coolant level ISUZU KB P190 2007 Workshop Manual PDF

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 3159 of 6020

Engine Cooling – V6 Engine Page 6B1–24

12 Open the coolant reservoir tank cap.

13 Top up the radiator coolant recovery reservoir to the MAX line.

14 Reinstall the coolant recovery reservoir cap.

NOTE

This condition only applies when the cooling

system is first being filled after a major loss of

coolant. The level of coolant in the reservoir

will then drop, once the engine is started and

normal operating temperature is reached. The

coolant level should then be maintained at the

correct level (between the MAX and MIN

Lines).

Figure 6B1 – 21

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3167 of 6020

Engine Cooling – V6 Engine Page 6B1–32

4 Attach coolant filler cap (2) to a commercially

available cooling system pressure tester (1), using

the pressure cap adaptor.

5 Slowly pressurise cap to 120 – 130 kPa. The cap is serviceable if it unloads slightly above this pressure

range and holds pressure at 120 kPa.

NOTE

Should the cap fail to reach or hold the

specified pressure, replace the cap.

Figure 6B1 – 30

6 Prior to installing coolant filler cap ensure that the coolant filler neck cap seating surface is clean and

free from obstruction.

Figure 6B1 – 31

Cooling System Pressure Testing

Refer to 3.1 Service Notes in this Section, for

important safety items.

1 Allow the engine to cool to ambient temperature (less than 50 ° C), then remove coolant filler cap.

2 Ensure that the coolant level is correct.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3191 of 6020

Engine Cooling – V6 Engine Page 6B1–56

Reinstall

Installation of the radiator is the reverse of removal procedures, noting the following points:

1 Before installing radiator, inspect core to ensure that there is no foreign matter in core fins. Clean out between core fins with compressed air, blowing from rear to front.

2 If the vehicle is fitted with an automatic transmission, remove plugs from the removed cooling pipe ends and the two quick connect fittings.

3 After wiping cooler line ends and smearing clean automatic transmission fluid over each flared line end, push into the quick connect fitting to engage. As a security check, tug on each line to ensure correct engagement.

4 Check the transmission fluid level. Refer to the following references as required:

• 7C4 Automatic Transmission

• 4L60E On-vehicle Servicing

5 Install the following hoses:

a. Lower radiator hose, securing with the hose clamp.

b. Upper radiator hose, securing with the hose clamp.

6 Install the radiator cooling fan and shroud assembly. Refer to 3.13Cooling Fan and Shroud Assembly in this Section. Ensure that electrical connectors and the transmission cooler lines are seated correctly in the integral

retainer clips before install upper radiator shroud.

7 Refill cooling system. Refer to 3.3 Draining and Filling Cooling System in this Section.

8 Check for coolant leaks. Refer to 3.7 Pressure Testing in this Section.

9 Reconnect battery ground lead. Refer to 8A Electrical Body & Chassis.

10 Check cooling fan operation. Refer to 6C1-2 Engine Management Diagnostics. Also check for correct rotational direction of cooling fan.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3196 of 6020

Engine Cooling – V6 Engine Page 6B1–61

4 Engine Cooling System

Diagnosis

4.1 Poor Heater Operation

Little or no heat coming from the heater, especially at idle could be an indication of a cooling system problem.

As the coolant level begins to get lower than normal, air enters the system to replace the missing coolant. The heater

core is one of the highest parts of the cooling system and therefore, the first area to lose coolant circulation.

At first, with a small amount of coolant loss, lack of heat will be most noticeable at idle. As driving speed increases, the

engine pumps more coolant and more heat is now able to pass through the heater core.

If coolant level drops even lower, heater operation will become less effective, even during normal driving. Cooling and

engine systems can be adversely affected if problem is not corrected before overheating occurs.

4.2 Leaking Cylinder Head Gasket

Combustion gases leaking past the cylinder head gasket can pressurise the cooling system, forcing coolant out of the

system and into the coolant recovery reservoir.

Indications are air bubbles in the coolant or an overflow condition of the recovery reservoir.

4.3 Question the Customer

To avoid needless time and cost in diagnosing cooling system complaints, the customer should be questioned about

driving conditions that place abnormal loads on the cooling system.

1 Is overheating occurring after prolonged idle, in gear, with air conditioning system operating?

If answer is YES – instruct owner on driving techniques that would avoid overheating such as:

• Idle in neutral as much as possible – increase engine rpm to get higher air flow (due to an increase in voltage

to the fan) and coolant flow through the radiator

• Turn air conditioning system off during extended idling periods if overheating is indicated on temperature

gauge. Further diagnostic checks should not be required

2 Is overheating occurring after prolonged driving in slow city traffic, traffic jams, parades, etc?

If answer is YES, explain driving technique to the customer, that would avoid overheating – same as for prolonged idle – No.1. Further diagnostic checks should not be required.

4.4 Diagnostic Chart

If none of the above conditions apply, refer to the following Diagnosis Chart.

To effectively use this chart, question the customer to determine which of the following three categories apply to the

complaint:

1 If complaint is hot indication on temperature gauge.

W as temperature reading accompanied by boiling?

• If answer is YES, go to overheating on diagnosis chart

• If answer is NO, check temperature gauge and sender

2 If complaint is boiling – go to overheating on diagnosis chart.

3 If complaint is coolant loss. Determine if customer is filling the system correctly.

4 If incorrect filling is not the problem, go to coolant loss in the diagnosis chart.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3197 of 6020

Engine Cooling – V6 Engine Page 6B1–62

Refer to 3.1 Service Notes in this Section, for

important safety items before removing the

coolant filler pressure cap or servicing the

system.

The cooling system is designed to operate at

120 –

––

–

130 kPa and a maximum temperature

not above 130 °

°°

°

C.

Cooling System Diagnosis

Step Action Result Yes No

1

Check Temperature gauge reading High Temp.

Low Temp. Go to Step 2

Go to Step 6 –

2

Check drive belt condition and tension. Refer to 6A1

Engine Mechanical. To Specification Go to Step 3 Replace drive

belt or

tensioner.

3 Check coolant Boiling Go to Step 4 Go to Step 5

4 Check coolant level. Refer to 3.2 Coolant

Maintenance in this Section. Low Go to Step 10 Go to Step 6

5

Check coolant filler cap. Refer to 3.7 Pressure

Testing – Coolant Filler Cap Pressure Testing in this

Section OK? Go to Step 8

Replace

Coolant filler

cap

6 Check thermostat. Refer to 3.8 Thermostat in this

Section. OK? Go to Step 9 Go to Step 13

7

Check Engine Coolant Temperature (ECT) sensor.

Refer to 6C1 Engine Management General Information. Faulty Replace Go to Step 12

8

Check cooling fan operation. Refer to 6C1 Engine

Management General Information. Operational Go to Step 10 Repair

9

Check for collapsed upper or lower radiator hose. Collapsed Replace Go to Step 13

10 Visual system check Leaks Go to Step 13 Go to Step 11

11 Check coolant concentration. Refer to 3.2 Coolant

Maintenance. To Specification Go to Step 12 Correct

Concentration Level

12 Check radiator core for bent fins, dirt, bugs or other

obstructions. Obstructed Clean or

straighten Go to Step 14

13

Pressure Test cooling system. Refer to 3.7 Pressure

Testing in this Section. Leaks Repair System OK

14

If none of the above require repair, the problem is

complex or of a major nature.

Refer to 4.5 Problems Not Requiring Disassembly of

Cooling System or 4.6 Problems Requiring Disassembly

of Cooling System. – – –

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3202 of 6020

Engine Cooling – V6 Engine Page 6B1–67

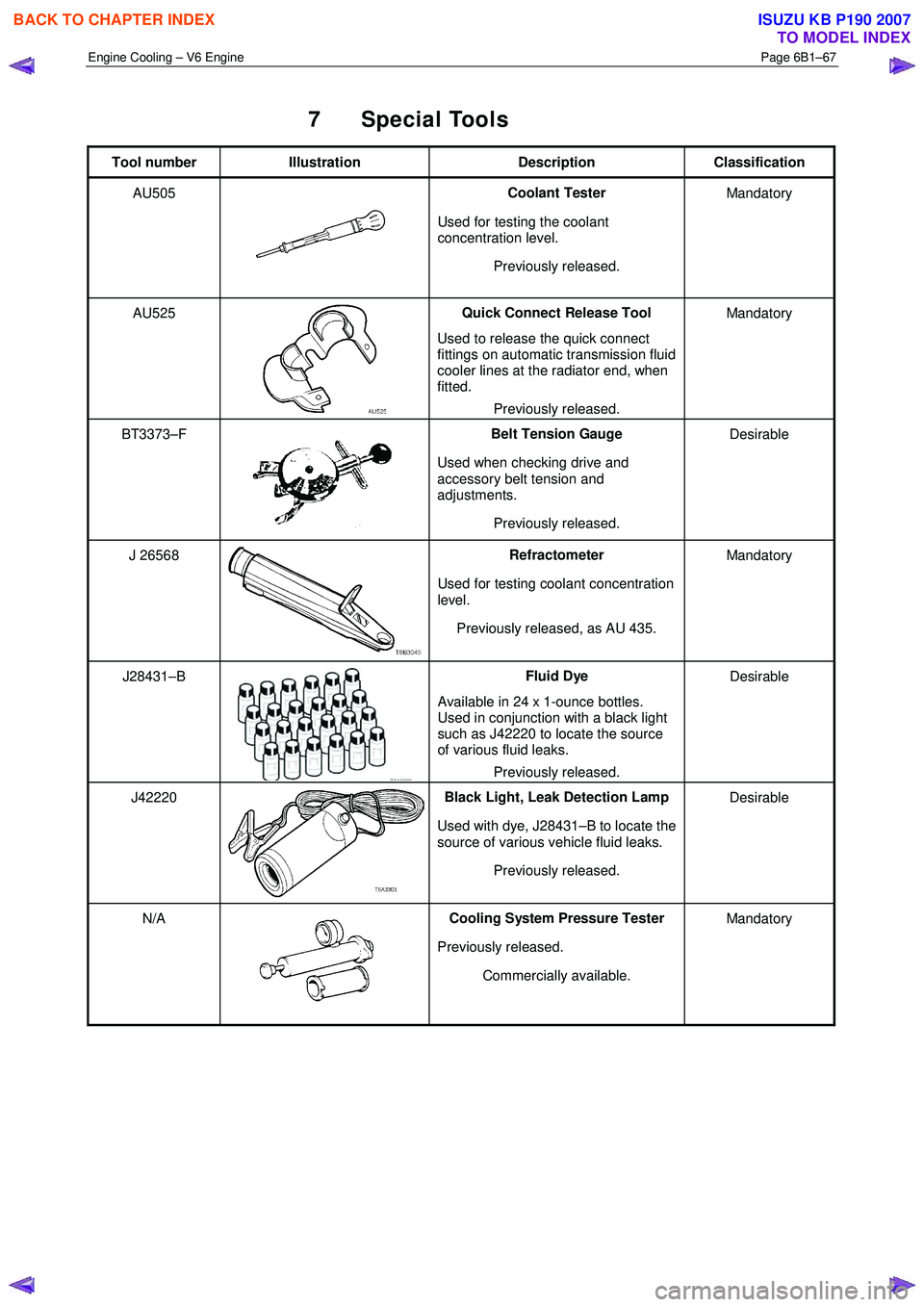

7 Special Tools

Tool number Illustration Description Classification

AU505

Coolant Tester

Used for testing the coolant

concentration level.

Previously released. Mandatory

AU525

Quick Connect Release Tool

Used to release the quick connect

fittings on automatic transmission fluid

cooler lines at the radiator end, when

fitted.

Previously released. Mandatory

BT3373–F

Belt Tension Gauge

Used when checking drive and

accessory belt tension and

adjustments.

Previously released. Desirable

J 26568 Refractometer

Used for testing coolant concentration

level.

Previously released, as AU 435. Mandatory

J28431–B Fluid Dye

Available in 24 x 1-ounce bottles.

Used in conjunction with a black light

such as J42220 to locate the source

of various fluid leaks.

Previously released. Desirable

J42220 Black Light, Leak Detection Lamp

Used with dye, J28431–B to locate the

source of various vehicle fluid leaks.

Previously released. Desirable

N/A Cooling System Pressure Tester

Previously released. Commercially available. Mandatory

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3244 of 6020

Engine Management – V6 – General Information Page 6C1-1–2

3.9 Serial Data Communication System ................................................................................................................... 17

3.10 Self Diagnostics System ..................................................................................................................................... 17

3.11 Service Programming System ..................................................................................................... ....................... 17

3.12 Immobiliser System ............................................................................................................................................. 18

4 Component Description and Operation ............................................................................................ .19

4.1 A/C Refrigerant Pressure Sensor ....................................................................................................................... 19

4.2 Brake Pedal Switch Assembly ............................................................................................................................ 19

Stop Lamp and Initial Brake Apply Switch ....................................................................................... ................. 19

Stop Lamp Switch ............................................................................................................................................ 19

Initial Brake Apply Switch ..................................................................................................... ............................ 19

4.3 Barometric Pressure Sensor..................................................................................................... .......................... 20

4.4 Camshaft Position Sensor .................................................................................................................................. 20

4.5 Crankshaft Position Sensor ................................................................................................................................ 21

4.6 Clutch Pedal Switch Assembly – Manual Vehicles Only ............................................................................ ...... 22

4.7 Engine Control Module........................................................................................................................................ 22

4.8 Engine Coolant Temperature Sensor .............................................................................................. ................... 23

4.9 Electric Cooling Fans .......................................................................................................................................... 23

4.10 Engine Oil Level and Temperature Sensor ........................................................................................ ................ 24

Engine Oil Temperature Sensor ......................................................................................................................... 24

Engine Oil Level Sensor ...................................................................................................................................... 25

4.11 Engine Oil Pressure Sensor..................................................................................................... ........................... 25

4.12 Fuel Injectors........................................................................................................................................................ 26

4.13 Fuel Rail Assembly ............................................................................................................. ................................. 27

4.14 Heated Oxygen Sensors .......................................................................................................... ............................ 27

LSF 4.2 Two-step Planar Heated Oxygen Sensors .................................................................................. ......... 27

LSU 4.2 Wide-band Planar Heated Oxygen Sensors ................................................................................. ....... 29

4.15 Ignition Coil and Spark Plug ............................................................................................................................... 31

4.16 Intake Air Temperature Sensor .................................................................................................. ......................... 32

4.17 Knock Sensor ....................................................................................................................................................... 32

4.18 Mass Air Flow Sensor........................................................................................................... ............................... 33

Air Intake System ................................................................................................................................................. 33

Mass Air Flow Sensor........................................................................................................... ............................... 33

Construction ..................................................................................................................................................... 34

Operation ......................................................................................................................................................... 34

5 Abbreviations and Glossary of Terms ............................................................................................ ...35

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3249 of 6020

Engine Management – V6 – General Information Page 6C1-1–7

Figure 6C1-1 – 4

Legend

1 Camshaft Position (CMP) Sensor

2 Fuel Rail Assembly

3 Fuel Injector (six places)

4 Evaporative Canister Purge (EVAP) Valve 5 Engine Coolant Temperature (ECT) Sensor

6 Engine Oil Level / Temperature Sensor

7 Knock (KS) Sensor (two places)

8 Engine Oil Pressure Sensor

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3339 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–61

• DTCs P0341, P0342, P0343, ran and passed:

• The engine is running.

• The ECM has learned the camshafts position.

DTC P0016

Run continuously once the following conditions are met.

• DTCs P0335, P0336, P0338, P0341, P0342 and P0343 ran and passed:

• The calculated engine oil temperature is less than 95 °C.

• The engine coolant temperature is 20 – 90 °C.

• The engine is running for greater than 5 seconds.

Conditions for Setting the DTC

DTC P0008

The ECM detects that both camshafts on bank 1 of the engine are misaligned with the crankshaft.

DTC P0009

The ECM detects that both camshafts on bank 2 of the engine are misaligned with the crankshaft.

DTC P0016

The ECM detects the following deviation in the correlation between the camshaft position and the crankshaft position for

greater than 10 minutes:

• a camshaft position is too advanced in relationship to the crankshaft, or

• a camshaft position is too retarded in relationship to the crankshaft.

Conditions for Clearing DTC

The CKP / CMP sensor correlation DTCs are Type B DTCs. Refer to 1.4 Diagnostic Trouble Codes in this Section, for

action taken when Type B DTCs set and conditions for clearing Type B DTCs.

Additional Information

• Refer to 6C1-1 Engine Management – V6 – General Information for details of the CMP system operation.

• Inspect the engine for recent engine mechanical repairs. Incorrect camshaft, camshaft actuator or timing chain

installation will trigger these DTCs.

• The engine oil condition has a major impact on the operation of the camshaft actuator.

• A low oil level may set these DTCs.

• For an intermittent fault condition, refer to 5.2 Intermittent Fault Conditions in this Section.

• Since fault condition in a wiring connector may trigger DTCs, always test the connectors related to this diagnostic

procedure for shorted terminals or poor wiring connection before replacing any component. Refer to 8A Electrical -

Body and Chassis for information on electrical fault diagnosis.

• To assist diagnosis, refer to 3 W iring Diagrams and Connector Charts in this Section, for the system wiring

diagram and connector charts.

Test Description

The following numbers refer to the step numbers in the diagnostic table:

3 A fault condition in any of the listed sensors will trigger these DTCs.

5 Incorrect camshaft, camshaft actuator or timing chain installation will trigger these DTCs.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3362 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–84

• The calculated exhaust temperature is 250ºC – 800ºC.

• The engine coolant temperature is less than 40ºC at start-up and greater than 60ºC when the ignition was turned

off last ignition cycle.

• The fuel tank level is greater than 25 percent.

DTC P0138 and P0158

Run continuously once the following conditions are met:

• The engine is operating for longer than two minutes.

• The ignition voltage is 10.0 – 16.0 V.

• The HO2S is at operating temperature.

• The calculated exhaust temperature is 250ºC – 800ºC.

DTC P0140 and P0160

Run continuously once the following conditions are met for longer than 90 seconds:

• The engine is operating.

• The ignition voltage is 10.0 – 16.0 V.

• The calculated exhaust temperature is 250º C – 800º C.

DTC P0141 and P0161

Run continuously once the following conditions are met:

• DTCs P0036, P0037, P0038, P0056, P0057, and P0058 ran and passed.

• DTCs P0137, P0138, P0140, P0157, P0158, or P0160 are not set.

• The engine is operating.

• The ECM internal sensing element resistance is valid.

• The fuel system is not in decel fuel shut-off.

• The intake air temperature is greater than -7ºC.

• If the engine is operating and the ignition is turned off, the engine must be off for at least 5 minutes for this DTC to

run.

• The ignition voltage is 10.0 – 16.0 V.

• The calculated exhaust temperature is 360ºC – 500ºC.

DTC P2243 and P2247

Run continuously once the following conditions are met:

• DTCs P0030, P0031, P0032, P0050, P0051 and P0052 ran and passed.

• The ECM internal sensing element resistance is greater than 570 Ω.

• The HO2S is at operating temperature.

DTC P2270 and P2272

Run continuously once the following conditions are met:

• DTCs P0036, P0037, P0038, P0056, P0057, P0058, P0137, P0138, P0140, P0141, P0157, P0158, P0160, P0161,

P0342, P0343, P0443, P0458 and P0459 ran and passed.

• The engine is running.

• The HO2S 2 are at operating temperature for longer than 10 seconds.

• The long term fuel control is enabled.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007