Speed Sensor JAGUAR X308 1998 2.G Repair Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1179 of 2490

generates a signal when th

e dr

ive plate passes the sensor

sen

ds the ECM signals indicating crankshaft position and engine speed

is e

ssential for calculating spark timing

En

gine Coolant Temperature (ECT) Sensor

sen

ds the ECM a signal indicating the temperature of the engine coolant

is a t

emperature dependent resistor with a negative temperature coefficient (resistance changes inversely with

respect to temperature) and is constantly monitored by the ECM

Intake Air Temperature (IAT) Sensor

is m

ounted in the same housing as the MA

F sensor but is not a serviceable item

sen

ds the ECM a signal indicating the temperature of the air entering the engine

is a t

emperature dependent resistor which has a negative

temperature coefficient (its resistance changes inversely

with respect to ambient temperature).

Knock S

ensor (KS)

is a pi

ezo-electric device which sends a signal

to the ECM indicating engine detonation

Between 700 and 6800 rpm, the ECM will retard individual cylinder ignition timing when detonation occurs while allowing

the other cylinders to continue operating normally.

During acceleration, at critical load and speed conditions, the ECM retards ignition timing to prevent the onset of detonation.

H

eated Oxygen Sensor (HO2S)

are

positioned upstream of the catalytic convertor

is equipped with

a heating element wh

ich improves the response time of the sensors during engine warm-up

h

as the ability to generate a voltage signal proportional to the oxygen content of the exhaust gases leaving the

engine

pr

ovides feedback information to the ECM used to calc

ulate fuel delivery and provide optimum gas emissions

Variable V

alve Timing (VVT) Solenoid

R

efer to section 303-01.

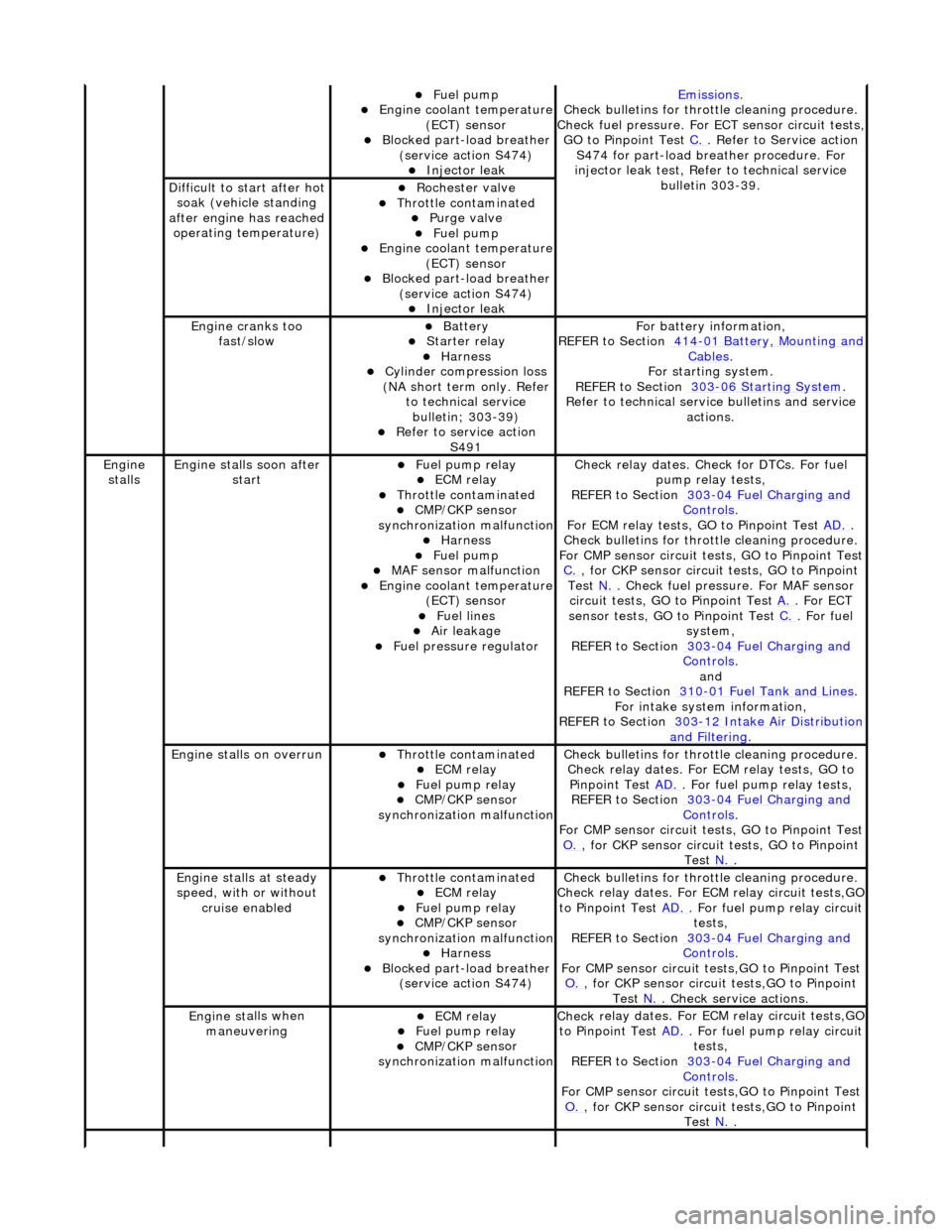

Page 1191 of 2490

Fue

l pump

Engine coolan

t temperature

(ECT) sensor

Blocked part-load breather (

service action S474)

Injec

tor leak

Emiss

ions

.

Check bull

etins for throttle cleaning procedure.

Check fuel pressure. For ECT sensor circuit tests,

GO to Pinpoint Test C.

. Refer to Servi

ce action

S474 for part-load breather procedure. For

injector leak test, Refer to technical service bulletin 303-39.

D

ifficult to start after hot

soak (vehicle standing

after engine has reached operating temperature)

Roc

hester valve

Thr

ottle contaminated

Purge

valve

Fue

l pump

Engine coolan

t temperature

(ECT) sensor

Blocked part-load breather (

service action S474)

Injec

tor leak

Engine cranks too

fa

st/slow

Batt

ery

Starter relay Harness Cyl

inder compression loss

(NA short term only. Refer to technical service bulletin; 303-39)

R

efer to service action

S491

F

or battery information,

REFER to Section 414

-0

1 Battery, Mounting and

Cables.

F

or starting system.

REFER to Section 303

-06 Sta

rting System

.

R

efer to technical servic

e bulletins and service

actions.

Engine

stalls

Engine st

alls soon after

start

F

uel pump relay

ECM relay Thr

ottle contaminated

CMP/CKP sen

sor

synchronization malfunction

Harness Fue

l pump

MAF

sensor malfunction

Engine coolan

t temperature

(ECT) sensor

Fue

l lines

Air leakage

F

uel pressure regulator

Check r

elay dates. Chec

k for DTCs. For fuel

pump relay tests,

REFER to Section 303

-0

4 Fuel Charging and

Controls.

F

or ECM relay tests, GO to Pinpoint Test

AD.

.

Check bull

etins for throttle cleaning procedure.

For CMP sensor circuit test s, GO to Pinpoint Test

C.

, for

CKP sensor circuit tests, GO to Pinpoint

Test N.

. Check fuel

pressure. For MAF sensor

circuit tests, GO to Pinpoint Test A.

. For EC

T

sensor tests, GO to Pinpoint Test C.

. F

or fuel

system,

REFER to Section 303

-0

4 Fuel Charging and

Controls.

and

REF

ER to Section 310

-0

1 Fuel Tank and Lines

. F

or intake system information,

REFER to Section 303

-1

2 Intake Air Distribution

and F

iltering

.

Engine

stalls on overrun

Thr

ottle contaminated

ECM relay F

uel pump relay

CMP/CKP sen

sor

synchronization malfunction

Check bull

etins for throttle cleaning procedure.

Check relay dates. For ECM relay tests, GO to Pinpoint Test AD.

. F

or fuel pump relay tests,

REFER to Section 303

-0

4 Fuel Charging and

Controls.

F

or CMP sensor circuit test

s, GO to Pinpoint Test

O.

, for

CKP sensor circuit tests, GO to Pinpoint

Test N.

.

E

ngine stalls at steady

speed, with or without cruise enabled

Thr

ottle contaminated

ECM relay F

uel pump relay

CMP/CKP sen

sor

synchronization malfunction

Harness Blocked part-load breather

(

service action S474)

Check bull

etins for throttle cleaning procedure.

Check relay dates. For EC M relay circuit tests,GO

to Pinpoint Test AD.

. F

or fuel pump relay circuit

tests,

REFER to Section 303

-0

4 Fuel Charging and

Controls.

F

or CMP sensor circuit test

s,GO to Pinpoint Test

O.

, for

CKP sensor circuit tests,GO to Pinpoint

Test N.

. Che

ck service actions.

Engine st

alls when

maneuvering

ECM relay F

uel pump relay

CMP/CKP sen

sor

synchronization malfunction

Check r

elay dates. For EC

M relay circuit tests,GO

to Pinpoint Test AD.

. F

or fuel pump relay circuit

tests,

REFER to Section 303

-0

4 Fuel Charging and

Controls.

F

or CMP sensor circuit test

s,GO to Pinpoint Test

O.

, for

CKP sensor circuit tests,GO to Pinpoint

Test N.

.

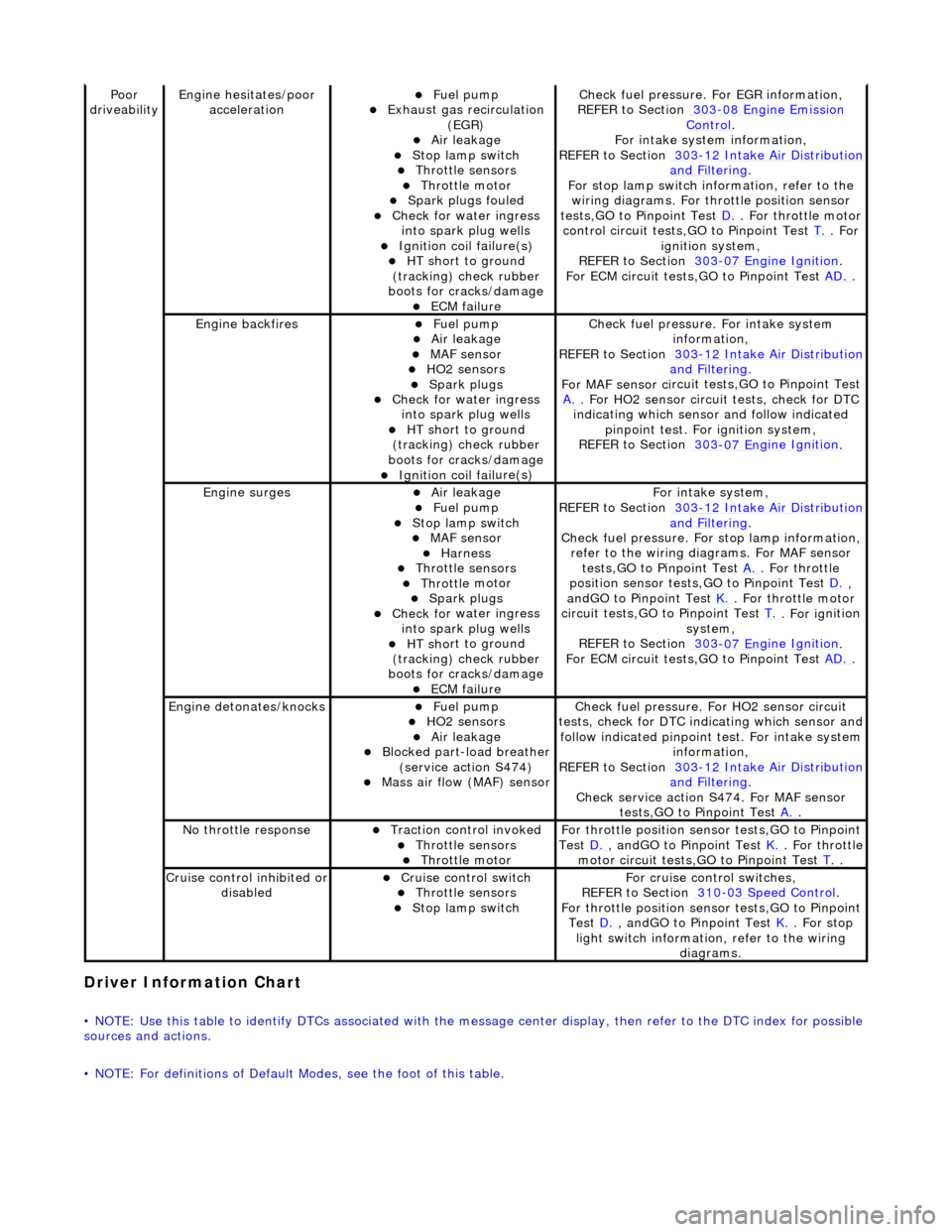

Page 1192 of 2490

Driver Information

Chart

•

NOTE: Use this table to identify DTCs associated with the me

ssage center display, then refer to the DTC index for possible

sources and actions.

• NOTE: For definitions of Default Modes, see the foot of this table.

Poor

dr iveabilityEngine h e

sitates/poor

acceleration

Fue l

pump

Exhaus

t gas

recirculation

(EGR)

Air leakage Stop lamp swi t

ch

Throttl

e

sensors

Throttl

e

motor

Spark

plugs

fouled

Check f

o

r water ingress

into spark plug wells

Ignition coil fail

ure(s)

HT sh

o

rt to ground

(tracking) check rubber

boots for cracks/damage

ECM failu r

e

Check f

u

el pressure. For EGR information,

REFER to Section 303

-08 En gin

e Emission

Control.

F or i

ntake system information,

REFER to Section 303

-1 2

Intake Air Distribution

and F

ilt

ering

.

F or stop l

amp switch in

formation, refer to the

wiring diagrams. For throttle position sensor

tests,GO to Pinpoint Test D.

. Fo

r throttle motor

control circuit tests,GO to Pinpoint Test T.

. For

igni t

ion system,

REFER to Section 303

-07 En

gine Ignition

.

F or ECM

circuit tests,GO to Pinpoint Test

AD.

.

Engine backfiresFuel

pump

Air leakage MAF se

nsor

HO2 sensors

Spark plugs Check fo

r water ingress

into spark plug wells

HT sh o

rt to ground

(tracking) check rubber

boots for cracks/damage

Ignition coil fail

ure(s)

Chec

k fu

el pressure. For intake system

information,

REFER to Section 303

-12

Intake Air Distribution

and Filt

ering

.

F or MAF sensor ci

rcuit test

s,GO to Pinpoint Test

A.

. F or HO2 sensor

circui

t tests, check for DTC

indicating which sensor and follow indicated pinpoint test. For ignition system,

REFER to Section 303

-07 En

gine Ignition

.

Engine

s

urges

Air leakage

Fuel

pump

Stop lamp swit

ch

MAF s

e

nsor

Harness Throttl

e

sensors

Throttl

e

motor

Spark plugs

Check fo

r water ingress

into spark plug wells

HT sh o

rt to ground

(tracking) check rubber

boots for cracks/damage

ECM failu r

e

Fo

r

intake system,

REFER to Section 303

-1 2

Intake Air Distribution

and Filt

ering

.

Check fu

el pressure. For

stop lamp information,

refer to the wiring diagrams. For MAF sensor tests,GO to Pinpoint Test A.

. Fo

r throttle

position sensor tests,GO to Pinpoint Test D.

,

a n

dGO to Pinpoint Test

K.

. Fo

r throttle motor

circuit tests,GO to Pinpoint Test T.

. For ig

nition

system,

REFER to Section 303

-07 En

gine Ignition

.

F or ECM

circuit tests,GO to Pinpoint Test

AD.

.

Engine detonates/k

nocks

Fue

l

pump

HO2 sensors

Air leakage Blocked part-load breather

(s

ervice action S474)

Mass ai

r fl

ow (MAF) sensor

Chec

k fu

el pressure. Fo

r HO2 sensor circuit

tests, check for DTC indicating which sensor and

follow indicated pinpoint test. For intake system

information,

REFER to Section 303

-1 2

Intake Air Distribution

and Filt

ering

.

Check service action S474

. For MAF sensor

tests,GO to Pinpoint Test A.

.

No t

hrottle response

Traction contr

o

l invoked

Throttl

e

sensors

Throttl

e

motor

Fo

r th

rottle position sensor tests,GO to Pinpoint

Test D.

, andG O to Pinpoint

Test

K.

. Fo

r throttle

motor circuit tests,GO to Pinpoint Test T.

.

Cru i

se control inhibited or

disabled

Cru i

se control switch

Throttle

sensors

Stop lamp swit

ch

For cru

i

se control switches,

REFER to Section 310

-03

Speed Control

.

For th

rottle position sensor tests,GO to Pinpoint

Test D.

, andG O to Pinpoint

Test

K.

. For s t

op

light switch information, refer to the wiring diagrams.

Page 1201 of 2490

leak

/blockage

EVAP valve failure

P0444Evaporati

ve emissions system

(EVAP) valve circuit open circuit

EVAP t

o ECM drive circuit open

circuit or high resistance

EVAP failu

re

F

or evaporative emissions pinpoint

tests,

REFER to Section 303

-1

3 Evaporative

Emiss

ions

.

P0445Evaporati

ve emissions system

(EVAP) valve circuit short circuit

E

VAP to ECM drive circuit short

circuit to ground

EVAP failu

re

F

or evaporative emissions pinpoint

tests,

REFER to Section 303

-1

3 Evaporative

Emiss

ions

.

P0447Cani

ster close valve (CCV) circuit

open circuit

CCV to ECM

drive circuit open

circuit, high resi stance or short

circuit to ground

EVAP failu

re

F

or evaporative emissions pinpoint

tests,

REFER to Section 303

-1

3 Evaporative

Emiss

ions

.

P0448Cani

ster close valve (CCV) circuit

short circuit

CCV to

ECM drive circuit short

circuit to high voltage

CCV failure

F

or evaporative emissions pinpoint

tests,

REFER to Section 303

-1

3 Evaporative

Emiss

ions

.

P0452F

uel tank pressure (FTP) sensor

circuit low voltage

FTP

sensor disconnected

FTP

sensor to ECM sense circuit

open circuit or short circuit to

ground

FTP sen

sor to ECM power supply

circuit open circuit or short circuit

to ground

F

TP sensor failure

F

or evaporative emissions pinpoint

tests,

REFER to Section 303

-1

3 Evaporative

Emiss

ions

.

P0453F

uel tank pressure (FTP) sensor

circuit high voltage

FTP

sensor to ECM signal ground

circuit open circuit

F

TP sensor to ECM wiring (supply,

sense, signal, ground) short circuit

to each other

FTP

sensor to ECM sense circuit

short circuit to high voltage

F

TP sensor failure

F

or evaporative emissions pinpoint

tests,

REFER to Section 303

-1

3 Evaporative

Emiss

ions

.

P0460Fue

l level sense signal

performance

Fue

l level sensor

to instrument

cluster circuits in termittent short or

open circuit

F

uel level sensor failure

Instrument cluster

faul

t (incorrect

fuel level data)

F

or fuel level sensor

circuit tests,

REFER to Section 303

-04

Fuel

Charging and Con

trols

.

P0506Idl

e rpm lower than expected

Ai

r intake blockage

Acce

ssory drive overload

(defective/siezed component)

Thr

ottle valve stuck closed

Throttl

e assembly failure

Chec

k the air intake system.

REFER to Section 303

-1

2 Intake Air

Distribu

tion and Filtering

.

Check t

he accessory drive

components,

REFER to Section 303

-0

5 Accessory

Dr

ive

.

F

or throttle body information,

REFER to Section 303

-04

Fuel

Charging and Con

trols

.

P0507Idle rpm

higher than expected

Inta

ke air leak between MAF

sensor and throttle

Inta

ke air leak between throttle

and engine

Engine

breather leak

Cruis

e (speed) control vacuum

failure

Thr

ottle valve stuck open

Throttl

e assembly failure

Chec

k the air intake system.

REFER to Section 303

-1

2 Intake Air

Distribu

tion and Filtering

.

Chec

k the engine breather system,

REFER to Section 303

-08

Engine

Emissi

on Control

.

F

or cruise (speed) control information,

REFER to Section 310

-03

Speed

Control.

F

or throttle body information,

REFER to Section 303

-04

Fuel

Charging and Con

trols

.

P0560Vehicle voltage

malfunction

ECM battery

power supply open

circuit, high resistance

F

or ECM power supply circuit tests,

GO to Pinpoint Test AD.

.

P0566Cruise (speed) contr

ol

CANCEL

switch ON fault

Cru

ise (speed) control switches

internal steering wheel short circuit

to ground

For cru

ise (speed) control circuit tests,

REFER to Section 310

-03

Speed

Page 1202 of 2490

St

eering wheel cassette reel short

circuit to ground

Cassette reel to ECM c

ircuit short

circuit to ground

CANC EL

switch failure (stuck ON)

Control.

P0567Cruise (speed) contr

o

l

RESUME

switch ON fault

Cru i

se (speed) control switches

internal steering wheel short circuit

to ground

S t

eering wheel cassette reel short

circuit to ground

Cassette reel to ECM c

ircuit short

circuit to ground

RESUME s

witch failure (stuck ON)

For cru

i

se (speed) control circuit tests,

REFER to Section 310

-03 Sp

eed

Control.

P0568Cru

i

se (speed) control switch

ground malfunction

Cru i

se (speed) control switches

internal steering wheel open circuit

St

eering wheel cassette reel open

circuit or high resistance

Cassette reel to ECM ci

rcuit

ACCEL/DECEL open circuit or high

resistance

ACC E

L/DECEL

switch failure

For crui

se (speed) control circuit tests,

REFER to Section 310

-03 Sp

eed

Control.

P0569Cruise (speed) contr

o

l

DECEL/SET (SET-) switch ON

fault

Cru i

se (speed) control switches

internal steering wheel short circuit

to ground

S t

eering wheel cassette reel short

circuit to ground

Cassette reel to ECM c

ircuit short

circuit to ground

DECE

L/SET

switch failure (stuck

ON)

For cru i

se (speed) control circuit tests,

REFER to Section 310

-03 Sp

eed

Control.

P0570Cruise (speed) contro

l

ACCEL/SET (SET+) switch ON

fault

Crui

se (speed) control switches

internal steering wheel short circuit

to ground

S t

eering wheel cassette reel short

circuit to ground

Cassette reel to ECM c

ircuit short

circuit to ground

ACC E

L/SET

switch failure (stuck

ON)

For crui

se (speed) control circuit tests,

REFER to Section 310

-03 Sp

eed

Control.

P0603ECM dat

a

corrupted

ECM failu

r

e

Contact deal

er techni

cal support for

advice on possible ECM failure.

P1000 Sy

stem checks not complete since

last memory clear

O B

D diagnostic monitors have not

completed

Carr y out comprehensi

ve component

monitor drive cycle. Refer to the DTC

section of JTIS.

P1104Mass ai r fl

ow (MAF) sensor ground

malfunction

MAF sensor to EC

M reference

ground circuit open circuit, short

circuit to high voltage, high

resistance

MAF s

ensor to ECM sensing circuit

open circuit

MAF sensor fai

lure

For MAF

se

nsor circuit tests,GO to

Pinpoint Test A.

.

P1111Syst

em checks complete since last

memory clear

O B

D diagnostic monitors have completed

N

o

action necessary.

P1112In

t

ake air temperature (IAT)

sensor 2 sense circuit high voltage

(low charge air temperature)

IAT sensor 2 di sconnect

ed

IAT sensor 2

to ECM sensing circuit

high resistance, open circuit or

short circuit to high voltage

IAT se nsor 2 failure

F

or IAT sensor

2 circuit tests,GO to

Pinpoint Test Q.

.

P1113Int

ake air temperature (IAT)

sensor 2 sense circuit low voltage

(high charge air temperature)

Supercharger interco

oler failure

IAT se

nsor 2

to ECM sensing circuit

short circuit to ground

IAT se nsor 2 failure

F

or IAT sensor

2 circuit tests,GO to

Pinpoint Test Q.

.

P1121Accele

rator pedal position (APP)

sensor circuit 'A'

range/performance

A P

P sensor to ECM sense circuit

'A' (sensor pin 5) open circuit,

short circuit or high resistance

Sensor power su pply fault

Sensor r

e

ference ground fault

APP s

e

nsor failure

For APP

sen

sor circuit tests,GO to

Pinpoint Test R.

, andGO to Pinpoint

Test S.

.

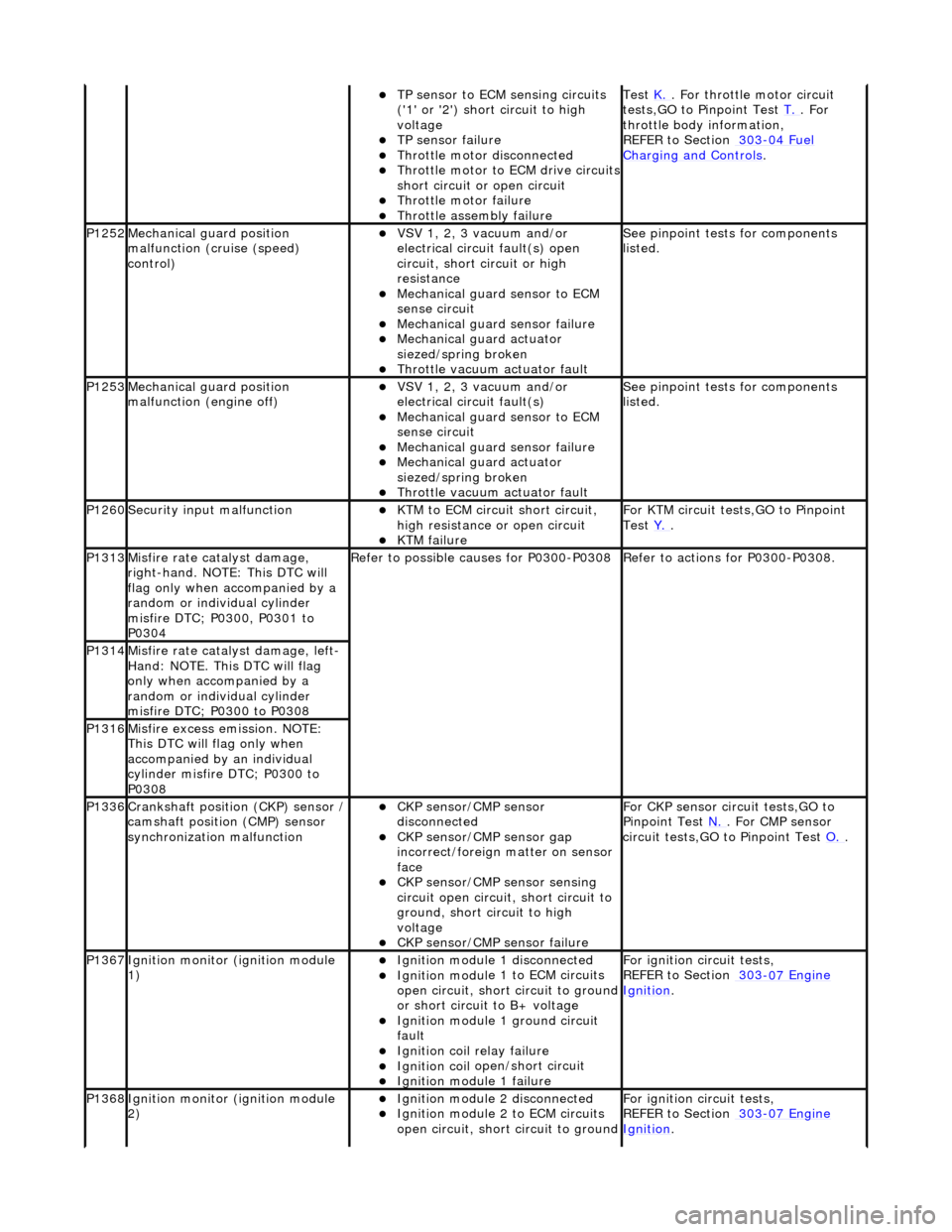

Page 1205 of 2490

TP se

nsor to ECM sensing circuits

('1' or '2') short circuit to high

voltage

TP sensor

failure

Throttl

e motor disconnected

Th

rottle motor to ECM drive circuits

short circuit or open circuit

Throttl

e motor failure

Throttl

e assembly failure

Test

K. . F

or throttle motor circuit

tests,GO to Pinpoint Test T.

. For

throttle body i

nformation,

REFER to Section 303

-04

Fuel

Charging and Con

trols

.

P1252Mec

hanical gu

ard position

malfunction (cruise (speed)

control)

VSV 1, 2, 3 v

acuum and/or

electrical circuit fault(s) open

circuit, short circuit or high

resistance

Mechanica

l guard sensor to ECM

sense circuit

Mechanica

l guard sensor failure

Mechanica

l guard actuator

siezed/spring broken

Throttl

e vacuum actuator fault

Se

e pinpoint tests for components

listed.

P1253Mec

hanical gu

ard position

malfunction (engine off)

VSV 1, 2, 3 v

acuum and/or

electrical circuit fault(s)

Mechanica

l guard sensor to ECM

sense circuit

Mechanica

l guard sensor failure

Mechanica

l guard actuator

siezed/spring broken

Throttl

e vacuum actuator fault

Se

e pinpoint tests for components

listed.

P1260Se

curity input malfunction

K

TM to ECM circuit short circuit,

high resistance or open circuit

KTM failu

re

F

or KTM circuit tests,GO to Pinpoint

Test Y.

.

P1313M

isfire rate catalyst damage,

right-hand. NOTE: This DTC will

flag only when accompanied by a

random or individual cylinder

misfire DTC; P0300, P0301 to

P0304

R

efer to possible causes for P0300-P0308

R

efer to actions for P0300-P0308.

P1314Mi

sfire rate catalyst damage, left-

Hand: NOTE. This DTC will flag

only when accompanied by a

random or individual cylinder

misfire DTC; P0300 to P0308

P1316M

isfire excess emission. NOTE:

This DTC will flag only when

accompanied by an individual

cylinder misfire DTC; P0300 to

P0308

P1336Cranksh

aft position

(CKP) sensor /

camshaft position (CMP) sensor

synchronization malfunction

CKP s

ensor/CMP sensor

disconnected

CKP sensor/CM

P sensor gap

incorrect/foreign matter on sensor

face

CKP s

ensor/CMP sensor sensing

circuit open circuit, short circuit to

ground, short circuit to high

voltage

CKP s

ensor/CMP sensor failure

F

or CKP sensor circ

uit tests,GO to

Pinpoint Test N.

. For CM

P sensor

circuit tests,GO to Pinpoint Test O.

.

P1367Ignit

ion monitor (ignition module

1)

Ignition modu

le

1 disconnected

Ignition modul

e 1 to ECM circuits

open circuit, short circuit to ground

or short circuit to B+ voltage

Ignition modul

e 1 ground circuit

fault

Ignition coil

relay failure

Ignition coil

open/short circuit

Ignition modul

e 1 failure

F

or ignition circuit tests,

REFER to Section 303

-07

Engine

Ignition.

P1368Ignit

ion monitor (ignition module

2)

Ignition modu

le

2 disconnected

Ignition modul

e 2 to ECM circuits

open circuit, short circuit to ground

F

or ignition circuit tests,

REFER to Section 303

-07

Engine

Ignition.

Page 1206 of 2490

or sho

rt circuit to B+ voltage

Ignition modul

e

2 ground circuit

fault

Ignition coil relay fai

lure

Ignition coil

open/short

circuit

Ignition modul

e

2 failure

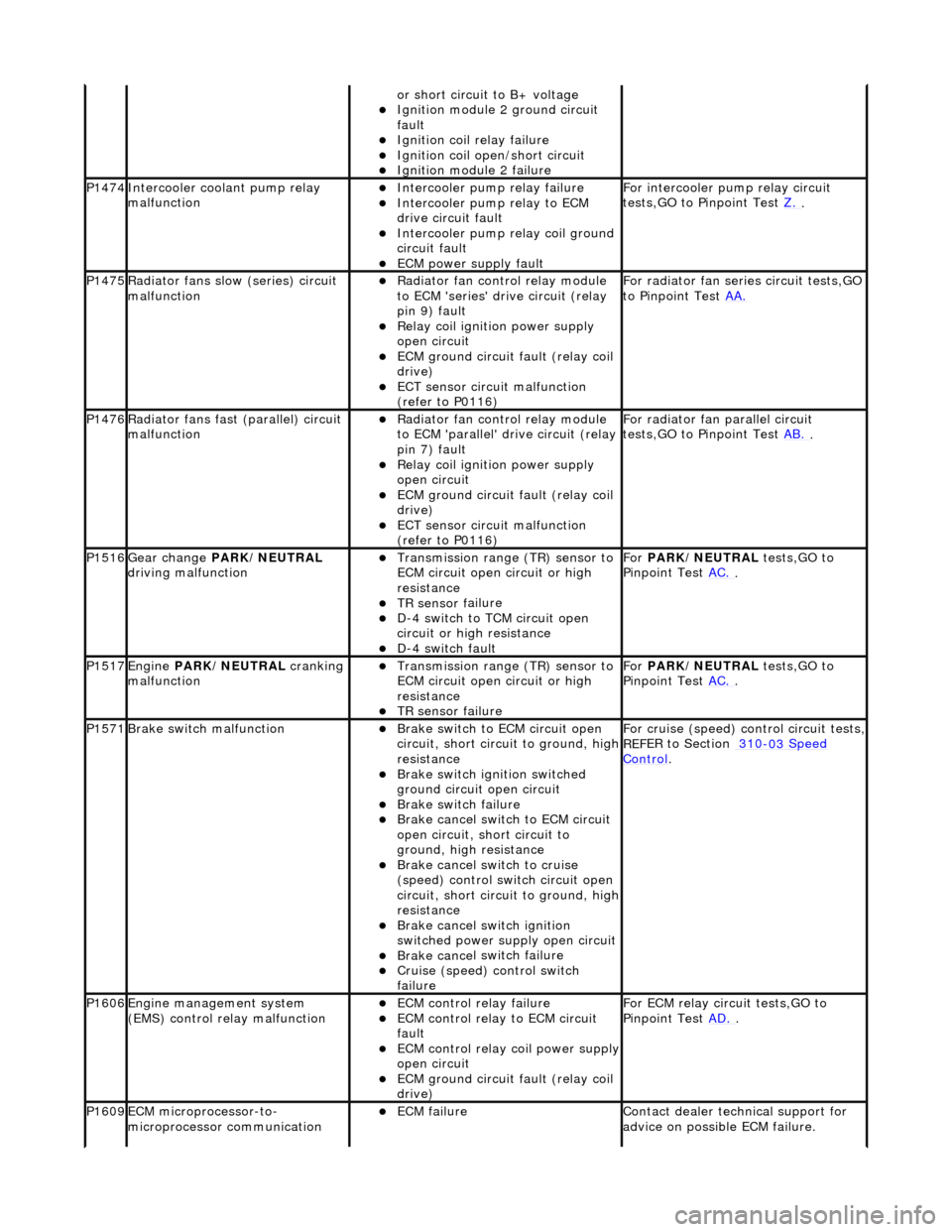

P1474Int

e

rcooler coolant pump relay

malfunction

Intercooler pump relay failure

Intercooler pump relay

to ECM

drive circuit fault

Intercooler pump relay coi

l ground

circuit fault

ECM power supply f

ault

F

or i

ntercooler pump relay circuit

tests,GO to Pinpoint Test Z.

.

P1475Ra

diator fans slow

(series) circuit

malfunction

R a

diator fan control relay module

to ECM 'series' drive circuit (relay

pin 9) fault

Relay coil ignition power supply

o p

en circuit

ECM ground circuit fault (relay coil

drive)

ECT se ns

or circuit malfunction

(refer to P0116)

F o

r radiator fan seri

es circuit tests,GO

to Pinpoint Test AA.

P1476Ra

diator fans fast (parallel) circuit

malfunction

R a

diator fan control relay module

to ECM 'parallel' drive circuit (relay

pin 7) fault

Relay coil ignition power supply

o p

en circuit

ECM ground circuit faul

t (relay coil

drive)

ECT sens

or circuit malfunction

(refer to P0116)

F or radi

ator fan parallel circuit

tests,GO to Pinpoint Test AB.

.

P1516Gear change PARK

/NEUTRAL

driving malfunction

Transmission range (T

R) sensor to

ECM circuit open circuit or high

resistance

TR sensor f

ailure

D-

4

switch to TCM circuit open

circuit or high resistance

D-4 swi

tch fault

For

PARK/NEUTRAL tests,GO to

Pinpoint Test AC.

.

P1517Engine PA

RK/NEUTRAL

cranking

malfunction

Transmissi on range (T

R) sensor to

ECM circuit open circuit or high

resistance

TR sensor f

ailure

Fo

r

PARK/NEUTRAL tests,GO to

Pinpoint Test AC.

.

P1571Brake swit

ch malfunction

Brake sw

it

ch to ECM circuit open

circuit, short circ uit to ground, high

resistance

Brake sw it

ch ignition switched

ground circuit open circuit

Brake sw it

ch failure

Brake ca

ncel

switch to ECM circuit

open circuit, short circuit to

ground, high resistance

Brake ca nce

l switch to cruise

(speed) control switch circuit open

circuit, short circ uit to ground, high

resistance

Brake cance

l switch ignition

switched power supply open circuit

Brake ca nce

l switch failure

Cru

i

se (speed) control switch

failure

For cru i

se (speed) control circuit tests,

REF

E

R to Section 310

-03

Sp

eed

Control.

P1606Engine

m

anagement system

(EMS) control relay malfunction

ECM co ntrol rel

ay failure

ECM c

o

ntrol relay to ECM circuit

fault

ECM co ntrol rel

ay coil power supply

open circuit

ECM ground circuit faul t (relay coil

drive)

F or ECM

relay circuit tests,GO to

Pinpoint Test AD.

.

P1609EC

M microprocessor-to-

microprocessor communication

ECM failu r

e

Contact deal

er techni

cal support for

advice on possible ECM failure.

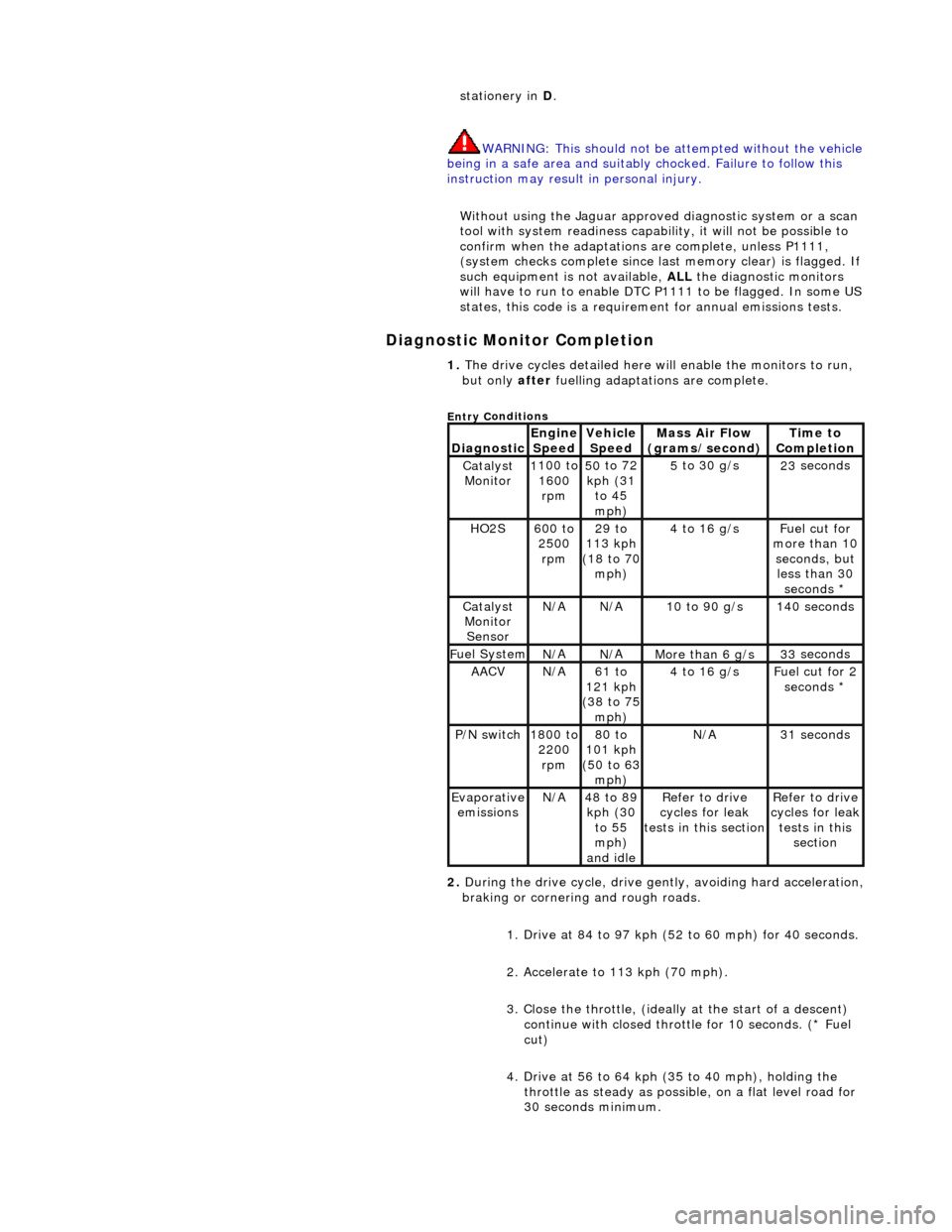

Page 1242 of 2490

Diagnostic Monitor Comp

letion

stat

ionery in

D.

WARNING: This should not be attempted without the vehicle

being in a safe area and suitably chocked. Failure to follow this

instruction may result in personal injury.

Without using the Jaguar approved diagnostic system or a scan

tool with system readiness capability, it will not be possible to

confirm when the adaptations are complete, unless P1111,

(system checks complete since last memory clear) is flagged. If

such equipment is not available, ALL the diagnostic monitors

will have to run to enable DTC P1111 to be flagged. In some US

states, this code is a requirem ent for annual emissions tests.

1. The dri v

e cycles detailed here w

ill enable the monitors to run,

but only after fuelling adaptations are complete.

Entry C

onditions

Di

agno

stic

Engine

S p

eed

Ve

h

icle

Speed

Mass Air Flow

(gra ms/sec

ond)

Ti

m

e to

Completion

Catalyst Monitor1 100

to

1600 rpm

50 to

72

kph (31 to 45

mph)

5 to

30 g/s

23

se

conds

HO2S6

00 t

o

2500 rpm

29 to

113 kph

(18 to 70

mph)

4 to

16 g/s

F

u

el cut for

more than 10 seconds, but less than 30 seconds *

Catalyst Monitor SensorN/ AN/A10

to 90 g/s

14

0

seconds

F

u

el System

N/

AN/AMore than 6 g/s33 se

conds

AACVN/

A61 to

121 kph

(38 to 75

mph)

4 to

16 g/s

F

u

el cut for 2

seconds *

P /

N switch

1

800

to

2200 rpm

80 to

101 kph

(50 to 63

mph)

N/ A31 se

conds

Evaporative

em is

sions

N/

A48 to

89

kph (30 to 55

mph)

and idle

R e

fer to drive

cycles for leak

tests in this section

Re

fer to drive

cycles for leak

tests in this section

2. During the drive cycle, drive gent ly, avoiding hard acceleration,

braking or cornering and rough roads.

1. Drive at 84 to 97 kph (52 to 60 mph) for 40 seconds.

2. Accelerate to 113 kph (70 mph).

3. Close the throttle, (ideally at the start of a descent)

continue with closed throttle for 10 seconds. (* Fuel

cut)

4. Drive at 56 to 64 kph (35 to 40 mph), holding the throttle as steady as possib le, on a flat level road for

30 seconds minimum.

Page 1261 of 2490

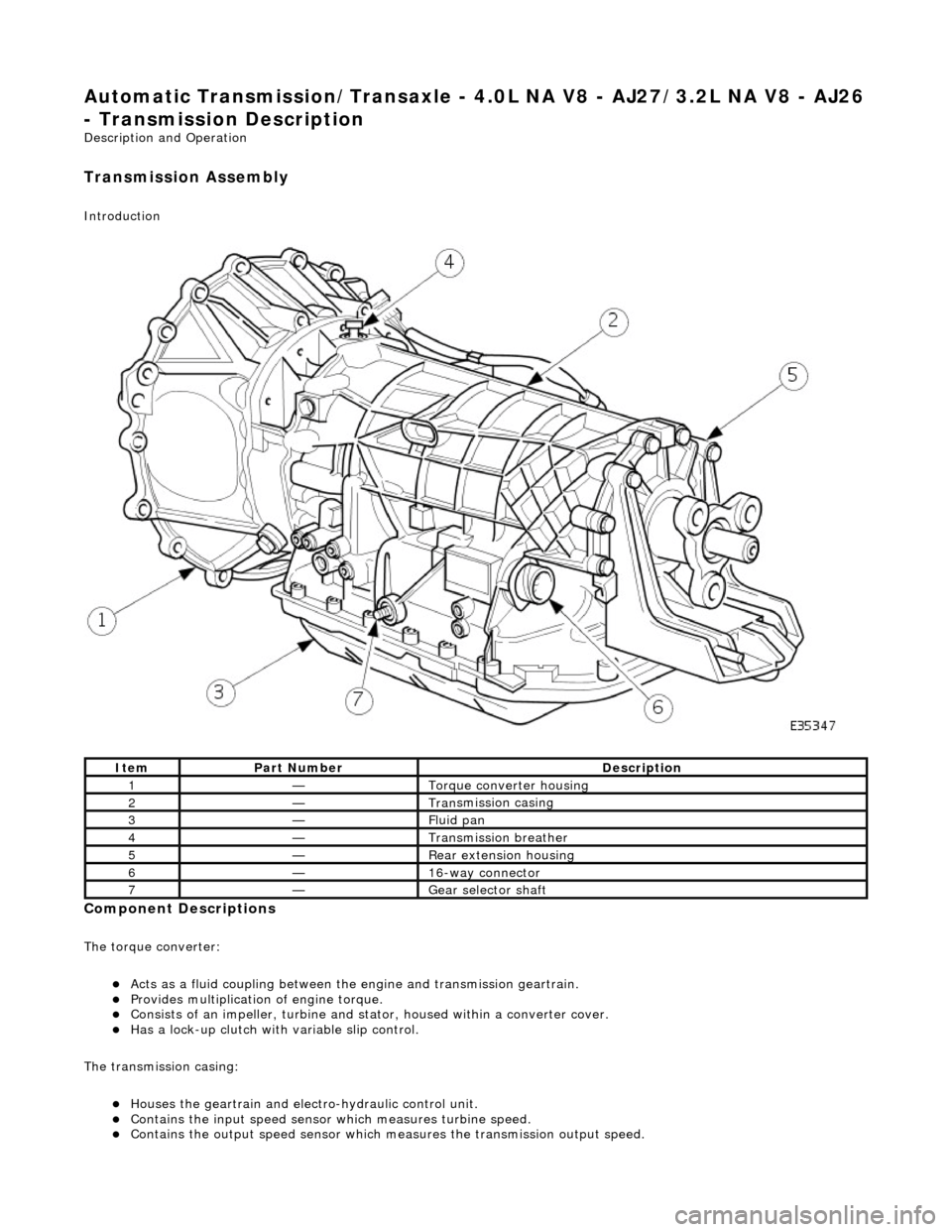

Automatic Transmission/Transaxle - 4.0L NA V8 - AJ27/3.2L NA V8 - AJ26

- Transmission Descriptio

n

Description an

d Operation

Transmission As

sembly

Int

roduction

Compon

ent Descriptions

The t

orque converter:

Acts as a fluid

coupling between the

engine and transmission geartrain.

P

rovides multiplication of engine torque.

Cons

ists of an impeller, turbine and stat

or, housed within a converter cover.

Has a l

ock-up clutch with variable slip control.

The transmission casing:

Houses the geartrain and elec t

ro-hydraulic control unit.

Contains

the input speed sensor which measures turbine speed.

Contai

ns the output speed sensor which measures the transmission output speed.

It

em

Par

t Number

De

scription

1—Torque c

onverter housing

2—Tran

smission casing

3—Fluid pan

4—Transmission bre

ather

5—Re

ar extension housing

6—16

-way connector

7—Gear s

elector shaft

Page 1267 of 2490

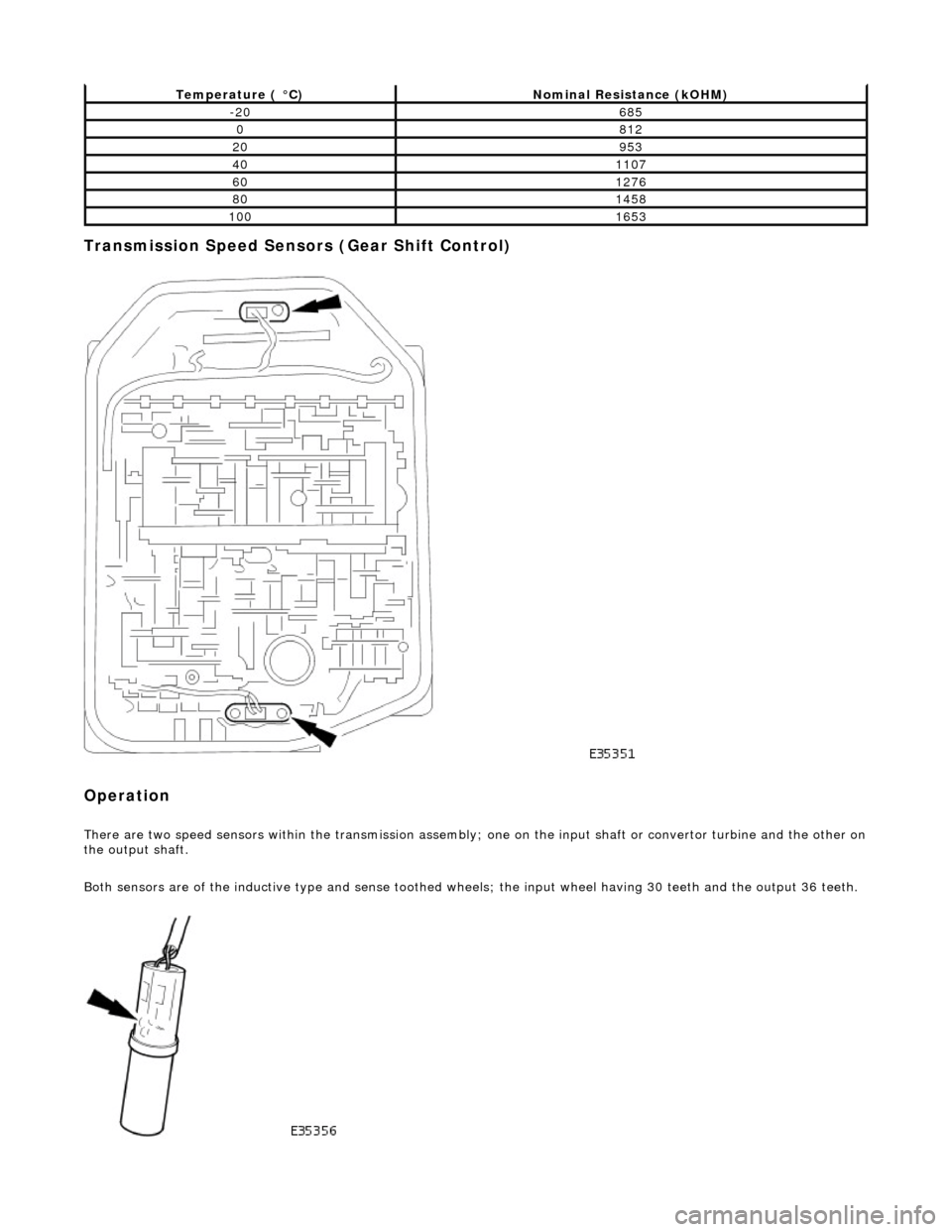

Transmission Speed Sensors (Gear Shift Control)

Operation

There are two speed sensors within the transmission assembly; one on the input shaft or convertor turbine and the other on the output shaft.

Both sensors are of the inductive type and sense toothed wheels; the input wheel having 30 teeth and the output 36 teeth.

Temperature ( °C)Nominal Resistance (kOHM)

-20685

0812

20953

401107

601276

801458

1001653