Circuit ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 3314 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–36

Checks Actions

Fuel System

• Check the fuel system for the following fault conditions. Refer to 6C Fuel System

– V6.

• restricted fuel filter,

• incorrect fuel pressure, and

• contaminated fuel.

• Check the operation of the fuel injectors. Refer to 6C1-3 Engine Management –

V6 – Service Operations.

• Perform the fuel injector balance test, refer to 6.3 Fuel Injector Balance

Test in this Section.

• Check the items that cause an engine to run rich.

• Check for fault conditions that can cause an engine to run lean.

Ignition System

• Inspect for moisture or corrosion around the spark plug / ignition coil area.

• Test the ignition coil voltage output. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

• Remove and inspect the spark plugs. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

NOTE

If the spark plugs are fouled, determine the cause of the fouling before

replacing the spark plugs. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

• Check for loose ignition coil ground circuit.

Additional Checks

• Check the torque converter clutch (TCC) operation. A TCC that applies too soon

can cause engine detonation, which will trigger spark retard activity. Refer to 7C2

Automatic Transmission – 4L60E – Electrical Diagnosis.

• Test the A/C clutch for correct operation. Refer to 2A Heater and Air-conditioning.

• Check the evaporative emission (EVAP) canister purge solenoid for the following

conditions: Refer to 6C1-3 Engine Management – V6 – Service Operations.

− stuck open condition, and

− charcoal contamination.

• Check the exhaust system for possible restrictions. Refer to 6F Exhaust System –

V6.

• Electromagnetic interference (EMI) on the crankshaft position (CKP) sensor can

cause an engine misfire condition.

Using Tech 2, monitor the engine speed parameter. A sudden increase in the engine speed parameters without moving the throttle position indicates that an

Electromagnetic Interference fault may be present.

W iring harness routing which may be positioned very close to a high voltage or high current device such as the following may induce EMI:

• secondary ignition components, or

• motors and generators.

When all diagnosis and repairs are completed, check the system for correct operation.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3315 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–37

6 Functional Checks

6.1 General Information

The items detailed in the following pages are to be used when there is a customer complaint and there are no diagnostic

trouble codes set, or one or more of the Tech 2 data values are not within the typical values. They are also to be used

when instructed from a DTC table. Before using these tables, you should refer to 5 Symptoms Diagnostics in this

Section, which may direct you to using the following functional checks.

The purpose of these tables is to diagnose engine control module (ECM) controlled components or sub-systems that do

not have diagnostic trouble codes assigned to them. Another purpose of these tables is for Technicians who feel

confident that a particular part of the sub-system is not operating properly and wants only to check that particular item

for proper operation without going through lengthy diagnostic procedures.

6.2 Fuel Injector Coil Test

The fuel injector coil test is divided into two parts. Begin by performing the fuel injector coil quick test. Then only perform

the Injector Coil Test – W ith Special Tool J39021 procedure if the quick test determines that there is a faulty fuel injector.

Fuel Injector Coil Quick Test

Test Description

The following numbers refer to the step numbers in the diagnostic table:

1 This step checks if the engine coolant temperature is within the correct range.

2 This step tests each fuel injector resistance within a specific temperature range.

3 This step determines if all of the fuel injectors are within 3 ohms of each other.

Step Action Value(s) Yes No

1 Using Tech 2, observe the engine coolant temperature

(ECT).

Is the ECT within the specified range? 10 – 32 °C Go to Step 2 Go to Step 3

2 1 Disconnect the fuel injector harness connector,

refer to 2.13 Fuel Rail Assembly, in 6C1-3 Engine

Management – V6 – Service Operations.

2 Using a digital ohmmeter and connector test adaptor kit J 35616-A, measure the resistance of

each fuel injector between the ignition voltage

circuit and the fuel injector control circuit. Refer to

8A Electrical - Body and Chassis for information

on testing for continuity and to Figure 6C1-2 – 9

and Figure 6C1-2 – 10 for the fuel injector

harness connector.

Do any of the fuel injectors display a resistance outside

the specified range? 11 – 14 ΩRefer to Injector

Coil Test – W ith

Special Tool J39021 in this Section Injectors OK

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3316 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–38

Step Action Value(s) Yes No

3 1 Disconnect the fuel injector harness connector,

refer to 2.13 Fuel Rail Assembly, in 6C1-3 Engine

Management – V6 – Service Operations.

2 Using a digital ohmmeter and connector test adaptor kit J 35616-A, measure the resistance of

each fuel injector between the ignition voltage

circuit and the fuel injector control circuit. Refer to

8A Electrical - Body and Chassis for information

on testing for continuity and to Figure 6C1-2 – 9

and Figure 6C1-2 – 10 for the fuel injector

harness connector.

3 Record each fuel injector value.

4 Subtract the lowest resistance value from the highest.

Is the difference equal to, or less than, the specified

value? 3

Ω

Injectors OK Refer to Injector

Coil Test – W ith

Special Tool J39021 in this Section.

Figure 6C1-2 – 9

Fuel Injector Harness to Engine Harness Connector

Pin Description

Pin Function Circuit

Number

1 Ignition Voltage Circuit – Cyl. 1, 3, 5 639

2 Ignition Voltage Circuit – Cyl. 2, 4, 6 1039

3 Injector 1 Control Circuit 1744

4 Injector 3 Control Circuit 1746

5 Injector 5 Control Circuit 845

6 Injector 2 Control Circuit 1745

7 Injector 4 Control Circuit 844

8 Injector 6 Control Circuit 846

Figure 6C1-2 – 10

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3325 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–47

6.7 Throttle Body Relearn

A throttle body relearn procedure is performed in one of two ways:

• Engine Control Module initiated throttle body relearn, or

• Tech 2 initiated throttle body relearn.

Engine Control Module Throttle Body Relearn

The engine control module (ECM) will automatically perform a throttle body relearn procedure if either of the following

conditions exist:

• The battery has been disconnected, or

• The ignition switch is in the ON position for greater than 29 seconds, and the following conditions are met:

− Engine speed is less than 40 rpm,

− Vehicle speed is 0 km/h,

− Engine coolant temperature is 5 – 60°C,

− Intake air temperature is 5 – 60°C,

− Accelerator pedal position sensor angle is less than 14.9%, and

− Ignition voltage is greater than 10 V.

Tech 2 Throttle Body Relearn

To perform a throttle body relearn using Tech 2, complete the following procedure:

NOTE

Tech 2 will not initiate a throttle body relearn if

the engine is running.

1 Connect Tech 2 to the data link connector (DLC) and turn the ignition on.

2 On Tech 2 select Engine / Programming / Throttle Body Relearn.

3 W hen Tech 2 displays ‘Do you really want to Reset?’, press the ‘Yes’ soft key.

4 W hen Tech 2 displays ‘Programming Completed’, and the electronic throttle control value displayed by Tech 2 is ‘11’, press the ‘Confirm’ soft key to return to the Tech 2 Programming screen.

5 The throttle body relearn is now complete.

6.8 Electronic Ignition (EI) System Diagnosis

Circuit Description

The engine control module (ECM) controls the ignition coils by pulsing the ignition control (IC) circuits, which triggers an

ignition coil and fires the spark plug. The ECM controls the sequencing and the timing of each ignition coil. The ignition

system consist of the following components:

• The six ignition coils

• The crankshaft position (CKP) sensor

• The four camshaft position (CMP) sensors

• The ECM

The ignition coils use the following circuits:

• An IC circuit

• An ignition 1 voltage circuit

• Two ground circuits

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3326 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–48

Additional Information

• Use the J 35616-B Connector Test Adapter Kit for any test that requires probing the ECM harness connector or a

component harness connector.

• Inspect the ignition coils for aftermarket devices. An aftermarket device connected to the ignition coil circuits, may

cause a condition with the ignition coils.

• For an intermittent fault condition, refer to 5.2 Intermittent Fault Conditions in this Section.

• To assist diagnosis, refer to 3 W iring Diagrams and Connector Charts in this Section, for the system wiring

diagram and connector charts.

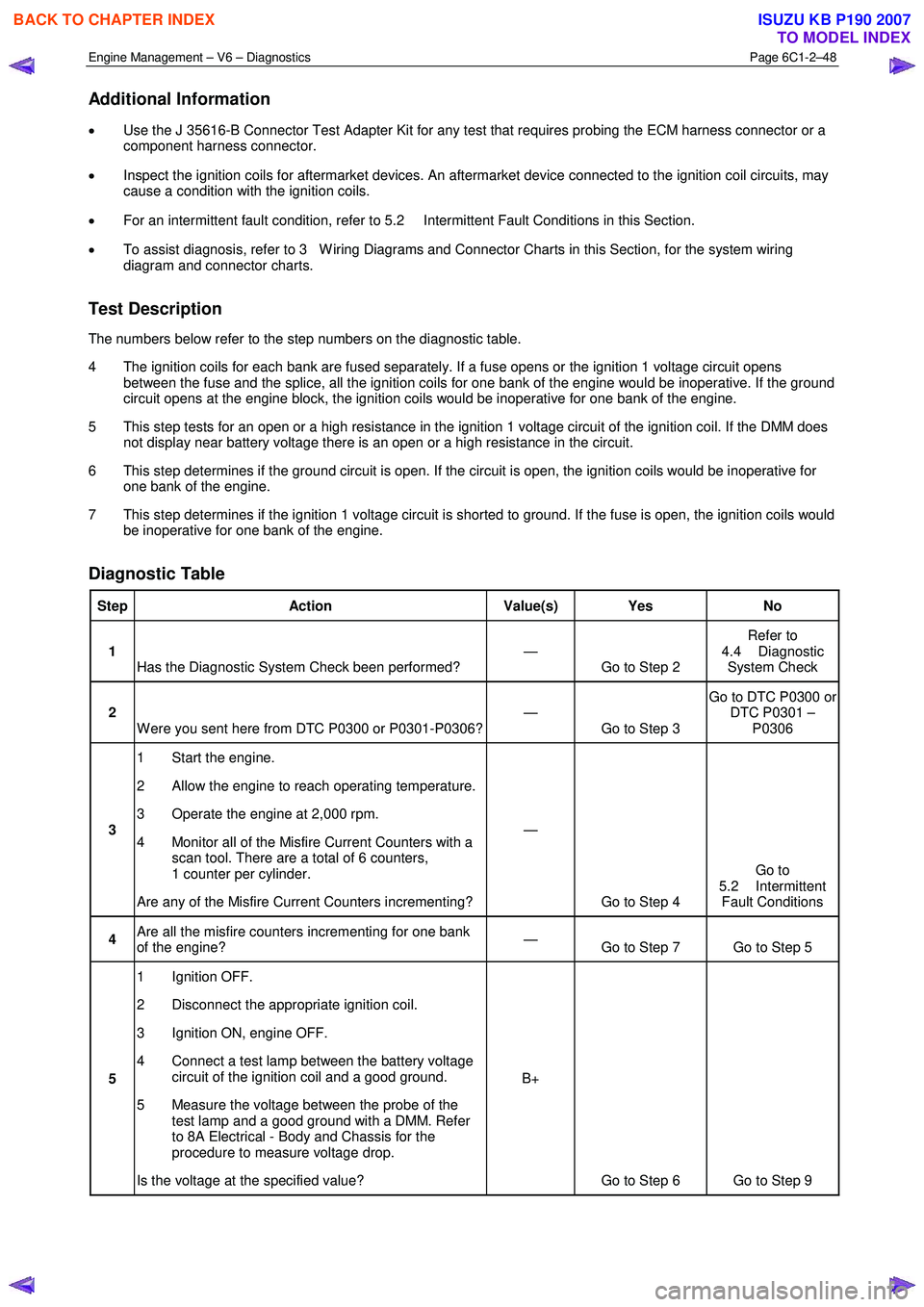

Test Description

The numbers below refer to the step numbers on the diagnostic table.

4 The ignition coils for each bank are fused separately. If a fuse opens or the ignition 1 voltage circuit opens between the fuse and the splice, all the ignition coils for one bank of the engine would be inoperative. If the ground

circuit opens at the engine block, the ignition coils would be inoperative for one bank of the engine.

5 This step tests for an open or a high resistance in the ignition 1 voltage circuit of the ignition coil. If the DMM does not display near battery voltage there is an open or a high resistance in the circuit.

6 This step determines if the ground circuit is open. If the circuit is open, the ignition coils would be inoperative for one bank of the engine.

7 This step determines if the ignition 1 voltage circuit is shorted to ground. If the fuse is open, the ignition coils would be inoperative for one bank of the engine.

Diagnostic Table

Step Action Value(s) Yes No

1

Has the Diagnostic System Check been performed? —

Go to Step 2 Refer to

4.4 Diagnostic System Check

2 W ere you sent here from DTC P0300 or P0301-P0306? —

Go to Step 3 Go to DTC P0300 or

DTC P0301 – P0306

3 1 Start the engine.

2 Allow the engine to reach operating temperature.

3 Operate the engine at 2,000 rpm.

4 Monitor all of the Misfire Current Counters with a scan tool. There are a total of 6 counters,

1 counter per cylinder.

Are any of the Misfire Current Counters incrementing? —

Go to Step 4 Go to

5.2 Intermittent Fault Conditions

4 Are all the misfire counters incrementing for one bank

of the engine? —

Go to Step 7 Go to Step 5

5 1 Ignition OFF.

2 Disconnect the appropriate ignition coil.

3 Ignition ON, engine OFF.

4 Connect a test lamp between the battery voltage circuit of the ignition coil and a good ground.

5 Measure the voltage between the probe of the test lamp and a good ground with a DMM. Refer

to 8A Electrical - Body and Chassis for the

procedure to measure voltage drop.

Is the voltage at the specified value? B+

Go to Step 6 Go to Step 9

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3327 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–49

6 1 Connect the test lamp between the battery

voltage circuit of the ignition coil and to each

ground circuit of the ignition coil.

Does the test lamp illuminate at each ground circuit? —

Go to Step 8 Go to Step 10

7 1 Test the battery voltage circuit for an open or high

resistance at the splice of the affected bank of

ignition coils. Refer to 8A Electrical - Body and

Chassis for circuit testing procedures.

Did you find and correct the condition? —

Go to Step 12 Go to Step 10

8 1 Test for an intermittent and for a poor connection

at the ignition coil. Refer to 8A Electrical - Body

and Chassis for circuit testing procedures.

Did you find and correct the condition? —

Go to Step 12 Go to Step 11

9 NOTE

The battery voltage circuit is shared with

other components. Disconnecting a

component on the shared battery voltage

circuit may isolate a shorted component.

Review the electrical schematic and

diagnose the shared circuits and

components.

1 Repair a short to ground, an open or high resistance in the ignition 1 voltage circuit. Refer to

Refer to 8A Electrical - Body and Chassis for

wiring repair procedures.

2 Replace the fuse as necessary.

Did you complete the repair? —

Go to Step 12 —

10 1 Repair the open or high resistance in the ground

circuit. Refer to 8A Electrical - Body and Chassis

for wiring repair procedures.

Did you complete the repair? —

Go to Step 12 —

11 1 Replace the ignition coil. Refer to 2.15 Ignition

Coils, in 6C1-3 Engine Management – V6 –

Service Operations.

Did you complete the replacement? —

Go to Step 12 —

12 1 Connect all disconnected components.

2 Use Tech 2 to clear the DTC/s.

3 Start the engine.

4 Observe the Capture Info with Tech 2.

Do any of the misfire counters increment? —

Go to Step 2 Go to Step 13

13 1 Using Tech 2, select the DTC display function.

Does Tech 2 display any DTCs? — Go to the

appropriate DTC

Table in this Section System OK

When all diagnosis and repairs are completed, clear all DTCs and verify correct operation

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3328 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–50

7 Diagnostic Trouble Code Tables

7.1 DTC List

As a number of diagnostic tables cater for multiple DTC numbers, a specific DTC table may be difficult to locate.

To make a specific DTC diagnostic table easier to find, the next list is arranged in numerical ascending order.

The actual diagnostic table can be located by selecting the link provided.

DTC Description Diagnostic Table

P0008 Engine Position System Performance (Bank 1) 7.2 DTC P0008, P0009 or P0016

P0009 Engine Position System Performance (Bank 2) 7.2 DTC P0008, P0009 or P0016

P0016 Crankshaft / Intake Camshaft Position not Plausible

(Bank 1) 7.2 DTC P0008, P0009 or P0016

P0030 O2 Sensor Heater Circuit Malfunction (Bank 1, Sensor 1) 7.3 DTC P0030, P0031, P0032, P0036,

P0037, P0038, P0050, P0051, P0052,

P0056, P0057 or P0058

P0031 O2 Sensor Heater Circuit Low Voltage (Bank 1, Sensor 1) 7.3 DTC P0030, P0031, P0032, P0036, P0037, P0038, P0050, P0051, P0052,

P0056, P0057 or P0058

P0032 O2 Sensor Heater Circuit High Voltage (Bank 1, Sensor 1) 7.3 DTC P0030, P0031, P0032, P0036, P0037, P0038, P0050, P0051, P0052,

P0056, P0057 or P0058

P0036 O2 Sensor Heater Circuit Malfunction (Bank 1, Sensor 2) 7.3 DTC P0030, P0031, P0032, P0036, P0037, P0038, P0050, P0051, P0052,

P0056, P0057 or P0058

P0037 O2 Sensor Heater Circuit Low Voltage (Bank 1, Sensor 2) 7.3 DTC P0030, P0031, P0032, P0036, P0037, P0038, P0050, P0051, P0052,

P0056, P0057 or P0058

P0038 O2 Sensor Heater Circuit High Voltage (Bank 1, Sensor 2) 7.3 DTC P0030, P0031, P0032, P0036, P0037, P0038, P0050, P0051, P0052,

P0056, P0057 or P0058

P0040 O2 Sensor Signals Not Plausible (Bank 1, Sensor 1 & Bank 2, Sensor 1) 7.4 DTC P0040 or P0041

P0041 O2 Sensor Signals Not Plausible (Bank 1, Sensor 2 &

Bank 2, Sensor 2) 7.4 DTC P0040 or P0041

P0050 O2 Sensor Heater Circuit Malfunction (Bank 2, Sensor 1) 7.3 DTC P0030, P0031, P0032, P0036,

P0037, P0038, P0050, P0051, P0052,

P0056, P0057 or P0058

P0051 O2 Sensor Heater Circuit Low Voltage (Bank 2, Sensor 1) 7.3 DTC P0030, P0031, P0032, P0036, P0037, P0038, P0050, P0051, P0052,

P0056, P0057 or P0058

P0052 O2 Sensor Heater Circuit High Voltage (Bank 2, Sensor 1) 7.3 DTC P0030, P0031, P0032, P0036, P0037, P0038, P0050, P0051, P0052,

P0056, P0057 or P0058

P0053 O2 Sensor Heater Resistance Range / Performance (Bank 1, Sensor 1) 7.5 DTC P0053 or P0059

P0056 O2 Sensor Heater Circuit Malfunction (Bank 2, Sensor 2) 7.3 DTC P0030, P0031, P0032, P0036,

P0037, P0038, P0050, P0051, P0052,

P0056, P0057 or P0058

P0057 O2 Sensor Heater Circuit Low Voltage (Bank 2, Sensor 2) 7.3 DTC P0030, P0031, P0032, P0036, P0037, P0038, P0050, P0051, P0052,

P0056, P0057 or P0058

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3329 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–51

DTC Description Diagnostic Table

P0058 O2 Sensor Heater Circuit High Voltage (Bank 2, Sensor 2) 7.3 DTC P0030, P0031, P0032, P0036,

P0037, P0038, P0050, P0051, P0052,

P0056, P0057 or P0058

P0059 O2 Sensor Heater Resistance Range / Performance (Bank 2, Sensor 1) 7.5 DTC P0053 or P0059

P0101 Mass Air Flow Sensor Circuit Range / Performance 7.6 DTC P0101, P0102 or P0103

P0102 Mass Air Flow Sensor Voltage Low

7.6 DTC P0101, P0102 or P0103

P0103 Mass Air Flow Sensor Voltage High 7.6 DTC P0101, P0102 or P0103

P0112 Intake Air Temperature Sensor Circuit Low Voltage 7.7 DTC P0112 or P0113

P0113 Intake Air Temperature Sensor Circuit High Voltage 7.7 DTC P0112 or P0113

P0116 Engine Coolant Temperature Sensor Circuit Range /

Performance 7.8 DTC P0116, P0117, P0118, P0125 or

P1258

P0117 Engine Coolant Temperature Sensor Circuit Low Voltage 7.8 DTC P0116, P0117, P0118, P0125 or P1258

P0118 Engine Coolant Temperature Sensor Circuit High Voltage 7.8 DTC P0116, P0117, P0118, P0125 or P1258

P0121 Throttle Position Sensor 1 Circuit Range / Performance 7.9 DTC P0121, P0122, P0123, P0221, P0222,or P0223

P0122 Throttle Position Sensor 1 Circuit Low Voltage 7.9 DTC P0121, P0122, P0123, P0221,

P0222,or P0223

P0123 Throttle Position Sensor 1 Circuit High Voltage 7.9 DTC P0121, P0122, P0123, P0221,

P0222,or P0223

P0125 Insufficient Engine Coolant Temperature For Closed Loop Fuel Control 7.8 DTC P0116, P0117, P0118, P0125 or

P1258

P0130 O2 Sensor Circuit Malfunction (Bank 1, Sensor 1) 7.10 DTC P0130, P0131, P0132, P0135, P0137, P0138, P0140, P0141, P0150

P0151, P0152, P0155, P0157, P0158,

P0160, P0161, P2243, P2247, P2270,

P2271, P2272, P2273, P2297 or P2298

P0131 O2 Sensor Circuit Low Voltage (Bank 1, Sensor 1) 7.10 DTC P0130, P0131, P0132, P0135, P0137, P0138, P0140, P0141, P0150

P0151, P0152, P0155, P0157, P0158,

P0160, P0161, P2243, P2247, P2270,

P2271, P2272, P2273, P2297 or P2298

P0132 O2 Sensor Circuit High Voltage (Bank 1 Sensor 1) 7.10 DTC P0130, P0131, P0132, P0135, P0137, P0138, P0140, P0141, P0150

P0151, P0152, P0155, P0157, P0158,

P0160, P0161, P2243, P2247, P2270,

P2271, P2272, P2273, P2297 or P2298

P0133 O2 Sensor Circuit Slow Response (Bank 1 Sensor 1) 7.11 DTC P0133 or P0153

P0135 O2 Sensor Heater Circuit Range / Performance (Bank 1, Sensor 1) 7.10 DTC P0130, P0131, P0132, P0135,

P0137, P0138, P0140, P0141, P0150

P0151, P0152, P0155, P0157, P0158,

P0160, P0161, P2243, P2247, P2270,

P2271, P2272, P2273, P2297 or P2298

P0137 O2 Sensor Circuit Low Voltage (Bank 1, Sensor 2) 7.10 DTC P0130, P0131, P0132, P0135, P0137, P0138, P0140, P0141, P0150

P0151, P0152, P0155, P0157, P0158,

P0160, P0161, P2243, P2247, P2270,

P2271, P2272, P2273, P2297 or P2298

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3330 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–52

DTC Description Diagnostic Table

P0138 O2 Sensor Circuit High Voltage (Bank 1, Sensor 2) 7.10 DTC P0130, P0131, P0132, P0135,

P0137, P0138, P0140, P0141, P0150

P0151, P0152, P0155, P0157, P0158,

P0160, P0161, P2243, P2247, P2270,

P2271, P2272, P2273, P2297 or P2298

P0139 O2 Sensor Slow Response (Bank1 Sensor 2) 7.12 DTC P0139 or P0159

P0140 O2 Sensor Circuit No Activity Detected (Bank 1

Sensor 2) 7.10 DTC P0130, P0131, P0132, P0135,

P0137, P0138, P0140, P0141, P0150

P0151, P0152, P0155, P0157, P0158,

P0160, P0161, P2243, P2247, P2270,

P2271, P2272, P2273, P2297 or P2298

P0141 O2 Sensor Heater Circuit Range / Performance (Bank 1, Sensor 2) 7.10 DTC P0130, P0131, P0132, P0135,

P0137, P0138, P0140, P0141, P0150

P0151, P0152, P0155, P0157, P0158,

P0160, P0161, P2243, P2247, P2270,

P2271, P2272, P2273, P2297 or P2298

P0150 O2 Sensor Circuit Malfunction (Bank 2, Sensor 1) 7.10 DTC P0130, P0131, P0132, P0135, P0137, P0138, P0140, P0141, P0150

P0151, P0152, P0155, P0157, P0158,

P0160, P0161, P2243, P2247, P2270,

P2271, P2272, P2273, P2297 or P2298

P0151 O2 Sensor Circuit Low Voltage (Bank 2, Sensor 1) 7.10 DTC P0130, P0131, P0132, P0135, P0137, P0138, P0140, P0141, P0150

P0151, P0152, P0155, P0157, P0158,

P0160, P0161, P2243, P2247, P2270,

P2271, P2272, P2273, P2297 or P2298

P0152 O2 Sensor Circuit High Voltage (Bank 2, Sensor 1) 7.10 DTC P0130, P0131, P0132, P0135, P0137, P0138, P0140, P0141, P0150

P0151, P0152, P0155, P0157, P0158,

P0160, P0161, P2243, P2247, P2270,

P2271, P2272, P2273, P2297 or P2298

P0153 O2 Sensor Circuit Slow Response (Bank 2 Sensor 1) 7.11 DTC P0133 or P0153

P0155 O2 Sensor Heater Circuit Range / Performance (Bank 2, Sensor 1) 7.10 DTC P0130, P0131, P0132, P0135,

P0137, P0138, P0140, P0141, P0150

P0151, P0152, P0155, P0157, P0158,

P0160, P0161, P2243, P2247, P2270,

P2271, P2272, P2273, P2297 or P2298

P0157 O2 Sensor Circuit Low Voltage (Bank 2, Sensor 2) 7.10 DTC P0130, P0131, P0132, P0135, P0137, P0138, P0140, P0141, P0150

P0151, P0152, P0155, P0157, P0158,

P0160, P0161, P2243, P2247, P2270,

P2271, P2272, P2273, P2297 or P2298

P0158 O2 Sensor Circuit High Voltage (Bank 2, Sensor 2) 7.10 DTC P0130, P0131, P0132, P0135, P0137, P0138, P0140, P0141, P0150

P0151, P0152, P0155, P0157, P0158,

P0160, P0161, P2243, P2247, P2270,

P2271, P2272, P2273, P2297 or P2298

P0159 O2 Sensor Slow Response (Bank1 Sensor 2) 7.12 DTC P0139 or P0159

P0160 O2 Sensor Circuit No Activity Detected (Bank 2, Sensor 2) 7.10 DTC P0130, P0131, P0132, P0135,

P0137, P0138, P0140, P0141, P0150

P0151, P0152, P0155, P0157, P0158,

P0160, P0161, P2243, P2247, P2270,

P2271, P2272, P2273, P2297 or P2298

P0161 O2 Sensor Heater Circuit Range / Performance (Bank 2, Sensor 2) 7.10 DTC P0130, P0131, P0132, P0135,

P0137, P0138, P0140, P0141, P0150

P0151, P0152, P0155, P0157, P0158,

P0160, P0161, P2243, P2247, P2270,

P2271, P2272, P2273, P2297 or P2298

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3331 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–53

DTC Description Diagnostic Table

P0196 Engine Oil Temperature Sensor Range / Performance 7.13 DTC P0196, P0197 or P0198

P0197 Engine Oil Temperature Voltage Low 7.13 DTC P0196, P0197 or P0198

P0198 Engine Oil Temperature Voltage High 7.13 DTC P0196, P0197 or P0198

P0201 Injector 1 Control Circuit Malfunction 7.14 DTC P0201, P0202, P0203, P0204,

P0205, P0206, P0261, P0262, P0264,

P0265, P0267, P0268, P0270, P0271,

P0273, P0274, P0276 or P0277

P0202 Injector 2 Control Circuit Malfunction 7.14 DTC P0201, P0202, P0203, P0204,

P0205, P0206, P0261, P0262, P0264,

P0265, P0267, P0268, P0270, P0271,

P0273, P0274, P0276 or P0277

P0203 Injector 3 Control Circuit Malfunction 7.14 DTC P0201, P0202, P0203, P0204,

P0205, P0206, P0261, P0262, P0264,

P0265, P0267, P0268, P0270, P0271,

P0273, P0274, P0276 or P0277

P0204 Injector 4 Control Circuit Malfunction 7.14 DTC P0201, P0202, P0203, P0204,

P0205, P0206, P0261, P0262, P0264,

P0265, P0267, P0268, P0270, P0271,

P0273, P0274, P0276 or P0277

P0205 Injector 5 Control Circuit Malfunction 7.14 DTC P0201, P0202, P0203, P0204,

P0205, P0206, P0261, P0262, P0264,

P0265, P0267, P0268, P0270, P0271,

P0273, P0274, P0276 or P0277

P0206 Injector 6 Control Circuit Malfunction 7.14 DTC P0201, P0202, P0203, P0204,

P0205, P0206, P0261, P0262, P0264,

P0265, P0267, P0268, P0270, P0271,

P0273, P0274, P0276 or P0277

P0219 Engine Overspeed Condition 7.15 DTC P0219

P0221 Throttle Position Sensor 2 Circuit Range / Performance 7.9 DTC P0121, P0122, P0123, P0221,

P0222,or P0223

P0222 Throttle Position Sensor 2 Circuit Low Voltage 7.9 DTC P0121, P0122, P0123, P0221,

P0222,or P0223

P0223 Throttle Position Sensor 2 Circuit High Voltage 7.9 DTC P0121, P0122, P0123, P0221,

P0222,or P0223

P0261 Injector 1 Control Circuit Low Voltage 7.14 DTC P0201, P0202, P0203, P0204,

P0205, P0206, P0261, P0262, P0264,

P0265, P0267, P0268, P0270, P0271,

P0273, P0274, P0276 or P0277

P0262 Injector 1 Control Circuit High Voltage 7.14 DTC P0201, P0202, P0203, P0204,

P0205, P0206, P0261, P0262, P0264,

P0265, P0267, P0268, P0270, P0271,

P0273, P0274, P0276 or P0277

P0264 Injector 2 Control Circuit Low Voltage 7.14 DTC P0201, P0202, P0203, P0204,

P0205, P0206, P0261, P0262, P0264,

P0265, P0267, P0268, P0270, P0271,

P0273, P0274, P0276 or P0277

P0265 Injector 2 Control Circuit High Voltage 7.14 DTC P0201, P0202, P0203, P0204,

P0205, P0206, P0261, P0262, P0264,

P0265, P0267, P0268, P0270, P0271,

P0273, P0274, P0276 or P0277

P0267 Injector 3 Control Circuit Low Voltage 7.14 DTC P0201, P0202, P0203, P0204,

P0205, P0206, P0261, P0262, P0264,

P0265, P0267, P0268, P0270, P0271,

P0273, P0274, P0276 or P0277

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007