ISUZU TROOPER 1998 Service Repair Manual

Manufacturer: ISUZU, Model Year: 1998, Model line: TROOPER, Model: ISUZU TROOPER 1998Pages: 3573, PDF Size: 60.36 MB

Page 141 of 3573

AIR CONDITIONING 1B Ð 15

COMPRESSOR LEAKS

If leaks are located around the compressor shaft seal or

shell, replace or repair the compressor.

RECOVERY, RECYCLING, EVACUATION AND

CHARGING

Handling Refrigerant-134a (HFC-134a)

Air conditioning systems contain HFC-134a.

This is a chemical mixture which requires special

handling procedures to avoid personal injury.

·Always wear safety goggles and protective gloves.

·Always work in a well-ventilated area. Do not weld or

steam clean on or near any vehicle-installed air

conditioning lines or components.

·If HFC-134a should come in contact with any part of

the body, flush the exposed area with cold water and

immediately seek medical help.

·If it is necessary to transport or carry any container of

HFC-134a in a vehicle, do not carry it in the passenger

compartment.

·If it is necessary to fill a small HFC-134a container

from a large one, never fill the container completely.

Space should always be allowed above the liquid for

expansion.

·Keep HFC-134a containers stored below 40 ¡C (104¡F).

LEAK AT REFRIGERANT LINE CONNECTIONS

1) Check the torque on the refrigerant line fitting and, if

too loose, tighten to the specified torque.

·Use two wrenches to prevent twisting and damage

to the Line.

·Do not over tighten.

2) Perform a leak test on the refrigerant line fitting.

3) If the leak is still present, discharge and recover the

refrigerant from the system.

4) Replace the O-rings.

·O-rings cannot be reused. Always replace with

new ones.

·Be sure to apply specified compressor oil to the

new O-rings.

5) Retighten the refrigerant line fitting to the specified

torque.

·Use two wrenches to prevent twisting and damage

to the line.

6) Evacuate, charge and retest the system.

LEAK IN THE HOSE

If the compressor inlet or outlet hose is leaking, the entire

hose must be replaced. Refrigerant hose must not be cut

or spliced for repair.

1) Locate the leak.

2) Discharge and recover the refrigerant.

3) Remove the hose assembly.

·Cap the open connections at once.

4) Connect the new hose assembly.

·Use two wrenches to prevent twisting or damage

to the hose fitting.

·Tighten the hose fitting to the specified torque.

5) Evacuate, charge and test the system.

Page 142 of 3573

1B Ð 16 AIR CONDITIONING

WARNING

·SHOULD HFC-134a CONTACT YOUR EYE(S),

CONSULT A DOCTOR IMMEDIATELY.

·DO NOT RUB THE AFFECTED EYE(S). INSTEAD,

SPLASH QUANTITIES OF FRESH COLD WATER

OVER THE AFFECTED AREA TO GRADUALLY

RAISE THE TEMPERATURE OF THE

REFRIGERANT ABOVE THE FREEZING POINT.

·OBTAIN PROPER MEDICAL TREATMENT AS

SOON AS POSSIBLE. SHOULD THE HFC-134a

TOUCH THE SKIN, THE INJURY MUST BE

TREATED THE SAME AS SKIN WHICH HAS

BEEN FROSTBITTEN OR FROZEN.

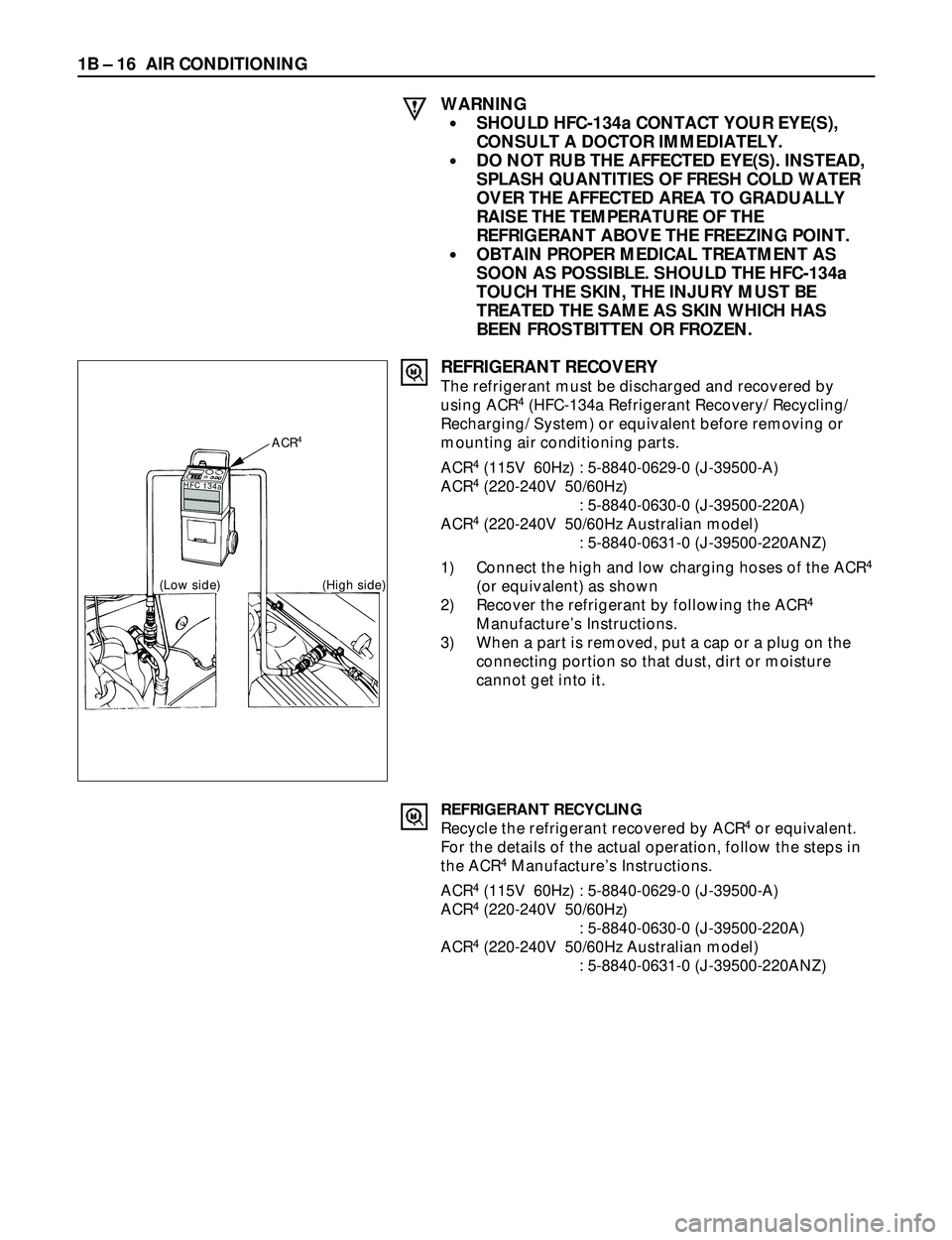

REFRIGERANT RECOVERY

The refrigerant must be discharged and recovered by

using ACR4(HFC-134a Refrigerant Recovery/ Recycling/

Recharging/ System) or equivalent before removing or

mounting air conditioning parts.

ACR

4(115V 60Hz) : 5-8840-0629-0 (J-39500-A)

ACR4(220-240V 50/60Hz)

: 5-8840-0630-0 (J-39500-220A)

ACR

4(220-240V 50/60Hz Australian model)

: 5-8840-0631-0 (J-39500-220ANZ)

1) Connect the high and low charging hoses of the ACR

4

(or equivalent) as shown

2) Recover the refrigerant by following the ACR4

ManufactureÕs Instructions.

3) When a part is removed, put a cap or a plug on the

connecting portion so that dust, dirt or moisture

cannot get into it.

ACR4

(Low side) (High side)

HFC 134a

REFRIGERANT RECYCLING

Recycle the refrigerant recovered by ACR4or equivalent.

For the details of the actual operation, follow the steps in

the ACR

4ManufactureÕs Instructions.

ACR

4(115V 60Hz) : 5-8840-0629-0 (J-39500-A)

ACR4(220-240V 50/60Hz)

: 5-8840-0630-0 (J-39500-220A)

ACR

4(220-240V 50/60Hz Australian model)

: 5-8840-0631-0 (J-39500-220ANZ)

Page 143 of 3573

AIR CONDITIONING 1B Ð 17

7) Check to ensure that the pressure does not change

after 10 minutes or more.

·If the pressure changes, check the system for leaks.

·If leaks occur, retighten the refrigerant line

connections and repeat the evacuation steps.

8) If no leaks are found, again operate the vacuum

pump for 20 minutes or more, After confirming that

the gauge manifold pressure is at 750 mmHg(30

inHg), close both hand valves.

9) Close positive shutoff valve.

Stop the vacuum pump and disconnect the center

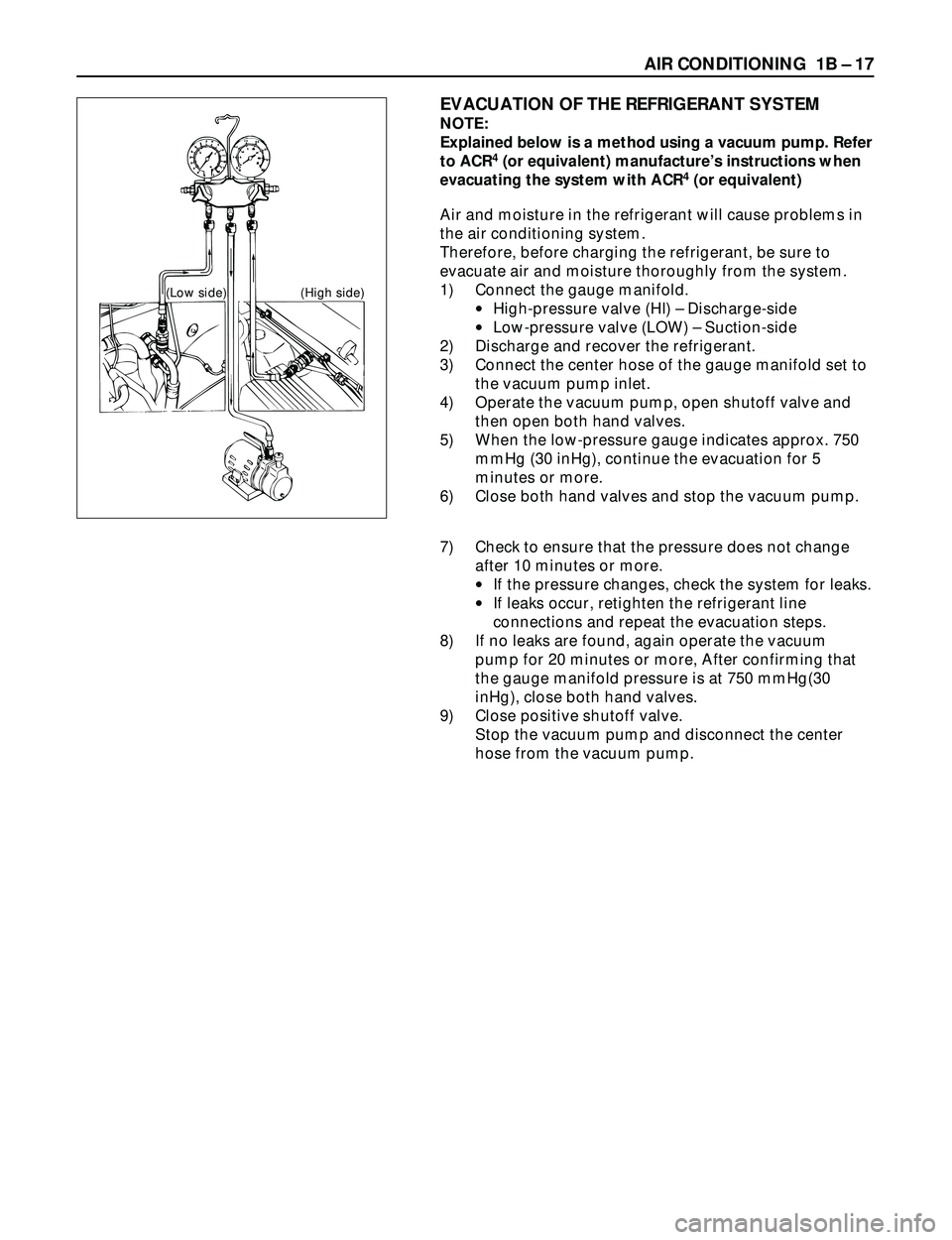

hose from the vacuum pump. Air and moisture in the refrigerant will cause problems in

the air conditioning system.

Therefore, before charging the refrigerant, be sure to

evacuate air and moisture thoroughly from the system.

1) Connect the gauge manifold.

·High-pressure valve (HI) Ð Discharge-side

·Low-pressure valve (LOW) Ð Suction-side

2) Discharge and recover the refrigerant.

3) Connect the center hose of the gauge manifold set to

the vacuum pump inlet.

4) Operate the vacuum pump, open shutoff valve and

then open both hand valves.

5) When the low-pressure gauge indicates approx. 750

mmHg (30 inHg), continue the evacuation for 5

minutes or more.

6) Close both hand valves and stop the vacuum pump.

EVACUATION OF THE REFRIGERANT SYSTEM

NOTE:

Explained below is a method using a vacuum pump. Refer

to ACR

4(or equivalent) manufactureÕs instructions when

evacuating the system with ACR4(or equivalent)

(Low side) (High side)

Page 144 of 3573

1B Ð 18 AIR CONDITIONING

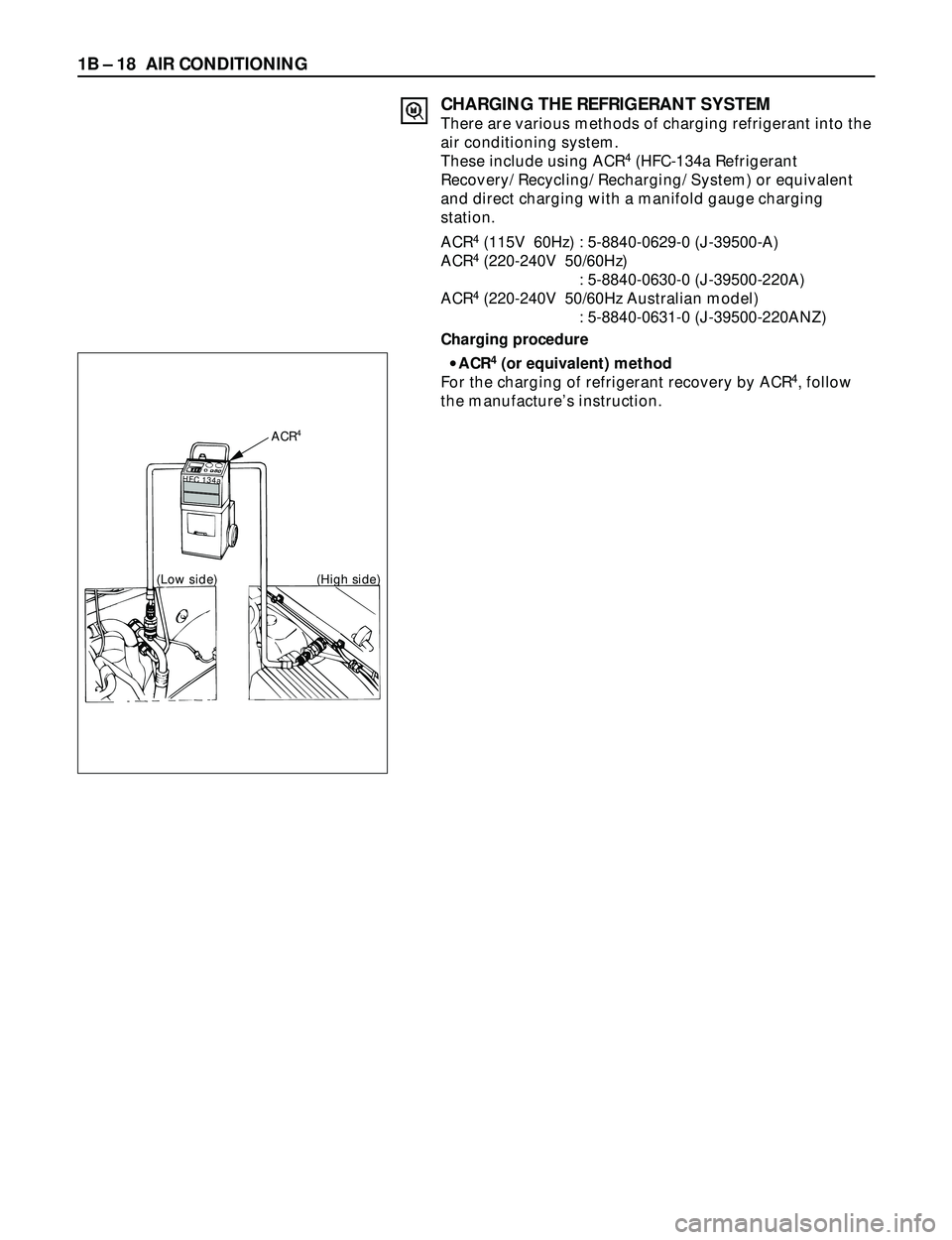

CHARGING THE REFRIGERANT SYSTEM

There are various methods of charging refrigerant into the

air conditioning system.

These include using ACR

4(HFC-134a Refrigerant

Recovery/ Recycling/ Recharging/ System) or equivalent

and direct charging with a manifold gauge charging

station.

ACR

4(115V 60Hz) : 5-8840-0629-0 (J-39500-A)

ACR4(220-240V 50/60Hz)

: 5-8840-0630-0 (J-39500-220A)

ACR

4(220-240V 50/60Hz Australian model)

: 5-8840-0631-0 (J-39500-220ANZ)

Charging procedure

·ACR4(or equivalent) method

For the charging of refrigerant recovery by ACR4, follow

the manufactureÕs instruction.

ACR4

(Low side) (High side)

HFC 134a

Page 145 of 3573

AIR CONDITIONING 1B Ð 19

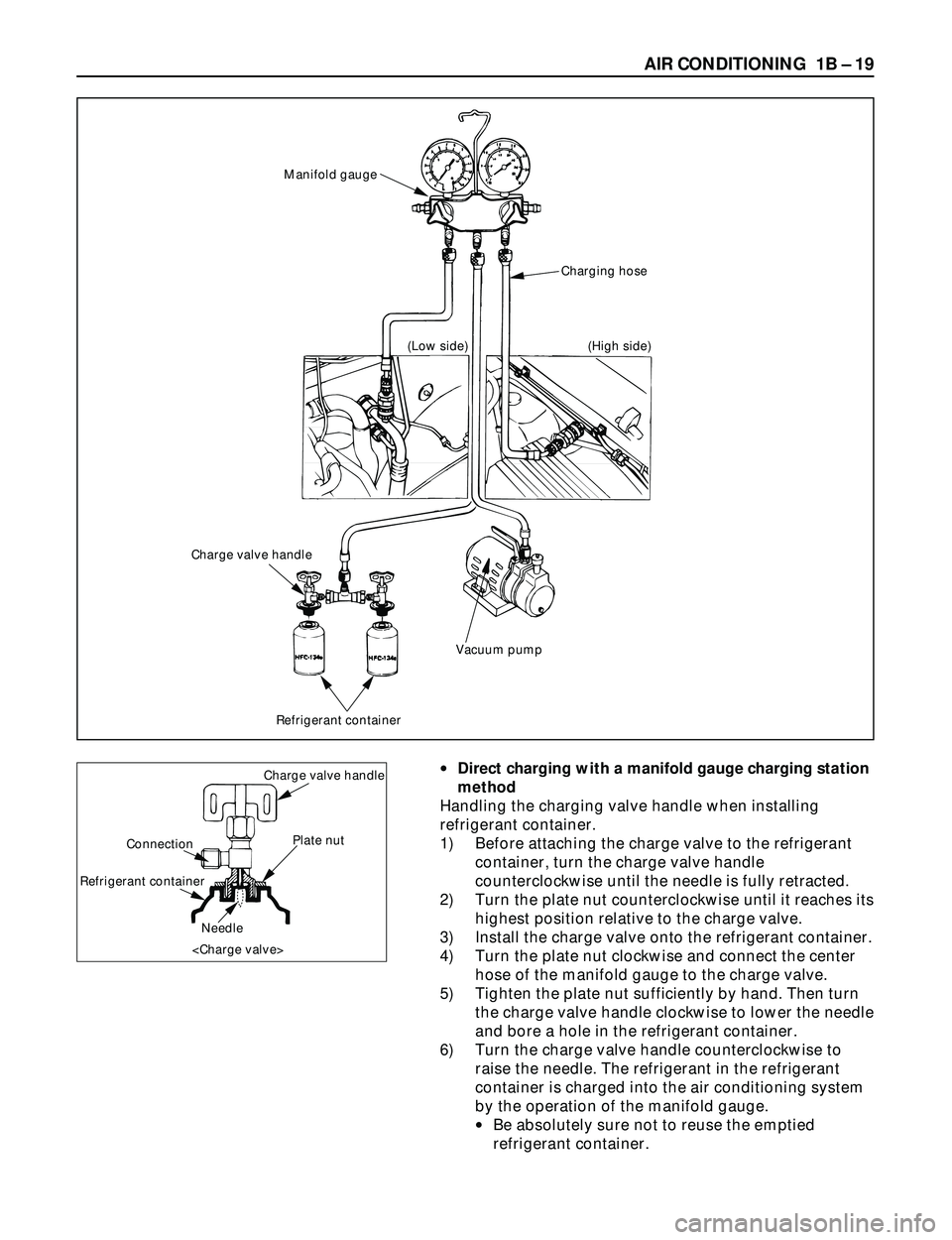

·Direct charging with a manifold gauge charging station

method

Handling the charging valve handle when installing

refrigerant container.

1) Before attaching the charge valve to the refrigerant

container, turn the charge valve handle

counterclockwise until the needle is fully retracted.

2) Turn the plate nut counterclockwise until it reaches its

highest position relative to the charge valve.

3) Install the charge valve onto the refrigerant container.

4) Turn the plate nut clockwise and connect the center

hose of the manifold gauge to the charge valve.

5) Tighten the plate nut sufficiently by hand. Then turn

the charge valve handle clockwise to lower the needle

and bore a hole in the refrigerant container.

6) Turn the charge valve handle counterclockwise to

raise the needle. The refrigerant in the refrigerant

container is charged into the air conditioning system

by the operation of the manifold gauge.

·Be absolutely sure not to reuse the emptied

refrigerant container.Charge valve handle

Plate nut

Needle Connection

Refrigerant container

Charging hose Manifold gauge

Vacuum pump

Refrigerant container

Charge valve handle

(Low side) (High side)

Page 146 of 3573

1B Ð 20 AIR CONDITIONING

1) Make sure the evacuation process is correctly

completed.

2) Connect the center-hose of the manifold gauge to the

refrigerant container.

·Turn the charge valve handle counterclockwise to

purge the charging line and purge any air existing

in the center-hose of the manifold gauge.

3) Open the low-pressure hand valve and charge the

refrigerant about 200 g(0.44 lbs.).

·Make sure the high-pressure hand valve is closed.

·Avoid charging the refrigerant by turning the

refrigerant container upside down.

4) Close the low-pressure hand valve of the manifold

gauge.

·Check to ensure that the degree of pressure does

not charge.

5) Check the refrigerant leaks by using a HFC-134a leak

detector.

·If a leak occurs, repair the leak connection, and

start all over again from the first step of

evacuation.

6) If no leaks are found, open the low-pressure hand

valve of the manifold gauge.Then continue charging

refrigerant to the system.

·When charging the system becomes difficult:

(1) Run the engine at Idling and close the all

vehicle doors.

(2) A/C switch is ÒONÓ.

(3) Set the fan control knob (fan switch) to its

highest position.

WARNING

BE ABSOLUTELY SURE NOT TO OPEN THE HIGH-

PRESSURE HAND VALVE. SHOULD THE HIGH-

PRESSURE HAND VALVE BE OPENED, THE HIGH-

PRESSURE REFRIGERANT GAS WOULD FLOW

BACKWARD, AND THIS MAY CAUSE THE

REFRIGERANT CONTAINER TO BURST.

7) When the refrigerant container is emptied, use the

following procedure to replace it with a new

refrigerant container.

(1) Close the low pressure hand valve.

(2) Raise the needle upward and remove the charge

valve.

(3) Reinstall the charge valve to the new refrigerant

container.

(4) Purge any air existing in the center hose of the

manifold gauge.

Page 147 of 3573

AIR CONDITIONING 1B Ð 21

8) Charge the system to the specified amount and then

close the low-pressure hand valve.

Refrigerant Amount g(lbs.)

750 (1.65)

DELPH1HD6/HT6 g(lbs.)

600 (1.32)

·A fully charged system is indicated by the sight

glass on the receiver/driver being free of any.

bubbles(Refer to ÒReading Sight GlassÓ).

·Check the high and low pressure value of the

manifold gauge.

·Check for refrigerant leaks by using a HFC-134a

leak detector.

Immediately after charging refrigerant, both high and low

pressures are slightly high and to the left of the gauge, but

they settle down to the guide pressure valves as shown

below:

·Ambient temperature; 25 ~30¡C (77 ~86¡F)

·Guide pressure

High-pressure side;

Approx. 1373 Ð 1863 kPa (14 Ð 19 kgácm

2/ 199 Ð 270 PSI)

Low-pressure side;

Approx. 147 Ð 294 kPa (1.4 Ð 3.0 kgácm

2/ 21 Ð 43 PSI)

9) Close the low pressure hand valve and charge valve

of the refrigerant container.

10) Stop the air conditioning and the engine.

11) Disconnect the high and low pressure hoses from the

manifold gauge fittings.

Page 148 of 3573

1B Ð 22 AIR CONDITIONING

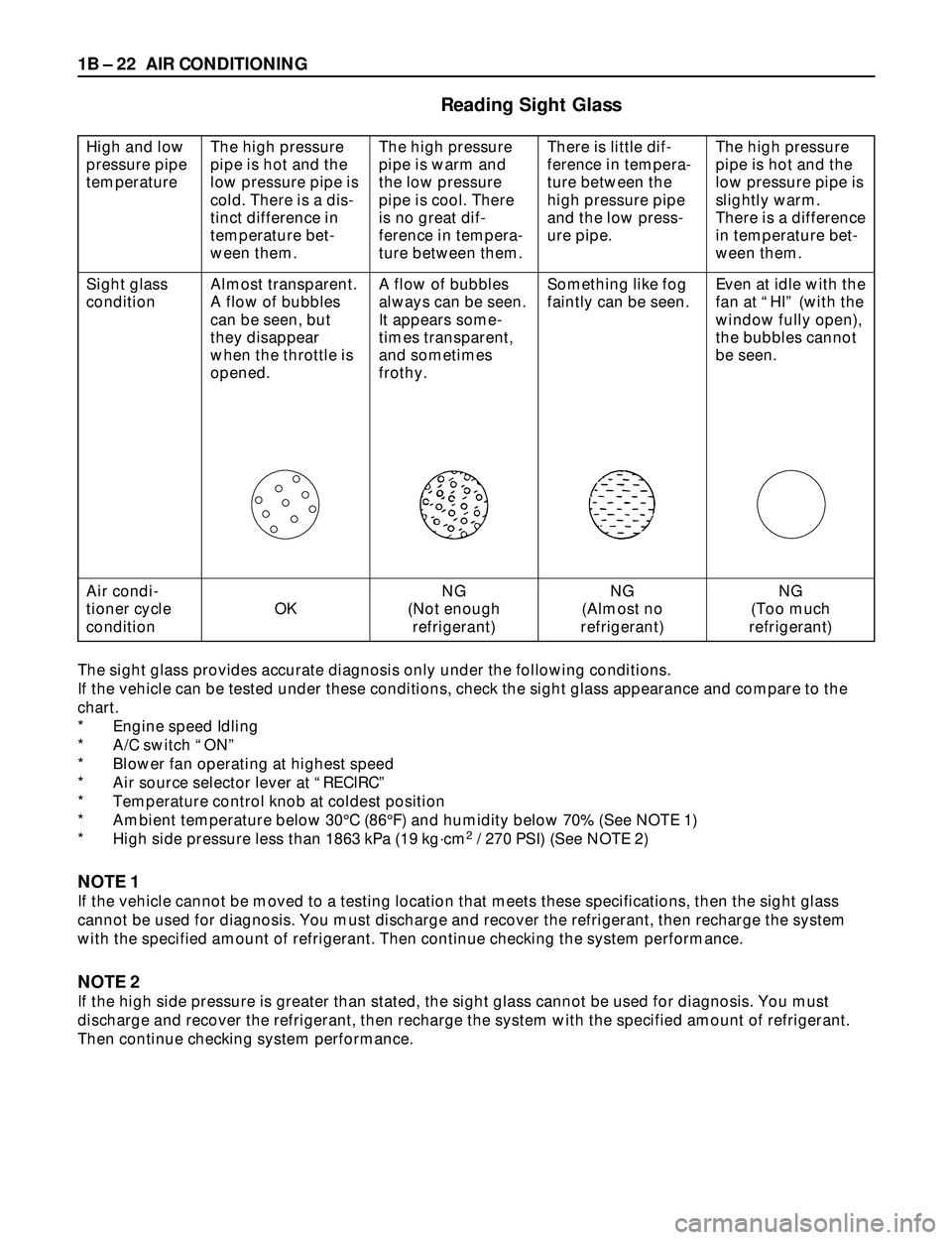

Almost transparent.

A flow of bubbles

can be seen, but

they disappear

when the throttle is

opened.

The sight glass provides accurate diagnosis only under the following conditions.

If the vehicle can be tested under these conditions, check the sight glass appearance and compare to the

chart.

* Engine speed Idling

* A/C switch ÒONÓ

* Blower fan operating at highest speed

* Air source selector lever at ÒRECIRCÓ

* Temperature control knob at coldest position

* Ambient temperature below 30¡C (86¡F) and humidity below 70% (See NOTE 1)

* High side pressure less than 1863 kPa (19 kgácm

2/ 270 PSI) (See NOTE 2)

NOTE 1

If the vehicle cannot be moved to a testing location that meets these specifications, then the sight glass

cannot be used for diagnosis. You must discharge and recover the refrigerant, then recharge the system

with the specified amount of refrigerant. Then continue checking the system performance.

NOTE 2

If the high side pressure is greater than stated, the sight glass cannot be used for diagnosis. You must

discharge and recover the refrigerant, then recharge the system with the specified amount of refrigerant.

Then continue checking system performance.

Reading Sight Glass

High and low

pressure pipe

temperature

Sight glass

condition

Air condi-

tioner cycle

condition

The high pressure

pipe is hot and the

low pressure pipe is

cold. There is a dis-

tinct difference in

temperature bet-

ween them.

OK

The high pressure

pipe is warm and

the low pressure

pipe is cool. There

is no great dif-

ference in tempera-

ture between them.

A flow of bubbles

always can be seen.

It appears some-

times transparent,

and sometimes

frothy.

NG

(Not enough

refrigerant)

There is little dif-

ference in tempera-

ture between the

high pressure pipe

and the low press-

ure pipe.

Something like fog

faintly can be seen.

NG

(Almost no

refrigerant)

The high pressure

pipe is hot and the

low pressure pipe is

slightly warm.

There is a difference

in temperature bet-

ween them.

Even at idle with the

fan at ÒHIÓ (with the

window fully open),

the bubbles cannot

be seen.

NG

(Too much

refrigerant)

Page 149 of 3573

AIR CONDITIONING 1B Ð 23

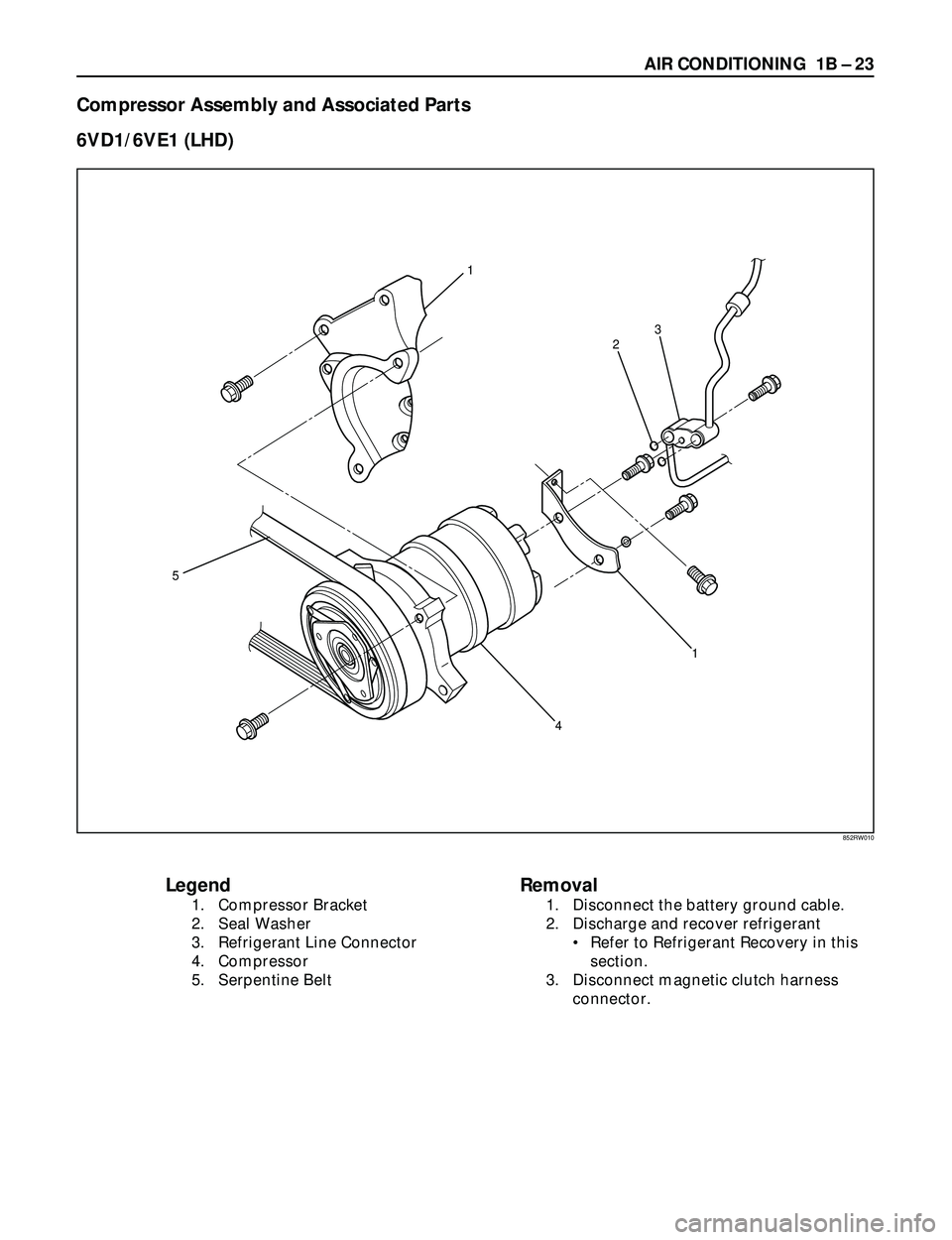

Legend

1. Compressor Bracket

2. Seal Washer

3. Refrigerant Line Connector

4. Compressor

5. Serpentine Belt

Removal

1. Disconnect the battery ground cable.

2. Discharge and recover refrigerant

¥ Refer to Refrigerant Recovery in this

section.

3. Disconnect magnetic clutch harness

connector.

Compressor Assembly and Associated Parts

6VD1/6VE1 (LHD)

1

5

23

4

1

852RW010

Page 150 of 3573

1B Ð 24 AIR CONDITIONING

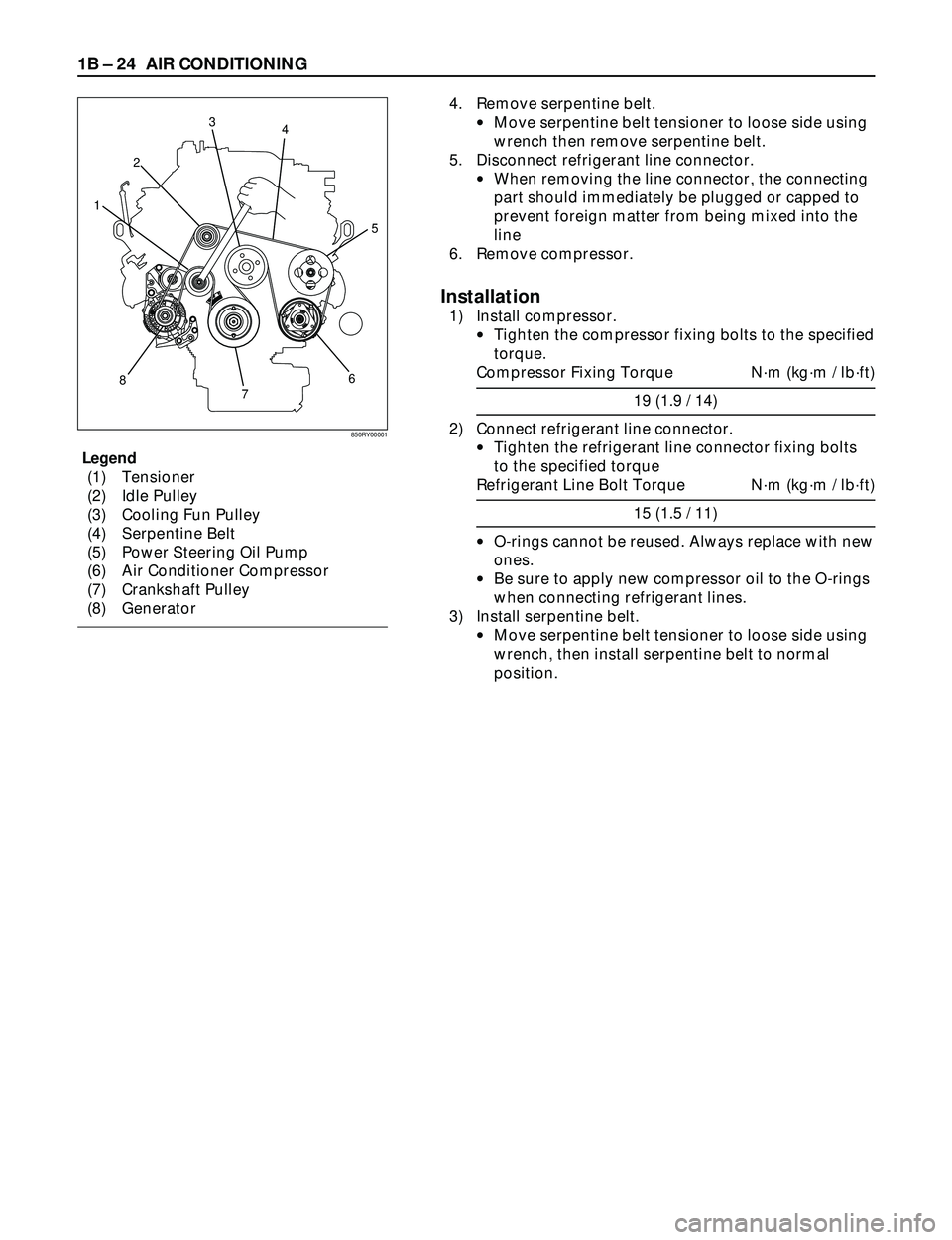

3

4

2

7 86 1

5

4. Remove serpentine belt.

·Move serpentine belt tensioner to loose side using

wrench then remove serpentine belt.

5. Disconnect refrigerant line connector.

·When removing the line connector, the connecting

part should immediately be plugged or capped to

prevent foreign matter from being mixed into the

line

6. Remove compressor.

Installation

1) Install compressor.

·Tighten the compressor fixing bolts to the specified

torque.

Compressor Fixing Torque Nám (kgám / lbáft)

19 (1.9 / 14)

2) Connect refrigerant line connector.

·Tighten the refrigerant line connector fixing bolts

to the specified torque

Refrigerant Line Bolt Torque Nám (kgám / lbáft)

15 (1.5 / 11)

·O-rings cannot be reused. Always replace with new

ones.

·Be sure to apply new compressor oil to the O-rings

when connecting refrigerant lines.

3) Install serpentine belt.

·Move serpentine belt tensioner to loose side using

wrench, then install serpentine belt to normal

position.

850RY00001

Legend

(1) Tensioner

(2) Idle Pulley

(3) Cooling Fun Pulley

(4) Serpentine Belt

(5) Power Steering Oil Pump

(6) Air Conditioner Compressor

(7) Crankshaft Pulley

(8) Generator