change time ISUZU KB P190 2007 Workshop Manual Online

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 4267 of 6020

7A1-28 CONSTRUCTION AND FUNCTION

Item Description

Learning function The learning function is provided to correct the oil pressure control timing to engage or

disengage the clutch optimally in order to compensate changes of the engine performance

and changes of the transmission with time. It is controlled to bring the shift time closer to

the value pre-set to the TCM.

Fail-safe function In the case of a malfunction of the vehicle speed sensor, APP sensor, all solenoids or the

inhibitor switch, TCM automatically begins fail-safe control to minimize effects on driving.

The gear is fixed in 3rd gear and the power supply to the solenoid is shut off so that the

solenoid does not work. Lock up clutch is disengaged in this mode.

Self-diagnosis function Parts required for controlling the automatic transmission are provided with a self-diagnosis

function. W hen any trouble occurs, the check trans indicator lamp blinks to warn the driver.

The trouble code is memorized in the TCM.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4272 of 6020

CONSTRUCTION AND FUNCTION 7A1-33

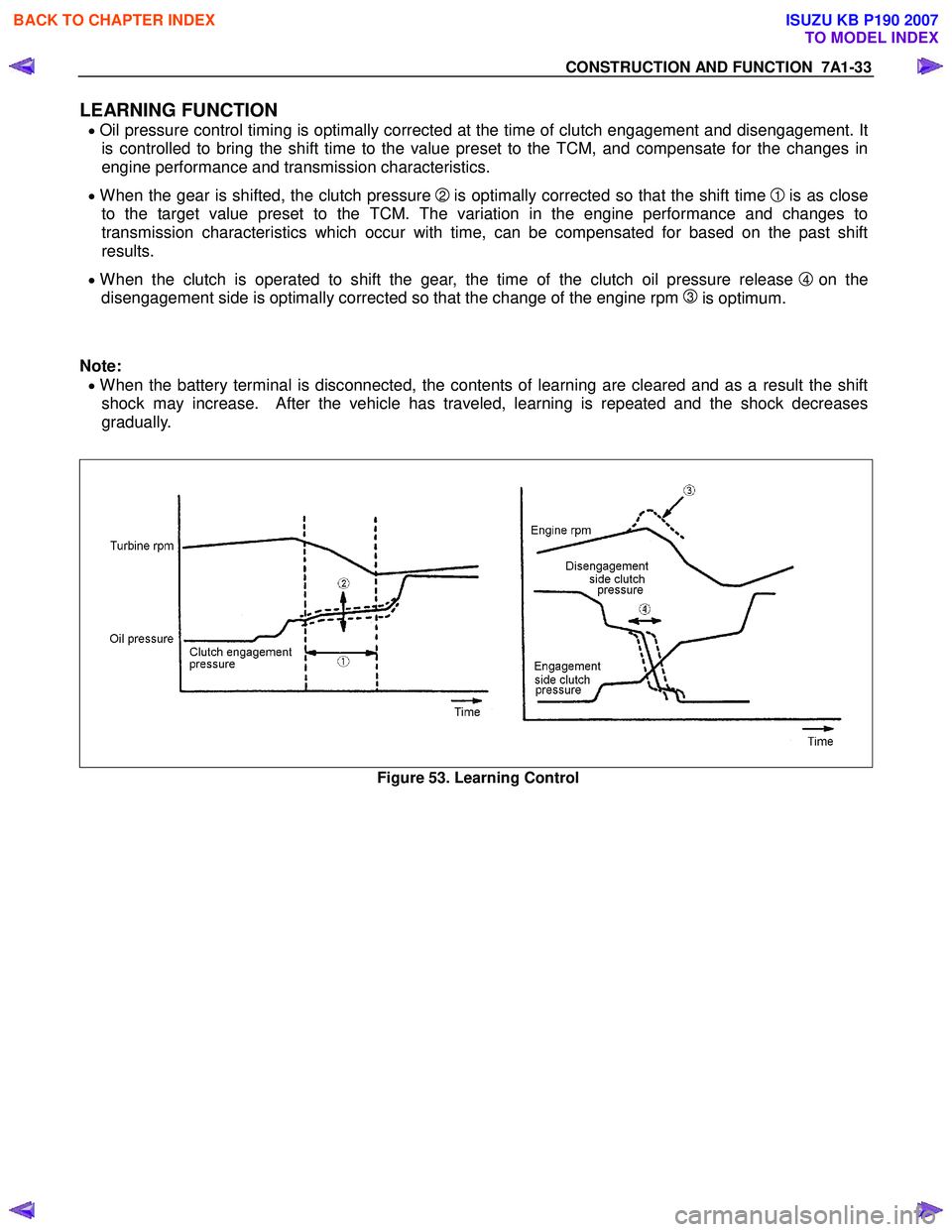

LEARNING FUNCTION

• Oil pressure control timing is optimally corrected at the time of clutch engagement and disengagement. It

is controlled to bring the shift time to the value preset to the TCM, and compensate for the changes in

engine performance and transmission characteristics.

• When the gear is shifted, the clutch pressure 2 is optimally corrected so that the shift time 1 is as close

to the target value preset to the TCM. The variation in the engine performance and changes to

transmission characteristics which occur with time, can be compensated for based on the past shift

results.

• When the clutch is operated to shift the gear, the time of the clutch oil pressure release 4 on the

disengagement side is optimally corrected so that the change of the engine rpm

3 is optimum.

Note:

• When the battery terminal is disconnected, the contents of learning are cleared and as a result the shift

shock may increase. After the vehicle has traveled, learning is repeated and the shock decreases

gradually.

Figure 53. Learning Control

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4379 of 6020

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-95

Vehicle Does Not Run

Trouble at Starting

Faulty Gearshift

Faulty Shift Pattern

No or Error Gearshift

Faulty Operation During Running

Faulty Operation in Stopping

Faulty Lock Up

No Lock Up

Transmission Fluid Leak

Others

Diagnostic CategoryCategory No.

This table consists of diagnostic categories that are located in the left column. Using this column, choose the appropriate

category based on the operating conditions of the vehicle or transmission. After selecting a category, use the right column to

locate the specific symptom diagnostic information.

Vehicle Does Not Run Vehicle does not run in D, 3, 2, L & L range A1

Vehicle does not run in R range A2

Vehicle does not run in D, 3, 2 and L range A3

Trouble at Starting Vehicle runs in N range B1

Poor acceleration at starting B2

Engine races up during starting (slip) B3

Large shock when selector lever is changed from N to D range or N to R

range B4

Engine stalls when selector lever is changed from N to R, D, 3, 2 or L

range B5

Engine does not crank in P or N range B6

Engine cranks in other than P or N range B7

Extended time lag when selector lever is changed from N to D B8

Extended time lag when selector lever is changed from N to R B9

Brake is applied in R range B10

Insufficient starting or shaking in D range B11

Noise or vibration occurs at starting B12

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4382 of 6020

7A2-98 TRANSMISSION CONTROL SYSTEM (JR405E)

A1Vehicle does not run in D, 3, 2, L & L rangeA2Vehicle does not run in R rangeA3Vehicle does not run in D, 3, 2 and L rangeB1Vehicle runs in N rangeB2Poor acceleration at startingB3Engine races up during starting (slip)B4

Large shock when selector lever is changed

from N to D range or N to R range

B5

Engine stalls when selector lever is changed

from N to R, D, 3, 2 or L range

B6 Engine does not crank in P or N rangeB7Engine cranks in other than P or N rangeB8

Extended time lag when selector lever is

changed from N to D

B9

Extended time lag when selector lever is

changed from N to R

B10 Brake is applied in R rangeB11Insufficient starting or shaking in D rangeB12Noise or vibration occurs at starting

Error, open or short circuit

Error, open or short circuit

Error, open or short circuit

Error, open or short circuit

Open or short circuit

Open or short circuit

Open or short circuit

Error, open or short circuit

Open or short circuit

Open or short circuit

Open or short circuit

Open or short circuit

Open or short circuit

Open or short circuit

Open or short circuit

Open or short circuit

Open or short circuit

Open or short circuit

Out of standard value

Faulty operation

Faulty operation

Faulty operation

Faulty operation

Faulty operation

Faulty operation

Faulty operation

Clogged passage

Clogged passage

Clogged passage

Clogged passage

Clogged passage

Clogged passage

Clogged passage

Slip

Seizure

Faulty operation

Separation

Faulty operation

Engine speed signal

Accelerator pedal position signal

Input shaft speed sensor

Output shaft speed sensor

Power drive or 3rd start switch

Transmission range switch

TCM power or ground

Transmission fluid temperature sensor

Pressure control solenoid

Torque converter clutch solenoid

Low & reverse brake solenoid

2-4 brake solenoid

High clutch solenoid

Low clutch solenoid

Ground return circuit

Low & reverse brake fluid pressure switch

2-4 brake fluid pressure switch

High clutch fluid pressure switch

Transmission fluid quantity

Control spool valve

High clutch solenoid accumulator

Low clutch solenoid accumulator

Low & reverse brake solenoid accumulator

2-4 brake solenoid accumulator

High clutch accumulator

2-4 brake accumulator

Pressure control solenoid hydraulic circuit

Torque converter clutch hydraulic circuit

High clutch solenoid hydraulic circuit

Low clutch solenoid hydraulic circuit

Low & reverse brake solenoid hydraulic circuit

2-4 brake solenoid hydraulic circuit

Oil cooler

Torque converter

Diagnostic category

Possible causes

Electrical

Disordered selector lever cable

Disordered transmission range switch

Faulty line pressure

Faulty engine idle speed

Clutch (brake)

Torque converter clutch piston

Hydraulic control

Powertrain

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4390 of 6020

7A2-106 TRANSMISSION CONTROL SYSTEM (JR405E)

B5: Engine Stalls When Selector Lever is Changed from N to R, D, 3, 2 or L Range

B6: Engine Does Not Crank in P or N Range

B7: Engine Cranks in other than P or N Range

B8: Extended Time Lag When Selector Lever is Changed from N to D

Checks Action

Definition:

The engine stalls when selector lever is changed from N or P position to a run position during engine idling.

Diagnosis Hints • As the correct cause is attributable to the engine, faulty idle up, insufficient

engine output, etc. are suspected.

• As this is a cause of the transmission, faulty torque converter clutch (TCC) piston is suspected.

• If the transmission fluid through resistance increases due to clogged oil cooler or some other reason, or if the transmission fluid level decreases, the TCC piston

works causing the engine stall.

Transmission Fluid Checks Inspect the transmission fluid for the following conditions. If the transmission fluid is

extremely blacked, contaminated or smells burnt, slipping of clutch is suspected.

• Low quantity

• Contamination

• Smell

Line Pressure Checks Inspect the line pressure in forward ranges for a possible dropped pressure. Refer to

Line Pressure Test in Test Instruction section.

Stall Speed Checks Inspect the stall speed in forward ranges. Refer to Stall Test in Test Instruction

section.

Control Valve Body Checks Inspect the valve body for the following conditions.

• Faulty operation

• Sticking lock up spool valve

• Sticking TCC solenoid valve. Perform function check. Refer to On-Vehicle Service section.

• Clogged hydraulic circuit

Additional Checks • Inspect the engine for proper outputs. Refer to appropriate inspection chart in

engine section.

• Inspect the engine for proper idle speed.

Checks Action

Definition: • The engine starter does not run even though the P or N range.

• The engine starter runs even though the R, D, 3, 2 or L range.

Transmission Range Switch & Selector

Lever Cable Checks Inspect the transmission range switch and selector lever cable for misadjusting or

disordering. Refer to On-Vehicle Service section.

Checks Action

Definition:

The shift time lag is longer than the standard value when the selector lever is changed from N to D.

Transmission Fluid Checks Inspect the transmission fluid for low quantity.

Line Pressure Checks Inspect the line pressure in D range for a possible dropped pressure. Refer to Line

Pressure Test in Test Instruction section.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4391 of 6020

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-107

B9: Extended Time Lag When Selector Lever is Changed from N to R

B10: Brake is Applied in R Range

B11: Insufficient Starting or Shaking in D Range

Control Valve Body Checks Inspect the valve body for the following conditions.

• Faulty operation

• Sticking spool valve

• Clogged hydraulic circuit

Clutch and Brake Checks Inspect the low clutch and low one-way clutch for slipping.

Solenoid Valve Checks • Inspect the low clutch solenoid valve for faulty operation.

Checks Action

Definition:

The shift time lag is longer than the standard value when the selector lever is changed from N to R.

Transmission Fluid Checks Inspect the transmission fluid for low quantity.

Line Pressure Checks Inspect the line pressure in R range for a possible dropped pressure. Refer to Line

Pressure Test in Test Instruction section.

Control Valve Body Checks Inspect the valve body for the following conditions.

• Faulty operation

• Sticking spool valve

• Clogged hydraulic circuit

Clutch and Brake Checks Inspect the low & reverse brake for slipping.

Solenoid Valve Checks • Inspect the low & reverse brake solenoid valve for faulty operation.

Checks

Action

Checks Action

Definition:

Brake is applied suddenly in R range.

Diagnosis Hints Trouble in transmission main unit is suspected. The trouble in the transmission main

unit may originate from the input circuits or output circuits; these circuits should also

be checked to prevent a reoccurrence of the trouble.

Transmission Range Switch & Selector

Lever Cable Checks Inspect the transmission range switch and selector lever cable for misadjusting or

disordering. Refer to On-Vehicle Service section.

Transmission Fluid Checks Inspect the transmission fluid for low quantity.

Control Valve Body Checks Inspect the valve body for the following conditions.

• Faulty operation

• Sticking spool valve

• Clogged hydraulic circuit

Clutch and Brake Checks Inspect the low clutch, high clutch or 2-4 brake for seizing.

Additional Checks • Inspect the parking mechanism for faulty operation.

Checks Action

Definition:

Insufficient starting or shaking in D range.

Transmission Fluid Checks Inspect the transmission fluid for low quantity.

Line Pressure Checks Inspect the line pressure in D range for a possible dropped pressure. Refer to Line

Pressure Test in Test Instruction section.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4396 of 6020

7A2-112 TRANSMISSION CONTROL SYSTEM (JR405E)

D3: Gearshift Point is Low or High at All Points

D4: Gearshift Point is Low or High at Limited Area

D5: No Kick-down

E1: No Gearshift

Checks Action

Definition: • Gearshift point is deviated from the shift speed chart.

• Gear is not shifted up properly, even though the vehicle is accelerating.

• Gear is not shifted immediately and enough acceleration cannot be obtained, even though the accelerator pedal is being stepped on.

Diagnosis Hints • Inspect the output shaft speed (OSS) sensor for faulty operation.

• Incorrect accelerator pedal position signal is suspected. Observe the Accelerator Pedal Position (APP). APP parameter should change linearly

from 0 to 99 or 100% according to the accelerator pedal operation.

Checks Action

Definition:

The engine speeds up but the vehicle speed does not increase when the accelerator pedal is being stepped on at starting.

Diagnosis Hints Incorrect accelerator pedal position signal is suspected. Observe the

Accelerator Pedal Position (APP). APP parameter should change linearly from

0 to 99 or 100% according to the accelerator pedal operation.

Checks Action

Definition: • Gear is fixed, such as no gearshift from 1st to 2nd, 2nd to 3rd, and 3rd to 4th.

• Sometimes the gear is shifted, and sometimes it is not possible.

Diagnosis Hints • Fixing at same gear speed, a signal error from the accelerator pedal

position (APP) sensor or trouble in the transmission main unit are

suspected.

• Slipping of the clutch is suspected. Gear ratio error DTC might be set.

Transmission Range Switch & Selector Lever

Cable Checks Inspect the transmission range switch and selector lever cable for misadjusting

or disordering. Refer to On-Vehicle Service section.

Transmission Fluid Checks Inspect the transmission fluid for the following conditions. If the transmission

fluid is extremely blacked, contaminated or smells burnt, slipping of clutch is

suspected.

• Low quantity

• Contamination

•Smell

Line Pressure Checks Inspect the line pressure in forward ranges for a possible dropped pressure.

Refer to Line Pressure Test in Test Instruction section.

Stall Speed Checks Inspect the stall speed in forward ranges. Refer to Stall Test in Test Instruction

section.

Control Valve Body Checks Inspect the valve body for the following conditions.

• Faulty operation

• Sticking spool valve

• Sticking shift solenoid valve. Perform function check. Refer to On-Vehicle Service section.

• Clogged hydraulic circuit

Clutch and Brake Checks Inspect the low clutch, high clutch or low & reverse brake for slipping.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4444 of 6020

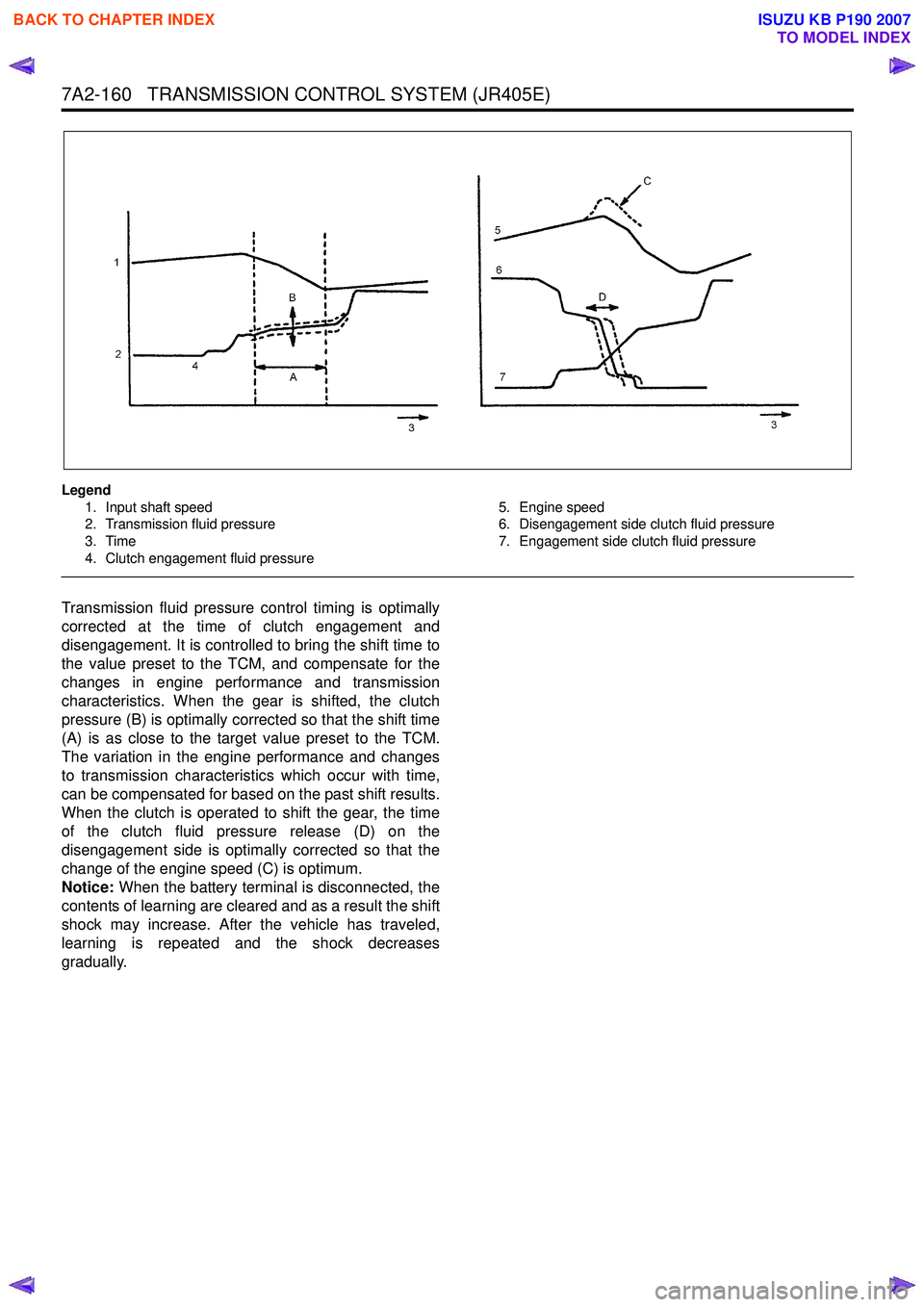

7A2-160 TRANSMISSION CONTROL SYSTEM (JR405E)

Legend1. Input shaft speed

2. Transmission fluid pressure

3. Time

4. Clutch engagement fluid pressure 5. Engine speed

6. Disengagement side clutch fluid pressure

7. Engagement side clutch fluid pressure

Transmission fluid pressure control timing is optimally

corrected at the time of clutch engagement and

disengagement. It is controlled to bring the shift time to

the value preset to the TCM, and compensate for the

changes in engine performance and transmission

characteristics. When the gear is shifted, the clutch

pressure (B) is optimally corrected so that the shift time

(A) is as close to the target value preset to the TCM.

The variation in the engine performance and changes

to transmission characteristics which occur with time,

can be compensated for based on the past shift results.

When the clutch is operated to shift the gear, the time

of the clutch fluid pressure release (D) on the

disengagement side is optimally corrected so that the

change of the engine speed (C) is optimum.

Notice: When the battery terminal is disconnected, the

contents of learning are cleared and as a result the shift

shock may increase. After the vehicle has traveled,

learning is repeated and the shock decreases

gradually.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4468 of 6020

7A3-14 ON-VEHICLE SERVICE (JR405E)

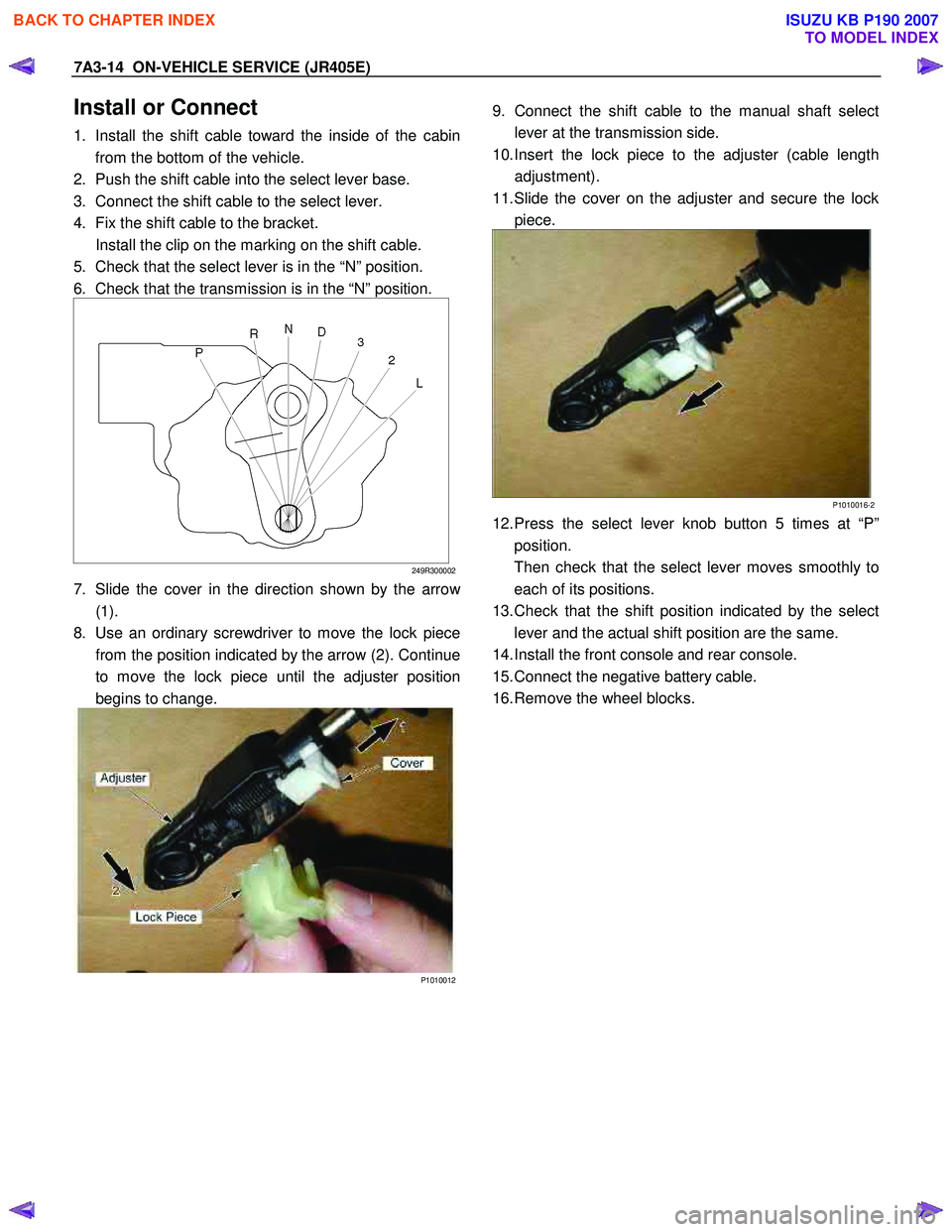

Install or Connect

1. Install the shift cable toward the inside of the cabin

from the bottom of the vehicle.

2. Push the shift cable into the select lever base.

3. Connect the shift cable to the select lever.

4. Fix the shift cable to the bracket.

Install the clip on the marking on the shift cable.

5. Check that the select lever is in the “N” position.

6. Check that the transmission is in the “N” position.

249R300002

7. Slide the cover in the direction shown by the arrow

(1).

8. Use an ordinary screwdriver to move the lock piece from the position indicated by the arrow (2). Continue

to move the lock piece until the adjuster position

begins to change.

P1010012

9. Connect the shift cable to the manual shaft select

lever at the transmission side.

10. Insert the lock piece to the adjuster (cable length adjustment).

11. Slide the cover on the adjuster and secure the lock piece.

P1010016-2

12. Press the select lever knob button 5 times at “P”position.

Then check that the select lever moves smoothly to each of its positions.

13. Check that the shift position indicated by the select lever and the actual shift position are the same.

14. Install the front console and rear console.

15. Connect the negative battery cable.

16. Remove the wheel blocks.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4538 of 6020

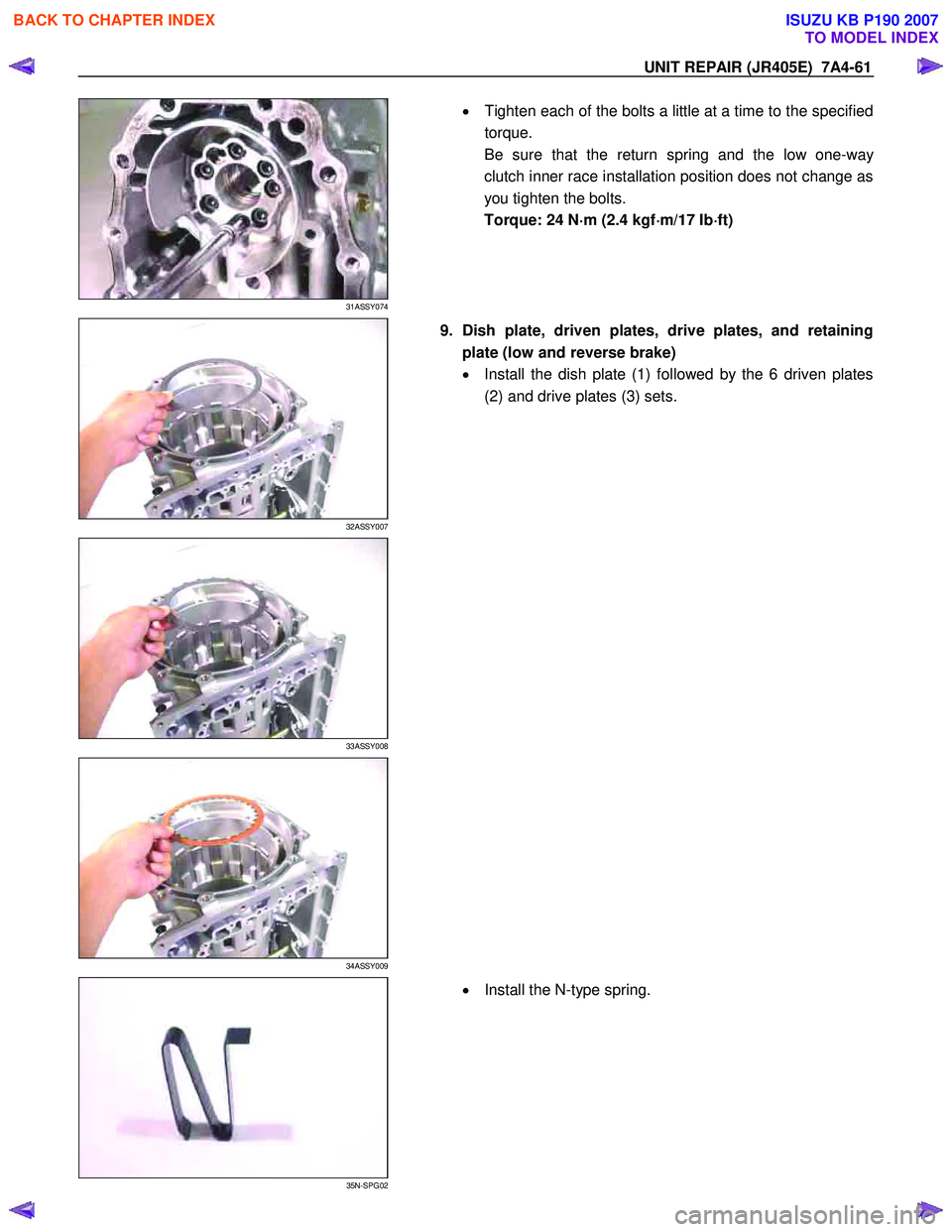

UNIT REPAIR (JR405E) 7A4-61

31ASSY074

•

Tighten each of the bolts a little at a time to the specified

torque.

Be sure that the return spring and the low one-wa

y

clutch inner race installation position does not change as

you tighten the bolts.

Torque: 24 N ⋅

⋅⋅

⋅

m (2.4 kgf ⋅

⋅⋅

⋅

m/17 Ib ⋅

⋅⋅

⋅

ft)

32ASSY007

9. Dish plate, driven plates, drive plates, and retaining

plate (low and reverse brake)

• Install the dish plate (1) followed by the 6 driven plates

(2) and drive plates (3) sets.

33ASSY008

34ASSY009

35N-SPG02

•

Install the N-type spring.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007