lock ISUZU TFS SERIES 1997 Manual Online

[x] Cancel search | Manufacturer: ISUZU, Model Year: 1997, Model line: TFS SERIES, Model: ISUZU TFS SERIES 1997Pages: 1600, PDF Size: 40.98 MB

Page 512 of 1600

CAB 10-15

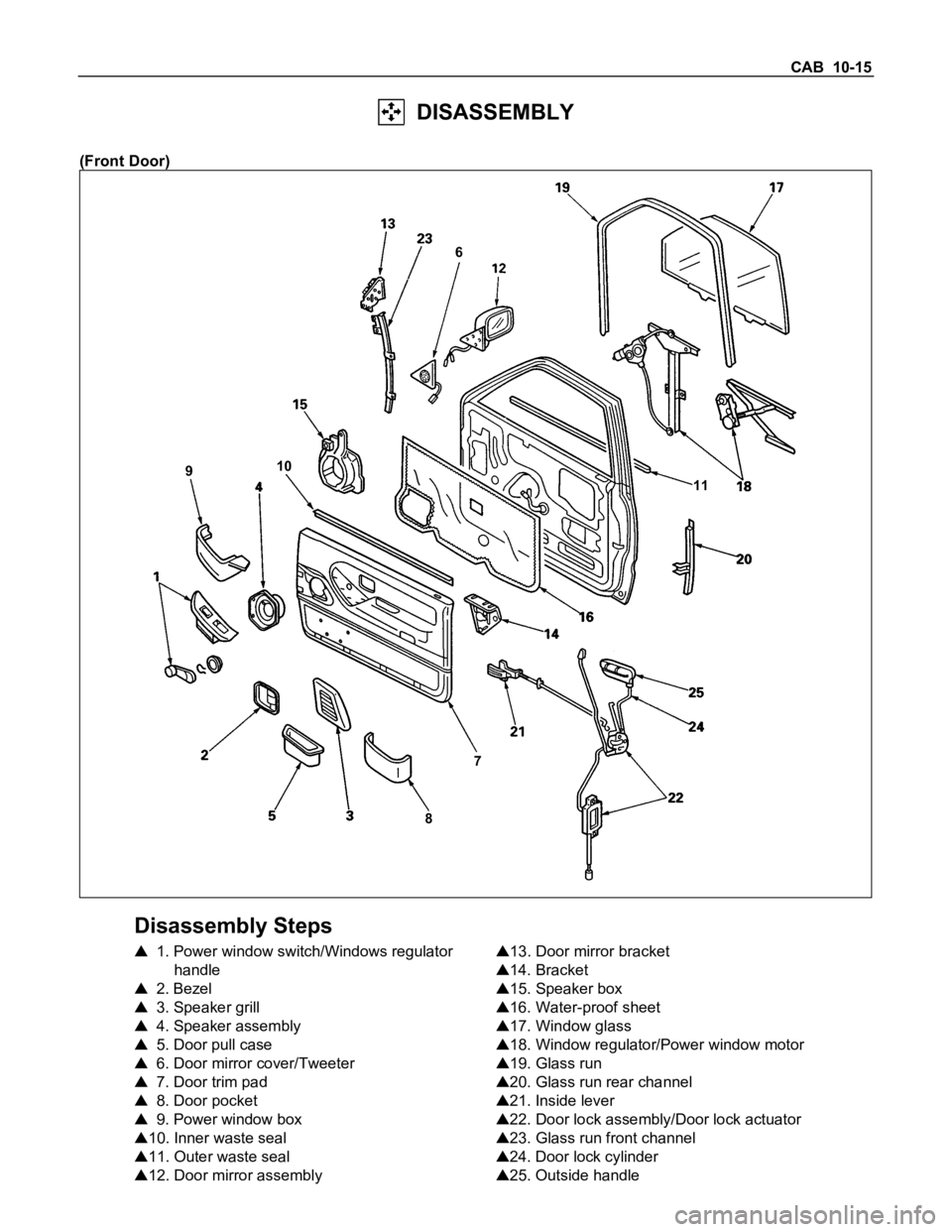

DISASSEMBLY

(Front Door)

87 910

11 6

Disassembly Steps

1. Power window switch/Windows regulator

handle

2. Bezel

3. Speaker grill

4. Speaker assembly

5. Door pull case

6. Door mirror cover/Tweeter

7. Door trim pad

8. Door pocket

9. Power window box

10. Inner waste seal

11. Outer waste seal

12. Door mirror assembly

13. Door mirror bracket

14. Bracket

15. Speaker box

16. Water-proof sheet

17. Window glass

18. Window regulator/Power window motor

19. Glass run

20. Glass run rear channel

21. Inside lever

22. Door lock assembly/Door lock actuator

23. Glass run front channel

24. Door lock cylinder

25. Outside handle

Page 515 of 1600

10-18 CAB

17.Window Glass

Remove 2 screws through the access hole and pull out

the window glass upward.

18.Window Regulator/Power Window Motor

Disconnect the power window motor connector.

19.Glass Run

Pull it out of the door piller of the channel. (front/rear)

20.Glass Run Rear Channel

Remove 2 screws.

21.Inside Lever

22.Door Lock Assembly/Door Lock Actuator

Disconnect the linkage with the outside handle, the

inside lever and the lock cylinder.

23.Glass Run Front Channel

24.Door Lock Cylinder

Remove the door lock cylinder by applying finger

pressure from inside while depressing the retaining clip.

25.Outside Handle

Page 516 of 1600

CAB 10-19

DISASSEMBLY AND REASSEMBLY

(Rear Door)

3

2

910 181219 13

1716

15 14

6

5 4 1611

7

68

Disassembly Steps

1.Power window switch/Window regurator

handle

2. Speaker grill

3. Speaker

4. Bezel

5. Inside pull handole

6. Door trim pad

7. Arm rest sm

8. Bracket

9. Water proof sheet

10. Glass guide

11. Upper cover

12. Window regurator/Power window motor

13. Window glass

14. Bracket15. Inside lever

16. Outside handle

17. Door lock cylinder

18. Outer waste seal

19. Glass run

Reassembly Steps

To reassemble, follow the disassembly steps

in the reverse order.

Page 518 of 1600

CAB 10-21

13.Window Glass

First, align the height of regulator to the access hole.

Remove 2 screws attaching bottom channel and

regulator, then remove the glass.

Remove the window glass by tilting it as necessary.

17.Door Lock Assembly

Disconnect the linkage from the door outside handle,

inside lever and lock cylinder.

Remove the 2 bolts holding the outside handle from

inner side.

Remove the 3 bolts holding the door lock assembly.

Page 520 of 1600

CAB 10-23

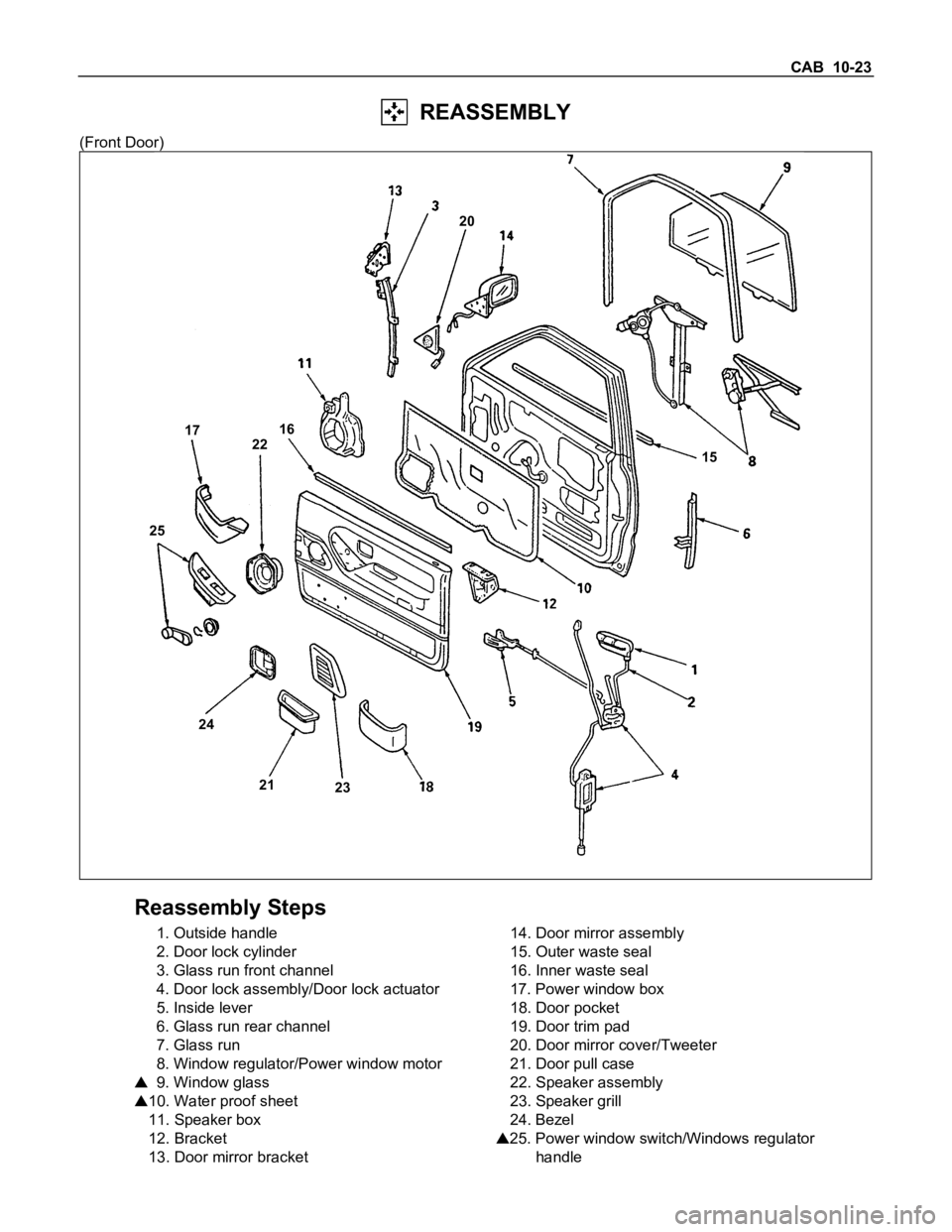

REASSEMBLY

(Front Door)

15

23 21 24 2522 171620

Reassembly Steps

1. Outside handle

2. Door lock cylinder

3. Glass run front channel

4. Door lock assembly/Door lock actuator

5. Inside lever

6. Glass run rear channel

7. Glass run

8. Window regulator/Power window motor

9. Window glass

10. Water proof sheet

11. Speaker box

12. Bracket

13. Door mirror bracket14. Door mirror assembly

15. Outer waste seal

16. Inner waste seal

17. Power window box

18. Door pocket

19. Door trim pad

20. Door mirror cover/Tweeter

21. Door pull case

22. Speaker assembly

23. Speaker grill

24. Bezel

25. Power window switch/Windows regulator

handle

Page 543 of 1600

CLUTCH 7C-3

GENERAL DESCRIPTION

HYDRAULIC CONTROL TYPE

HEC Engine Series4J Engine Series

6VD1

The clutch assembly consists of the pressure plate, the clutch cover, the diaphragm spring pivot pin and the driven

plate assembly.

The clutch pedal is connected to the shift block through the clutch shaft and the shift fork.

The driven plate assembly is installed between the flywheel and the pressure plate.

Diaphragm spring pressure holds the driven plate against flywheel and the pressure plate to provide the friction

necessary to engage the clutch.

Depressing the clutch pedal moves the shift fork against the shift block.

The shift block forces the release bearing against the diaphragm to overcome the force of the diaphragm spring and

separate the driven plate from the flywheel and pressure plate to disengage the clutch.

Except 6VD1 (3.2L) engine model, the conventional push-type clutch is used.

For 6VD1 (3.2L) engine model, the pull-type clutch is employed. The pull-type clutch is disengaged by pulling the

release lever (release bearing) to disengage the pressure plate.

Page 553 of 1600

CLUTCH 7C-13

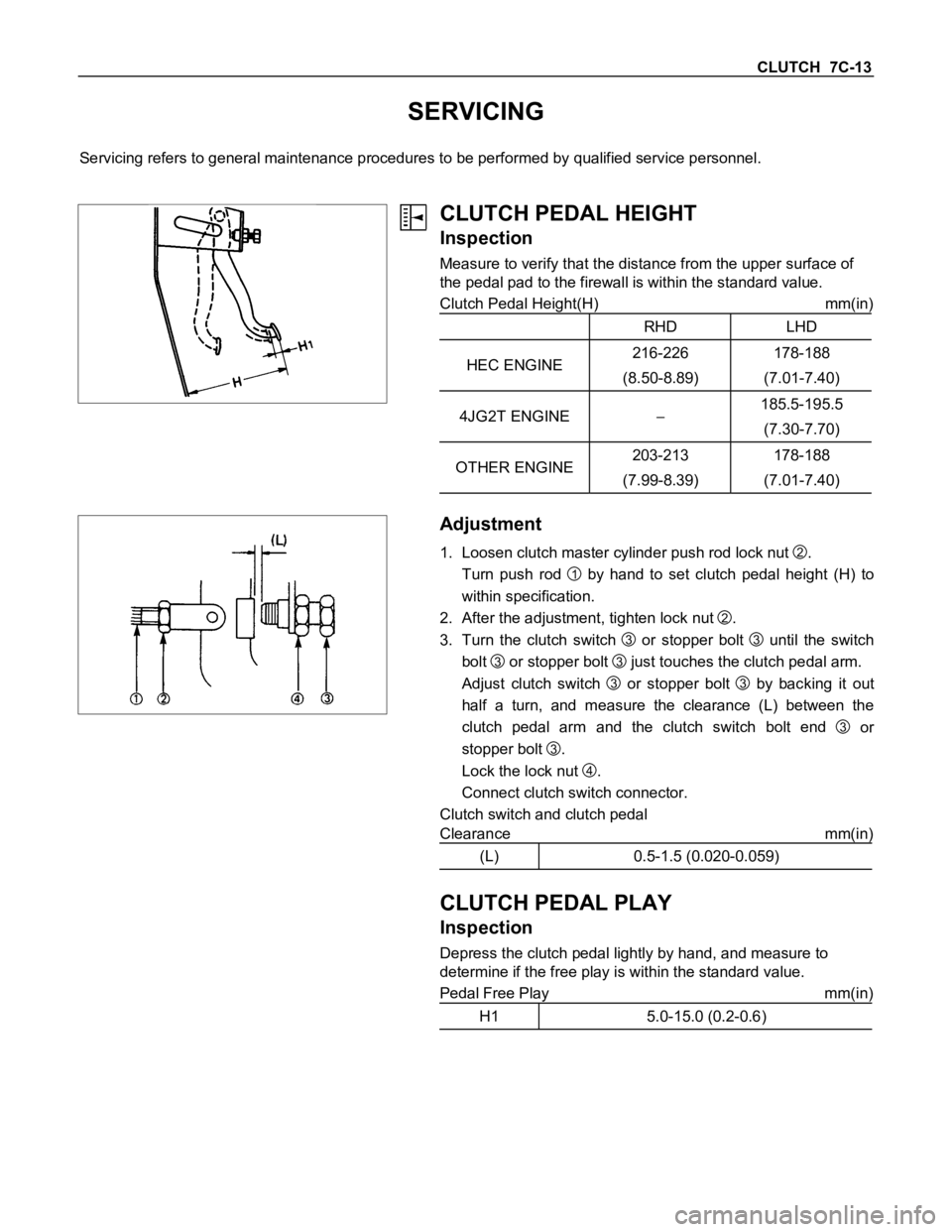

SERVICING

Servicing refers to general maintenance procedures to be performed by qualified service personnel.

CLUTCH PEDAL HEIGHT

Inspection

Measure to verify that the distance from the upper surface of

the pedal pad to the firewall is within the standard value.

Clutch Pedal Height(H) mm(in)

RHD LHD

HEC ENGINE216-226

(8.50-8.89)178-188

(7.01-7.40)

4JG2T ENGINE185.5-195.5

(7.30-7.70)

OTHER ENGINE203-213

(7.99-8.39)178-188

(7.01-7.40)

Adjustment

1. Loosen clutch master cylinder push rod lock nut

2.

Turn push rod

1 by hand to set clutch pedal height (H) to

within specification.

2. After the adjustment, tighten lock nut

2.

3. Turn the clutch switch

3 or stopper bolt

3 until the switch

bolt

3 or stopper bolt

3 just touches the clutch pedal arm.

Adjust clutch switch

3 or stopper bolt

3 by backing it out

half a turn, and measure the clearance (L) between the

clutch pedal arm and the clutch switch bolt end

3 or

stopper bolt

3.

Lock the lock nut

4.

Connect clutch switch connector.

Clutch switch and clutch pedal

Clearance mm(in)

(L) 0.5-1.5 (0.020-0.059)

CLUTCH PEDAL PLAY

Inspection

Depress the clutch pedal lightly by hand, and measure to

determine if the free play is within the standard value.

Pedal Free Play mm(in)

H1 5.0-15.0 (0.2-0.6)

Page 563 of 1600

CLUTCH 7C-23

Release Bearing Replacement

Removal (Except 6VD1)

Use the bearing puller and the adapter to remove the release

bearing.

Bearing Puller : 5-8840-0013-0 (J-22888)

Adapter : 5-8840-0124-0 (J-2241-11)

Release Bearing Installation (Except 6VD1)

1. Set the release bearing to the shift block bearing fitting

surfaces.

The release bearing must be perfectly horizontal.

2. Use a bench press to fit the release bearing to the shift

block.

Install the parts as illustrated after applying wheel bearing

grease or multi-purpose type grease (NLGI No.2 or No.3).

6VD1Release Bearing (6VD1)

1. Visually check the release bearing for excessive play, noise

and breakage.

If any of these conditions are discovered, the release

bearing must be replaced.

6VD1NOTE:

When replacing the release bearing, replace both the

wedge collar and wire ring at the same time.

Page 564 of 1600

7C-24 CLUTCH

Wedge Collar (6VD1)

1. Visually check the surfaces of the wedge collar making

contact with the release bearing for excessive wear and

damage.

2. Replace any exhibiting excessive wear damage.

Shift Fork (Except 6VD1)

1. Visually inspect the surfaces of the shift fork making contact

with the shift block for excessive wear and damage.

2. Remove any minor stepping or abrasion from the shift block

with an oil stone.

Replace any exhibiting excessive wear or damage.

3. Apply multi-purpose type grease (NLGI No.2 or No.3) to

area.

6VD1Shift Fork (6VD1)

1. Visually check the surfaces of the shift fork making contact

with the release bearing for excessive wear and damage.

2. Remove any minor stepping or abrasion from shift fork with

an oil stone.

Replace any exhibiting excessive wear of damage.

DRIVEN PLATE ASSEMBLY

1. Visually inspect the torsion spring

1 for looseness,

breakage, and weakening.

If any of these conditions are discovered, the driven plate

assembly must be replaced.

2. Visually inspect the facing surfaces

2 for cracking and

excessive scorching.

Visually inspect the facing surfaces for the presence of oil or

grease.

If any of these conditions are discovered, the facing must be

cleaned or replaced.

Page 565 of 1600

CLUTCH 7C-25

3. Check that the driven plate moves smoothly on the

transmission top gear shaft spline.

Minor ridges on the top gear shaft spline may be removed

with an oil stone.

Driven Plate Warpage

1. Insert the clutch pilot aligner into the driven plate splined

hub.

The clutch pilot aligner must be held perfectly horizontal.

Clutch Pilot Aligner : 5-8840-2634-0 (HEC Engine Series)

5-8525-3001-0 (J-24547) (Except HEC Engine Series)

2. Set a dial indicator to the driven plate outside

circumference.

3. Slowly turn the driven plate.

Read the dial indicator as you turn the driven plate.

If the measured value exceeds the specified limit, the driven

plate assembly and/or the facing must be replaced.

Driven Plate Warpage mm(in)

Standard Limit

0.7 (0.028) 1.0 (0.039)

Driven Plate Splined Hub Spline Wear

1. Clean the driven plate splined hub.

2. Install the driven plate to the transmission top gear shaft

spline.

3. Set a surface gauge to the driven plate outside

circumference.

4. Slowly turn the driven plate counterclockwise.

Measure the spline rotation play as you turn the driven

plate.

If the measured value exceeds the specified limit, the driven

plate assembly must be replaced.

Driven Plate Splined Hub Spline Wear mm(in)

Standard Limit

0.5 (0.020) 1.0 (0.039)