JAGUAR X308 1998 2.G Owners Manual

X308 1998 2.G

JAGUAR

JAGUAR

https://www.carmanualsonline.info/img/21/7640/w960_7640-0.png

JAGUAR X308 1998 2.G Owners Manual

Page 1323 of 2490

With EM007 and EM046 disconnected, measure the resistance between EM046/014 and EM007/006 1

Is the resistance < 0.5 OHM?

Yes GO to I4

No Inspect harness / connectors EM007 and EM046 for damage,

corrosion, bent / pushed back pins. Repair as necessary and

test the system for normal operation.

I4: CHECK INPUT SPEED SENSOR COIL CONTINUITY

Page 1324 of 2490

With, EM007 disconnected, measure the sensor value

between EM007/042 and EM007/014 1

Is the resistance between 280 and 1200 OHM?

Yes GO to I5

No Renew the input speed sensor

I5: CHECK HARNESS +VE CONTIN UITY (OUTPUT SPEED SENSOR)

Page 1325 of 2490

With EM007 and EM046 disconnected, measure the resistance between EM046/001 and EM007/016 1

Is the resistance < 0.5 OHM?

Yes Reconnect EM046

GO to I6

No Inspect harness / connectors EM007 and EM046 for damage,

corrosion, bent / pushed back pins. Repair as necessary and

test the system for normal operation.

I6: CHECK HARNESS -VE CONTINUITY (OUTPUT SPEED SENSOR)

Page 1326 of 2490

With EM007 and EM046 disconnected, measure the resistance between EM046/010 and EM007/044 1

Is the resistance < 0.5 OHM?

Yes GO to I7

No Inspect EM007 and EM046 for corrosion, bent / pushed back

pins or locate and repair th e harness Test the system for

normal operation

I7: CHECK OUTPUT SPEED SENSOR COIL CONTINUITY

Page 1327 of 2490

With, EM007 disconnected, measure the sensor value

between EM007/016 and EM007/044 1

Is the resistance between 280 and 1200 OHM?

Yes GO to I8

No Renew the output speed sensor

I8: CHECK FOR SHORT TO B+

Page 1348 of 2490

Automatic Transmission/Transaxle - 4.0L NA V8 - AJ27/3.2L NA V8 - AJ26

- Main Control Valve Body

In-vehicle Repair

Removal

1. Disconnect battery ground cable.

Remove the battery cover.

2. Raise the vehicle for access.

2. WARNING: TRANSMISSION FLUID MAY CAUSE

SEVERE BURNS, ENSURE THAT ALL SAFETY PROCEDURES

ARE OBSERVED.

Carefully remove the drain plug and drain the

transmission fluid.

3. Remove the twenty-two bolts which secure the fluid pan.

Remove the fluid pan and all tr aces of gasket material.

4. Remove the fluid filter, (44.24.07).

5. Remove the input speed sensor.

• NOTE: M5 fixing.

1. Remove the screw from the input speed sensor securing bracket and pu ll the sensor clear.

Disconnect the harness multiplug.

Page 1349 of 2490

6. Remove the output speed sensor.

• NOTE: M6 fixing.

1. Remove the screw from the output speed sensor

securing bracket and pu ll the sensor clear.

Disconnect the harness multiplug.

7. Disconnect the five pressure regulator connectors and three

solenoid connectors.

8. Reposition the internal harness for access.

Release the internal harness from the retaining clips.

9. Drain the valve body.

1. Position a suitable drain tin below the valve body.

2. Slacken (do not remove) the twenty-two screws, valve body to transmission case.

Allow the fluid to drain.

10. Remove the valve body.

Remove five M6 X 30 screws, valve body to transmission

case.

Remove seventeen M6 X 60 screws, valve body to

transmission case.

Page 1350 of 2490

Installation

1. Installation is the re verse of the removal procedure, noting the

following steps.

2. Fit the valve body retaining screws.

Note the location of the five screws M6 X 30. Fit and

tighten to the specified torque figure.

Note the location of the seve nteen screws M6 X 60. Fit and tighten to the specified torque figure.

3. NOTE: M6 fixing.

Fit the output speed sensor and tighten the retaining screw to

the specified to rque figure..

4. NOTE: M5 fixing.

Page 1351 of 2490

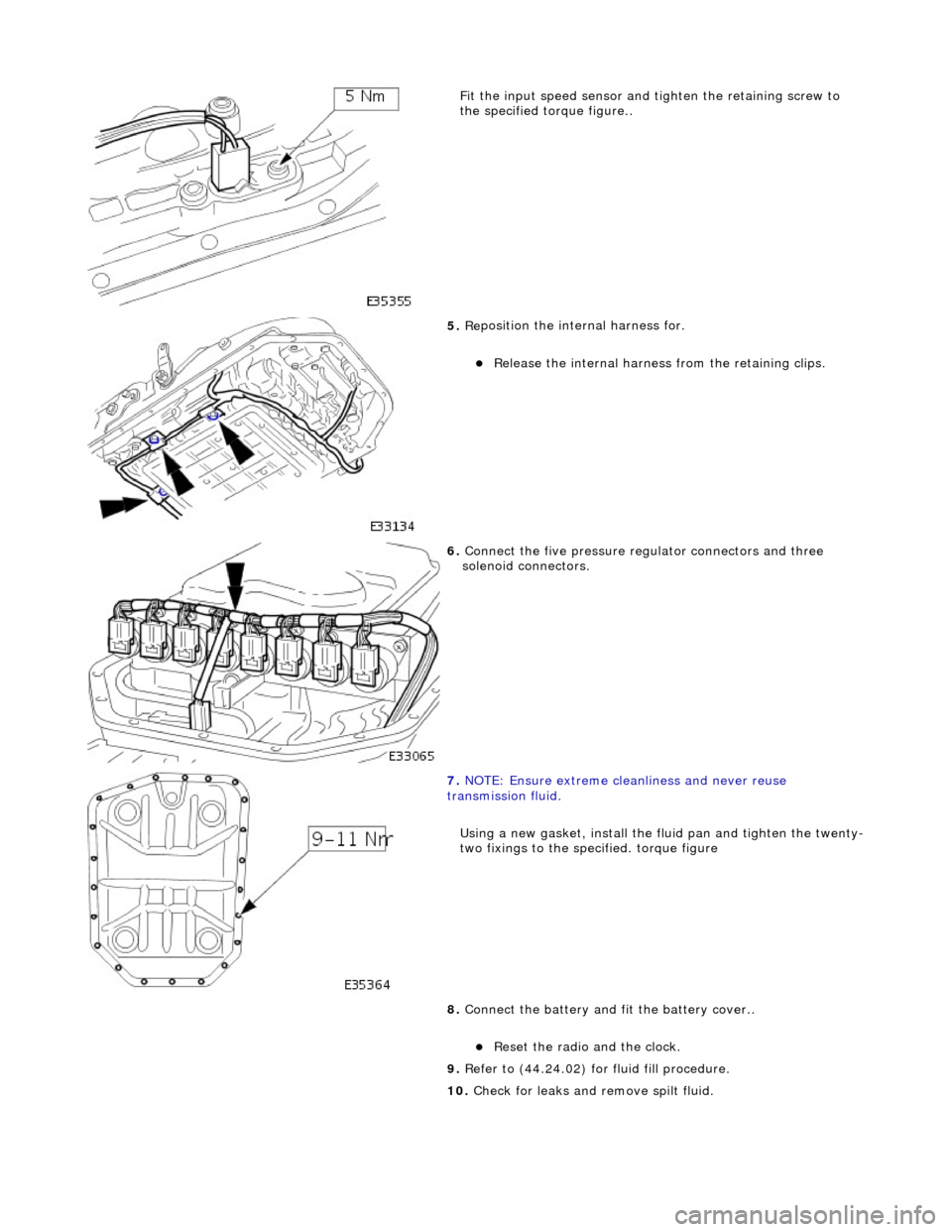

Fit the inpu

t speed sensor and

tighten the retaining screw to

the specified to rque figure..

5. Re

position the inte

rnal harness for.

R

elease the internal harness

from the retaining clips.

6. Connect

the five pressure re

gulator connectors and three

solenoid connectors.

7. N

OTE: Ensure extreme clea

nliness and never reuse

transmission fluid.

Using a new gasket, install the fl uid pan and tighten the twenty-

two fixings to the specified. torque figure

8. Connect the battery and fit the battery cover..

Reset th

e radio and the clock.

9. Refer to (44.24.02) for fluid fill procedure.

10. Check for leaks and remove spilt fluid.

Page 1352 of 2490

Automatic Transmission/Transaxle - 4.0L NA V8 - AJ27/3.2L NA V8 - AJ26

- Output Shaft Speed (OSS) Sensor

In-vehicle Repair

Removal

1. Disconnect battery ground cable.

Remove the battery cover.

2. Raise the vehicle on a lift.

2. WARNING: TRANSMISSION FLUID MAY CAUSE

SEVERE BURNS, ENSURE THAT ALL SAFETY PROCEDURES

ARE OBSERVED.

Carefully remove the drain plug and drain the

transmission fluid.

3. Remove the twenty-two bolts which secure the fluid pan.

Remove the fluid pan and all tr aces of gasket material.

4. Remove the output speed sensor.

• NOTE: M6 fixing.

1. Release the screw which secures the output speed sensor bracket and pull the sensor clear.

5. Disconnect the multiplug from the speed sensor.