lock ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 3539 of 6020

Engine Management – V6 – Service Operations Page 6C1-3–15

Test

To prevent component and damage use

connector test adaptor kit J 35616-A.

Resistance Check

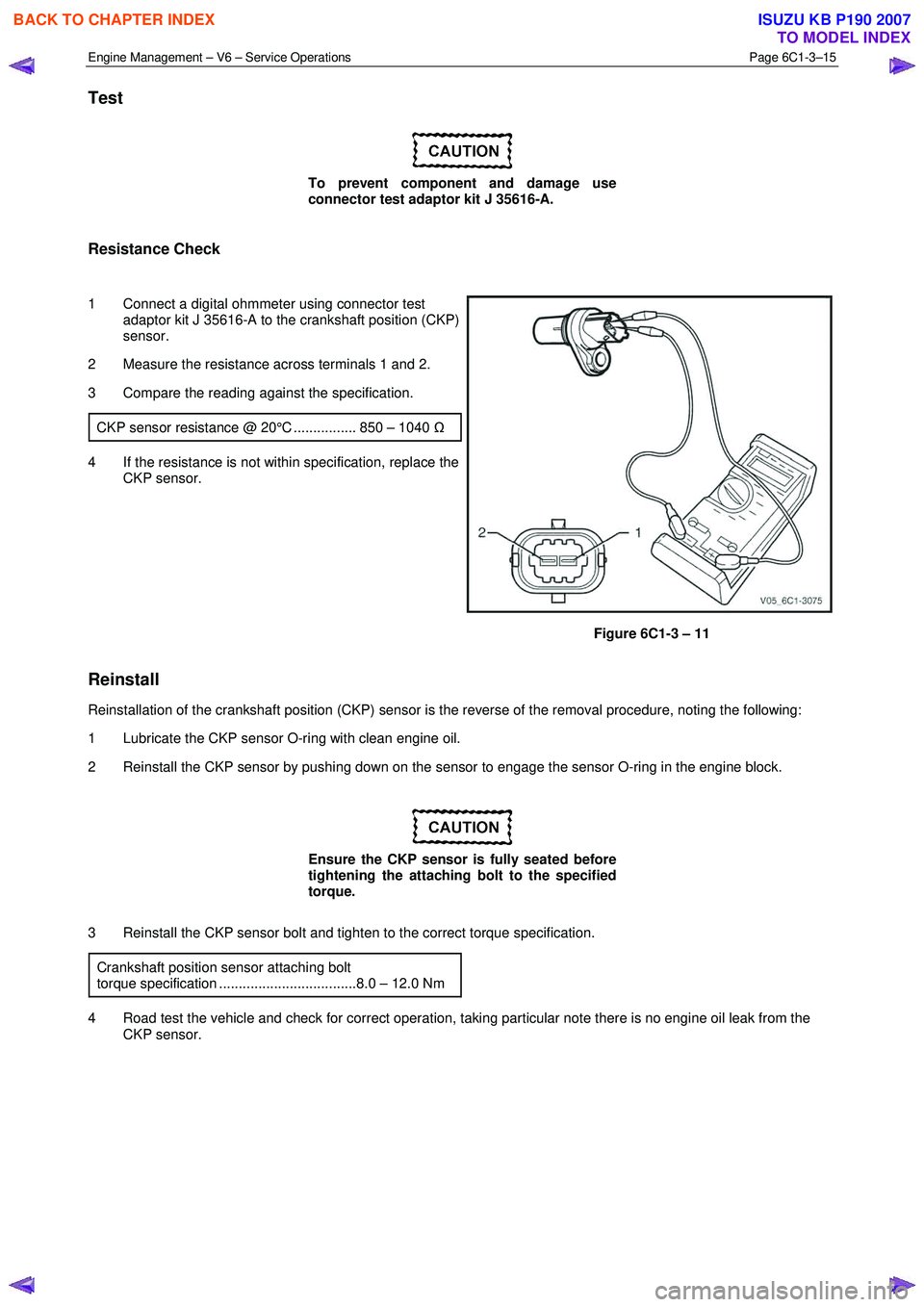

1 Connect a digital ohmmeter using connector test adaptor kit J 35616-A to the crankshaft position (CKP)

sensor.

2 Measure the resistance across terminals 1 and 2.

3 Compare the reading against the specification.

CKP sensor resistance @ 20°C ................ 850 – 1040 Ω

4 If the resistance is not within specification, replace the

CKP sensor.

Figure 6C1-3 – 11

Reinstall

Reinstallation of the crankshaft position (CKP) sensor is the reverse of the removal procedure, noting the following:

1 Lubricate the CKP sensor O-ring with clean engine oil.

2 Reinstall the CKP sensor by pushing down on the sensor to engage the sensor O-ring in the engine block.

Ensure the CKP sensor is fully seated before

tightening the attaching bolt to the specified

torque.

3 Reinstall the CKP sensor bolt and tighten to the correct torque specification. Crankshaft position sensor attaching bolt

torque specification ...................................8.0 – 12.0 Nm

4 Road test the vehicle and check for correct operation, taking particular note there is no engine oil leak from the CKP sensor.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3543 of 6020

Engine Management – V6 – Service Operations Page 6C1-3–19

Remove

If replacing the ECM, it must be reset prior to

removal. Failure to perform this procedure

will result in the inability to test the ECM for

warranty purposes, refer to ECM Reset in this

Section.

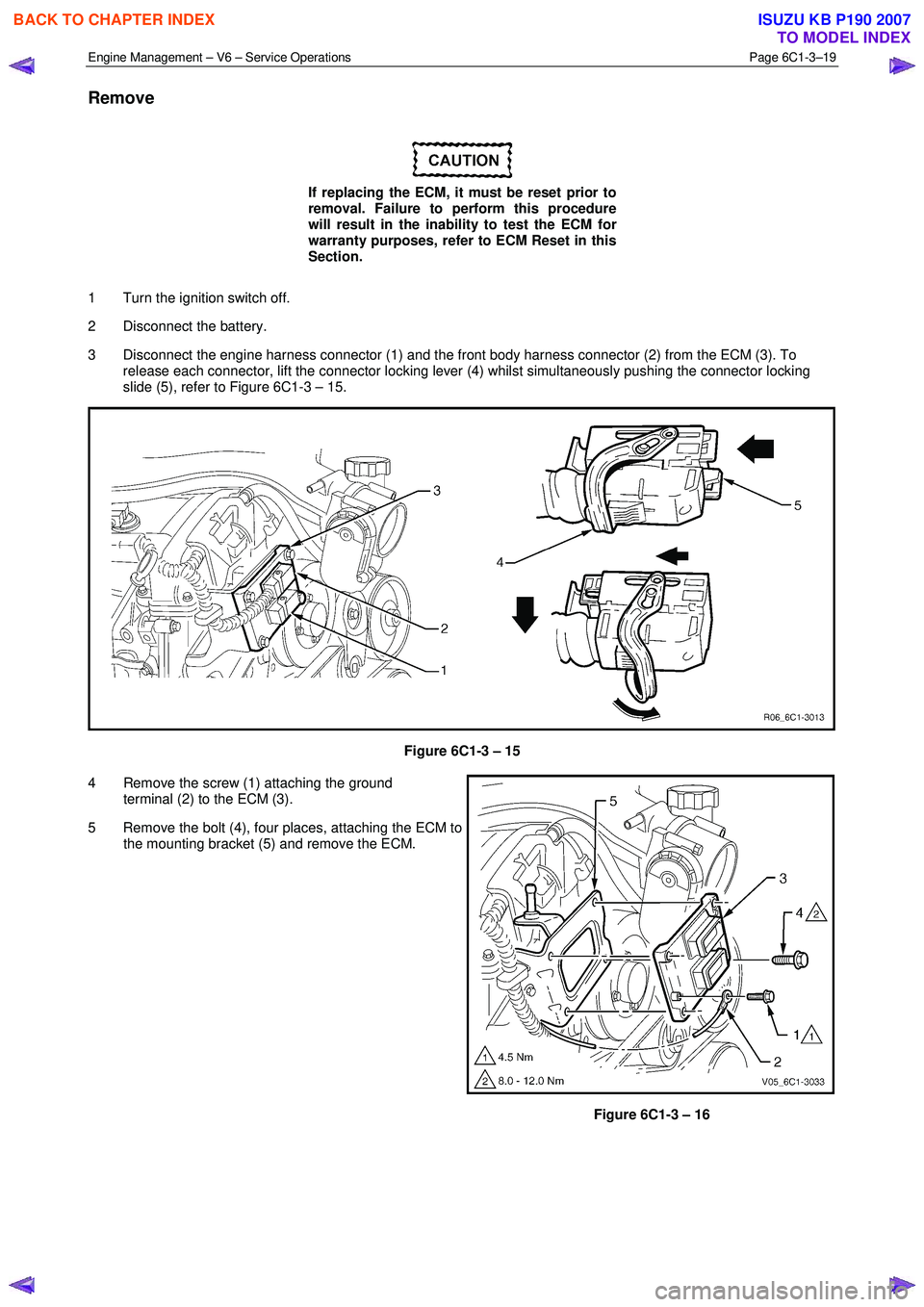

1 Turn the ignition switch off.

2 Disconnect the battery.

3 Disconnect the engine harness connector (1) and the front body harness connector (2) from the ECM (3). To release each connector, lift the connector locking lever (4) whilst simultaneously pushing the connector locking

slide (5), refer to Figure 6C1-3 – 15.

Figure 6C1-3 – 15

4 Remove the screw (1) attaching the ground terminal (2) to the ECM (3).

5 Remove the bolt (4), four places, attaching the ECM to the mounting bracket (5) and remove the ECM.

Figure 6C1-3 – 16

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3544 of 6020

Engine Management – V6 – Service Operations Page 6C1-3–20

Reinstall

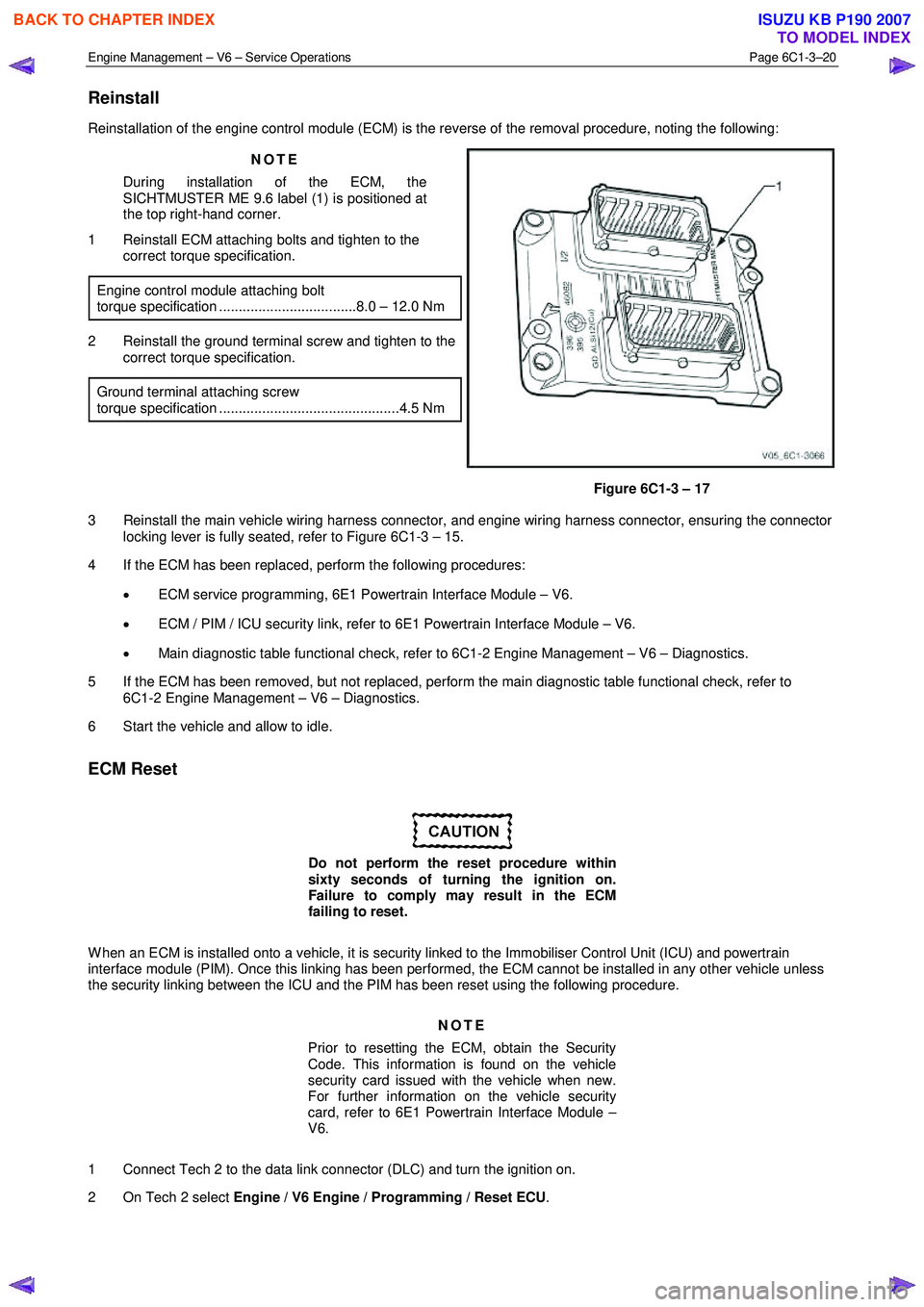

Reinstallation of the engine control module (ECM) is the reverse of the removal procedure, noting the following:

NOTE

During installation of the ECM, the

SICHTMUSTER ME 9.6 label (1) is positioned at

the top right-hand corner.

1 Reinstall ECM attaching bolts and tighten to the correct torque specification.

Engine control module attaching bolt

torque specification ...................................8.0 – 12.0 Nm

2 Reinstall the ground terminal screw and tighten to the correct torque specification.

Ground terminal attaching screw

torque specification ..............................................4.5 Nm

Figure 6C1-3 – 17

3 Reinstall the main vehicle wiring harness connector, and engine wiring harness connector, ensuring the connector locking lever is fully seated, refer to Figure 6C1-3 – 15.

4 If the ECM has been replaced, perform the following procedures:

• ECM service programming, 6E1 Powertrain Interface Module – V6.

• ECM / PIM / ICU security link, refer to 6E1 Powertrain Interface Module – V6.

• Main diagnostic table functional check, refer to 6C1-2 Engine Management – V6 – Diagnostics.

5 If the ECM has been removed, but not replaced, perform the main diagnostic table functional check, refer to 6C1-2 Engine Management – V6 – Diagnostics.

6 Start the vehicle and allow to idle.

ECM Reset

Do not perform the reset procedure within

sixty seconds of turning the ignition on.

Failure to comply may result in the ECM

failing to reset.

W hen an ECM is installed onto a vehicle, it is security linked to the Immobiliser Control Unit (ICU) and powertrain

interface module (PIM). Once this linking has been performed, the ECM cannot be installed in any other vehicle unless

the security linking between the ICU and the PIM has been reset using the following procedure.

NOTE

Prior to resetting the ECM, obtain the Security

Code. This information is found on the vehicle

security card issued with the vehicle when new.

For further information on the vehicle security

card, refer to 6E1 Powertrain Interface Module –

V6.

1 Connect Tech 2 to the data link connector (DLC) and turn the ignition on.

2 On Tech 2 select Engine / V6 Engine / Programming / Reset ECU .

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3549 of 6020

Engine Management – V6 – Service Operations Page 6C1-3–25

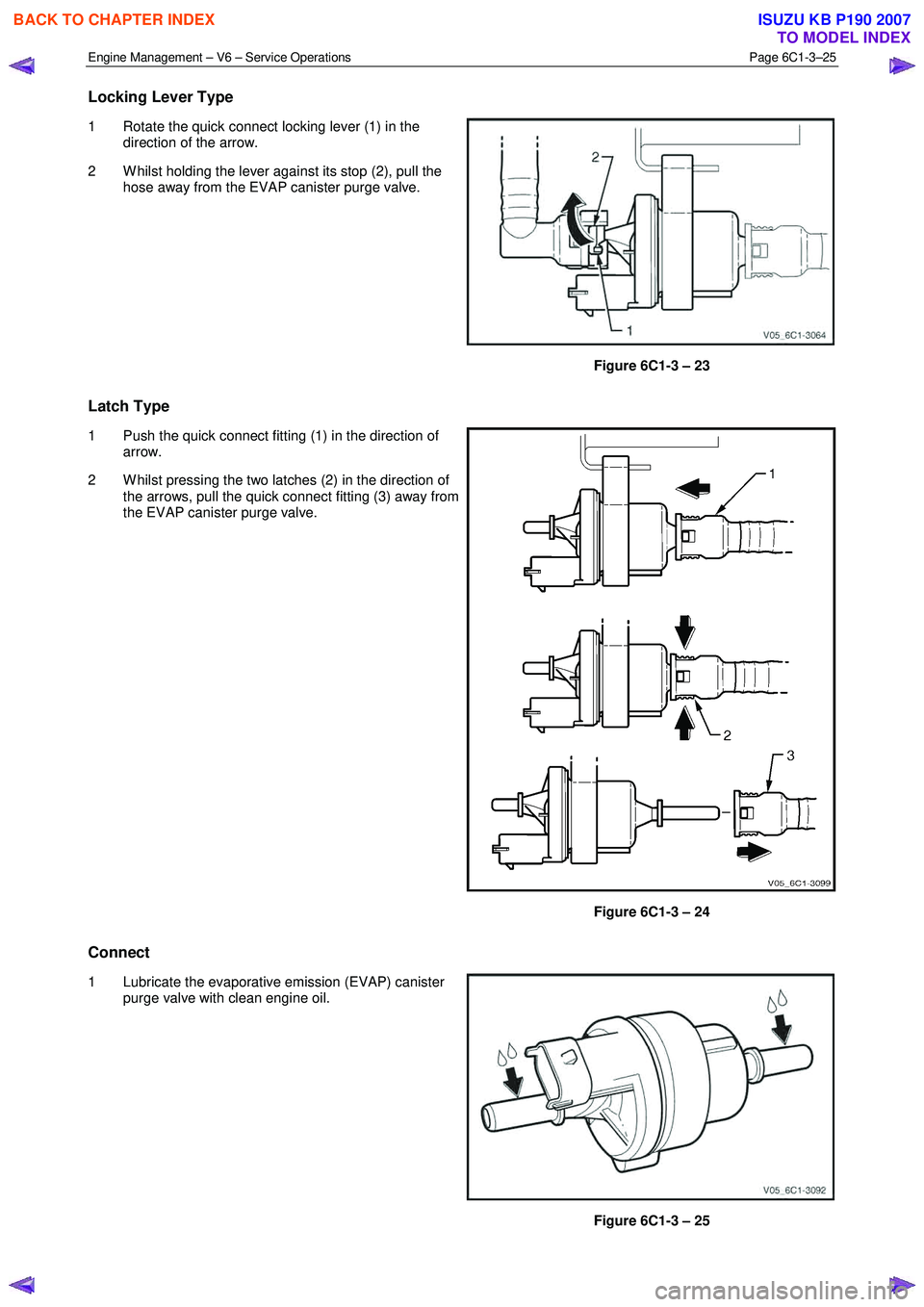

Locking Lever Type

1 Rotate the quick connect locking lever (1) in the

direction of the arrow.

2 W hilst holding the lever against its stop (2), pull the hose away from the EVAP canister purge valve.

Figure 6C1-3 – 23

Latch Type

1 Push the quick connect fitting (1) in the direction of

arrow.

2 W hilst pressing the two latches (2) in the direction of the arrows, pull the quick connect fitting (3) away from

the EVAP canister purge valve.

Figure 6C1-3 – 24

Connect

1 Lubricate the evaporative emission (EVAP) canister purge valve with clean engine oil.

Figure 6C1-3 – 25

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3550 of 6020

Engine Management – V6 – Service Operations Page 6C1-3–26

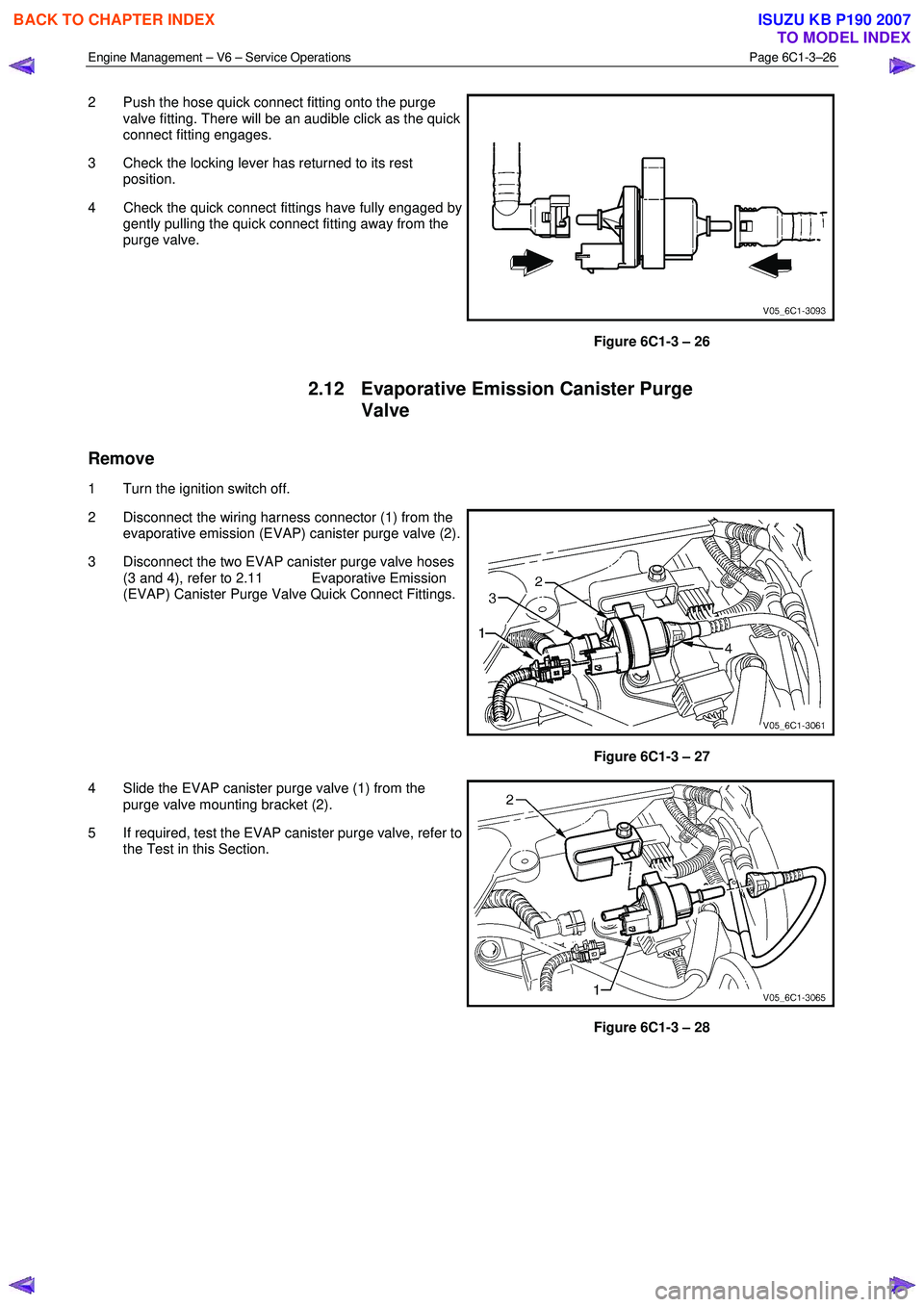

2 Push the hose quick connect fitting onto the purge

valve fitting. There will be an audible click as the quick

connect fitting engages.

3 Check the locking lever has returned to its rest position.

4 Check the quick connect fittings have fully engaged by gently pulling the quick connect fitting away from the

purge valve.

Figure 6C1-3 – 26

2.12 Evaporative Emission Canister Purge

Valve

Remove

1 Turn the ignition switch off.

2 Disconnect the wiring harness connector (1) from the evaporative emission (EVAP) canister purge valve (2).

3 Disconnect the two EVAP canister purge valve hoses (3 and 4), refer to 2.11 Evaporative Emission

(EVAP) Canister Purge Valve Quick Connect Fittings.

Figure 6C1-3 – 27

4 Slide the EVAP canister purge valve (1) from the purge valve mounting bracket (2).

5 If required, test the EVAP canister purge valve, refer to the Test in this Section.

Figure 6C1-3 – 28

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3554 of 6020

Engine Management – V6 – Service Operations Page 6C1-3–30

Disassemble

Fuel Injector

Remove

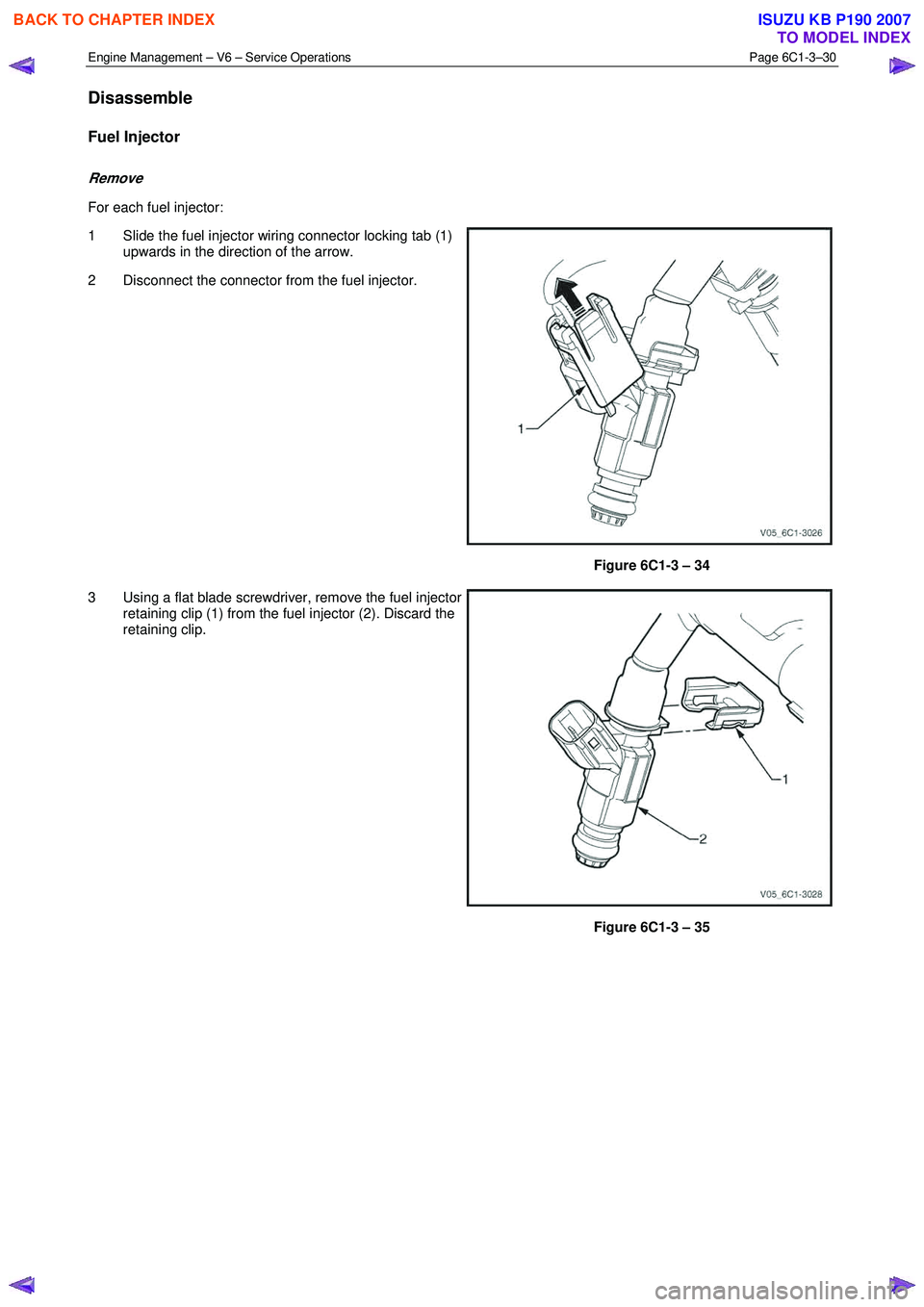

For each fuel injector:

1 Slide the fuel injector wiring connector locking tab (1) upwards in the direction of the arrow.

2 Disconnect the connector from the fuel injector.

Figure 6C1-3 – 34

3 Using a flat blade screwdriver, remove the fuel injector retaining clip (1) from the fuel injector (2). Discard the

retaining clip.

Figure 6C1-3 – 35

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3556 of 6020

Engine Management – V6 – Service Operations Page 6C1-3–32

Fuel Injector Wiring Harness Assembly

Remove

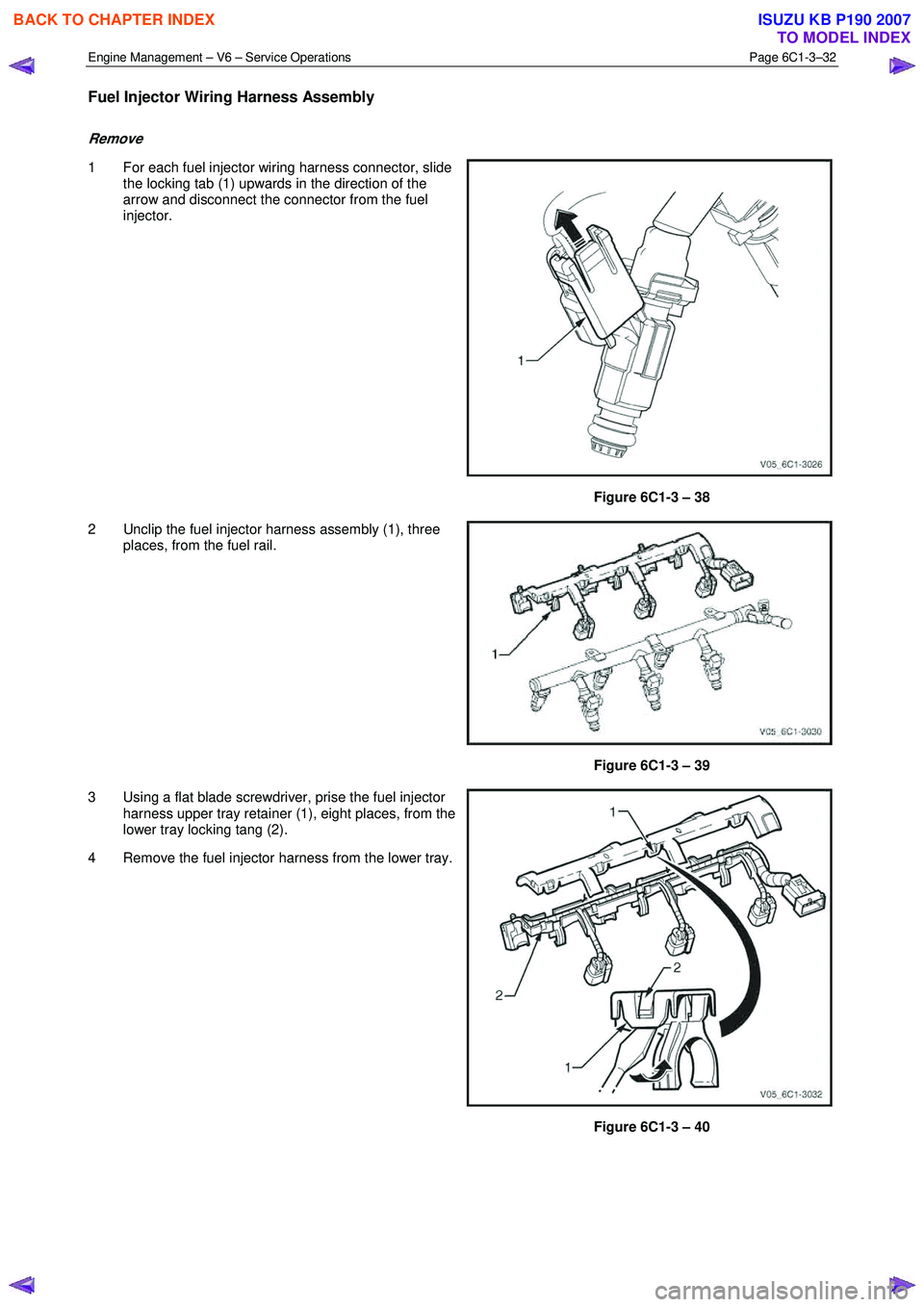

1 For each fuel injector wiring harness connector, slide

the locking tab (1) upwards in the direction of the

arrow and disconnect the connector from the fuel

injector.

Figure 6C1-3 – 38

2 Unclip the fuel injector harness assembly (1), three places, from the fuel rail.

Figure 6C1-3 – 39

3 Using a flat blade screwdriver, prise the fuel injector harness upper tray retainer (1), eight places, from the

lower tray locking tang (2).

4 Remove the fuel injector harness from the lower tray.

Figure 6C1-3 – 40

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3558 of 6020

Engine Management – V6 – Service Operations Page 6C1-3–34

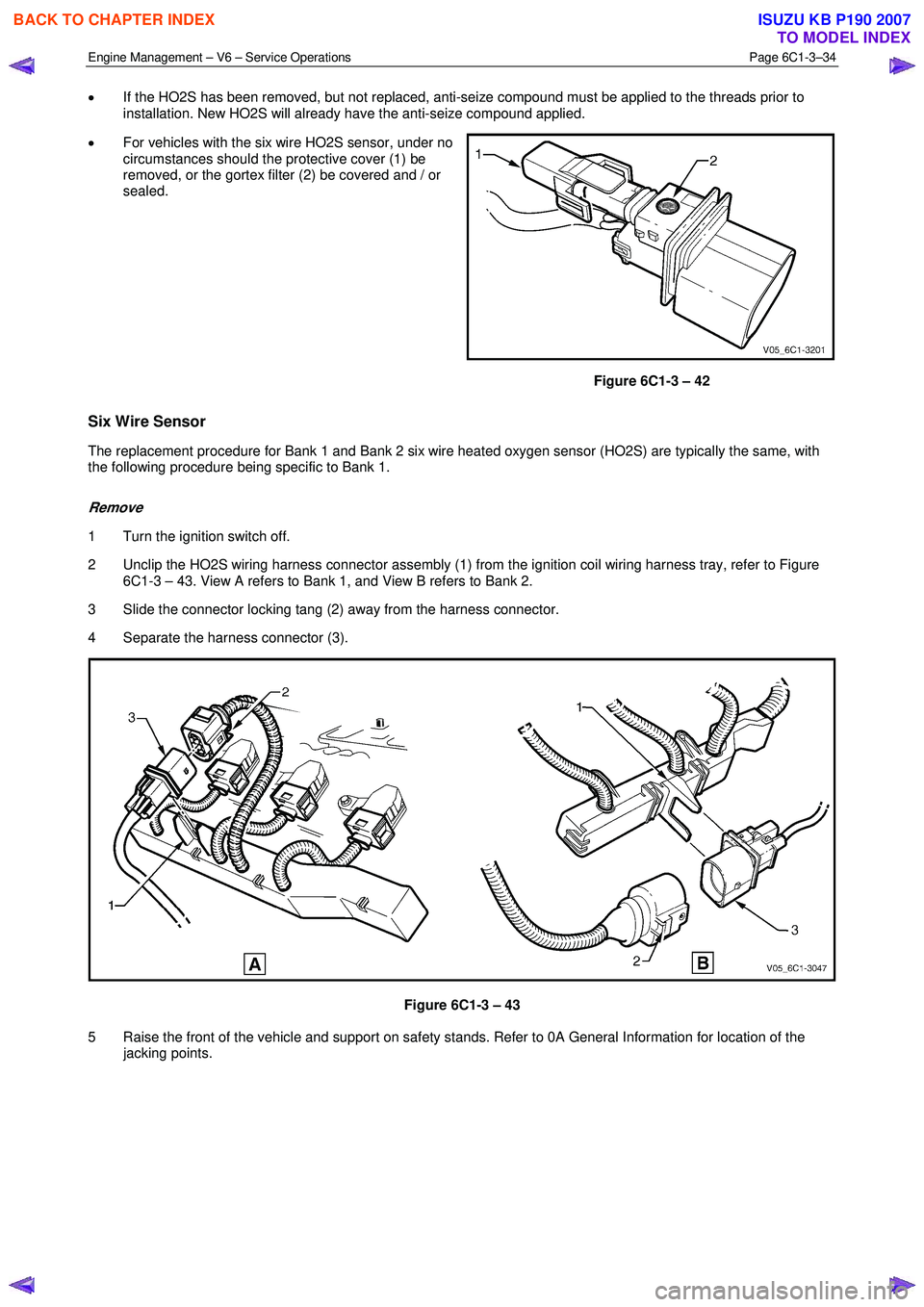

• If the HO2S has been removed, but not replaced, anti-seize compound must be applied to the threads prior to

installation. New HO2S will already have the anti-seize compound applied.

• For vehicles with the six wire HO2S sensor, under no

circumstances should the protective cover (1) be

removed, or the gortex filter (2) be covered and / or

sealed.

Figure 6C1-3 – 42

Six Wire Sensor

The replacement procedure for Bank 1 and Bank 2 six wire heated oxygen sensor (HO2S) are typically the same, with

the following procedure being specific to Bank 1.

Remove

1 Turn the ignition switch off.

2 Unclip the HO2S wiring harness connector assembly (1) from the ignition coil wiring harness tray, refer to Figure 6C1-3 – 43. View A refers to Bank 1, and View B refers to Bank 2.

3 Slide the connector locking tang (2) away from the harness connector.

4 Separate the harness connector (3).

Figure 6C1-3 – 43

5 Raise the front of the vehicle and support on safety stands. Refer to 0A General Information for location of the jacking points.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3567 of 6020

Engine Management – V6 – Service Operations Page 6C1-3–43

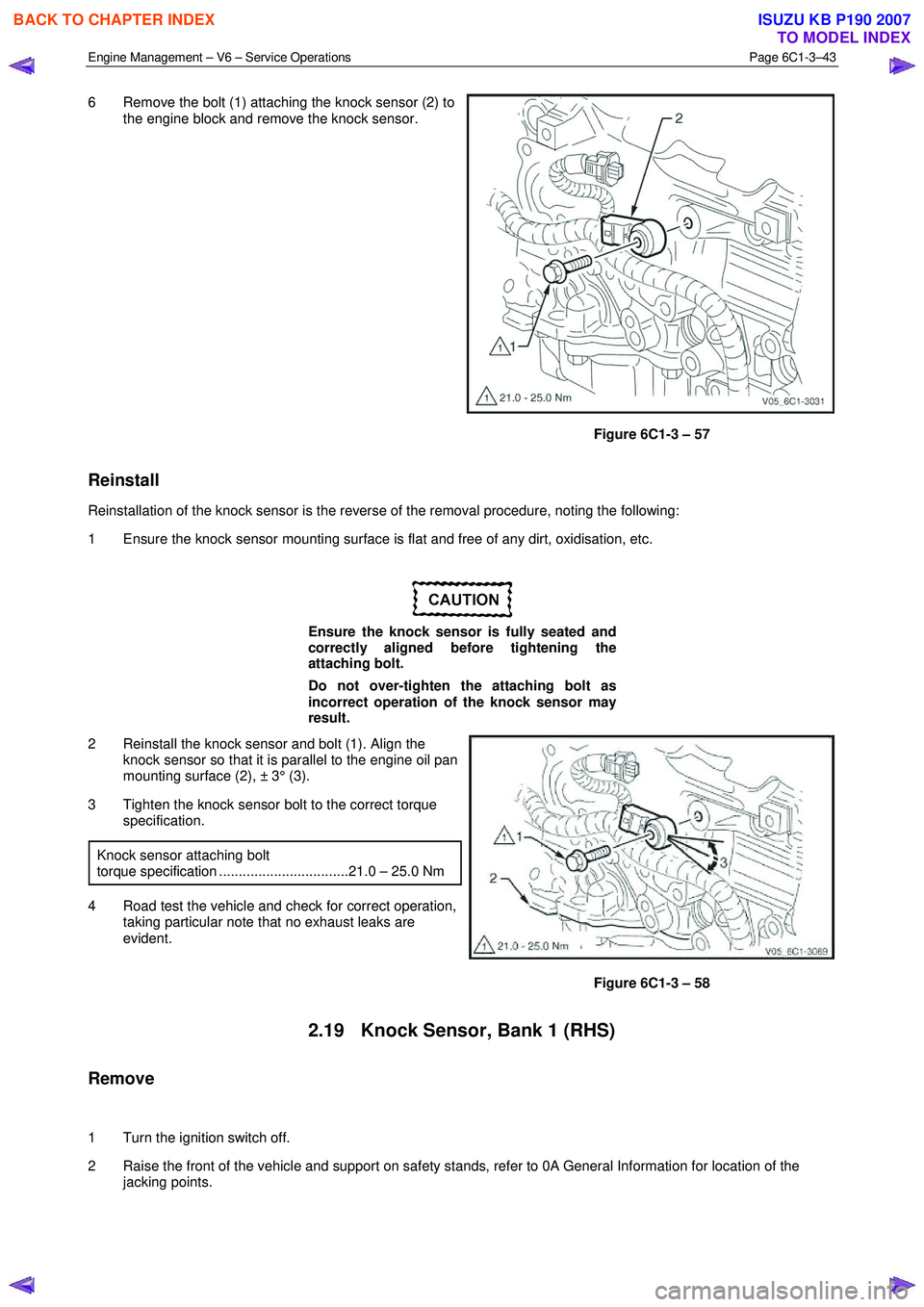

6 Remove the bolt (1) attaching the knock sensor (2) to

the engine block and remove the knock sensor.

Figure 6C1-3 – 57

Reinstall

Reinstallation of the knock sensor is the reverse of the removal procedure, noting the following:

1 Ensure the knock sensor mounting surface is flat and free of any dirt, oxidisation, etc.

Ensure the knock sensor is fully seated and

correctly aligned before tightening the

attaching bolt.

Do not over-tighten the attaching bolt as

incorrect operation of the knock sensor may

result.

2 Reinstall the knock sensor and bolt (1). Align the knock sensor so that it is parallel to the engine oil pan

mounting surface (2), ± 3° (3).

3 Tighten the knock sensor bolt to the correct torque specification.

Knock sensor attaching bolt

torque specification .................................21.0 – 25.0 Nm

4 Road test the vehicle and check for correct operation, taking particular note that no exhaust leaks are

evident.

Figure 6C1-3 – 58

2.19 Knock Sensor, Bank 1 (RHS)

Remove

1 Turn the ignition switch off.

2 Raise the front of the vehicle and support on safety stands, refer to 0A General Information for location of the jacking points.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3568 of 6020

Engine Management – V6 – Service Operations Page 6C1-3–44

3 Disconnect the wiring harness connector (1) from the

knock sensor (2).

Figure 6C1-3 – 59

4 Remove the bolt (1) attaching the knock sensor (2) to the engine block, and remove the knock sensor.

Figure 6C1-3 – 60

Reinstall

Reinstallation of the knock sensor is the reverse of the removal procedure, noting the following:

1 Ensure the knock sensor mounting surface is flat and free of any dirt, oxidisation, etc.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007