body ISUZU KB P190 2007 Workshop Manual PDF

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 875 of 6020

6A – 70 ENGINE MECHANICAL

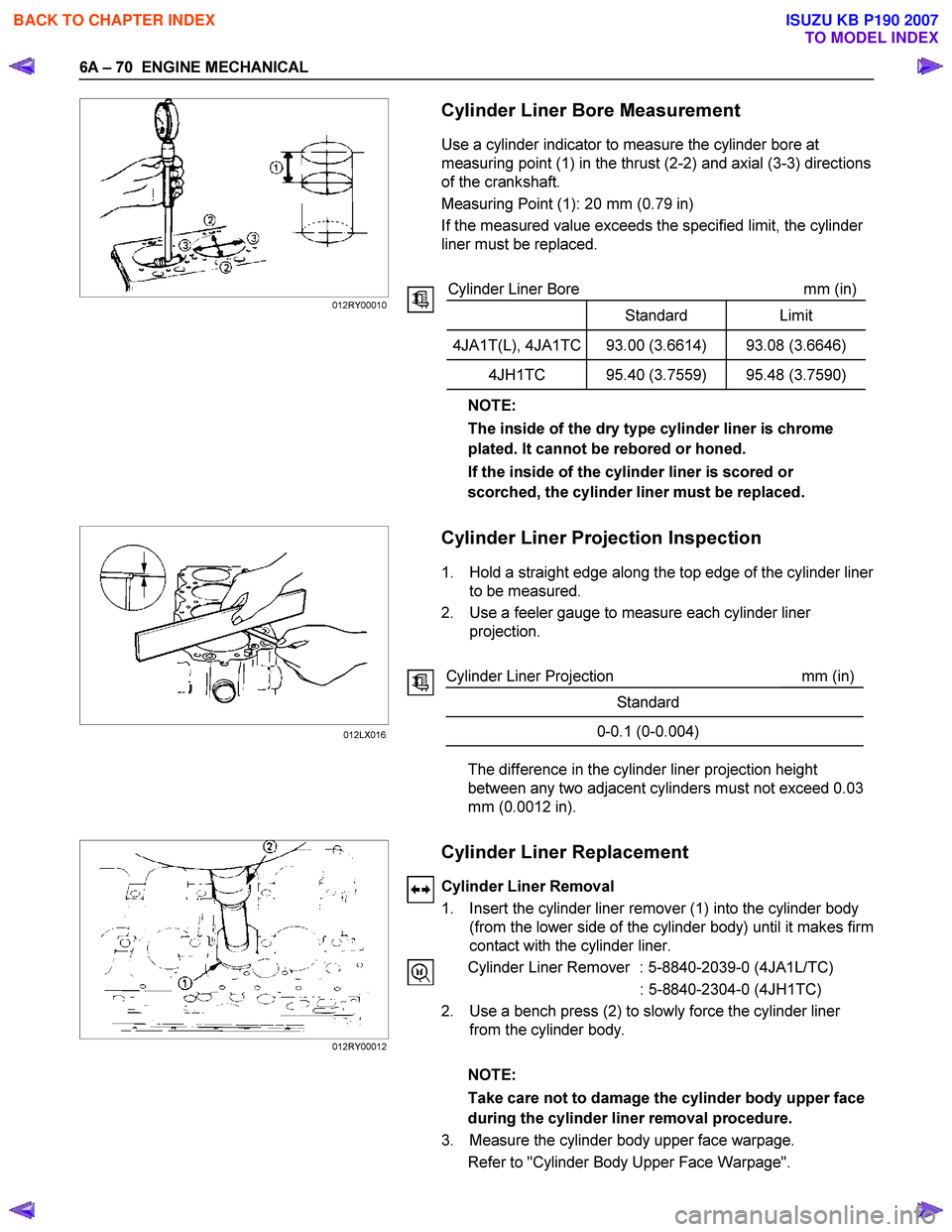

Cylinder Liner Bore Measurement

Use a cylinder indicator to measure the cylinder bore at

measuring point (1) in the thrust (2-2) and axial (3-3) directions

of the crankshaft.

Measuring Point (1): 20 mm (0.79 in)

If the measured value exceeds the specified limit, the cylinder

liner must be replaced.

Cylinder Liner Bore mm (in)

Standard Limit

4JA1T(L), 4JA1TC 93.00 (3.6614) 93.08 (3.6646)

4JH1TC 95.40 (3.7559) 95.48 (3.7590)

NOTE:

The inside of the dry type cylinder liner is chrome

plated. It cannot be rebored or honed.

If the inside of the cylinder liner is scored or

scorched, the cylinder liner must be replaced.

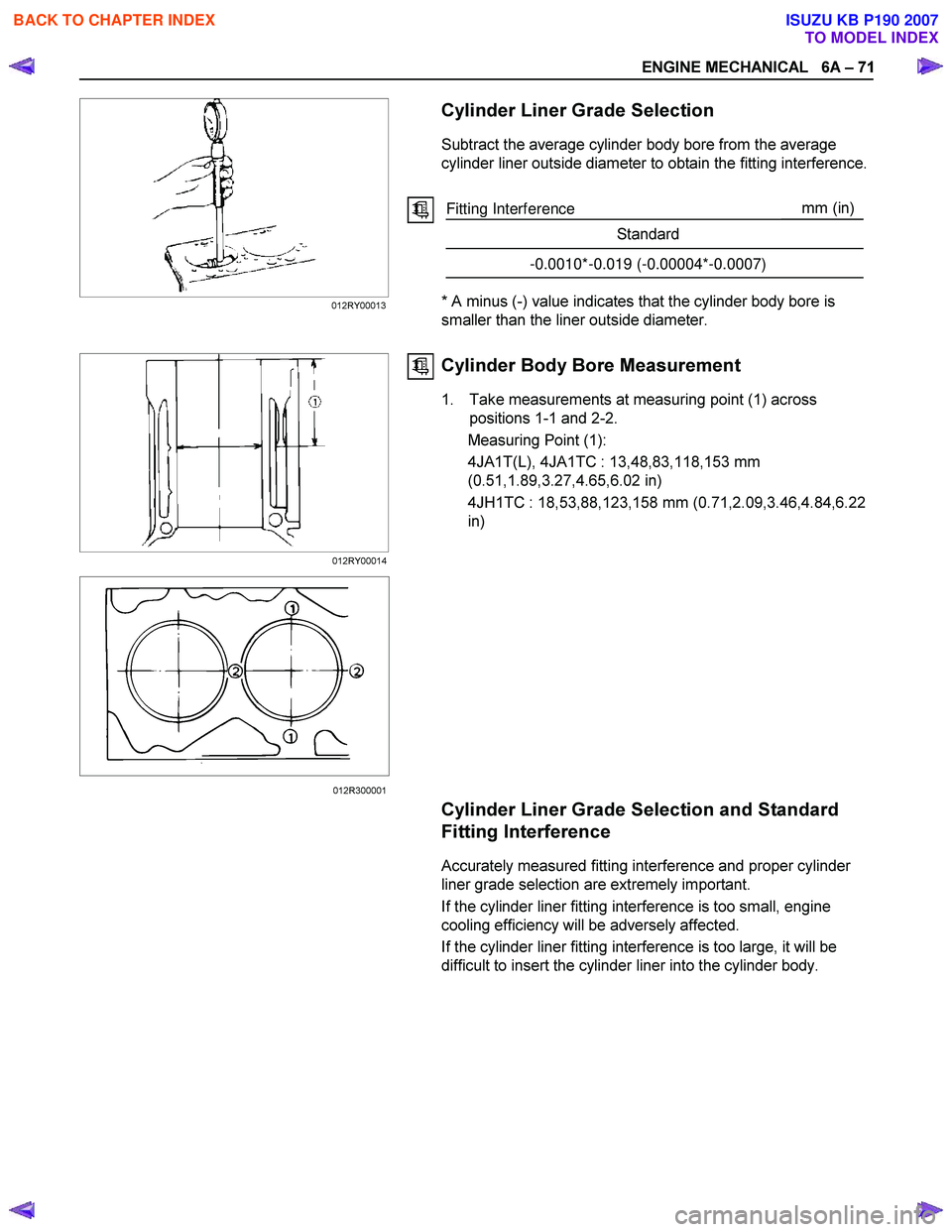

Cylinder Liner Projection Inspection

1. Hold a straight edge along the top edge of the cylinder liner

to be measured.

2. Use a feeler gauge to measure each cylinder liner projection.

Cylinder Liner Projection mm (in)

Standard

0-0.1 (0-0.004)

The difference in the cylinder liner projection height

between any two adjacent cylinders must not exceed 0.03

mm (0.0012 in).

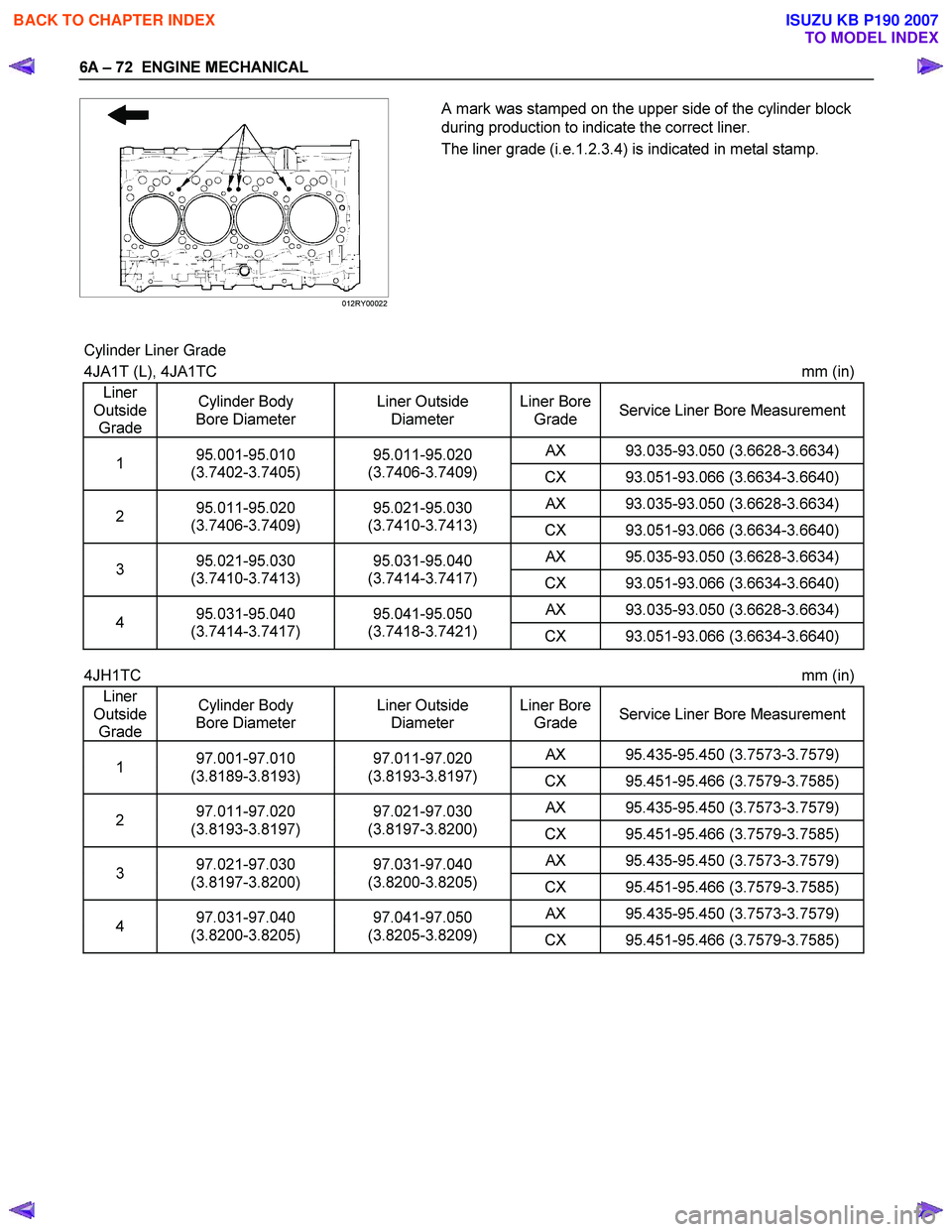

Cylinder Liner Replacement

Cylinder Liner Removal

1. Insert the cylinder liner remover (1) into the cylinder body (from the lower side of the cylinder body) until it makes firm

contact with the cylinder liner.

Cylinder Liner Remover : 5-8840-2039-0 (4JA1L/TC)

: 5-8840-2304-0 (4JH1TC)

2. Use a bench press (2) to slowly force the cylinder liner from the cylinder body.

NOTE:

Take care not to damage the cylinder body upper face

during the cylinder liner removal procedure.

3. Measure the cylinder body upper face warpage. Refer to "Cylinder Body Upper Face Warpage".

012RY00010

012LX016

012RY00012

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 876 of 6020

ENGINE MECHANICAL 6A – 71

Cylinder Liner Grade Selection

Subtract the average cylinder body bore from the average

cylinder liner outside diameter to obtain the fitting interference.

Fitting Interference mm

(in)

Standard

-0.0010*-0.019 (-0.00004*-0.0007)

* A minus (-) value indicates that the cylinder body bore is

smaller than the liner outside diameter.

Cylinder Body Bore Measurement

1. Take measurements at measuring point (1) across positions 1-1 and 2-2.

Measuring Point (1):

4JA1T(L), 4JA1TC : 13,48,83,118,153 mm

(0.51,1.89,3.27,4.65,6.02 in)

4JH1TC : 18,53,88,123,158 mm (0.71,2.09,3.46,4.84,6.22

in)

Cylinder Liner Grade Selection and Standard

Fitting Interference

Accurately measured fitting interference and proper cylinder

liner grade selection are extremely important.

If the cylinder liner fitting interference is too small, engine

cooling efficiency will be adversely affected.

If the cylinder liner fitting interference is too large, it will be

difficult to insert the cylinder liner into the cylinder body.

012RY00013

012RY00014 012R300001

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 877 of 6020

6A – 72 ENGINE MECHANICAL

012RY00022

A mark was stamped on the upper side of the cylinder block

during production to indicate the correct liner.

The liner grade (i.e.1.2.3.4) is indicated in metal stamp.

Cylinder Liner Grade

4JA1T (L), 4JA1TC mm (in)

Liner

Outside Grade Cylinder Body

Bore Diameter Liner Outside

Diameter Liner Bore

Grade Service Liner Bore Measurement

AX 93.035-93.050 (3.6628-3.6634) 1 95.001-95.010

(3.7402-3.7405) 95.011-95.020

(3.7406-3.7409) CX 93.051-93.066 (3.6634-3.6640)

AX 93.035-93.050 (3.6628-3.6634) 2 95.011-95.020

(3.7406-3.7409) 95.021-95.030

(3.7410-3.7413) CX 93.051-93.066 (3.6634-3.6640)

AX 95.035-93.050 (3.6628-3.6634) 3 95.021-95.030

(3.7410-3.7413) 95.031-95.040

(3.7414-3.7417) CX 93.051-93.066 (3.6634-3.6640)

AX 93.035-93.050 (3.6628-3.6634) 4 95.031-95.040

(3.7414-3.7417) 95.041-95.050

(3.7418-3.7421) CX 93.051-93.066 (3.6634-3.6640)

4JH1TC mm (in)

Liner

Outside Grade Cylinder Body

Bore Diameter Liner Outside

Diameter Liner Bore

Grade Service Liner Bore Measurement

AX 95.435-95.450 (3.7573-3.7579) 1 97.001-97.010

(3.8189-3.8193) 97.011-97.020

(3.8193-3.8197) CX 95.451-95.466 (3.7579-3.7585)

AX 95.435-95.450 (3.7573-3.7579) 2 97.011-97.020

(3.8193-3.8197) 97.021-97.030

(3.8197-3.8200) CX 95.451-95.466 (3.7579-3.7585)

AX 95.435-95.450 (3.7573-3.7579) 3 97.021-97.030

(3.8197-3.8200) 97.031-97.040

(3.8200-3.8205) CX 95.451-95.466 (3.7579-3.7585)

AX 95.435-95.450 (3.7573-3.7579) 4 97.031-97.040

(3.8200-3.8205) 97.041-97.050

(3.8205-3.8209) CX 95.451-95.466 (3.7579-3.7585)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 878 of 6020

ENGINE MECHANICAL 6A – 73

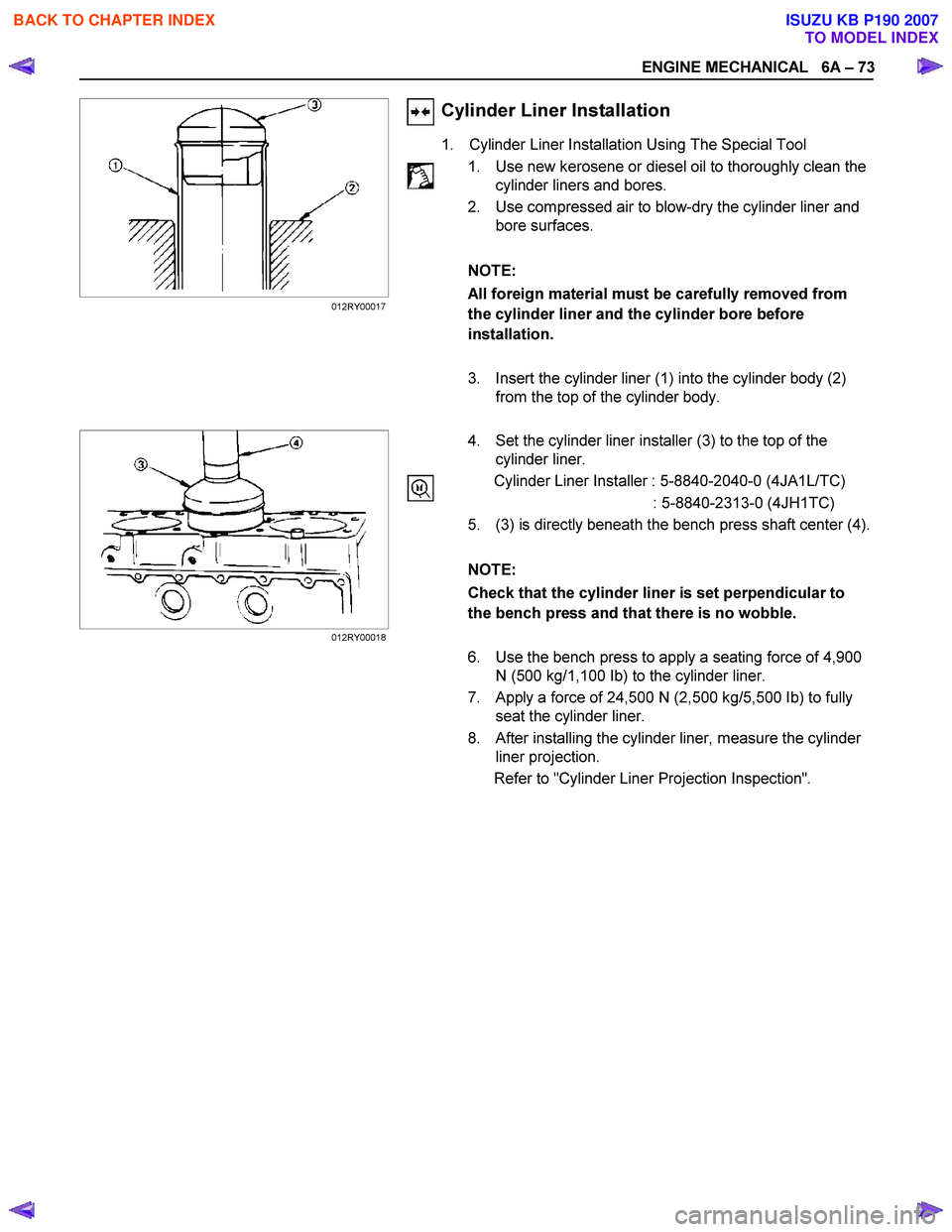

Cylinder Liner Installation

1. Cylinder Liner Installation Using The Special Tool

1. Use new kerosene or diesel oil to thoroughly clean the cylinder liners and bores.

2. Use compressed air to blow-dry the cylinder liner and bore surfaces.

NOTE:

All foreign material must be carefully removed from

the cylinder liner and the cylinder bore before

installation.

3. Insert the cylinder liner (1) into the cylinder body (2) from the top of the cylinder body.

4. Set the cylinder liner installer (3) to the top of the

cylinder liner.

Cylinder Liner Installer : 5-8840-2040-0 (4JA1L/TC)

: 5-8840-2313-0 (4JH1TC)

5. (3) is directly beneath the bench press shaft center (4).

NOTE:

Check that the cylinder liner is set perpendicular to

the bench press and that there is no wobble.

6. Use the bench press to apply a seating force of 4,900 N (500 kg/1,100 Ib) to the cylinder liner.

7. Apply a force of 24,500 N (2,500 kg/5,500 Ib) to fully seat the cylinder liner.

8. After installing the cylinder liner, measure the cylinder liner projection.

Refer to "Cylinder Liner Projection Inspection".

012RY00017

012RY00018

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 881 of 6020

6A – 76 ENGINE MECHANICAL

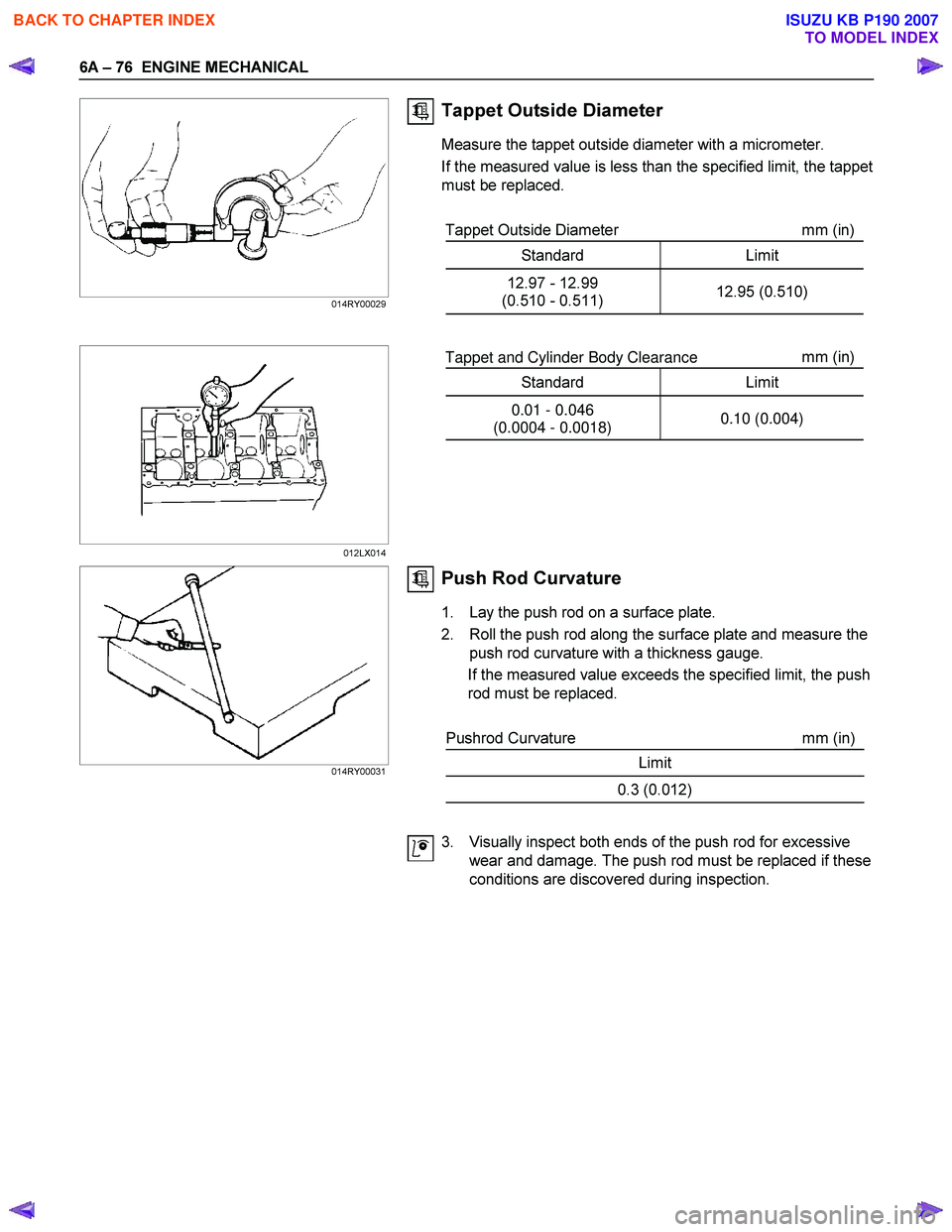

Tappet Outside Diameter

Measure the tappet outside diameter with a micrometer.

If the measured value is less than the specified limit, the tappet

must be replaced.

Tappet Outside Diameter mm (in)

Standard Limit

12.97 - 12.99

(0.510 - 0.511) 12.95 (0.510)

Tappet and Cylinder Body Clearance mm

(in)

Standard Limit

0.01 - 0.046

(0.0004 - 0.0018) 0.10 (0.004)

Push Rod Curvature

1. Lay the push rod on a surface plate.

2. Roll the push rod along the surface plate and measure the push rod curvature with a thickness gauge.

If the measured value exceeds the specified limit, the push

rod must be replaced.

Pushrod Curvature mm (in)

Limit

0.3 (0.012)

3. Visually inspect both ends of the push rod for excessive wear and damage. The push rod must be replaced if these

conditions are discovered during inspection.

014RY00029

012LX014

014RY00031

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 883 of 6020

6A – 78 ENGINE MECHANICAL

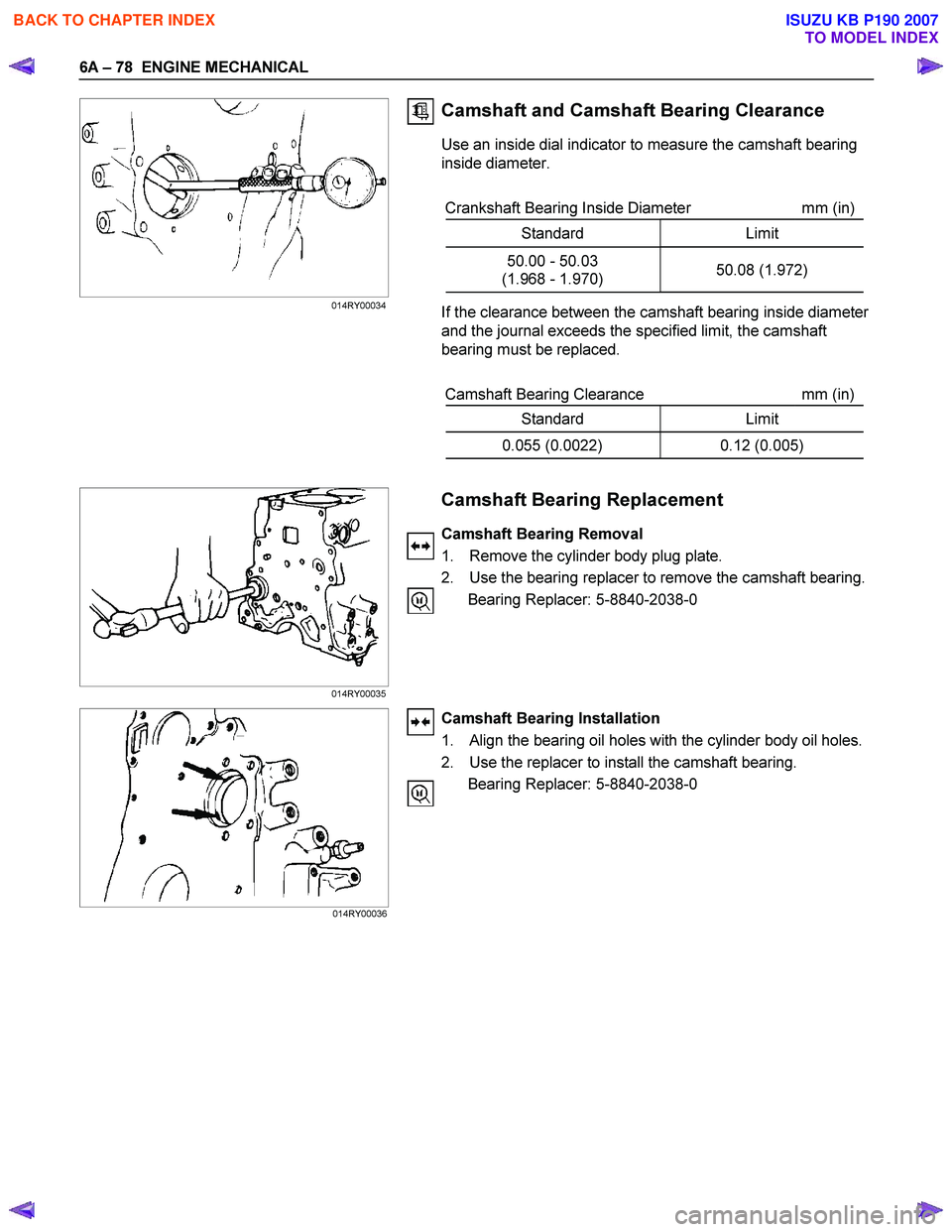

Camshaft and Camshaft Bearing Clearance

Use an inside dial indicator to measure the camshaft bearing

inside diameter.

Crankshaft Bearing Inside Diameter mm (in)

Standard Limit

50.00 - 50.03

(1.968 - 1.970) 50.08 (1.972)

If the clearance between the camshaft bearing inside diameter

and the journal exceeds the specified limit, the camshaft

bearing must be replaced.

Camshaft Bearing Clearance mm (in)

Standard Limit

0.055 (0.0022) 0.12 (0.005)

Camshaft Bearing Replacement

Camshaft Bearing Removal

1. Remove the cylinder body plug plate.

2. Use the bearing replacer to remove the camshaft bearing. Bearing Replacer: 5-8840-2038-0

Camshaft Bearing Installation

1. Align the bearing oil holes with the cylinder body oil holes.

2. Use the replacer to install the camshaft bearing. Bearing Replacer: 5-8840-2038-0

014RY00034

014RY00035 014RY00036

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 886 of 6020

ENGINE MECHANICAL 6A – 81

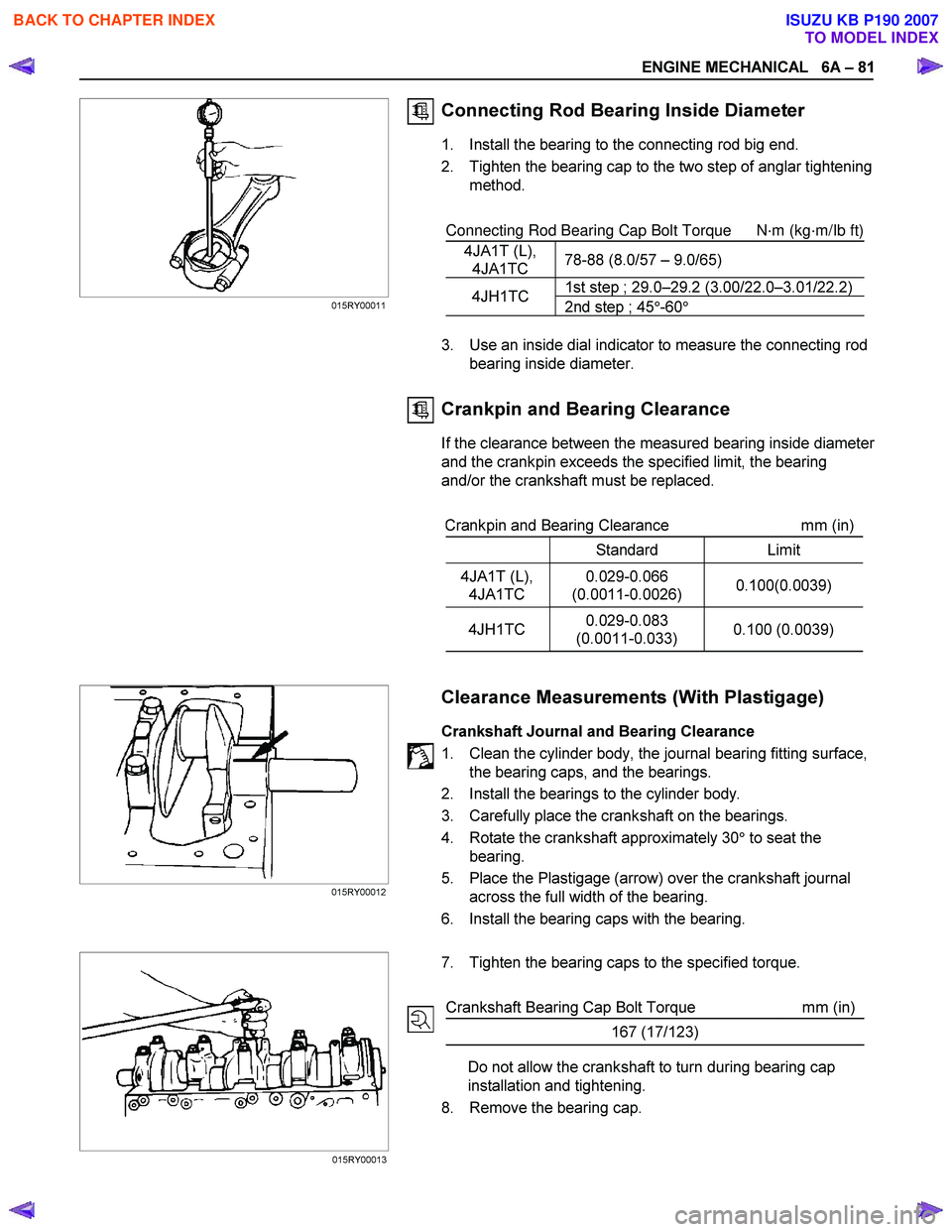

Connecting Rod Bearing Inside Diameter

1. Install the bearing to the connecting rod big end.

2. Tighten the bearing cap to the two step of anglar tightening method.

Connecting Rod Bearing Cap Bolt Torque

N·m (kg·m/Ib ft)

4JA1T (L), 4JA1TC 78-88 (8.0/57 – 9.0/65)

1st step ; 29.0–29.2 (3.00/22.0–3.01/22.2)4JH1TC

2nd step ; 45°-60 °

3. Use an inside dial indicator to measure the connecting rod

bearing inside diameter.

Crankpin and Bearing Clearance

If the clearance between the measured bearing inside diameter

and the crankpin exceeds the specified limit, the bearing

and/or the crankshaft must be replaced.

Crankpin and Bearing Clearance mm (in)

Standard Limit

4JA1T (L),

4JA1TC 0.029-0.066

(0.0011-0.0026) 0.100(0.0039)

4JH1TC

0.029-0.083

(0.0011-0.033) 0.100 (0.0039)

Clearance Measurements (With Plastigage)

Crankshaft Journal and Bearing Clearance

1. Clean the cylinder body, the journal bearing fitting surface, the bearing caps, and the bearings.

2. Install the bearings to the cylinder body.

3. Carefully place the crankshaft on the bearings.

4. Rotate the crankshaft approximately 30 ° to seat the

bearing.

5. Place the Plastigage (arrow) over the crankshaft journal across the full width of the bearing.

6. Install the bearing caps with the bearing.

7. Tighten the bearing caps to the specified torque.

Crankshaft Bearing Cap Bolt Torque mm (in)

167 (17/123)

Do not allow the crankshaft to turn during bearing cap

installation and tightening.

8. Remove the bearing cap.

015RY00012

015RY00013

015RY00011

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 888 of 6020

ENGINE MECHANICAL 6A – 83

6. Remove the bearing cap.

7. Compare the width of the Plastigage attached to either the crankshaft or the bearing against the scale printed on the

Plastigage container.

If the measured value exceeds the specified limit, perform

the following additional steps.

1. Use a micrometer to measure the crankpin outside diameter.

2. Use an inside dial indicator to measure the bearing inside diameter.

If the crank pin and bearing clearance exceeds the

specified limit, the crankshaft and/or the bearing must

be replaced.

Crankpin and Bearing Clearance mm (in)

Standard Limit

4JA1T (L),

4JA1TC 0.029-0.066

(0.0011-0.0026) 0.100 (0.0039)

4JH1TC

0.029-0.083

(0.0011-0.0033) 0.100 (0.0039)

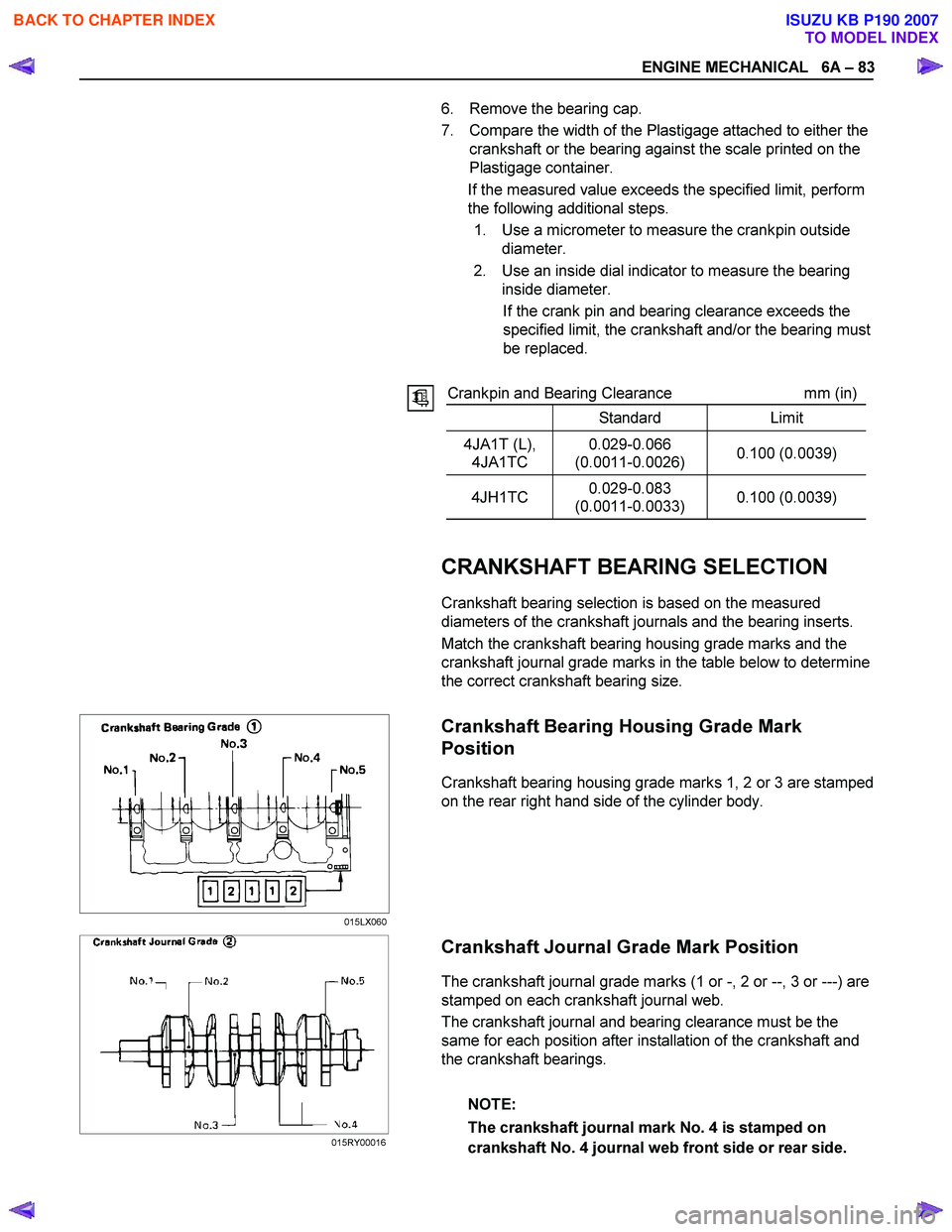

CRANKSHAFT BEARING SELECTION

Crankshaft bearing selection is based on the measured

diameters of the crankshaft journals and the bearing inserts.

Match the crankshaft bearing housing grade marks and the

crankshaft journal grade marks in the table below to determine

the correct crankshaft bearing size.

Crankshaft Bearing Housing Grade Mark

Position

Crankshaft bearing housing grade marks 1, 2 or 3 are stamped

on the rear right hand side of the cylinder body.

Crankshaft Journal Grade Mark Position

The crankshaft journal grade marks (1 or -, 2 or --, 3 or ---) are

stamped on each crankshaft journal web.

The crankshaft journal and bearing clearance must be the

same for each position after installation of the crankshaft and

the crankshaft bearings.

NOTE:

The crankshaft journal mark No. 4 is stamped on

crankshaft No. 4 journal web front side or rear side.

015LX060

015RY00016

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 891 of 6020

6A – 86 ENGINE MECHANICAL

Ring Gear Replacement

Ring Gear Removal

Strike around the edges of the ring gear with a hammer and

chisel to remove it.

Ring Gear Installation

1. Heat the ring gear evenly with a gas burner to invite thermal expansion.

Do not allow the temperature of the gas burner to exceed

200 °C (390 °F).

2. Install the ring gear when it is sufficiently heated. The ring gear must be installed with the chamfer facing the

clutch.

PISTON

Piston Grade Selection and Cylinder Bore

Measurement

Refer to the Section "Cylinder Body", Item "Cylinder Liner Bore

Measurement" for details on piston grade selection and

cylinder liner bore measurement.

Piston Ring Gap

1. Insert the piston ring horizontally (in the position it would assume if it were installed to the piston) into the cylinder

liner.

2. Push the piston ring into the cylinder bore until it reaches the measuring point 1 or 2 where the cylinder liner bore is

the smallest.

Do not allow the piston ring to slant to one side or the

other. It must be perfectly horizontal.

Measuring Point 1 10 mm (0.4 in) or

Measuring Point 2 120 mm (4.7 in)

020LX008

020LX009

015LX023

015RY00020

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 893 of 6020

6A – 88 ENGINE MECHANICAL

4. Visually inspect the piston rings.

If a piston ring groove is damaged or distorted, the piston

must be replaced.

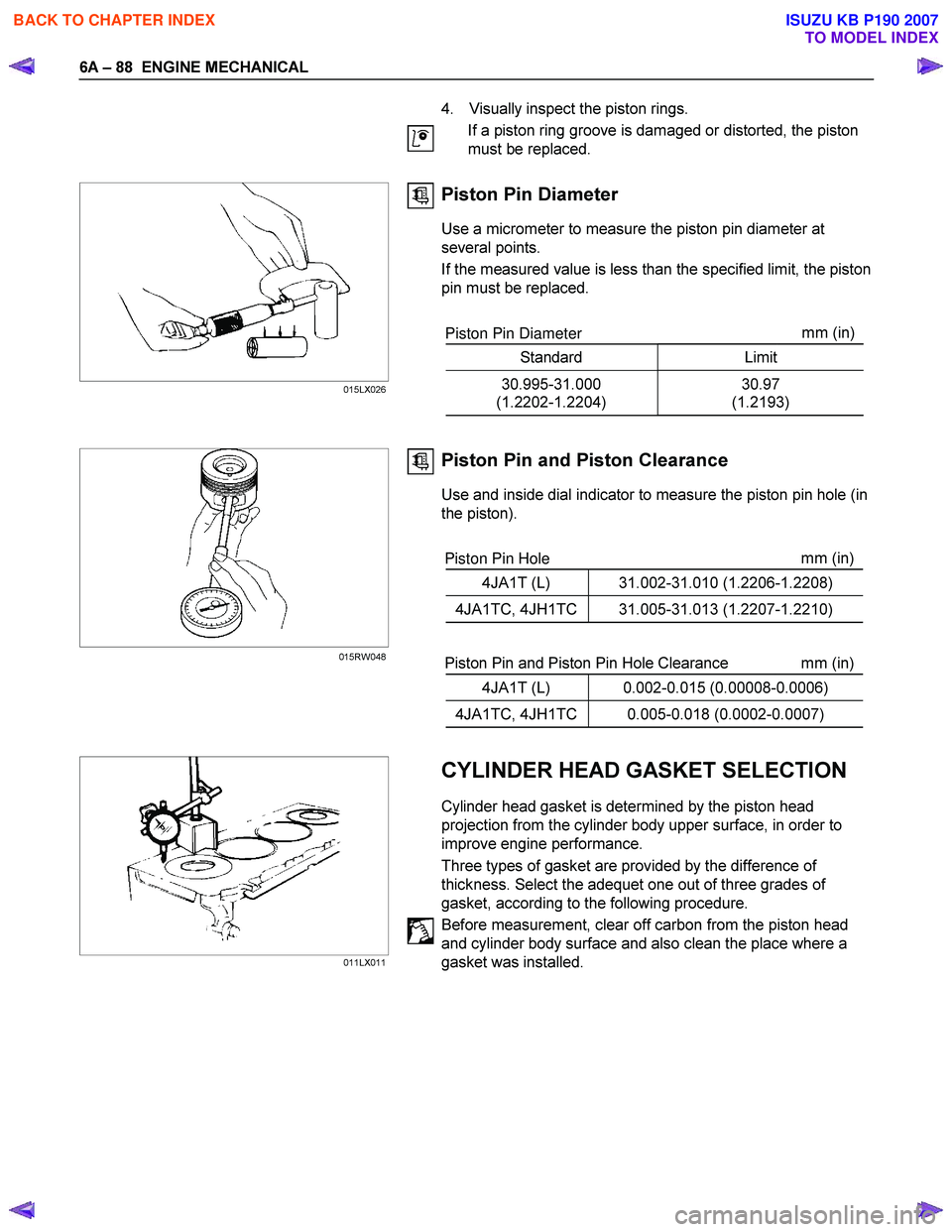

Piston Pin Diameter

Use a micrometer to measure the piston pin diameter at

several points.

If the measured value is less than the specified limit, the piston

pin must be replaced.

Piston Pin Diameter mm

(in)

Standard Limit

30.995-31.000

(1.2202-1.2204) 30.97

(1.2193)

Piston Pin and Piston Clearance

Use and inside dial indicator to measure the piston pin hole (in

the piston).

Piston Pin Hole mm

(in)

4JA1T (L) 31.002-31.010 (1.2206-1.2208)

4JA1TC, 4JH1TC 31.005-31.013 (1.2207-1.2210)

Piston Pin and Piston Pin Hole Clearance mm (in)

4JA1T (L) 0.002-0.015 (0.00008-0.0006)

4JA1TC, 4JH1TC 0.005-0.018 (0.0002-0.0007)

CYLINDER HEAD GASKET SELECTION

Cylinder head gasket is determined by the piston head

projection from the cylinder body upper surface, in order to

improve engine performance.

Three types of gasket are provided by the difference of

thickness. Select the adequet one out of three grades of

gasket, according to the following procedure.

Before measurement, clear off carbon from the piston head

and cylinder body surface and also clean the place where a

gasket was installed.

015LX026

015RW048

011LX011

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007