90.0 – 110.0 Nm

Stage 2 ............................... 150°

Figure 6A1 – 80

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2572 of 6020

Engine Mechanical – V6 Page 6A1–93

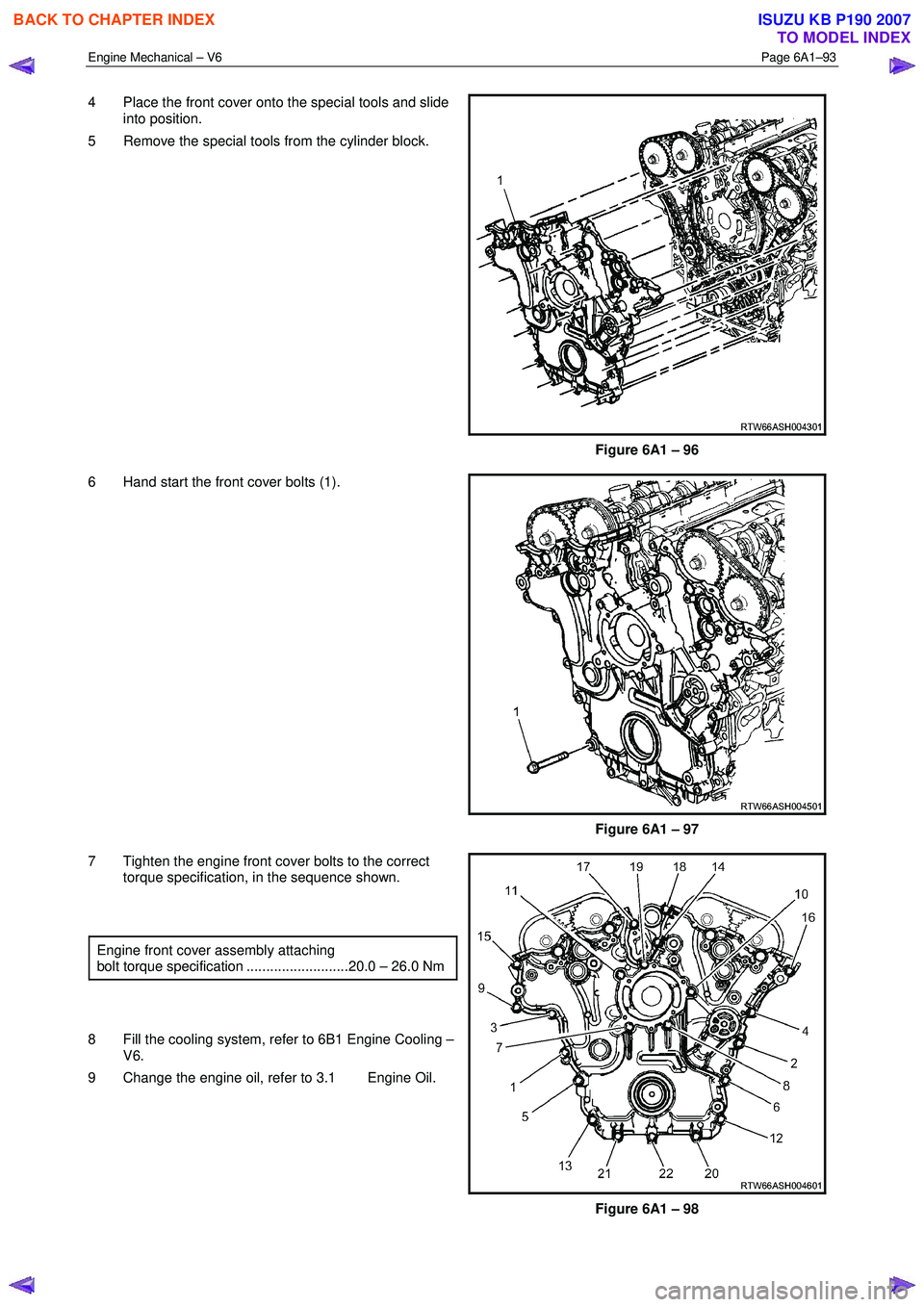

4 Place the front cover onto the special tools and slide

into position.

5 Remove the special tools from the cylinder block.

Figure 6A1 – 96

6 Hand start the front cover bolts (1).

Figure 6A1 – 97

7 Tighten the engine front cover bolts to the correct torque specification, in the sequence shown.

Engine front cover assembly attaching

bolt torque specification ..........................20.0 – 26.0 Nm

8 Fill the cooling system, refer to 6B1 Engine Cooling – V6.

9 Change the engine oil, refer to 3.1 Engine Oil.

Figure 6A1 – 98

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2595 of 6020

Engine Mechanical – V6 Page 6A1–116

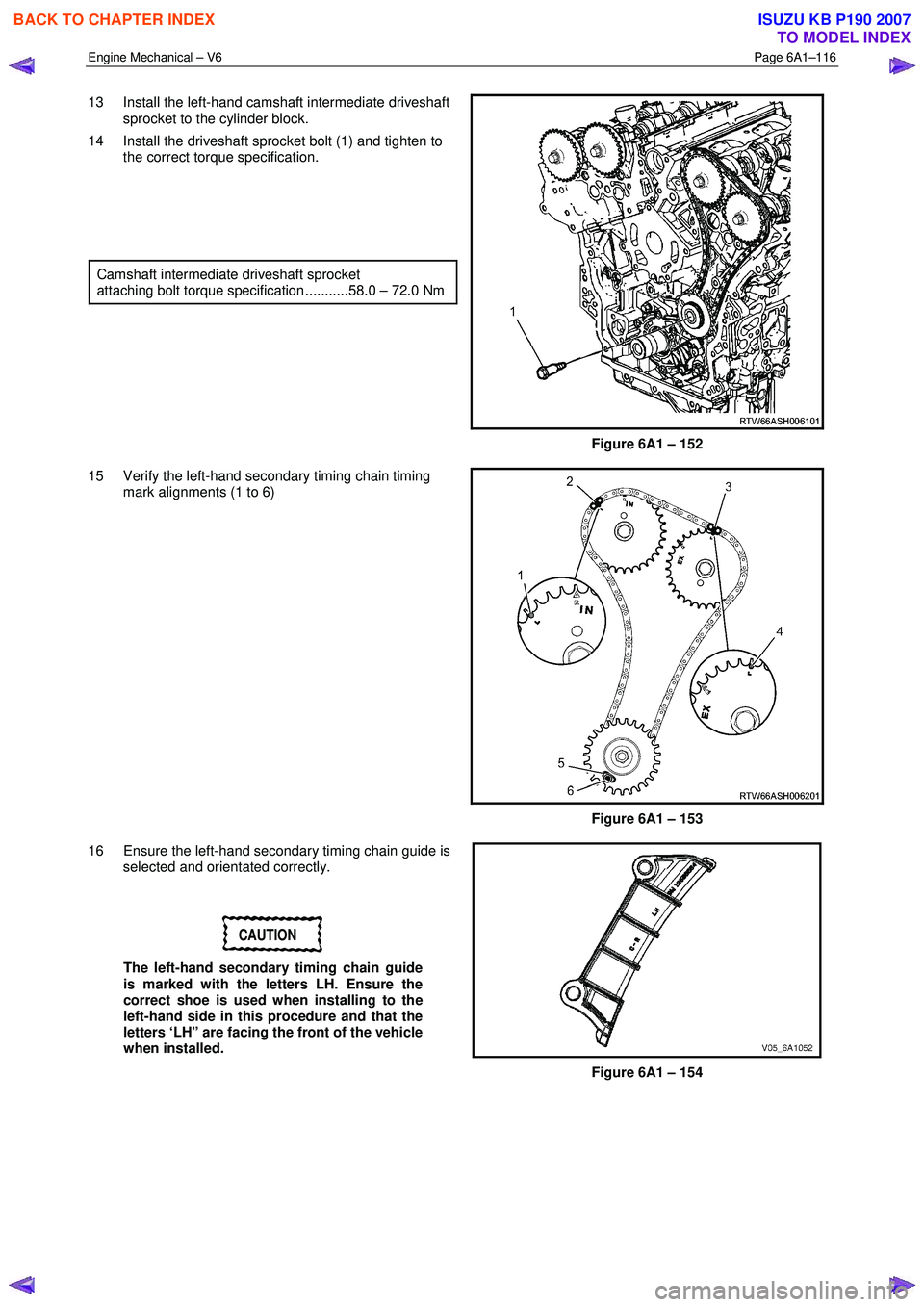

13 Install the left-hand camshaft intermediate driveshaft

sprocket to the cylinder block.

14 Install the driveshaft sprocket bolt (1) and tighten to the correct torque specification.

Camshaft intermediate driveshaft sprocket

attaching bolt torque specification ...........58.0 – 72.0 Nm

Figure 6A1 – 152

15 Verify the left-hand secondary timing chain timing mark alignments (1 to 6)

Figure 6A1 – 153

16 Ensure the left-hand secondary timing chain guide is selected and orientated correctly.

CAUTION

The left-hand secondary timing chain guide

is marked with the letters LH. Ensure the

correct shoe is used when installing to the

left-hand side in this procedure and that the

letters ‘LH” are facing the front of the vehicle

when installed.

Figure 6A1 – 154

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2596 of 6020

Engine Mechanical – V6 Page 6A1–117

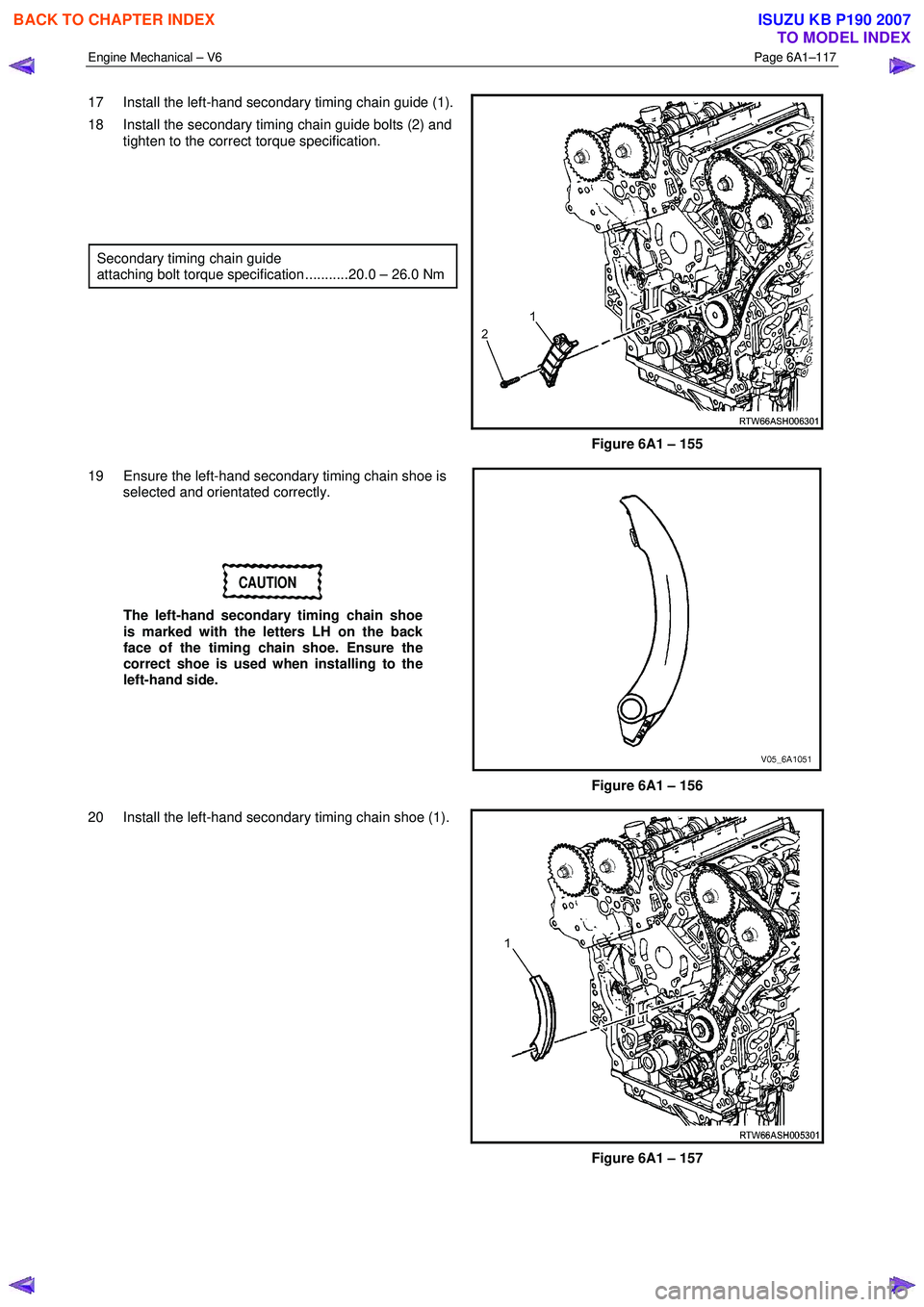

17 Install the left-hand secondary timing chain guide (1).

18 Install the secondary timing chain guide bolts (2) and tighten to the correct torque specification.

Secondary timing chain guide

attaching bolt torque specification ...........20.0 – 26.0 Nm

Figure 6A1 – 155

19 Ensure the left-hand secondary timing chain shoe is selected and orientated correctly.

CAUTION

The left-hand secondary timing chain shoe

is marked with the letters LH on the back

face of the timing chain shoe. Ensure the

correct shoe is used when installing to the

left-hand side.

Figure 6A1 – 156

20 Install the left-hand secondary timing chain shoe (1).

Figure 6A1 – 157

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2597 of 6020

Engine Mechanical – V6 Page 6A1–118

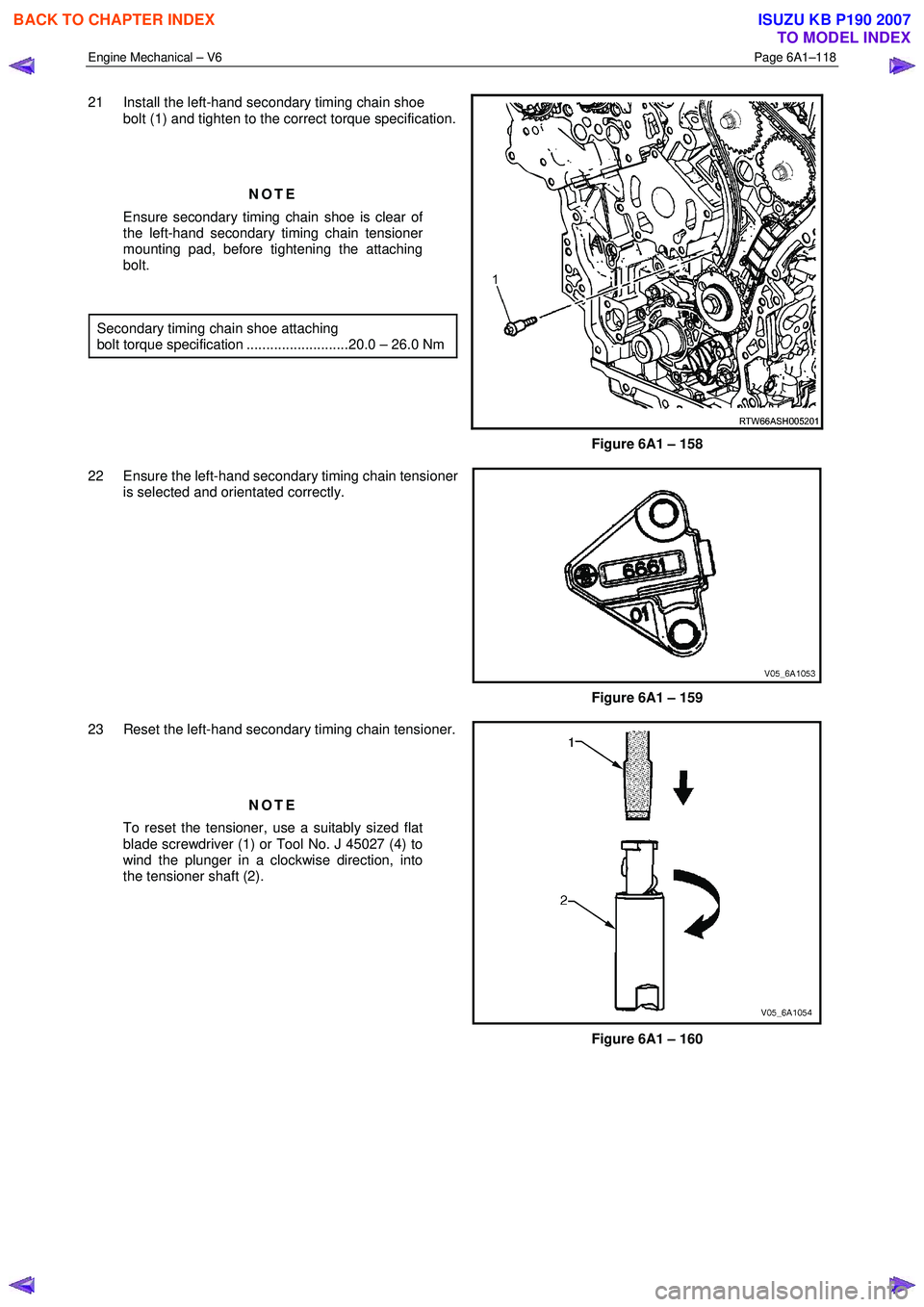

21 Install the left-hand secondary timing chain shoe

bolt (1) and tighten to the correct torque specification.

NOTE

Ensure secondary timing chain shoe is clear of

the left-hand secondary timing chain tensioner

mounting pad, before tightening the attaching

bolt.

Secondary timing chain shoe attaching

bolt torque specification ..........................20.0 – 26.0 Nm

Figure 6A1 – 158

22 Ensure the left-hand secondary timing chain tensioner is selected and orientated correctly.

Figure 6A1 – 159

23 Reset the left-hand secondary timing chain tensioner.

NOTE

To reset the tensioner, use a suitably sized flat

blade screwdriver (1) or Tool No. J 45027 (4) to

wind the plunger in a clockwise direction, into

the tensioner shaft (2).

Figure 6A1 – 160

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007