body ISUZU KB P190 2007 Workshop Owners Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 936 of 6020

ENGINE MECHANICAL 6A – 131

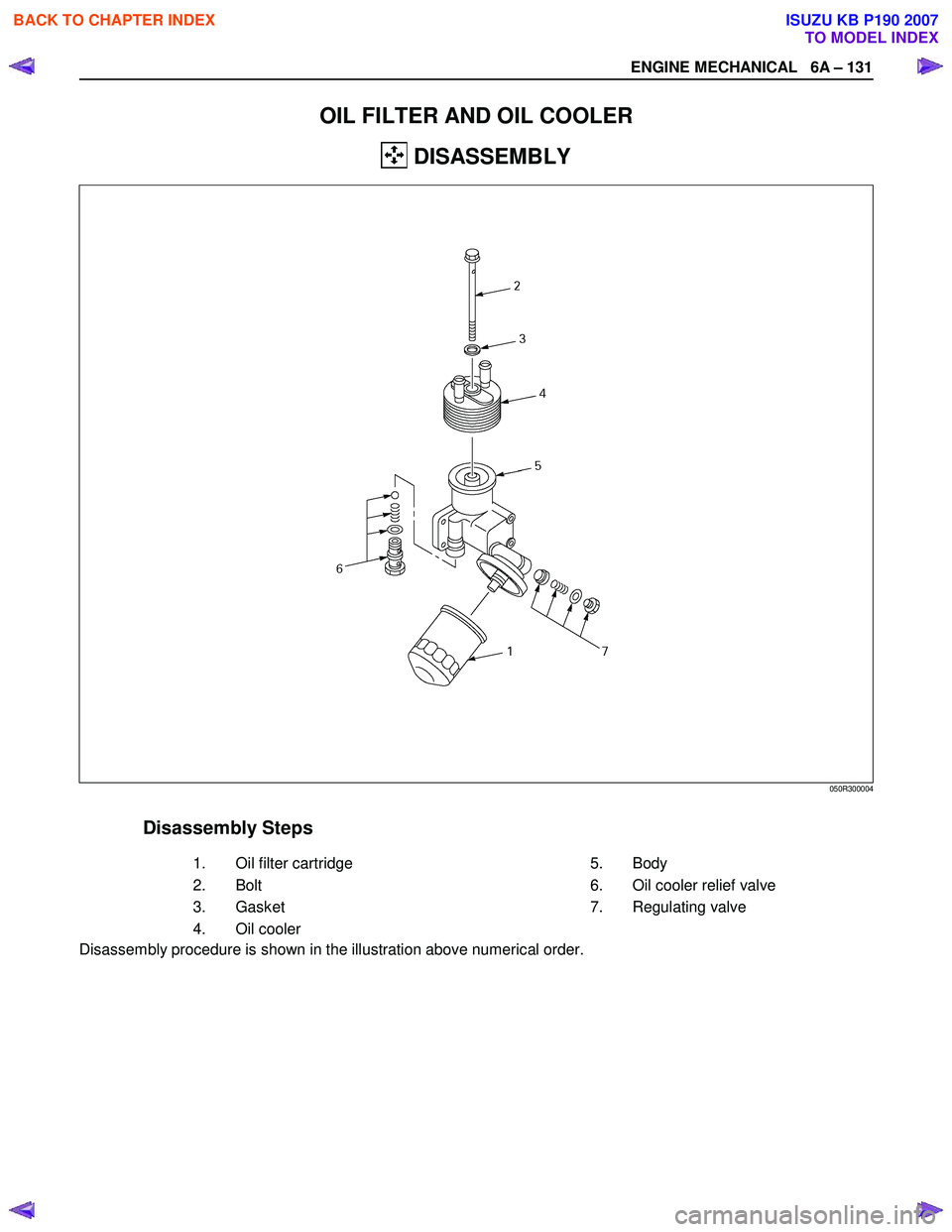

OIL FILTER AND OIL COOLER

DISASSEMBLY

Disassembly Steps

1.

Oil filter cartridge 5.

Body

2.

Bolt 6. Oil cooler relief valve

3. Gasket 7. Regulating valve

4. Oil cooler

Disassembly procedure is shown in the illustration above numerical order.

050R300004

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 938 of 6020

ENGINE MECHANICAL 6A – 133

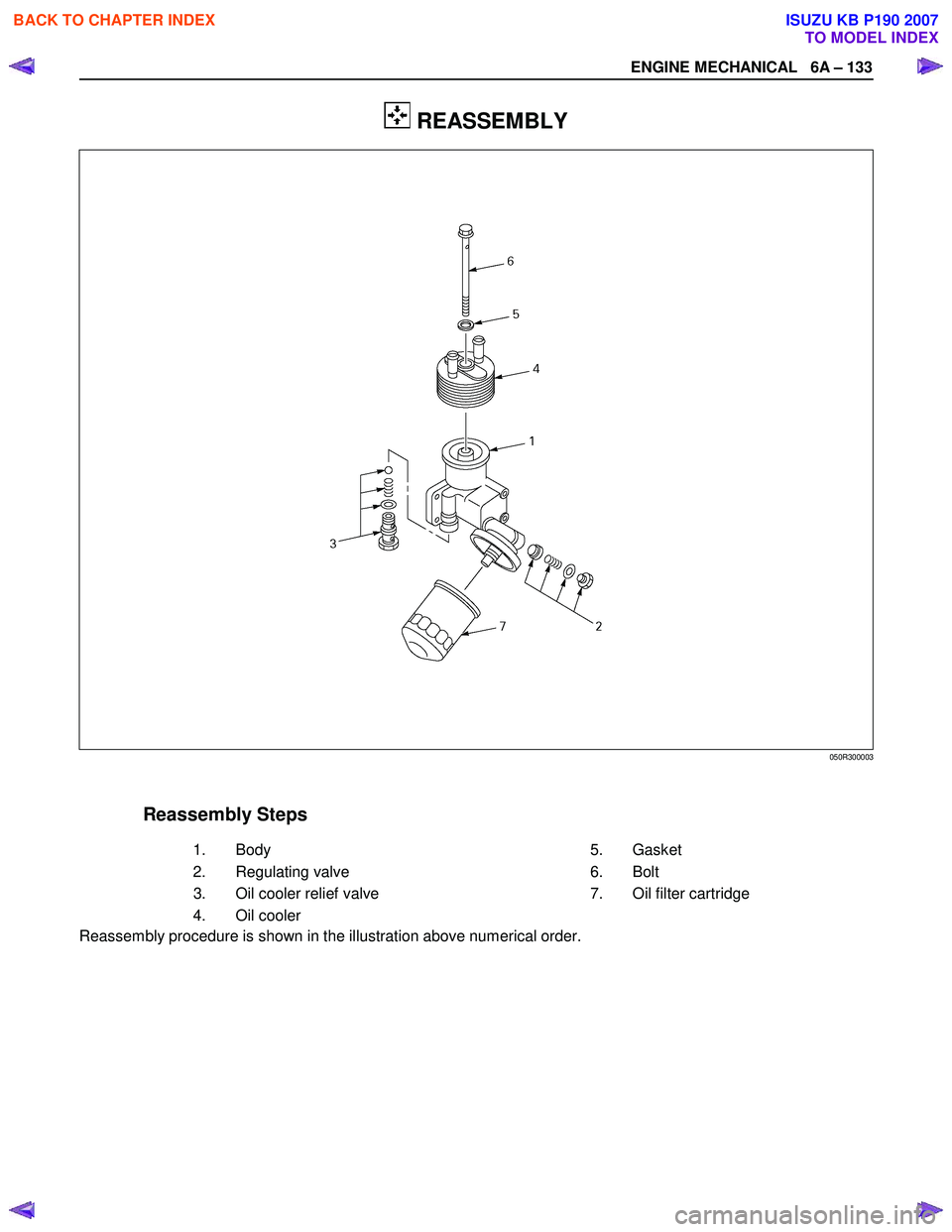

REASSEMBLY

Reassembly Steps

1.

Body 5.

Gasket

2.

Regulating valve 6. Bolt

3. Oil cooler relief valve 7. Oil filter cartridge

4. Oil cooler

Reassembly procedure is shown in the illustration above numerical order.

050R300003

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 939 of 6020

6A – 134 ENGINE MECHANICAL

RTW 46ASH001701

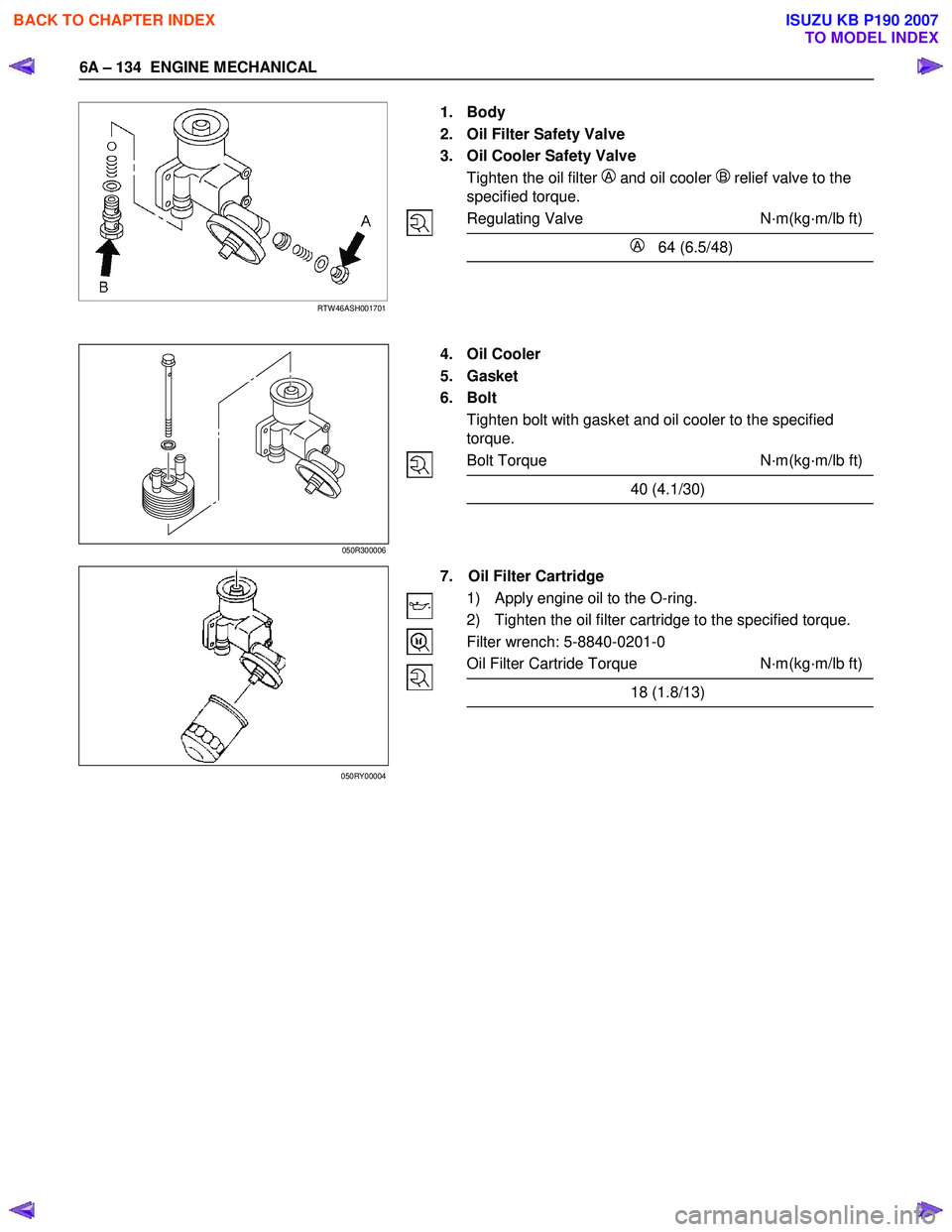

1. Body

2. Oil Filter Safety Valve

3. Oil Cooler Safety Valve

Tighten the oil filter

A and oil cooler B relief valve to the

specified torque.

Regulating Valve N·m(kg·m/lb ft)

A 64 (6.5/48)

4. Oil Cooler

5. Gasket

6. Bolt

Tighten bolt with gasket and oil cooler to the specified

torque.

Bolt Torque N·m(kg·m/lb ft)

40 (4.1/30)

7. Oil Filter Cartridge

1) Apply engine oil to the O-ring.

2) Tighten the oil filter cartridge to the specified torque.

Filter wrench: 5-8840-0201-0

Oil Filter Cartride Torque N·m(kg·m/lb ft)

18 (1.8/13)

050R300006

050RY00004

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 948 of 6020

6B – 4 ENGINE COOLING

GENERAL DESCRIPTION

COOLANT FLOW

RTW 66ALF000101

The engine cooling system consists of the radiator, the water pump, the cooling fan, and the thermostat.

To quickly increase cold engine coolant temperature for smooth engine operation, the coolant is circulated by the

water pump and thermostat through the bypass hose and back to the cylinder body.

The coolant does not circulate through the radiator.

W hen the coolant temperature reaches specified value, the thermostat will begin to open and a gradually increasing

amount of coolant will circulate through the radiator.

The thermostat will be fully open when the coolant temperature reaches specified value. All of the coolant is now

circulating through the radiator for effective engine cooling.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 955 of 6020

ENGINE COOLING 6B – 11

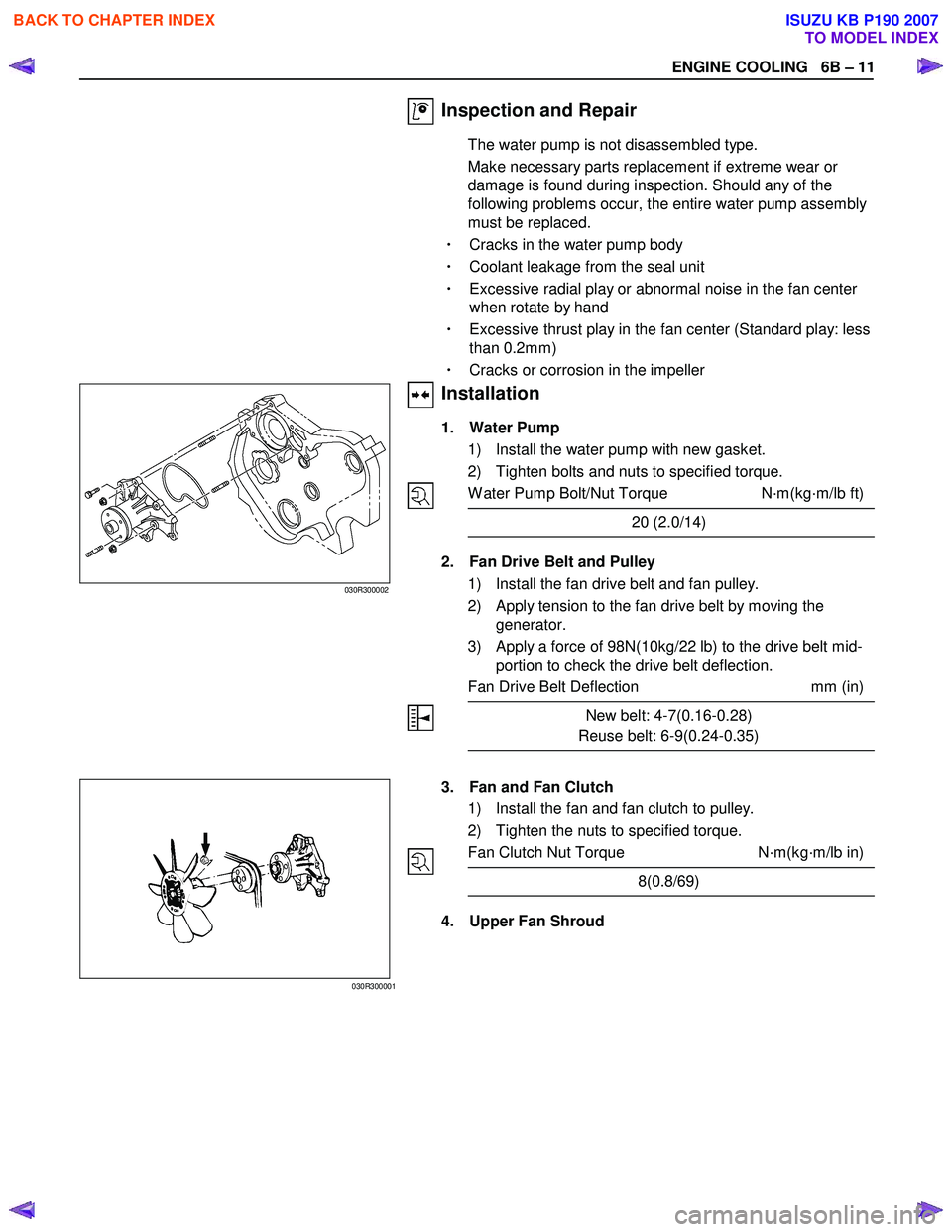

Inspection and Repair

The water pump is not disassembled type.

Make necessary parts replacement if extreme wear or

damage is found during inspection. Should any of the

following problems occur, the entire water pump assembly

must be replaced.

・ Cracks in the water pump body

・ Coolant leakage from the seal unit

・ Excessive radial play or abnormal noise in the fan center

when rotate by hand

・ Excessive thrust play in the fan center (Standard play: less

than 0.2mm)

・ Cracks or corrosion in the impeller

Installation

1. Water Pump

1) Install the water pump with new gasket.

2) Tighten bolts and nuts to specified torque.

W ater Pump Bolt/Nut Torque N·m(kg·m/lb ft)

20 (2.0/14)

2. Fan Drive Belt and Pulley

1) Install the fan drive belt and fan pulley.

2) Apply tension to the fan drive belt by moving the generator.

3) Apply a force of 98N(10kg/22 lb) to the drive belt mid- portion to check the drive belt deflection.

Fan Drive Belt Deflection mm (in)

New belt: 4-7(0.16-0.28)

Reuse belt: 6-9(0.24-0.35)

030R300002

030R300001

3. Fan and Fan Clutch

1) Install the fan and fan clutch to pulley.

2) Tighten the nuts to specified torque.

Fan Clutch Nut Torque N·m(kg·m/lb in)

8(0.8/69)

4. Upper Fan Shroud

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 971 of 6020

FUEL SYSTEM 6C – 7

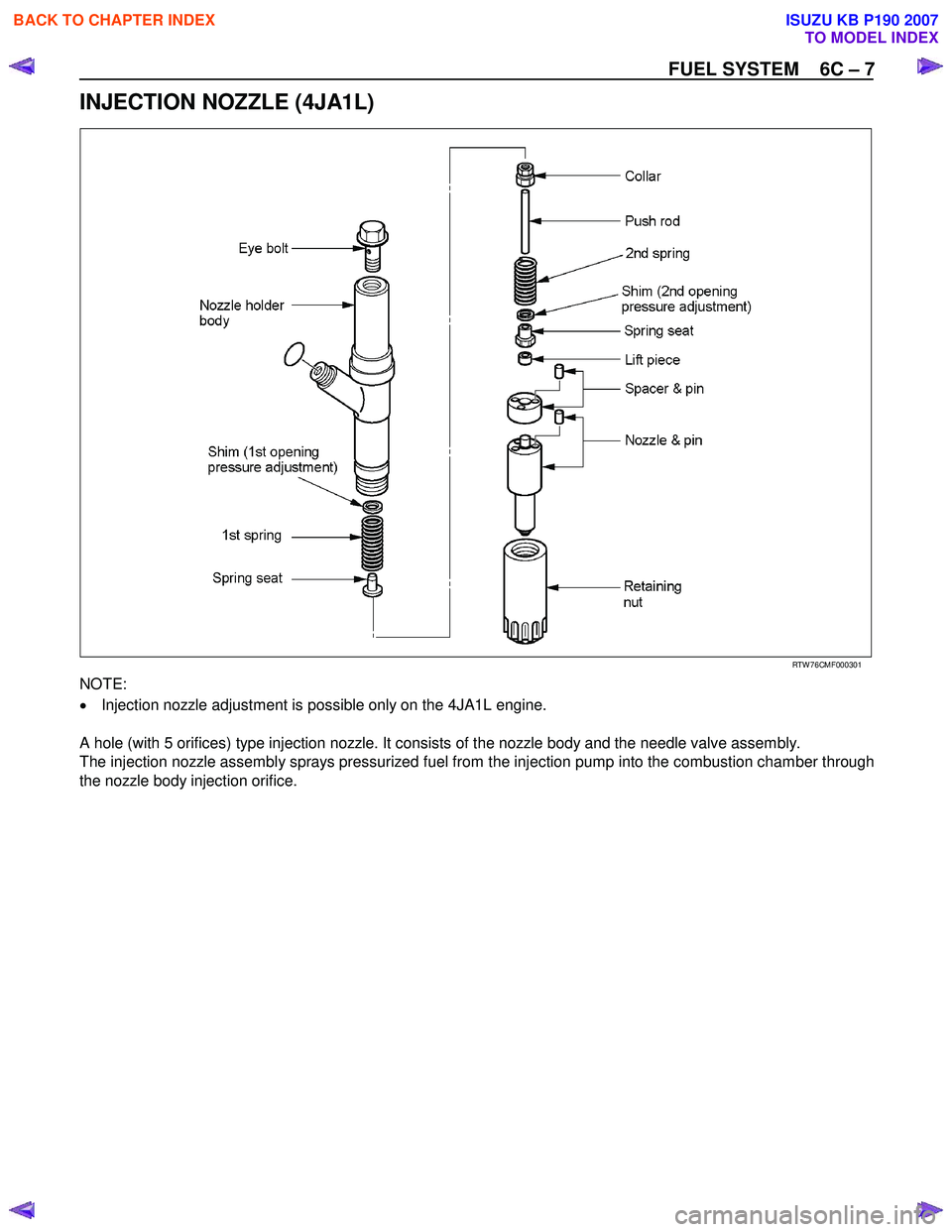

INJECTION NOZZLE (4JA1L)

RTW 76CMF000301

NOTE:

• Injection nozzle adjustment is possible only on the 4JA1L engine.

A hole (with 5 orifices) type injection nozzle. It consists of the nozzle body and the needle valve assembly.

The injection nozzle assembly sprays pressurized fuel from the injection pump into the combustion chamber through

the nozzle body injection orifice.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 973 of 6020

FUEL SYSTEM 6C – 9

Removal

CAUTION: When repair to the fuel system has been

completed, start engine and check the fuel system for

loose connection or leakage. For the fuel system

diagnosis, see Section “Driveability and Emission".

1. Disconnect battery ground cable.

2. Loosen slowly the fuel filler cap.

NOTE: Be careful not to spouting out fuel because of change

the pressure in the fuel tank.

NOTE: Cover opening of the filler neck to prevent any dust

entering.

3. Jack up the vehicle.

4. Support underneath of the fuel tank with a lifter.

5. Remove the inner liner of the wheel house at rear left side.

6. Remove fixing bolt of the filler neck from the body.

7. Disconnect the quick connector (3) of the fuel tube from the

fuel pipe.

NOTE: Cover the quick connector to prevent any dust entering

and fuel leakage.

NOTE: Refer to “Fuel Tube/Quick Connector Fittings” in this

section when performing any repairs.

8. Remove fixing bolt (1) of the tank band and remove the tank band (2).

9. Disconnect the pump and sender connector on the fuel

pump and remove the harness from weld clip on the fuel

tank.

10. Lower the fuel tank (5).

NOTE: W hen lower the fuel tank from the vehicle, don’t scratch

each hose and tube by around other parts.

Installation

1. Raise the fuel tank.

NOTE: W hen raise the fuel tank to the vehicle, don’t scratch

each hose and tube by around other parts.

2. Connect the pump and sender connector to the fuel pump and install the harness to weld clip on the tank.

NOTE: The connector must be certainly connected against

stopper.

3. Install the tank band and fasten bolt.

Torque N·m (kg·m / lb ft)

68 (6.9 / 50)

NOTE: The anchor of the tank band must be certainly installed

to guide hole on frame.

4. Connect the quick connector of the fuel tube to the fuel pipe and the evapo tube from evapo joint connector.

NOTE: Pull off the left checker on the fuel pipe.

NOTE: Refer to “Fuel Tube/Quick Connector Fittings” in this

section when performing any repairs.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 974 of 6020

6C – 10 FUEL SYSTEM

5. Install the filler neck to the body with bolt.

6. Install the inner liner of the wheel house at rear left side.

7. Remove lifter from the fuel tank.

8. Lower the vehicle.

9. Tigten the filler cap until at least three clicks.

10. Connect the battery ground cable.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 986 of 6020

6C – 22 FUEL SYSTEM

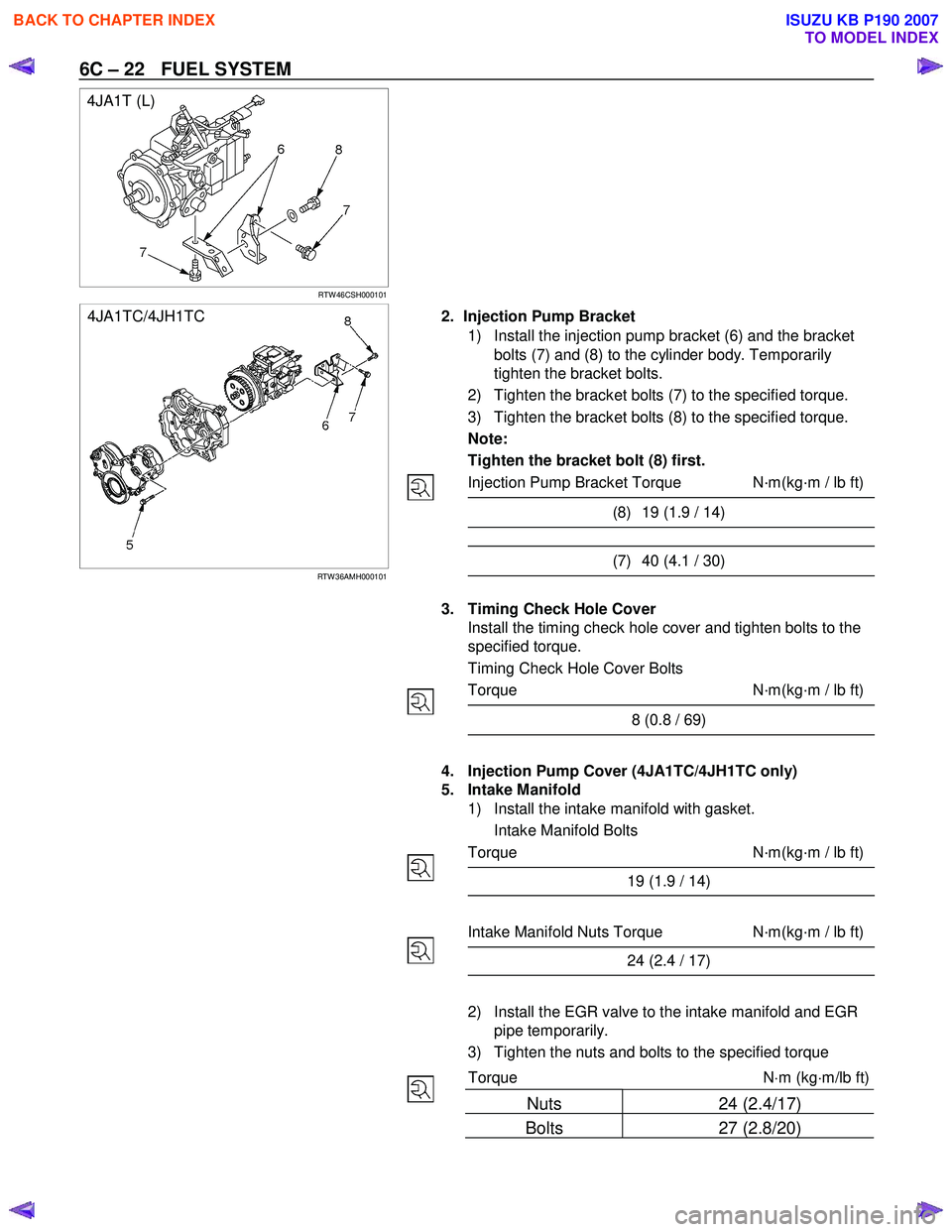

4JA1T (L)

RTW 46CSH000101

4JA1TC/4JH1TC

RTW 36AMH000101

2. Injection Pump Bracket

1) Install the injection pump bracket (6) and the bracket bolts (7) and (8) to the cylinder body. Temporarily

tighten the bracket bolts.

2) Tighten the bracket bolts (7) to the specified torque.

3) Tighten the bracket bolts (8) to the specified torque.

Note:

Tighten the bracket bolt (8) first.

Injection Pump Bracket Torque N·m(kg·m / lb ft)

(8) 19 (1.9 / 14)

(7) 40 (4.1 / 30)

3. Timing Check Hole Cover

Install the timing check hole cover and tighten bolts to the

specified torque.

Timing Check Hole Cover Bolts

Torque N·m(kg·m / lb ft)

8 (0.8 / 69)

4. Injection Pump Cover (4JA1TC/4JH1TC only)

5. Intake Manifold

1) Install the intake manifold with gasket.

Intake Manifold Bolts

Torque N·m(kg·m / lb ft)

19 (1.9 / 14)

Intake Manifold Nuts Torque N·m(kg·m / lb ft)

24 (2.4 / 17)

2) Install the EGR valve to the intake manifold and EGR pipe temporarily.

3) Tighten the nuts and bolts to the specified torque

Torque N ⋅m (kg ⋅m/lb ft)

Nuts 24 (2.4/17)

Bolts 27 (2.8/20)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 989 of 6020

FUEL SYSTEM 6C – 25

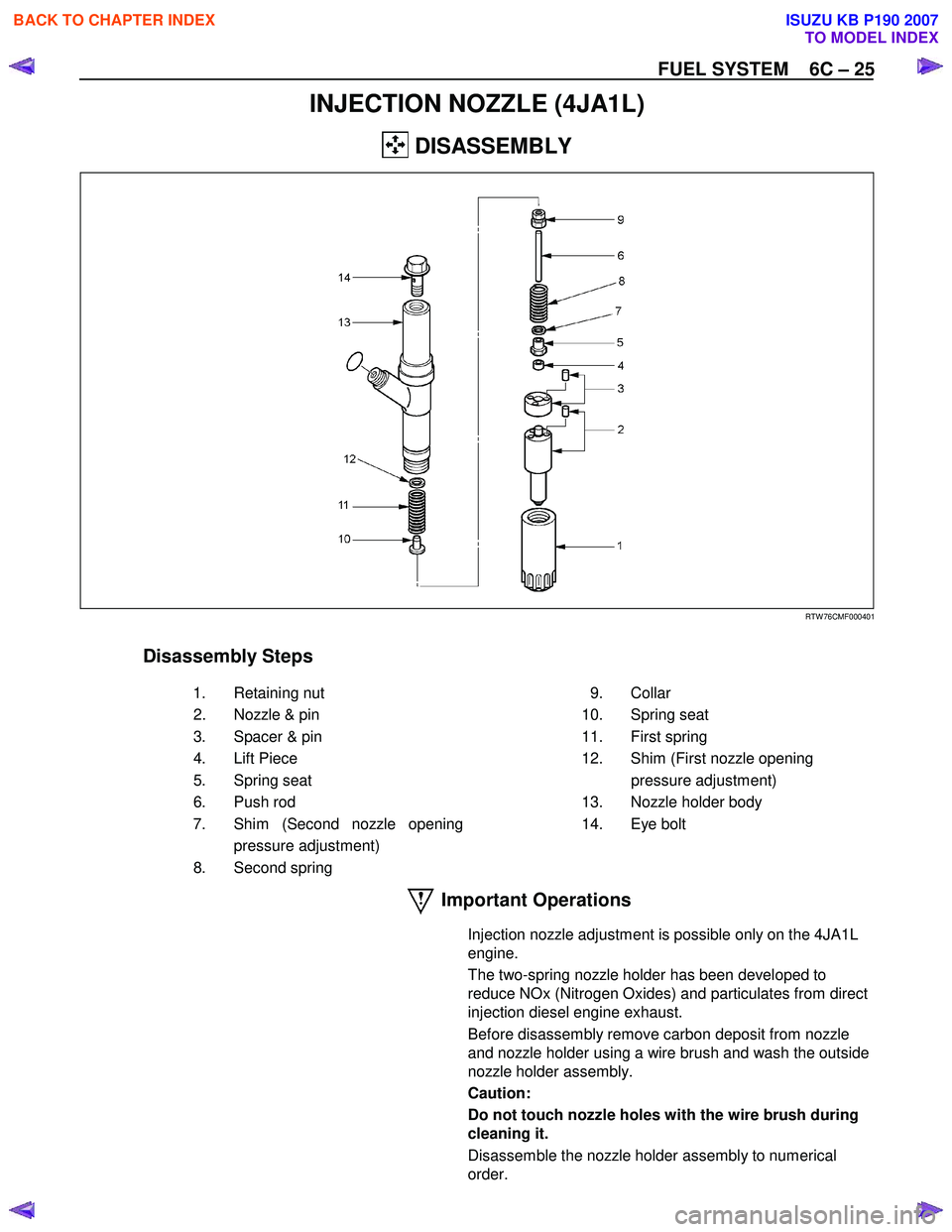

INJECTION NOZZLE (4JA1L)

DISASSEMBLY

RTW 76CMF000401

Disassembly Steps

1. Retaining nut 2. Nozzle & pin

3. Spacer & pin

4. Lift Piece

5. Spring seat

6. Push rod

7. Shim (Second nozzle opening pressure adjustment)

8. Second spring 9. Collar

10. Spring seat

11. First spring

12. Shim (First nozzle opening pressure adjustment)

13. Nozzle holder body

14. Eye bolt

Important Operations

Injection nozzle adjustment is possible only on the 4JA1L

engine.

The two-spring nozzle holder has been developed to

reduce NOx (Nitrogen Oxides) and particulates from direct

injection diesel engine exhaust.

Before disassembly remove carbon deposit from nozzle

and nozzle holder using a wire brush and wash the outside

nozzle holder assembly.

Caution:

Do not touch nozzle holes with the wire brush during

cleaning it.

Disassemble the nozzle holder assembly to numerical

order.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007