engine ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 1604 of 6020

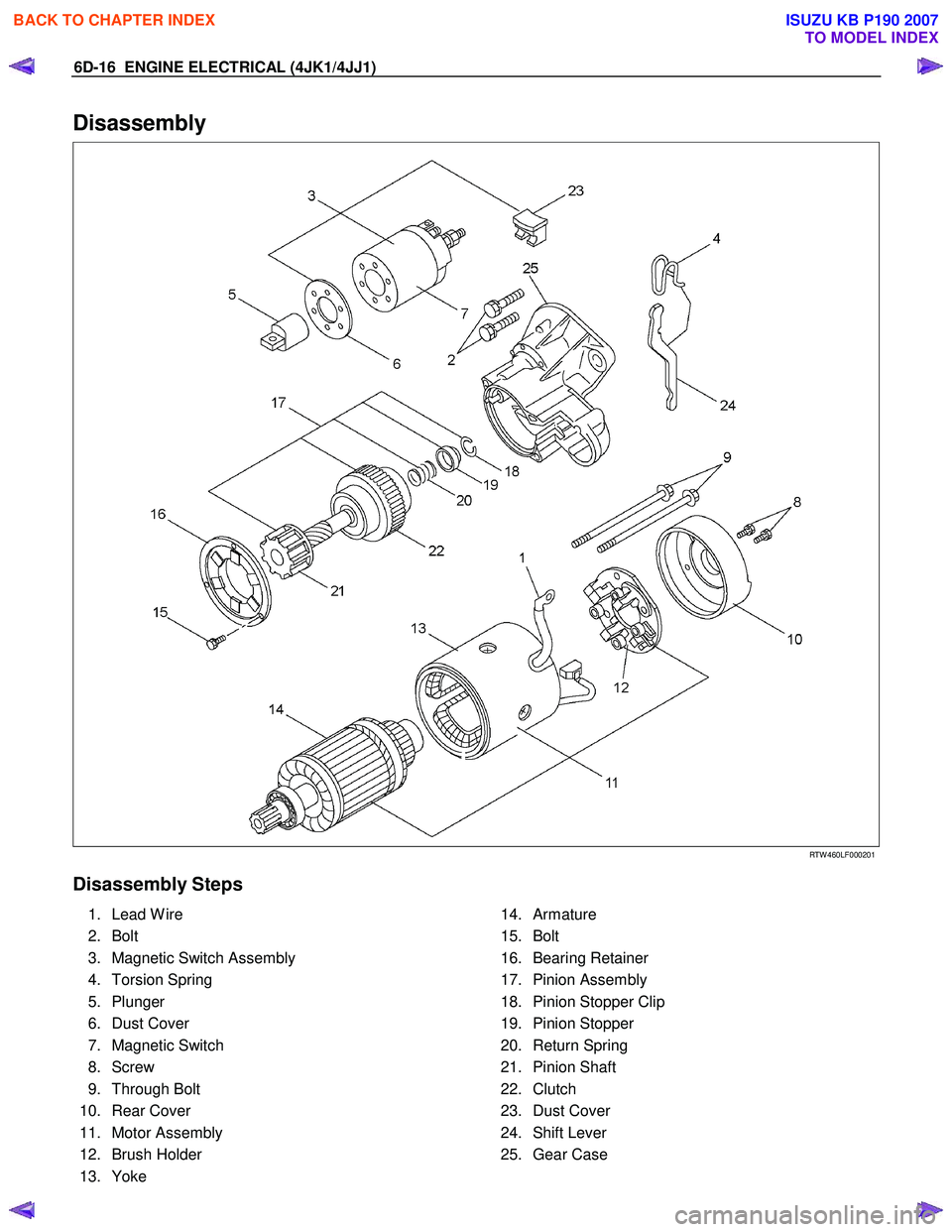

6D-16 ENGINE ELECTRICAL (4JK1/4JJ1)

Disassembly

RTW 460LF000201

Disassembly Steps

1. Lead W ire

2. Bolt

3. Magnetic Switch Assembly

4. Torsion Spring

5. Plunger

6. Dust Cover

7. Magnetic Switch

8. Screw

9. Through Bolt

10. Rear Cover

11. Motor Assembly

12. Brush Holder

13. Yoke 14. Armature

15. Bolt

16. Bearing Retainer

17. Pinion Assembly

18. Pinion Stopper Clip

19. Pinion Stopper

20. Return Spring

21. Pinion Shaft

22. Clutch

23. Dust Cover

24. Shift Lever

25. Gear Case

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1605 of 6020

ENGINE ELECTRICAL (4JK1/4JJ1) 6D-17

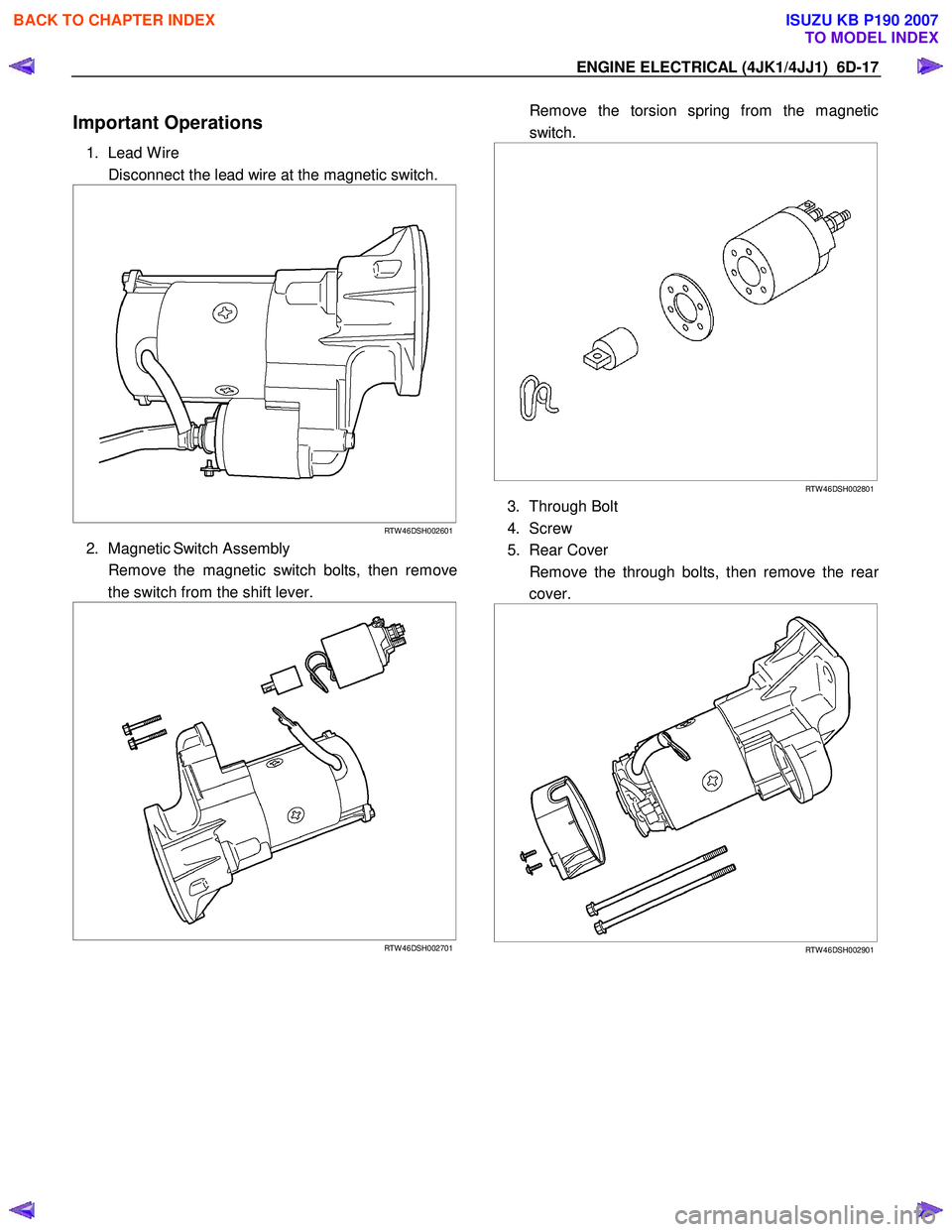

Important Operations

1. Lead W ire

Disconnect the lead wire at the magnetic switch.

RTW 46DSH002601

2. Magnetic Switch Assembly

Remove the magnetic switch bolts, then remove the switch from the shift lever.

RTW 46DSH002701

Remove the torsion spring from the magnetic

switch.

RTW 46DSH002801

3. Through Bolt

4. Screw

5. Rear Cover

Remove the through bolts, then remove the rea

r

cover.

RTW 46DSH002901

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1606 of 6020

6D-18 ENGINE ELECTRICAL (4JK1/4JJ1)

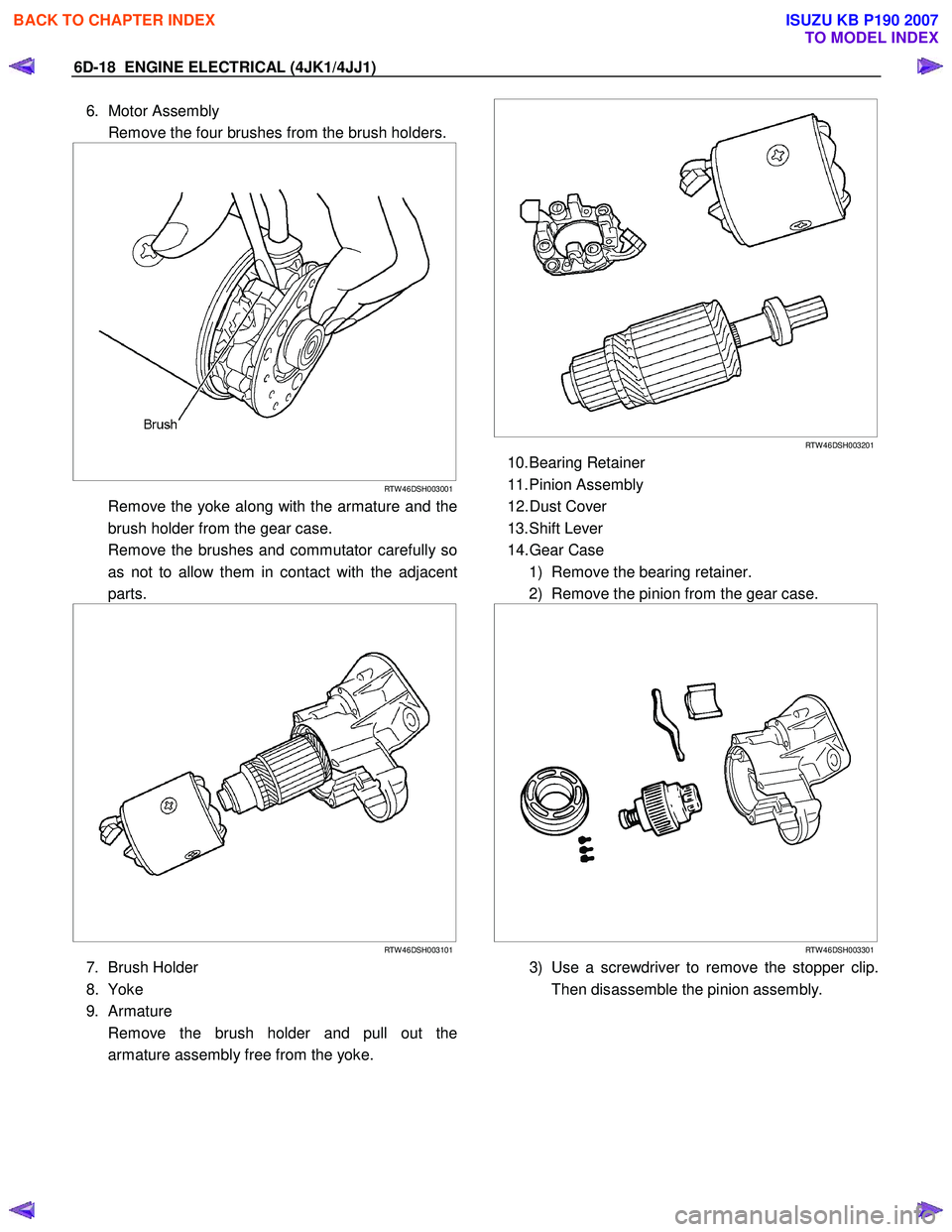

6. Motor Assembly

Remove the four brushes from the brush holders.

RTW 46DSH003001

Remove the yoke along with the armature and the

brush holder from the gear case.

Remove the brushes and commutator carefully so as not to allow them in contact with the adjacent

parts.

RTW 46DSH003101

7. Brush Holder

8. Yoke

9. Armature

Remove the brush holder and pull out the armature assembly free from the yoke.

RTW 46DSH003201

10. Bearing Retainer

11. Pinion Assembly

12. Dust Cover

13. Shift Lever

14. Gear Case 1) Remove the bearing retainer.

2) Remove the pinion from the gear case.

RTW 46DSH003301

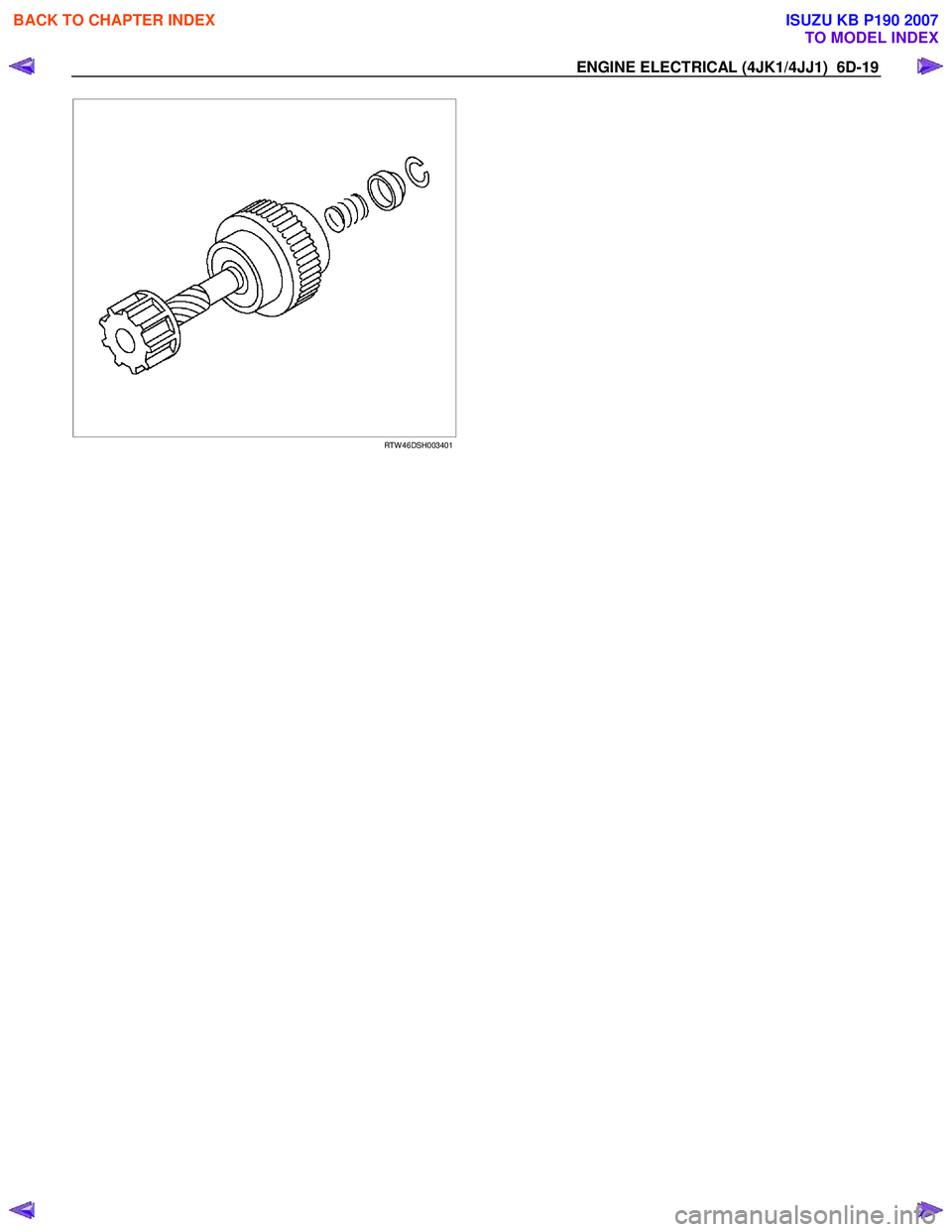

3) Use a screwdriver to remove the stopper clip.

Then disassemble the pinion assembly.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1607 of 6020

ENGINE ELECTRICAL (4JK1/4JJ1) 6D-19

RTW 46DSH003401

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1608 of 6020

6D-20 ENGINE ELECTRICAL (4JK1/4JJ1)

Inspection and Repair

Make the necessary adjustments, repairs, and part

replacement if excessive wear or damage is discovered

during inspection.

Armature

1. Measure the commutator run-out.

Replace the commutator if the measured run-out

exceeds the specified limit.

Commutator Run-Out mm (in)

Standard Limit

0.05 (0.002) 0.25 (0.010)

RTW 46DSH003501

2. Check the commutator mica segments for

excessive wear.

3. Measure the mica segment depth.

Mica Segment Depth mm (in)

Standard Limit

0.5 - 0.8 (0.020 - 0.030) 0.2 (0.008)

If the mica segment depth is less than the standard but more than the limit, the commutato

r

may be reground.

If the mica segment depth is less than the limit, the commutator must be replaced.

RTW 56DSH000701

Legend

1. Insulator

2. 0.5 - 0.8 mm (0.020 - 0.030 in)

3. Commutator Segments

4. Correct

5. Incorrect

4. Measure the commutator outside diameter.

Commutator Outside Diameter mm (in)

Standard Limit

36.5 (1.44) 35.5 (1.40)

If the measured outside diameter is less than the

specified limit, the commutator must be replaced.

HCW 51ESH000901

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1609 of 6020

ENGINE ELECTRICAL (4JK1/4JJ1) 6D-21

5. Use a circuit tester to check the armature for

grounding.

1) Hold one probe of the circuit tester against the commutator segment.

2) Hold the other circuit tester probe against the armature core.

If the circuit tester indicates continuity, the armature is grounded.

The armature must be replaced.

RTW 46DSH003601

6. Use the circuit tester to check the armature for

continuity.

1) Hold the circuit tester probes against two commutator segments.

2) Repair Step 1 at different segments of the armature core.

There should be continuity between all segments of the commutator.

If there is not, the armature must be replaced.

RTW 46DSH003701

Yoke

1. Use a circuit tester to check the field winding

ground.

1) Hold one circuit tester probe against the field winding end or brush.

2) Hold the other circuit tester probe against the bare surface of the yoke body.

There should be no continuity. If there is continuity, the field coil is grounded. The yoke

must be replaced.

RTW 46DSH003801

2. Use the circuit tester to check the field winding

continuity.

1) Hold one circuit tester probe against the “M” terminal lead wire.

2) Hold the other circuit tester probe against the field winding brush.

There should be continuity.If there is no continuity, the yoke must be replaced.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1610 of 6020

6D-22 ENGINE ELECTRICAL (4JK1/4JJ1)

RTW 46DSH003901

Brush and Brush Holder

1. Use a vernier caliper to measure the brush length

(four brushes).

Replace the brushes as a set if one or more of the brush lengths is less than the specified limit.

Brush Length mm (in)

Standard Limit

15 (0.59) 12 (0.47)

RTW 46DSH004001

2. Use a circuit tester to check the brush holder

insulation.

Touch one probe to the holder plate and the othe

r

probe to the positive brush holder.

There should be no continuity.

RTW 46DSH004101

3. Inspect the brushes for excessive wear.

If the negative brushes have excessive wear, the entire brush holder assembly must be replaced.

If the positive brushes have excessive wear, the entire yoke must be replaced.

Overrunning Clutch

1. Inspect the overrunning clutch gear teeth for

excessive wear and damage.

Replace the overrunning clutch if necessary.

2. Rotate the pinion clockwise.

It should turn smoothly.

3. Try to rotate the pinion in the opposite direction.

The pinion should lock.

065RY00035

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1611 of 6020

ENGINE ELECTRICAL (4JK1/4JJ1) 6D-23

Bearing

Inspect the bearings for excessive wear and damage.

Replace the bearings if necessary.

RTW 46DSH004401

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1612 of 6020

6D-24 ENGINE ELECTRICAL (4JK1/4JJ1)

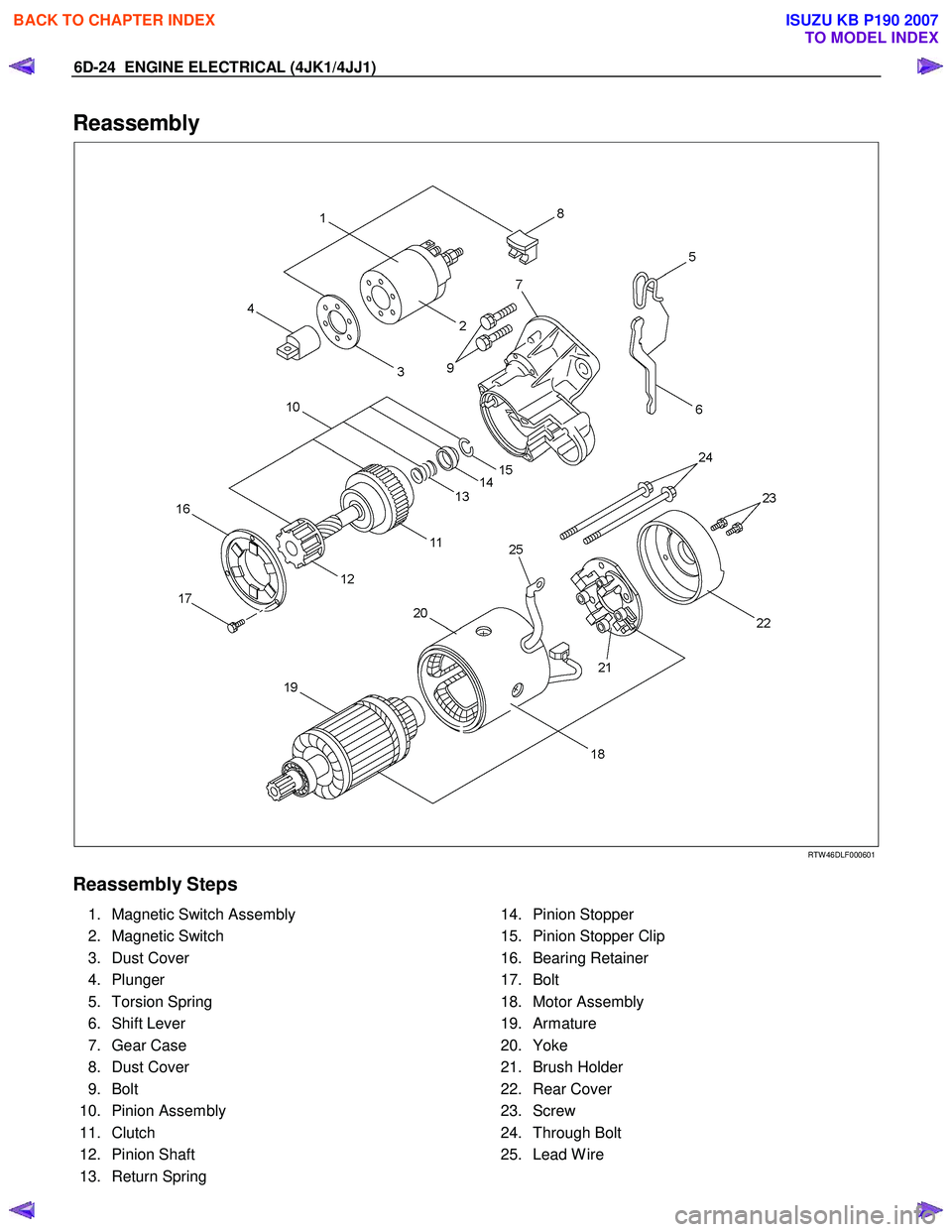

Reassembly

RTW 46DLF000601

Reassembly Steps

1. Magnetic Switch Assembly

2. Magnetic Switch

3. Dust Cover

4. Plunger

5. Torsion Spring

6. Shift Lever

7. Gear Case

8. Dust Cover

9. Bolt

10. Pinion Assembly

11. Clutch

12. Pinion Shaft

13. Return Spring 14. Pinion Stopper

15. Pinion Stopper Clip

16. Bearing Retainer

17. Bolt

18. Motor Assembly

19. Armature

20. Yoke

21. Brush Holder

22. Rear Cover

23. Screw

24. Through Bolt

25. Lead W ire

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1613 of 6020

ENGINE ELECTRICAL (4JK1/4JJ1) 6D-25

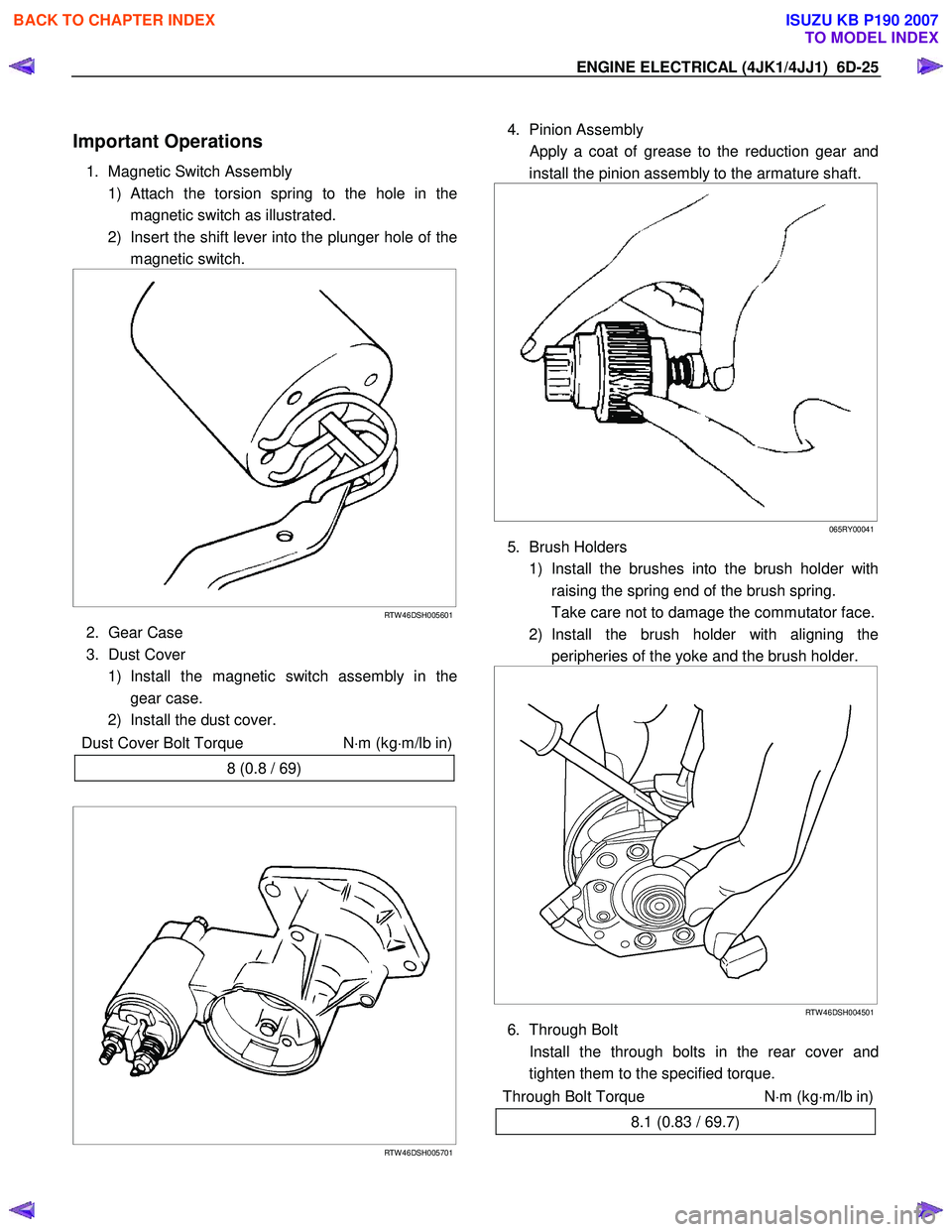

Important Operations

1. Magnetic Switch Assembly

1)

Attach the torsion spring to the hole in the

magnetic switch as illustrated.

2) Insert the shift lever into the plunger hole of the magnetic switch.

RTW 46DSH005601

2. Gear Case

3. Dust Cover 1) Install the magnetic switch assembly in the gear case.

2) Install the dust cover.

Dust Cover Bolt Torque N⋅m (kg ⋅m/lb in)

8 (0.8 / 69)

RTW 46DSH005701

4. Pinion Assembly

Apply a coat of grease to the reduction gear and

install the pinion assembly to the armature shaft.

065RY00041

5. Brush Holders

1) Install the brushes into the brush holder with raising the spring end of the brush spring.

Take care not to damage the commutator face.

2) Install the brush holder with aligning the peripheries of the yoke and the brush holder.

RTW 46DSH004501

6. Through Bolt

Install the through bolts in the rear cover and tighten them to the specified torque.

Through Bolt Torque N⋅m (kg ⋅m/lb in)

8.1 (0.83 / 69.7)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007