steering wheel ISUZU KB P190 2007 Workshop Manual PDF

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 569 of 6020

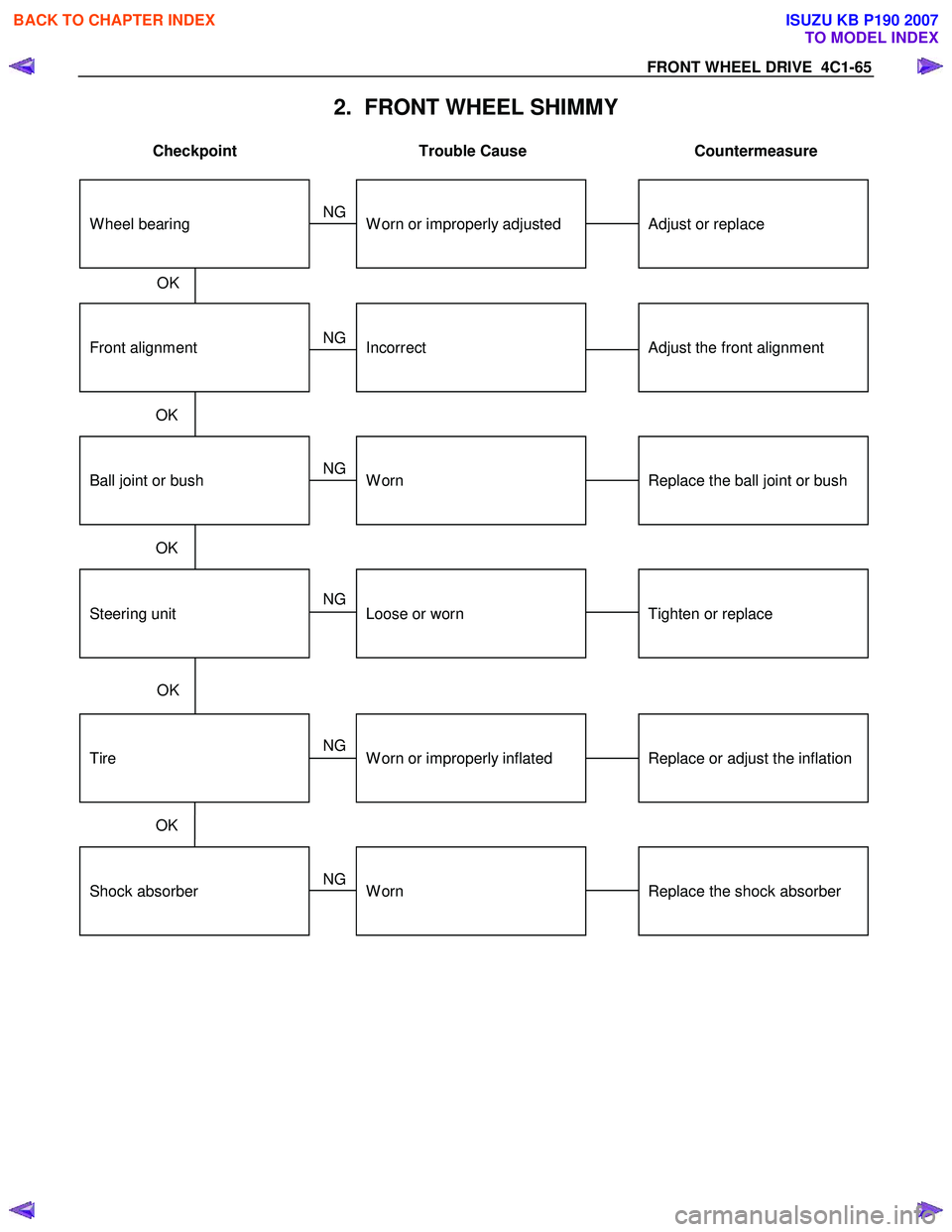

FRONT WHEEL DRIVE 4C1-65

2. FRONT WHEEL SHIMMY

Checkpoint Trouble Cause Countermeasure

Ball joint or bush

Replace the ball joint or bush

Worn

Front alignment

Adjust the front alignment

Adjust or replace

Incorrect

W orn or improperly adjusted

OK

OK NG

NG

NG

OK

W heel bearing

Tighten or replace

Loose or worn

NG

Shock absorber

Replace the shock absorber

Worn

Tire

Replace or adjust the inflation

W orn or improperly inflated

OK

NG

NG

OK

Steering unit

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 572 of 6020

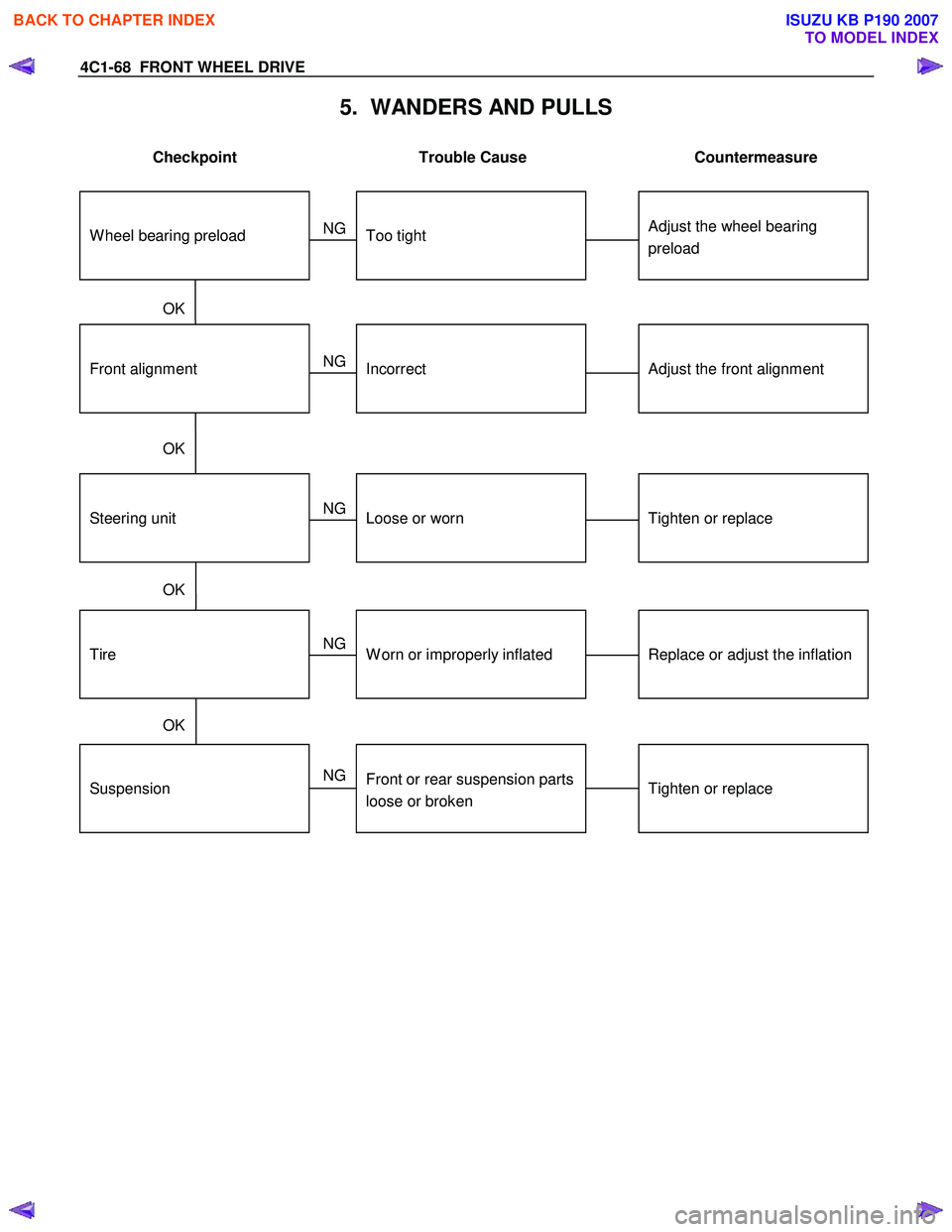

4C1-68 FRONT WHEEL DRIVE

5. WANDERS AND PULLS

Checkpoint Trouble Cause Countermeasure

Adjust the wheel bearing

preload

Too tight

NG

Adjust the front alignment

Front alignment

Incorrect

Tighten or replace

Steering unit

Loose or worn

NG

NG

OK

OK

Tighten or replace

Replace or adjust the inflation

Suspension

Front or rear suspension parts

loose or broken

Tire

W orn or improperly inflated

NG

NG

OK

OK

W heel bearing preload

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 573 of 6020

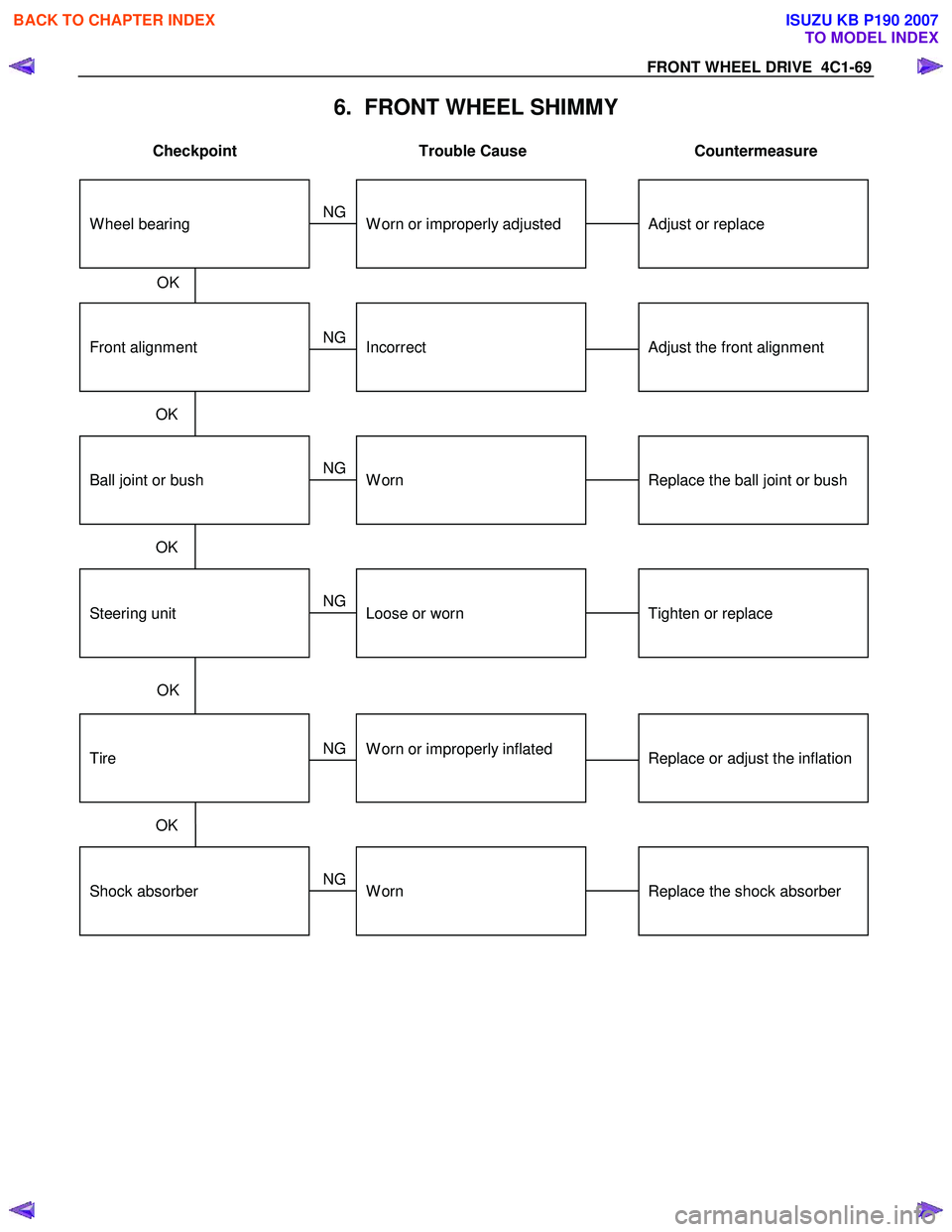

FRONT WHEEL DRIVE 4C1-69

6. FRONT WHEEL SHIMMY

Checkpoint Trouble Cause Countermeasure

Ball joint or bush

Replace the ball joint or bush

Worn

Front alignment

Adjust the front alignment

Adjust or replace

Incorrect

W orn or improperly adjusted

OK

OK NG

NG

NG

OK

W heel bearing

Tighten or replace

Loose or worn

NG

Shock absorber

Replace the shock absorber

Worn

Tire

Replace or adjust the inflation

W orn or improperly inflated

OK NG

NG

OK

Steering unit

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2063 of 6020

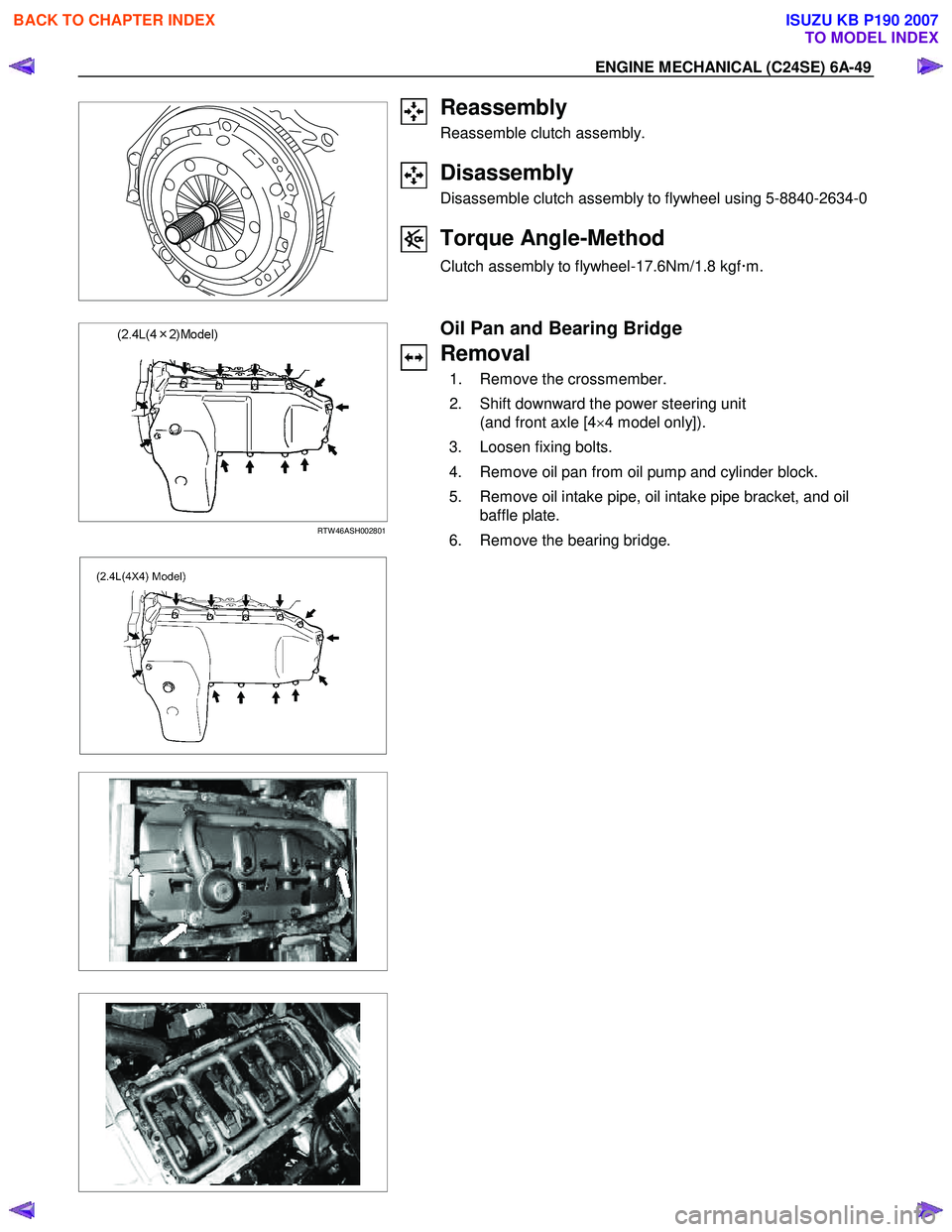

ENGINE MECHANICAL (C24SE) 6A-49

Reassembly

Reassemble clutch assembly.

Disassembly

Disassemble clutch assembly to flywheel using 5-8840-2634-0

Torque Angle-Method

Clutch assembly to flywheel-17.6Nm/1.8 kgf �xm.

RTW 46ASH002801

Oil Pan and Bearing Bridge

Removal

1. Remove the crossmember.

2. Shift downward the power steering unit (and front axle [4 ×4 model only]).

3. Loosen fixing bolts.

4. Remove oil pan from oil pump and cylinder block.

5. Remove oil intake pipe, oil intake pipe bracket, and oil baffle plate.

6. Remove the bearing bridge.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2102 of 6020

6A-88 ENGINE MECHANICAL (C24SE)

Recommended Torque Values

N⋅m (kgf ⋅m)

Bearing cover to cylinder block ........................................................................................ 60

1) 6.1 +40 ° to 50 °

Bracket for alternator to cylinder block ............................................................................ 40 4.1

Bracket for engine damping block to transmission .......................................................... 60

2) 6.1

Bracket for engine damping block to engine block .......................................................... 60 6.1

Bracket for pump/compressor to engine block ................................................................ 35 3.6

Camshaft housing cover to housing ................................................................................ 8 0.8

Camshaft timing gear to camshaft ................................................................................... 50 5.1

Clamping bracket for alternator to intake manifold .......................................................... 25 2.5

Clamping bracket to alternator ......................................................................................... 25 2.5

Con-rod bearing cap to con-rod ....................................................................................... 35

1) 3.5 +45 ° to 60 °

Crankshaft pulley bolts ..................................................................................................... 2 0 2.0

Cylinder head to cylinder block ........................................................................................ 25

1)2) 2.5 +90 ° +90 °

+90 °

Engine damping block to engine bracket ......................................................................... 85 8.7

Engine damping block to side member ............................................................................ 52

1) 5.3

Exhaust manifold to cylinder head ................................................................................... 22 2.2

1) Use new bolts

2) Use new locking plates

Recommended Torque Values

N⋅m (kgf ⋅m)

Flywheel to crankshaft ..................................................................................................... 65

1) 6.6 +30° to 45 °

Front exhaust pipe to exhaust manifold ........................................................................... 25 2.5

Guide sleeve for pressure bearing to transmission ......................................................... 22 2.2

Intake manifold to cylinder head ...................................................................................... 22 2.2

Lower alternator bracket .................................................................................................. 25 2.5

Oil drain plug to oil pan .................................................................................................... 45 4.6

Oil intake pipe bracket to cylinder block ........................................................................... 6

2) 0.6

Oil intake pipe to oil pump ................................................................................................ 8 0.8

Oil pan to cylinder block ................................................................................................... 8

2)3) 0.8

Bearing bridge to cylinder block ....................................................................................... 8 2)3) 0.8

Oil pressure switch to oil pump ........................................................................................ 30 3.2

Pump for power steering (ribbed V-belt) to engine block ................................................. 30 3.2

Spark plugs in cylinder head ............................................................................................ 20 2. 3

Starter support to cylinder block ...................................................................................... 25 2.5

Starter to cylinder block - engine side .............................................................................. 45 4.6

Starter to cylinder block - transmission side .................................................................... 75 7.6

Thermostat housing to cylinder head ............................................................................... 15 1.5

Toothed belt drive gear to crankshaft .............................................................................. 130

1) 13.3

Toothed belt front cover ................................................................................................... 4 0.4

Toothed belt rear cover .................................................................................................... 6 0.6

Toothed belt tension roller to oil pump ............................................................................. 20 2.3 (M10) ............................................................................ 45 4.6

Transmission to engine block ......................................................................................... 76 7.7 (M12) ............................................................................ 60 6.1

W ater pump to cylinder block .......................................................................................... 17 1.7

1) Use new bolts

2) Use Locking Compound

3) Maximum installation time - 10 minutes

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3800 of 6020

Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–14

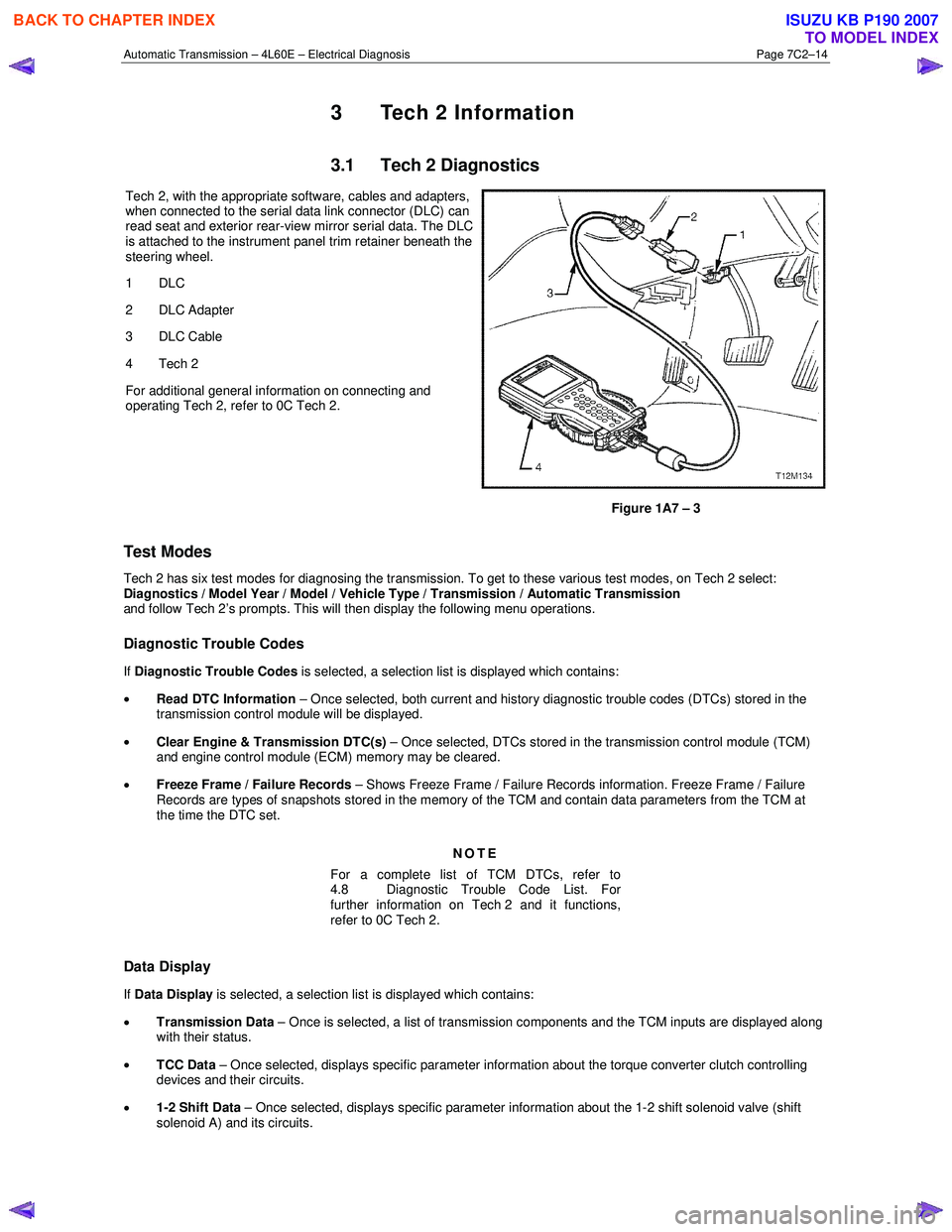

3 Tech 2 Information

3.1 Tech 2 Diagnostics

Tech 2, with the appropriate software, cables and adapters,

when connected to the serial data link connector (DLC) can

read seat and exterior rear-view mirror serial data. The DLC

is attached to the instrument panel trim retainer beneath the

steering wheel.

1 DLC

2 DLC Adapter

3 DLC Cable

4 Tech 2

For additional general information on connecting and

operating Tech 2, refer to 0C Tech 2.

Figure 1A7 – 3

Test Modes

Tech 2 has six test modes for diagnosing the transmission. To get to these various test modes, on Tech 2 select:

Diagnostics / Model Year / Model / Vehicle Type / Transmission / Automatic Transmission

and follow Tech 2’s prompts. This will then display the following menu operations.

Diagnostic Trouble Codes

If Diagnostic Trouble Codes is selected, a selection list is displayed which contains:

• Read DTC Information – Once selected, both current and history diagnostic trouble codes (DTCs) stored in the

transmission control module will be displayed.

• Clear Engine & Transmission DTC(s) – Once selected, DTCs stored in the transmission control module (TCM)

and engine control module (ECM) memory may be cleared.

• Freeze Frame / Failure Records – Shows Freeze Frame / Failure Records information. Freeze Frame / Failure

Records are types of snapshots stored in the memory of the TCM and contain data parameters from the TCM at

the time the DTC set.

NOTE

For a complete list of TCM DTCs, refer to

4.8 Diagnostic Trouble Code List. For

further information on Tech 2 and it functions,

refer to 0C Tech 2.

Data Display

If Data Display is selected, a selection list is displayed which contains:

• Transmission Data – Once is selected, a list of transmission components and the TCM inputs are displayed along

with their status.

• TCC Data – Once selected, displays specific parameter information about the torque converter clutch controlling

devices and their circuits.

• 1-2 Shift Data – Once selected, displays specific parameter information about the 1-2 shift solenoid valve (shift

solenoid A) and its circuits.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 5107 of 6020

ELECTRICAL-BODY AND CHASSIS 8A-169

Installation

Follow the removal procedure in the reverse order to install the

headlight.

Pay close attention to the important points mentioned in the

following paragraphs.

Connector

Be absolutely sure that the headlight connector is securely

connected.

This will prevent a contact and an open circuit.

RTW 780SH000901

This illustration is based on RHD model

LIGHTING SWITCH

Removal

1. Disconnect the battery ground cable.

2. Remove the steering wheel

1.

Refer to the “STEERING” Section of this manual.

3. Remove the Instrument panel lower cover

2.

4. Remove the steering column cover

3.

RTW 780SH001001

This illustration is based on RHD model

5. Disconnect the connector.

6. Remove the lighting switch

4 from the steering shaft.

Installation

Follow the removal procedure in the reverse order to install the

lighting switch.

Pay close attention to the important points mentioned in the

following paragraphs.

Connector

Be absolutely sure that the lighting switch connector is securely

connected.

This will prevent a poor contact and an open circuit.

Wire Harness

Do not pinch the wire harnesses between the cluster and the

meter hood during the cluster installation procedure.

W ire damage will result.

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5111 of 6020

ELECTRICAL-BODY AND CHASSIS 8A-173

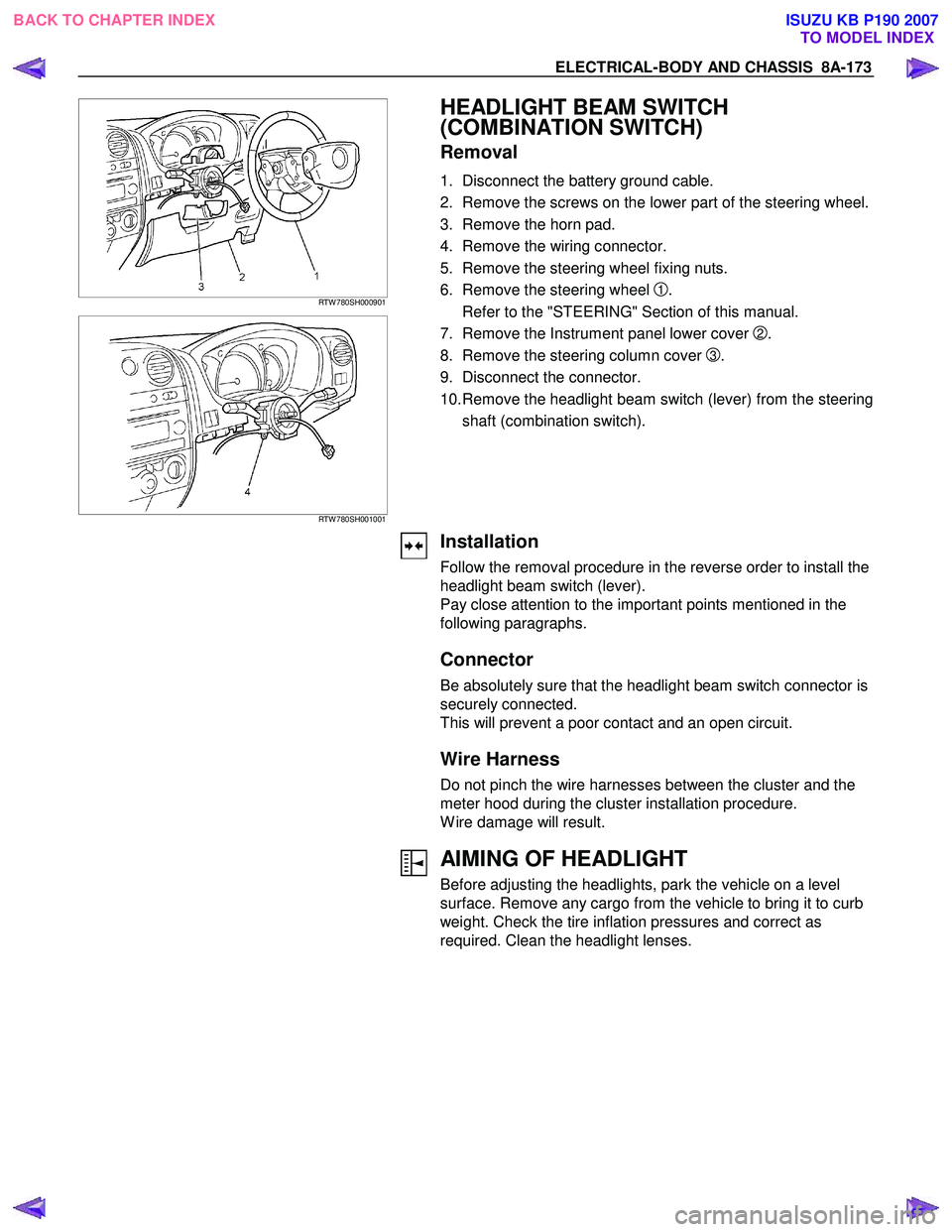

RTW 780SH000901

RTW 780SH001001

HEADLIGHT BEAM SWITCH

(COMBINATION SWITCH)

Removal

1. Disconnect the battery ground cable.

2. Remove the screws on the lower part of the steering wheel.

3. Remove the horn pad.

4. Remove the wiring connector.

5. Remove the steering wheel fixing nuts.

6. Remove the steering wheel

1.

Refer to the "STEERING" Section of this manual.

7. Remove the Instrument panel lower cover

2.

8. Remove the steering column cover

3.

9. Disconnect the connector.

10. Remove the headlight beam switch (lever) from the steering shaft (combination switch).

Installation

Follow the removal procedure in the reverse order to install the

headlight beam switch (lever).

Pay close attention to the important points mentioned in the

following paragraphs.

Connector

Be absolutely sure that the headlight beam switch connector is

securely connected.

This will prevent a poor contact and an open circuit.

Wire Harness

Do not pinch the wire harnesses between the cluster and the

meter hood during the cluster installation procedure.

W ire damage will result.

AIMING OF HEADLIGHT

Before adjusting the headlights, park the vehicle on a level

surface. Remove any cargo from the vehicle to bring it to curb

weight. Check the tire inflation pressures and correct as

required. Clean the headlight lenses.

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5171 of 6020

ELECTRICAL-BODY AND CHASSIS 8A-233

HORN

1. Both sides of horn do not sound

Checkpoint Trouble Cause Countermeasure

Repair the grounding point

Poor ground contact

NG

Horn relay

Grounding point

Reinstall or replace fuse No.

EB15 (10A)

Fuse No EB15 (10A, Relay

and fuse box)

Poor fuse contact or blown

fuse

NG

OK

OK

Reinstall or replace the horn

relay

Poor relay contact or faulty

horn relay

NG

Voltage between connector

3

X3 - ground or 1 X3

- ground (Should be battery

v oltage present) OK

Repair open circuit or

reconnect the connector

Open circuit or poor connector

contact between fuse No.

EB15 (10A) and horn relay

NG

Remov e steering pad and

steering wheel

OK

Horn switch continuity

OK

Repair or replace the horn

switch

Poor switch point contact or

faulty switch

NG

Continuity between

5

X3 - 10 B60

2

X3 - 1 C20 (1 C21 )

OK

Repair open circuit or

connector contact

Open circuit or poor connector

contact

NG

BACK TO CHAPTER INDEX

TO MODEL INDEXISUZU KB P190 2007

Page 5177 of 6020

ELECTRICAL-BODY AND CHASSIS 8A-239

Bulb

Be absolutely sure that the rear combination light bulb is

correctly installed.

This will prevent a poor contact and an open circuit.

RTW 780SH000901

This illustration is based on RHD model

TURN SIGNAL LIGHT SWITCH

Removal

1. Disconnect the battery ground cable.

2. Remove the steering wheel

1.

Refer to the “STEERING” Section of this Manual.

3. Remove the instruments panel lower cover

2.

4. Remove the steering column cover

3.

RTW 780SH001001

This illustration is based on RHD model

5. Disconnect the connector.

6. Remove the turn signal switch from the steering shaft.

Installation

Follow the removal procedure in the reverse order to install the

turn signal switch (lever).

Pay close attention to the important points mentioned in the

following paragraphs.

Connector

Be absolutely sure that the turn signal switch connector is

securely connected.

This will prevent a poor contact and at an open circuit.

A Type

RTW 780SH002101

REAR COMBINATION LIGHT

Backup Light

Removal

1. Open the rear gate.

2. Remove the screws.

3. Remove the rear combination light assembly.

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007