lock ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 3226 of 6020

Fuel System – V6 Page 6C – 24

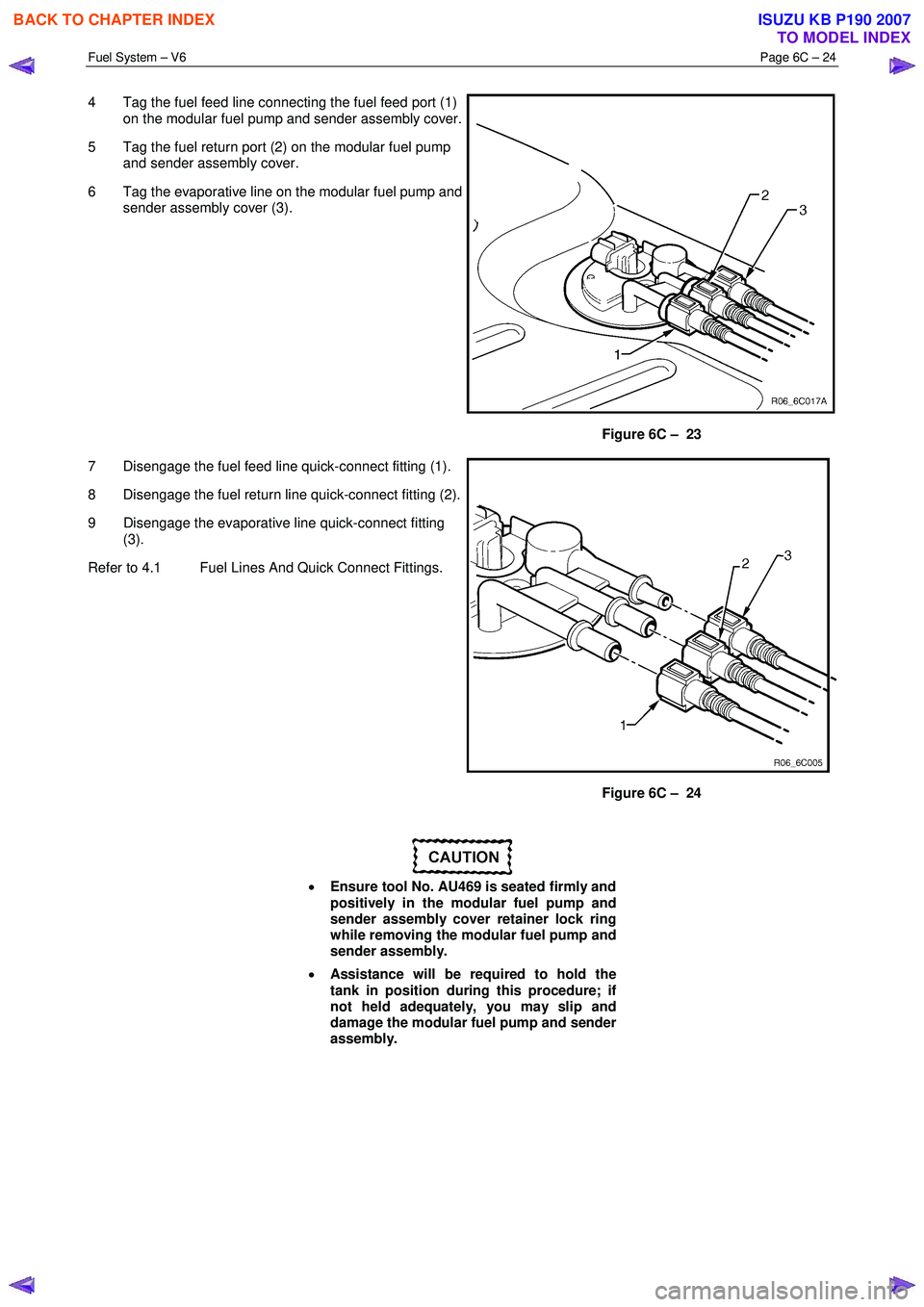

4 Tag the fuel feed line connecting the fuel feed port (1)

on the modular fuel pump and sender assembly cover.

5 Tag the fuel return port (2) on the modular fuel pump and sender assembly cover.

6 Tag the evaporative line on the modular fuel pump and sender assembly cover (3).

Figure 6C – 23

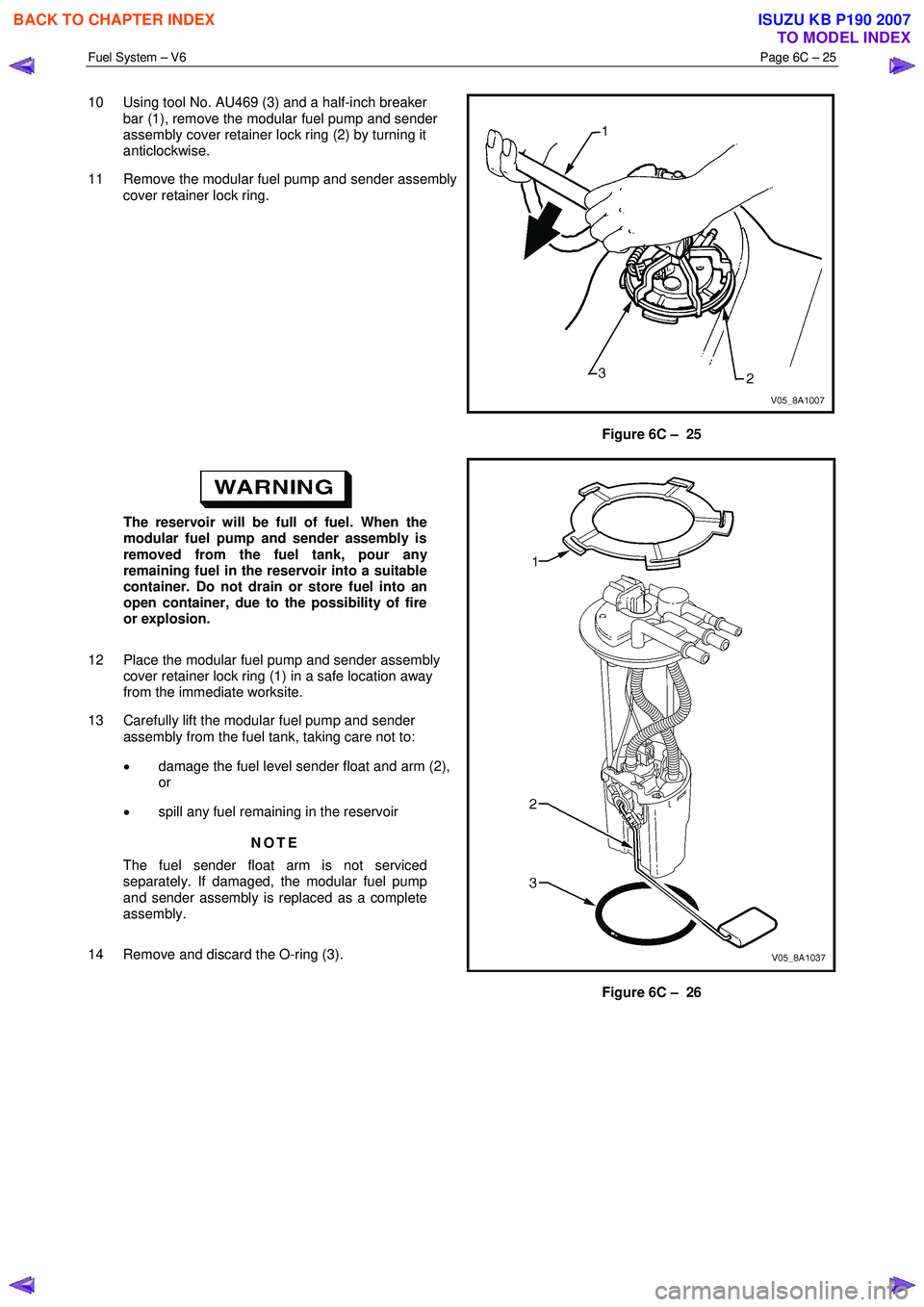

7 Disengage the fuel feed line quick-connect fitting (1).

8 Disengage the fuel return line quick-connect fitting (2).

9 Disengage the evaporative line quick-connect fitting (3).

Refer to 4.1 Fuel Lines And Quick Connect Fittings.

Figure 6C – 24

• Ensure tool No. AU469 is seated firmly and

positively in the modular fuel pump and

sender assembly cover retainer lock ring

while removing the modular fuel pump and

sender assembly.

• Assistance will be required to hold the

tank in position during this procedure; if

not held adequately, you may slip and

damage the modular fuel pump and sender

assembly.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3227 of 6020

Fuel System – V6 Page 6C – 25

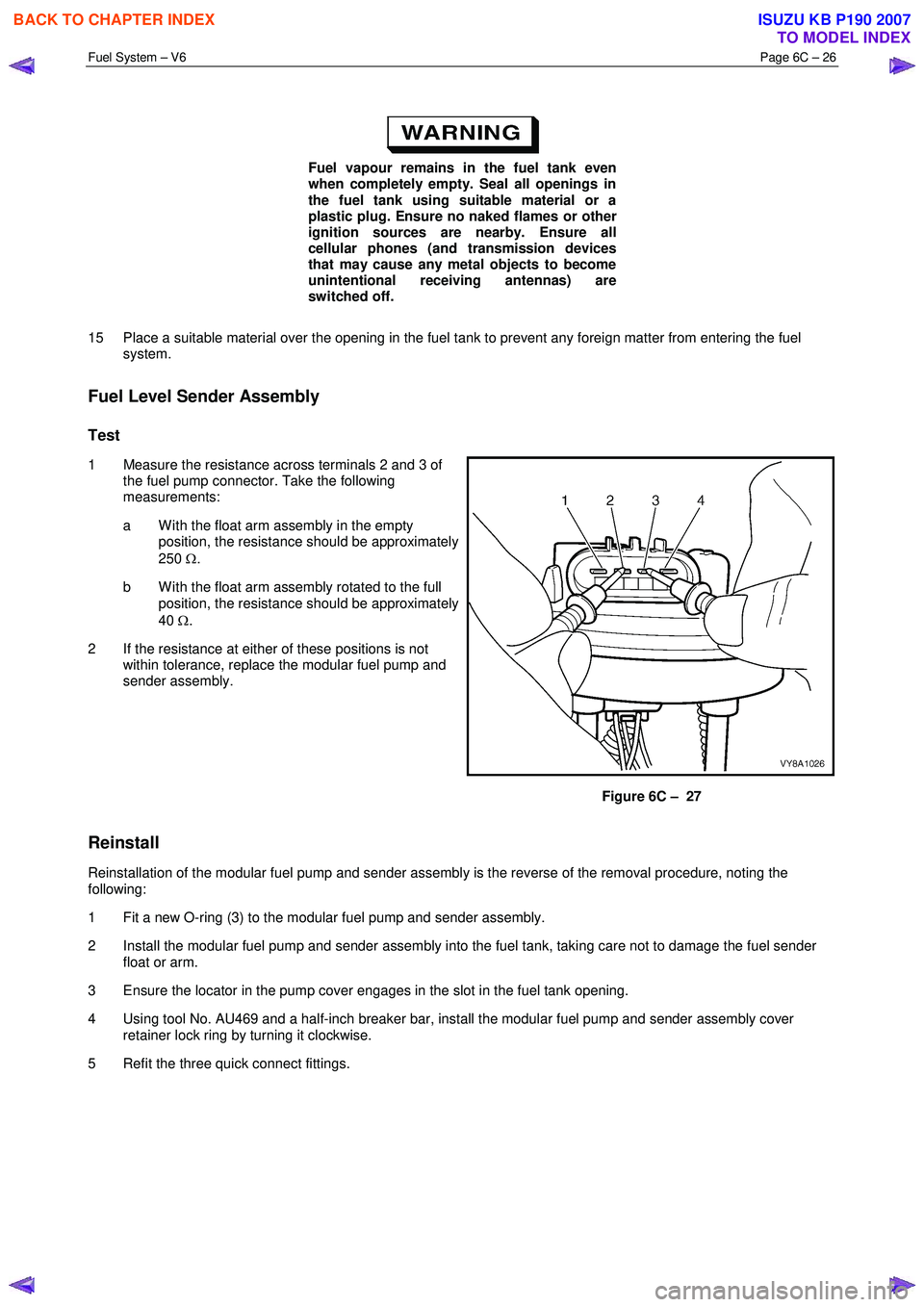

10 Using tool No. AU469 (3) and a half-inch breaker

bar (1), remove the modular fuel pump and sender

assembly cover retainer lock ring (2) by turning it

anticlockwise.

11 Remove the modular fuel pump and sender assembly cover retainer lock ring.

Figure 6C – 25

The reservoir will be full of fuel. When the

modular fuel pump and sender assembly is

removed from the fuel tank, pour any

remaining fuel in the reservoir into a suitable

container. Do not drain or store fuel into an

open container, due to the possibility of fire

or explosion.

12 Place the modular fuel pump and sender assembly cover retainer lock ring (1) in a safe location away

from the immediate worksite.

13 Carefully lift the modular fuel pump and sender assembly from the fuel tank, taking care not to:

• damage the fuel level sender float and arm (2),

or

• spill any fuel remaining in the reservoir

NOTE

The fuel sender float arm is not serviced

separately. If damaged, the modular fuel pump

and sender assembly is replaced as a complete

assembly.

14 Remove and discard the O-ring (3).

Figure 6C – 26

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3228 of 6020

Fuel System – V6 Page 6C – 26

Fuel vapour remains in the fuel tank even

when completely empty. Seal all openings in

the fuel tank using suitable material or a

plastic plug. Ensure no naked flames or other

ignition sources are nearby. Ensure all

cellular phones (and transmission devices

that may cause any metal objects to become

unintentional receiving antennas) are

switched off.

15 Place a suitable material over the opening in the fuel tank to prevent any foreign matter from entering the fuel system.

Fuel Level Sender Assembly

Test

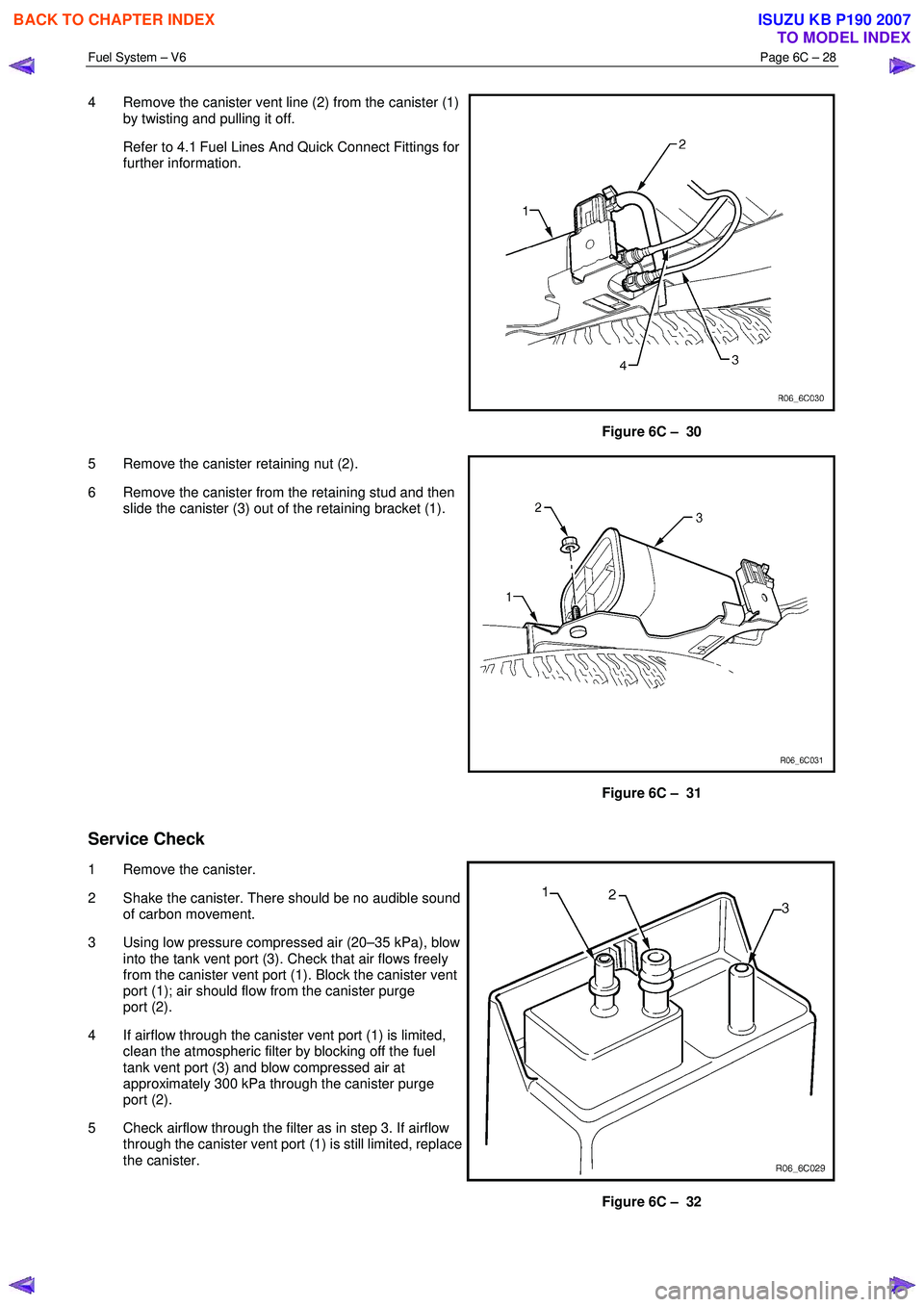

1 Measure the resistance across terminals 2 and 3 of the fuel pump connector. Take the following

measurements:

a W ith the float arm assembly in the empty position, the resistance should be approximately

250 Ω.

b W ith the float arm assembly rotated to the full position, the resistance should be approximately

40 Ω.

2 If the resistance at either of these positions is not within tolerance, replace the modular fuel pump and

sender assembly.

Figure 6C – 27

Reinstall

Reinstallation of the modular fuel pump and sender assembly is the reverse of the removal procedure, noting the

following:

1 Fit a new O-ring (3) to the modular fuel pump and sender assembly.

2 Install the modular fuel pump and sender assembly into the fuel tank, taking care not to damage the fuel sender float or arm.

3 Ensure the locator in the pump cover engages in the slot in the fuel tank opening.

4 Using tool No. AU469 and a half-inch breaker bar, install the modular fuel pump and sender assembly cover retainer lock ring by turning it clockwise.

5 Refit the three quick connect fittings.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3230 of 6020

Fuel System – V6 Page 6C – 28

4 Remove the canister vent line (2) from the canister (1)

by twisting and pulling it off.

Refer to 4.1 Fuel Lines And Quick Connect Fittings for further information.

Figure 6C – 30

5 Remove the canister retaining nut (2).

6 Remove the canister from the retaining stud and then slide the canister (3) out of the retaining bracket (1).

Figure 6C – 31

Service Check

1 Remove the canister.

2 Shake the canister. There should be no audible sound of carbon movement.

3 Using low pressure compressed air (20–35 kPa), blow into the tank vent port (3). Check that air flows freely

from the canister vent port (1). Block the canister vent

port (1); air should flow from the canister purge

port (2).

4 If airflow through the canister vent port (1) is limited, clean the atmospheric filter by blocking off the fuel

tank vent port (3) and blow compressed air at

approximately 300 kPa through the canister purge

port (2).

5 Check airflow through the filter as in step 3. If airflow through the canister vent port (1) is still limited, replace

the canister.

Figure 6C – 32

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3231 of 6020

Fuel System – V6 Page 6C – 29

6 Block the canister vent port (1) and the canister purge port (2). Apply low-pressure compressed air

(20–35 kPa) to the tank vent port (3). If any air leaks from the canister (that is, around the ports or seams), replace

the canister.

NOTE

In dusty areas, an alternative is to block the

canister purge port (2). Blow air through the

canister vent (1) port and check that air is

expelled through the tank vent port (3).

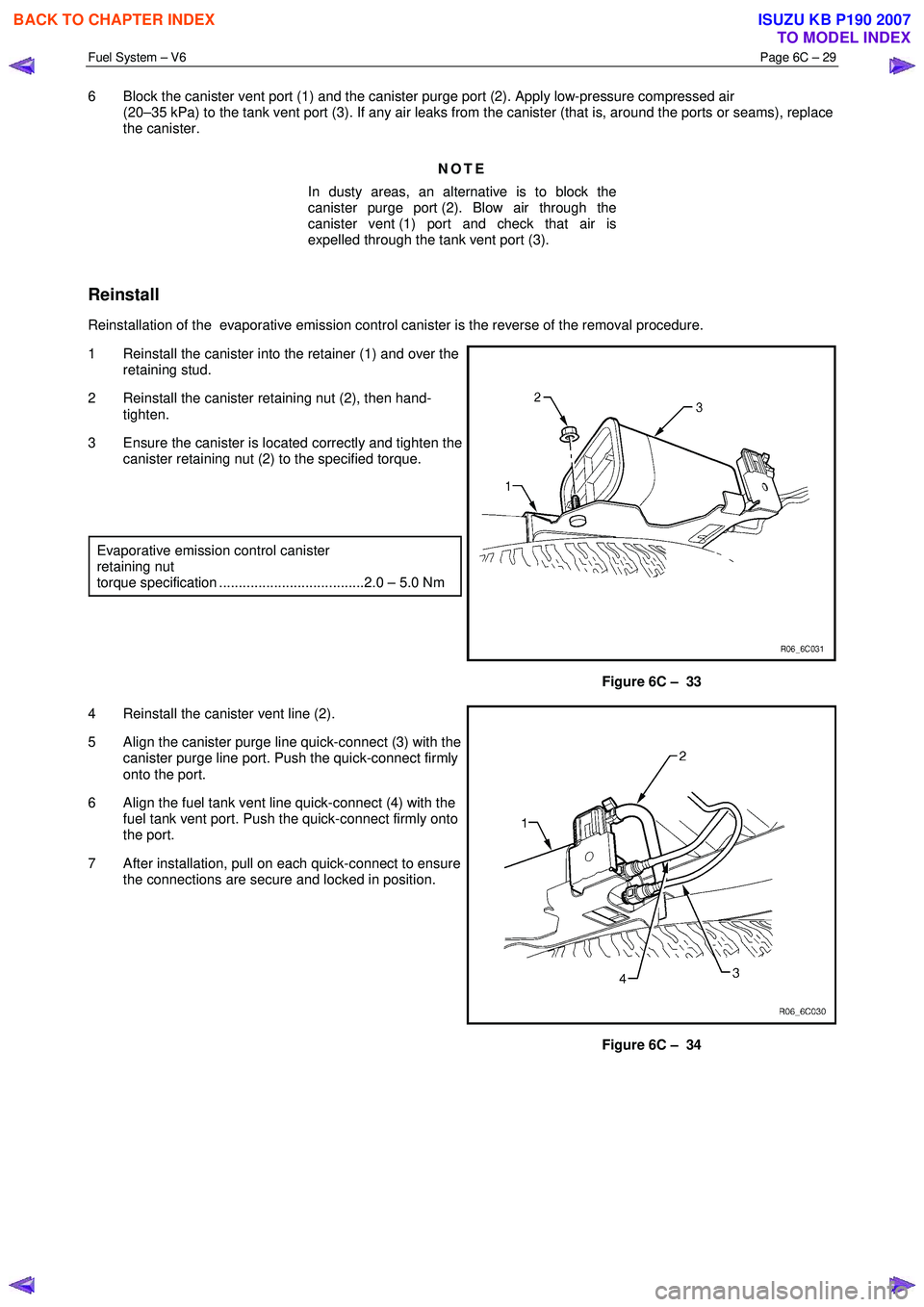

Reinstall

Reinstallation of the evaporative emission control canister is the reverse of the removal procedure.

1 Reinstall the canister into the retainer (1) and over the retaining stud.

2 Reinstall the canister retaining nut (2), then hand- tighten.

3 Ensure the canister is located correctly and tighten the canister retaining nut (2) to the specified torque.

Evaporative emission control canister

retaining nut

torque specification .....................................2.0 – 5.0 Nm

Figure 6C – 33

4 Reinstall the canister vent line (2).

5 Align the canister purge line quick-connect (3) with the canister purge line port. Push the quick-connect firmly

onto the port.

6 Align the fuel tank vent line quick-connect (4) with the fuel tank vent port. Push the quick-connect firmly onto

the port.

7 After installation, pull on each quick-connect to ensure the connections are secure and locked in position.

Figure 6C – 34

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3234 of 6020

Fuel System – V6 Page 6C – 32

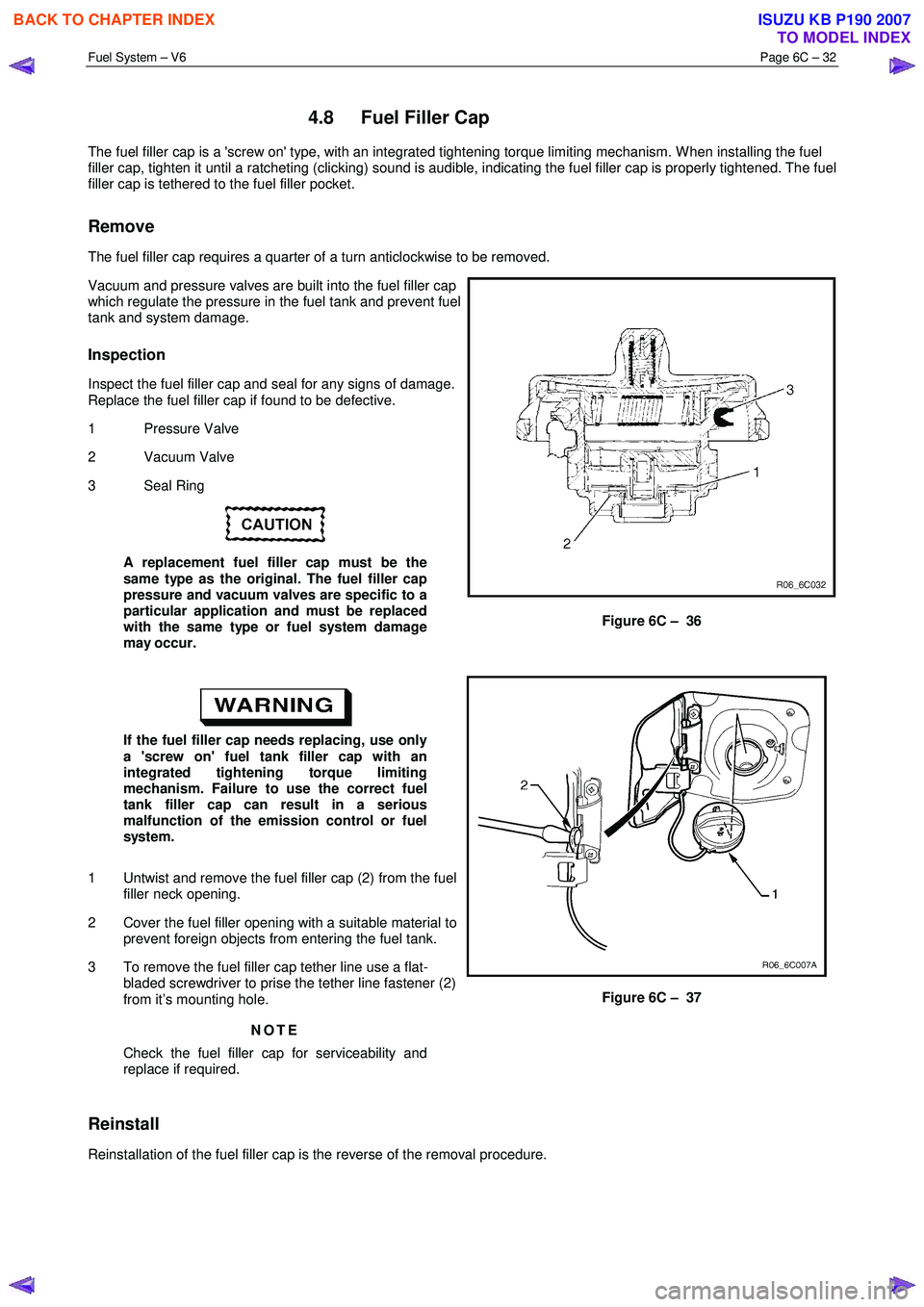

4.8 Fuel Filler Cap

The fuel filler cap is a 'screw on' type, with an integrated tightening torque limiting mechanism. W hen installing the fuel

filler cap, tighten it until a ratcheting (clicking) sound is audible, indicating the fuel filler cap is properly tightened. Th e fuel

filler cap is tethered to the fuel filler pocket.

Remove

The fuel filler cap requires a quarter of a turn anticlockwise to be removed.

Vacuum and pressure valves are built into the fuel filler cap

which regulate the pressure in the fuel tank and prevent fuel

tank and system damage.

Inspection

Inspect the fuel filler cap and seal for any signs of damage.

Replace the fuel filler cap if found to be defective.

1 Pressure Valve

2 Vacuum Valve

3 Seal Ring

A replacement fuel filler cap must be the

same type as the original. The fuel filler cap

pressure and vacuum valves are specific to a

particular application and must be replaced

with the same type or fuel system damage

may occur.

Figure 6C – 36

If the fuel filler cap needs replacing, use only

a 'screw on' fuel tank filler cap with an

integrated tightening torque limiting

mechanism. Failure to use the correct fuel

tank filler cap can result in a serious

malfunction of the emission control or fuel

system.

1 Untwist and remove the fuel filler cap (2) from the fuel filler neck opening.

2 Cover the fuel filler opening with a suitable material to prevent foreign objects from entering the fuel tank.

3 To remove the fuel filler cap tether line use a flat- bladed screwdriver to prise the tether line fastener (2)

from it’s mounting hole.

NOTE

Check the fuel filler cap for serviceability and

replace if required.

Figure 6C – 37

Reinstall

Reinstallation of the fuel filler cap is the reverse of the removal procedure.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3236 of 6020

Fuel System – V6 Page 6C – 34

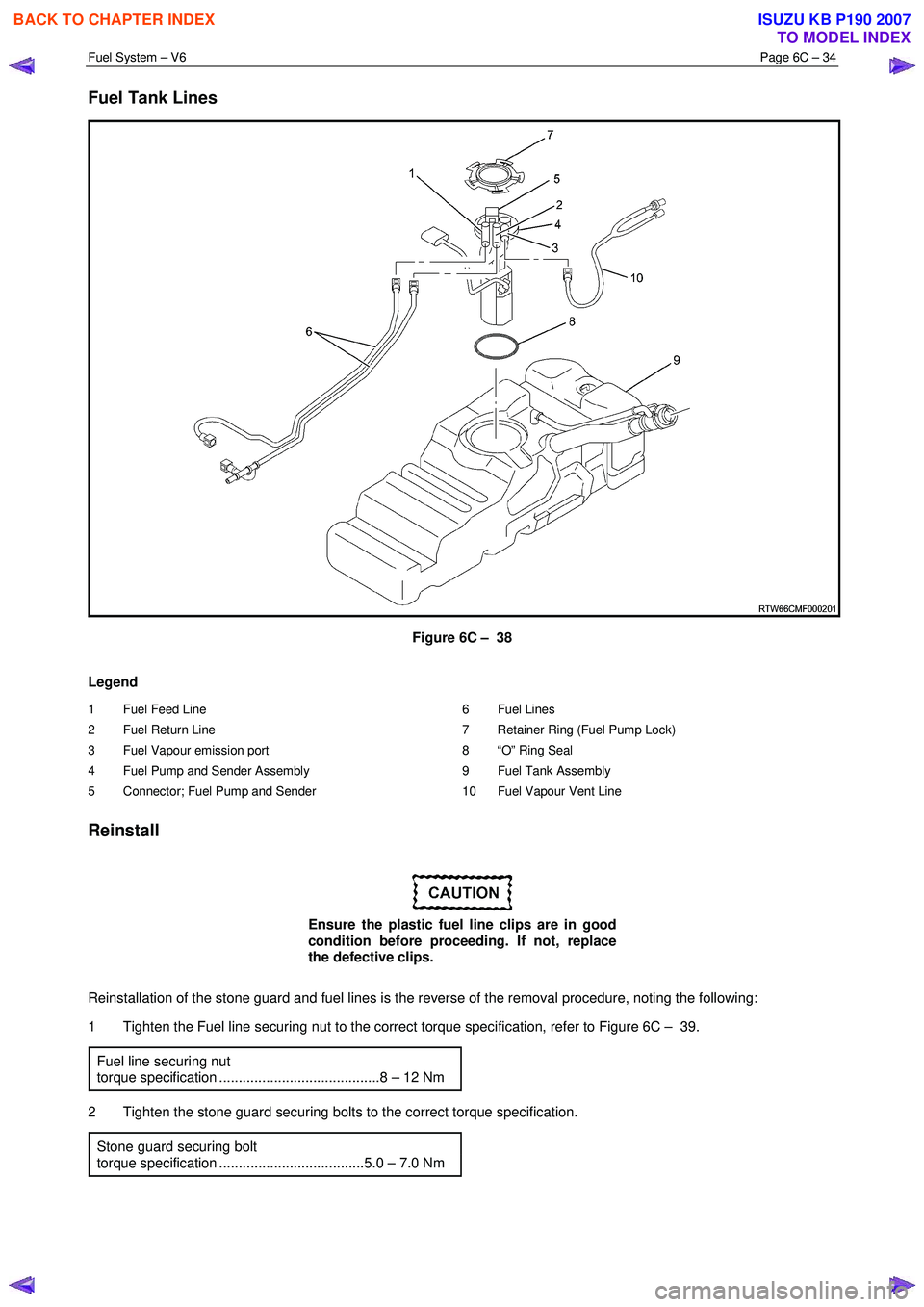

Fuel Tank Lines

Figure 6C – 38

Legend

1 Fuel Feed Line

2 Fuel Return Line

3 Fuel Vapour emission port

4 Fuel Pump and Sender Assembly

5 Connector; Fuel Pump and Sender 6 Fuel Lines

7 Retainer Ring (Fuel Pump Lock)

8 “O” Ring Seal

9 Fuel Tank Assembly

10 Fuel Vapour Vent Line

Reinstall

Ensure the plastic fuel line clips are in good

condition before proceeding. If not, replace

the defective clips.

Reinstallation of the stone guard and fuel lines is the reverse of the removal procedure, noting the following:

1 Tighten the Fuel line securing nut to the correct torque specification, refer to Figure 6C – 39.

Fuel line securing nut

torque specification .........................................8 – 12 Nm

2 Tighten the stone guard securing bolts to the correct torque specification. Stone guard securing bolt

torque specification .....................................5.0 – 7.0 Nm

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3275 of 6020

Engine Management – V6 – General Information Page 6C1-1–33

The knock sensor is tuned to detect the frequency of the

vibration created by combustion knock. The vibration is

transferred to the knock sensor through the cylinder

block (1).

Inside the sensor is a mass (2) that is excited by this

vibration, and the mass exerts a compressive force onto a

piezo-ceramic element (3). The compressive force causes a

charge transfer inside the element, so that an AC voltage

appears across the two outer faces (4) of the element. The

amount of the AC voltage produced is proportional to the

amount of knock.

Figure 6C1-1 – 42

4.18 Mass Air Flow Sensor

Air Intake System

The air intake system draws outside air through an air

cleaner assembly (1). The air is then routed through a mass

air flow (MAF) sensor (2) and into the throttle body and

intake manifold. The air is then directed into the intake

manifold runners, through the cylinder heads and into the

cylinders.

An arrow marked on the body of the MAF sensor indicates

correct air flow direction. The arrow must point toward the

engine.

Figure 6C1-1 – 43

Mass Air Flow Sensor

A hot film type mass air flow (MAF) sensor is used which

measures the air mass inducted into the engine, regardless

of the engine’s operating state. The MAF precisely

measures a portion of the total airflow and takes into

account the pulsation and reverse flows generated by the

engine’s inlet and exhaust valves.

Changes in intake air temperature have no effect on

measuring accuracy.

Figure 6C1-1 – 44

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3305 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–27

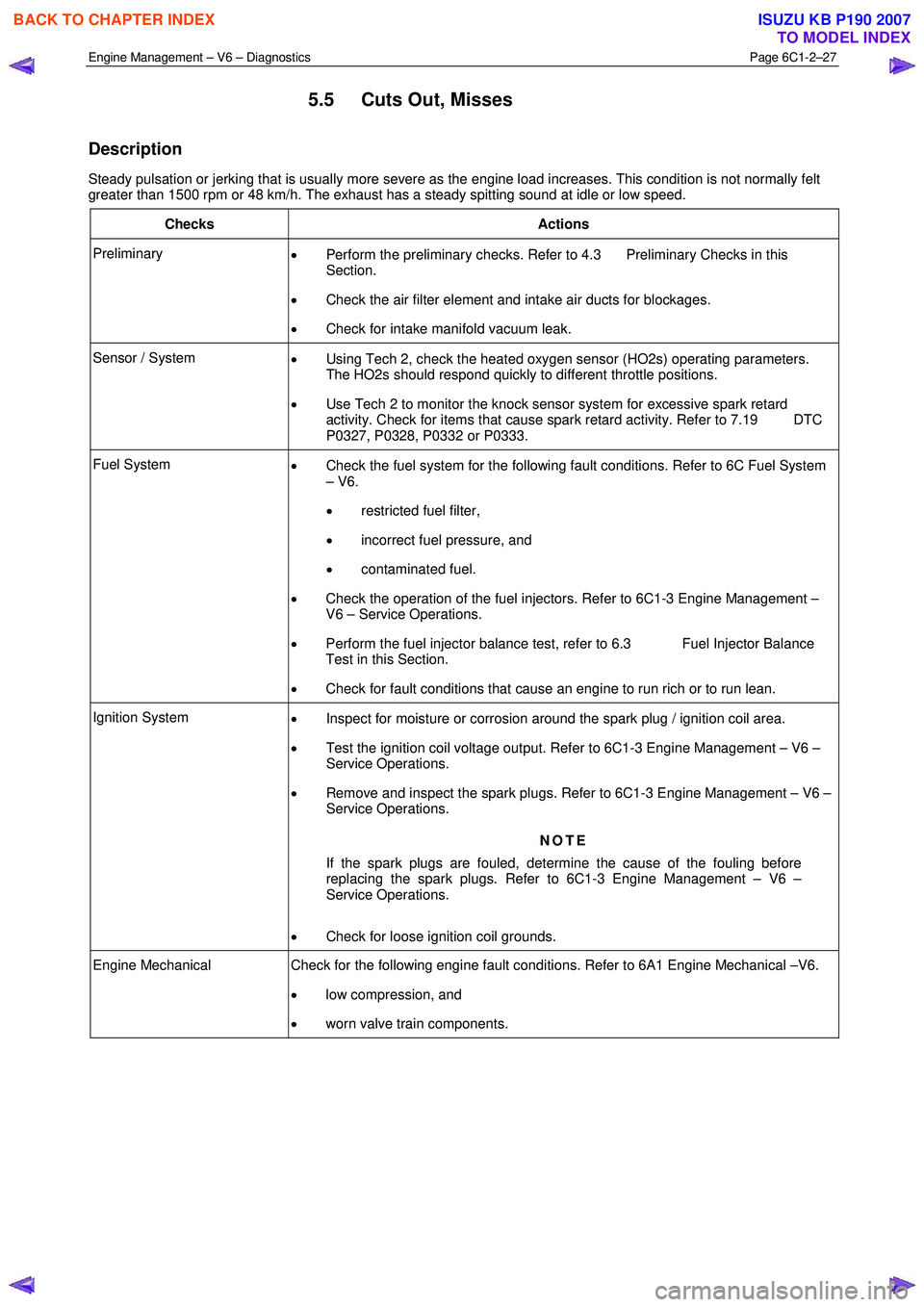

5.5 Cuts Out, Misses

Description

Steady pulsation or jerking that is usually more severe as the engine load increases. This condition is not normally felt

greater than 1500 rpm or 48 km/h. The exhaust has a steady spitting sound at idle or low speed.

Checks Actions

Preliminary • Perform the preliminary checks. Refer to 4.3 Preliminary Checks in this

Section.

• Check the air filter element and intake air ducts for blockages.

• Check for intake manifold vacuum leak.

Sensor / System

• Using Tech 2, check the heated oxygen sensor (HO2s) operating parameters.

The HO2s should respond quickly to different throttle positions.

• Use Tech 2 to monitor the knock sensor system for excessive spark retard

activity. Check for items that cause spark retard activity. Refer to 7.19 DTC

P0327, P0328, P0332 or P0333.

Fuel System • Check the fuel system for the following fault conditions. Refer to 6C Fuel System

– V6.

• restricted fuel filter,

• incorrect fuel pressure, and

• contaminated fuel.

• Check the operation of the fuel injectors. Refer to 6C1-3 Engine Management –

V6 – Service Operations.

• Perform the fuel injector balance test, refer to 6.3 Fuel Injector Balance

Test in this Section.

• Check for fault conditions that cause an engine to run rich or to run lean.

Ignition System

• Inspect for moisture or corrosion around the spark plug / ignition coil area.

• Test the ignition coil voltage output. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

• Remove and inspect the spark plugs. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

NOTE

If the spark plugs are fouled, determine the cause of the fouling before

replacing the spark plugs. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

• Check for loose ignition coil grounds.

Engine Mechanical Check for the following engine fault conditions. Refer to 6A1 Engine Mechanical –V6.

• low compression, and

• worn valve train components.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3308 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–30

Checks Actions

Ignition System

• Inspect for moisture or corrosion around the spark plug / ignition coil area.

• Test the ignition coil voltage output. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

• Remove and inspect the spark plugs. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

NOTE

If the spark plugs are fouled, determine the cause of the fouling before

replacing the spark plugs. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

• Check for loose ignition coil ground circuit.

Engine Mechanical

• Check for excessive oil in combustion chamber. Refer to 6A1 Engine Mechanical

– V6.

• Check for the following engine fault conditions. Refer to 6A1 Engine Mechanical –

V6.

• low compression, and

• worn valve train components.

When all diagnosis and repairs are completed, check the system for correct operation.

5.9 Hesitation, Sag and Stumble

Description

Momentary lack of response or hesitation as the accelerator is depressed. This condition is usually more severe when

first trying to make the vehicle move from a standing start but can occur at any vehicle speed.

Checks Actions

Preliminary • Perform the preliminary checks. Refer to 4.3 Preliminary Checks in this

Section.

• Check the air filter element and intake air ducts for blockages.

Sensor / System

• Using Tech 2, check the heated oxygen sensor (HO2s) operating parameters.

The HO2s should respond quickly to different throttle positions.

• Inspect the accelerator pedal position (APP) sensor harness connector for correct

connection. Poor connection of this connector will not set a DTC.

Fuel System • Check the fuel system for the following fault conditions. Refer to 6C Fuel System

– V6.

• restricted fuel filter,

• incorrect fuel pressure, and

• contaminated fuel.

• Check the operation of the fuel injectors. Refer to 6C Fuel System – V6.

• Perform the fuel injector balance test, refer to 6.3 Fuel Injector Balance

Test in this Section.

• Check for fault conditions that cause an engine to run rich or to run lean.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007