engine ignition JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1824 of 2490

External temperature < -10 °C Vehicle speed > 65 km / h The first two conditions exist > 2 minutes. Engine speed > 50 revs / min

14. 14. Heated Backlight (R)

Pressing the heated backlight button will simultaneously energize the heater elements for timed cycles of;

21 minutes backlight 11 minutes exterior mirrors

Pressing the button again within the 21 minute timer will cancel the request.

If the engine is stalled, or the ignition switched OFF, the backlight and door mirror timers will be cleared, resulting in both

functions being switched off.

• NOTE: Both the backlight and door mirrors may be activated with the climate control system OFF, but the engine must be

running.

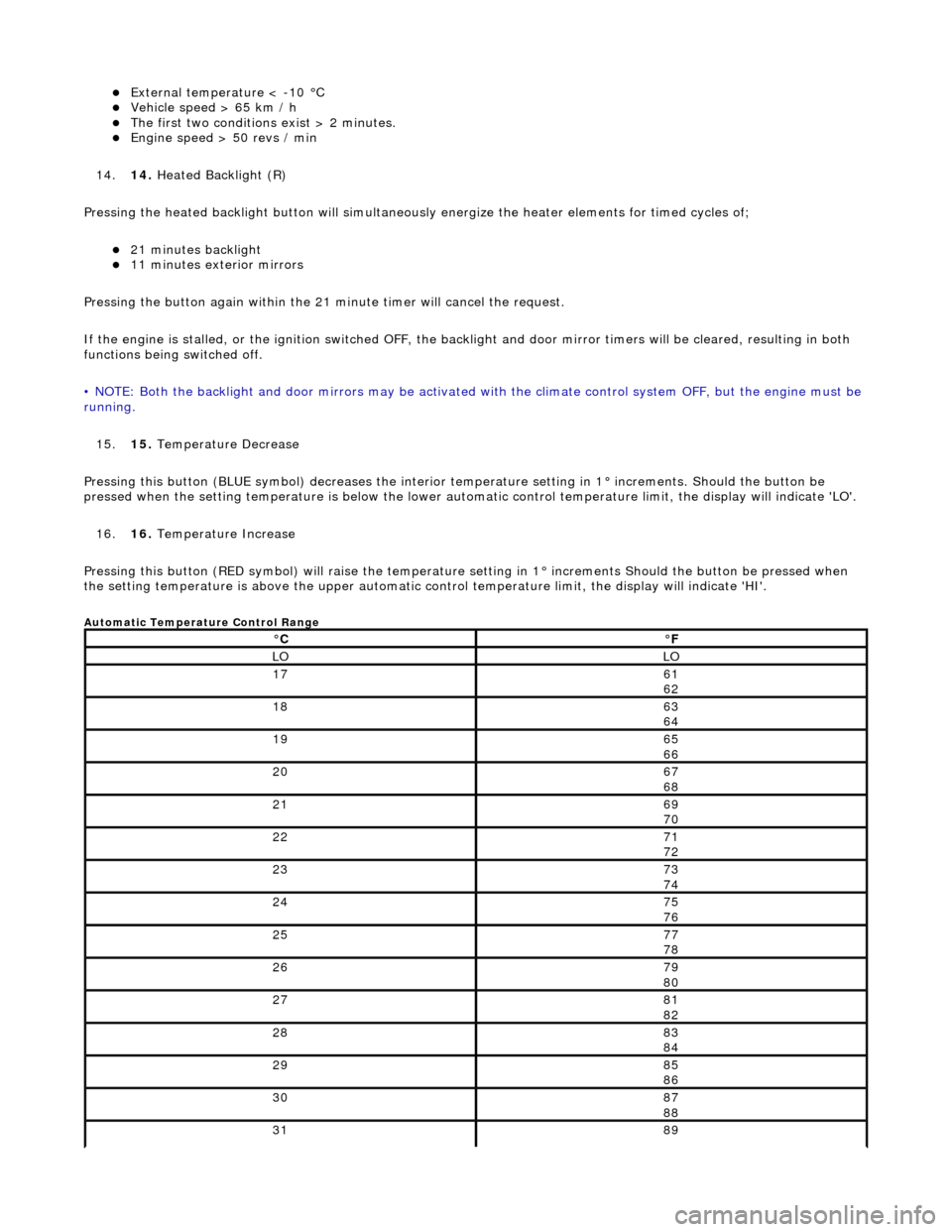

15. 15. Temperature Decrease

Pressing this button (BLUE symbol) decreases the interior temperature setting in 1° increments. Should the button be

pressed when the setting temperature is below the lower automatic control temperature limit, the display will indicate 'LO'.

16. 16. Temperature Increase

Pressing this button (RED symbol) will raise the temperature setting in 1° increments Should the button be pressed when

the setting temperature is above the upper automatic control temperature limit, the display will indicate 'HI'.

Automatic Temperature Control Range

°C°F

LOLO

1761

62

1863

64

1965

66

2067

68

2169

70

2271

72

2373

74

2475

76

2577

78

2679

80

2781

82

2883

84

2985

86

3087

88

3189

Page 1835 of 2490

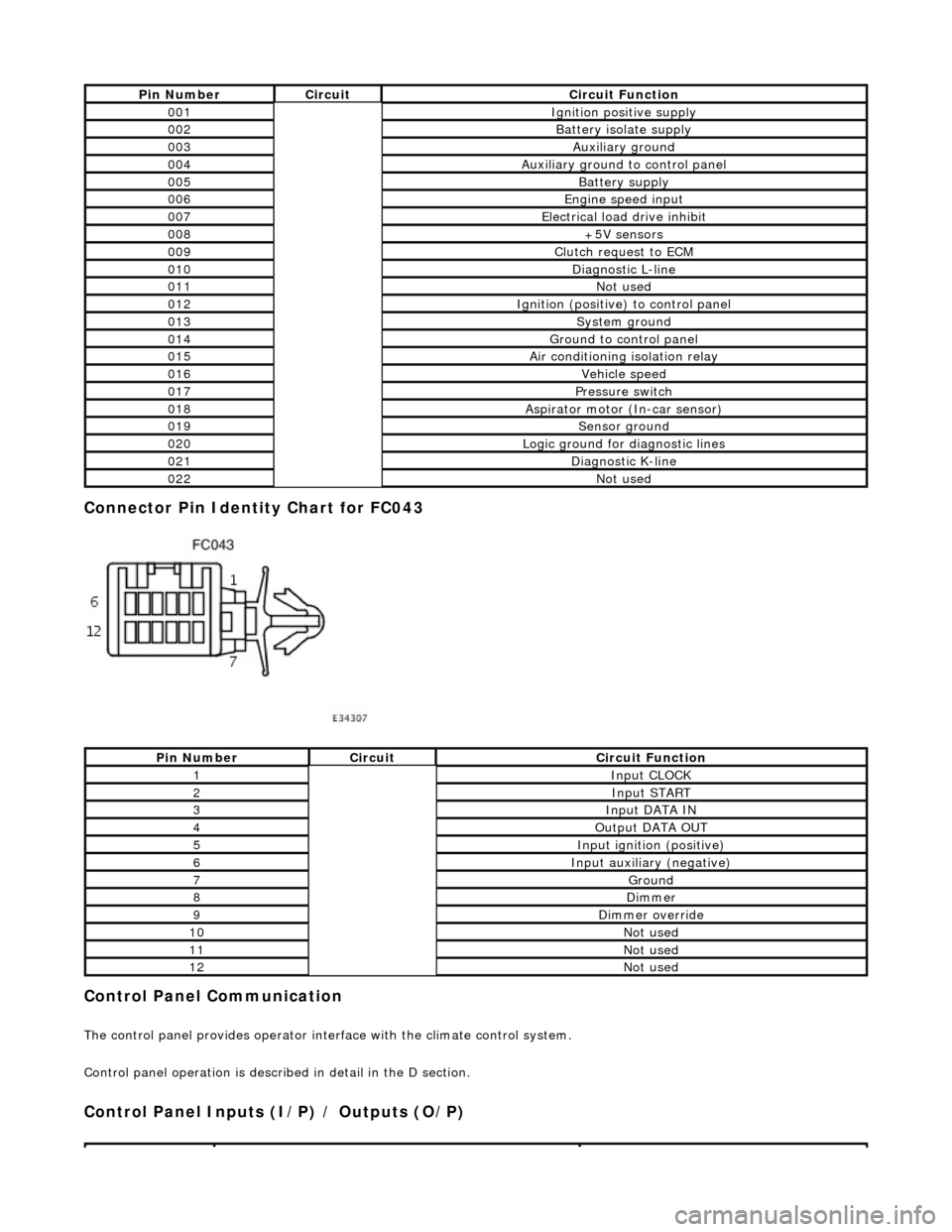

Connector Pin Identity Chart for FC043

Control Panel Communication

The control panel provides operator interface with the climate control system.

Control panel operation is described in detail in the D section.

Control Panel Inputs (I/P) / Outputs (O/P)

Pin NumberCircuitCircuit Function

001Ignition positive supply

002Battery isolate supply

003Auxiliary ground

004Auxiliary ground to control panel

005Battery supply

006Engine speed input

007Electrical load drive inhibit

008+5V sensors

009Clutch request to ECM

010Diagnostic L-line

011Not used

012Ignition (positive) to control panel

013System ground

014Ground to control panel

015Air conditioning isolation relay

016Vehicle speed

017Pressure switch

018Aspirator motor (In-car sensor)

019Sensor ground

020Logic ground for diagnostic lines

021Diagnostic K-line

022Not used

Pin NumberCircuitCircuit Function

1Input CLOCK

2Input START

3Input DATA IN

4Output DATA OUT

5Input ignition (positive)

6Input auxiliary (negative)

7Ground

8Dimmer

9Dimmer override

10Not used

11Not used

12Not used

Page 1837 of 2490

System Self-test

Control Panel Fault Code Listing • NOTE: Reference fault code #23*: In ambient temperatures below 0° C, this code may be logged because the low

ambient causes a tempor ary low gas pressure.

• NOTE: Where the ambient temperature rises above 40° C, with the engine close to overheating, electrical feed to the

compressor clutch may be cut and code #23 registered.

SymptomPossible SourcesAction

0 Normal operation no

fault codes presentNone

*Wait 30 seconds for system

self-check.

*

11 Motorized in-car

aspirator malfunctionHarness / connector fault

Sensor open / short circuit

*

*Panel fault codes are not

stored for motorized in-car

aspirator motor failure.

*

12 Ambient

temperature sensor

malfunctionHarness / connector fault

Sensor open / short circuit

*

*After rectification, disconnect

the vehicle battery for 10

seconds to reset the system.

*

13 Evaporator

temperature sensor

malfunctionHarness / connector fault

Sensor open / short circuit

*

*Refer to PDU

*

14 Water temperature

input malfunctionInstrument cl uster output

*Refer to PDU

*

15 Heater matrix

temperature sensor

malfunctionHarness / connector fault

Sensor open / short circuit

*

*Refer to PDU

*

21 Solar sensorSensor open /short circuit

*Refer to PDU

*

22 Compressor lock

signal faultLow refrigerant charge, low compressor oil level, loose drive

belt Harness / connector fault

*

*Adjust items as required

*

23 Refrigerant pressure

switch malfunctionHarness / connector fault

Switch open / short circuit

*

*Refer to PDU

*

23 Refrigerant pressure

low refrigerant charge * Leak from damaged pipe or joint

*Rectify as required and

recharge system

*

24 Face vent demand

potentiometer faultPotentiometer open / short circuit

Harness / connector fault

*

*Refer to PDU

*

31 LH fresh / recirc.

potentiometer faultHarness / connector fault

In certain circumstances the servo motor may over-travel

and cause further logged faults. This may be cured, following

fault rectification, by cycling the ignition ON-OFF-ON 3 times

*

*Refer to PDU

*

32 RH fresh / recirc.

potentiometer faultHarness / connector fault

In certain circumstances the servo motor may over-travel

and cause further logged faults. This may be cured, following

fault rectification, by cycling the ignition ON-OFF-ON 3 times

*

*Refer to PDU

*

33 Cool air by-pass

potentiometer faultHarness / connector fault

In certain circumstances the servo motor may over-travel

and cause further logged faults. This may be cured, following

fault rectification, by cycling the ignition ON-OFF-ON 3 times

*

*Refer to PDU

*

34 Defrost vent

potentiometer faultHarness / connector fault

In certain circumstances the servo motor may over-travel

and cause further logged faults. This may be cured, following

fault rectification, by cycling the ignition ON-OFF-ON 3 times

*

*Refer to PDU

*

35 Centre vent

potentiometer faultHarness / connector fault

In certain circumstances the servo motor may over-travel

and cause further logged faults. This may be cured, following

fault rectification, by cycling the ignition ON-OFF-ON 3 times

*

*Refer to PDU

*

36 Foot vent

potentiometer faultHarness / connector fault

In certain circumstances the servo motor may over-travel

and cause further logged faults. This may be cured, following

fault rectification, by cycling the ignition ON-OFF-ON 3 times

*

*Refer to PDU

*

41 LH fresh / recirc.

motor faultHarness / connector fault

Servo motor seized or sticking

Flap seized or sticking

*

*

*Refer to PDU

*

42 RH fresh / recirc.

motor faultHarness / connector fault

Servo motor seized or sticking

Flap seized or sticking

*

*

*Refer to PDU

*

Page 1838 of 2490

System Self-test

Other conditions which may exist but will NOT log fault codes:

Associated Faults

System Self-test

Panel Communication Check

The panel communication check veri fies the inputs and outputs from the control panel to the A/CCM.

Actuator Check Procedure

The system self test procedure drives all the actuator moto rs, to check their operation. If an actuator is operating

incorrectly or operating outside of its limi ts then a fault code will be present.

Before commencing with the actuator check procedure, ensure the ca r is operating under normal conditions.

1. 1. Switch ignition OFF.

2. 2. Press and hold the RECIRC and AUTO buttons simult aneously, switch ignition ON and run the engine.

3. 3. All the control panel LEDs and all LCD segments will flas h on and off. Any function LED indicator which does not

flash on / off suggests a fault condition within that area of the panel or, with the LED.

Any LCD element which fails to flash on / off indicates a fault within the display element or panel.

4. 4. Press AUTO

43 Cool air by-pass

motor faultHarness / connector fault

Servo motor seized or sticking

Flap seized or sticking

*

*

*Refer to PDU

*

43 Cool Air by-pass

motor faultHarness / connector fault

Servo motor seized or sticking

Flap seized or sticking

*

*

*Refer to PDU

*

44 Defrost vent motor

faultHarness / connector fault

Servo motor seized or sticking

Flap seized or sticking

*

*

*Refer to PDU

*

45 Centre vent motor

faultHarness / connector fault

Servo motor seized or sticking

Flap seized or sticking

*

*

*Refer to PDU

*

46 Foot vent motor

faultHarness / connector fault

Servo motor seized or sticking

Flap seized or sticking

*

*

*Refer to PDU

*

SymptomPossible SourcesAction

No heatAirlock in system.

*Refer section 303-03 for fill / bleed procedure

*

Heater water pump inoperative

Coolant flow valve stuck closed

*

*Check operation and circuit

*

Faulty engine coolant thermostat

*Renew as required

*

One vent failing to open / closeBroken linkage.

*Renew as required

*

Poor airflowBlower motors - incorrect operation

*Check operation and circuit

*

ItemCheck LEDCondition

IgnitionDefrostIGN input at 12V, check LED is illuminated

AuxiliaryFaceAUX input at 12V, check LED is illuminated

ClockFeet / faceClock input normal, check LED is illuminated

Start inputFootStart input normal, check LED is illuminated

Data outScreen / footData out input normal, check LED is illuminated

Dimmer overrideRecirc.Dimmer override input ON, check LED is illuminated

Page 1884 of 2490

The interference suppression module (where fitted) connects to the generator main terminal 'B +' and a ground stud on the

rear face of the generator.

A multi-plug (3 pin) is connecte d to the rear of the generator:

Pin 1 not connected. Pin 2 ignition supply to the regulator. Pin 3 output to the charge warning lamp.

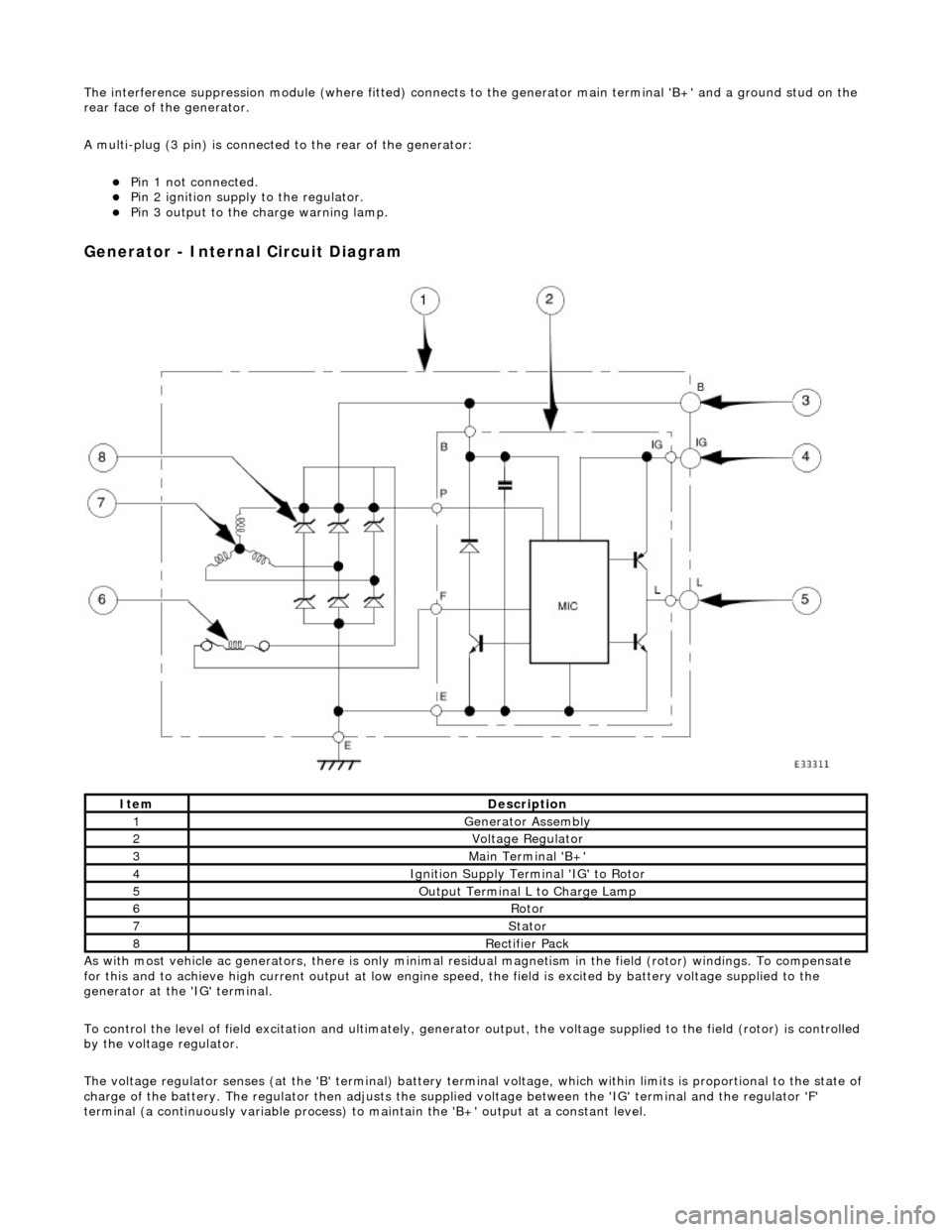

Generator - Internal Circuit Diagram

As with most vehicle ac generators, there is only minimal residual magnet ism in the field (rotor) windings. To compensate

for this and to achieve high current outp ut at low engine speed, the field is excited by battery voltage supplied to the

generator at the 'IG' terminal.

To control the level of field excitation and ultimately, generator output, the voltag e supplied to the field (rotor) is controlled

by the voltage regulator.

The voltage regulator senses (at the 'B' terminal) battery terminal voltage, which within limits is proportional to the state o f

charge of the battery. The regulator then adjusts the supplied voltage between the 'IG' terminal and the regulator 'F'

terminal (a continuously variable process) to maintain the 'B+' output at a constant level.

ItemDescription

1Generator Assembly

2Voltage Regulator

3Main Terminal 'B+'

4Ignition Supply Terminal 'IG' to Rotor

5Output Terminal L to Charge Lamp

6Rotor

7Stator

8Rectifier Pack

Page 1889 of 2490

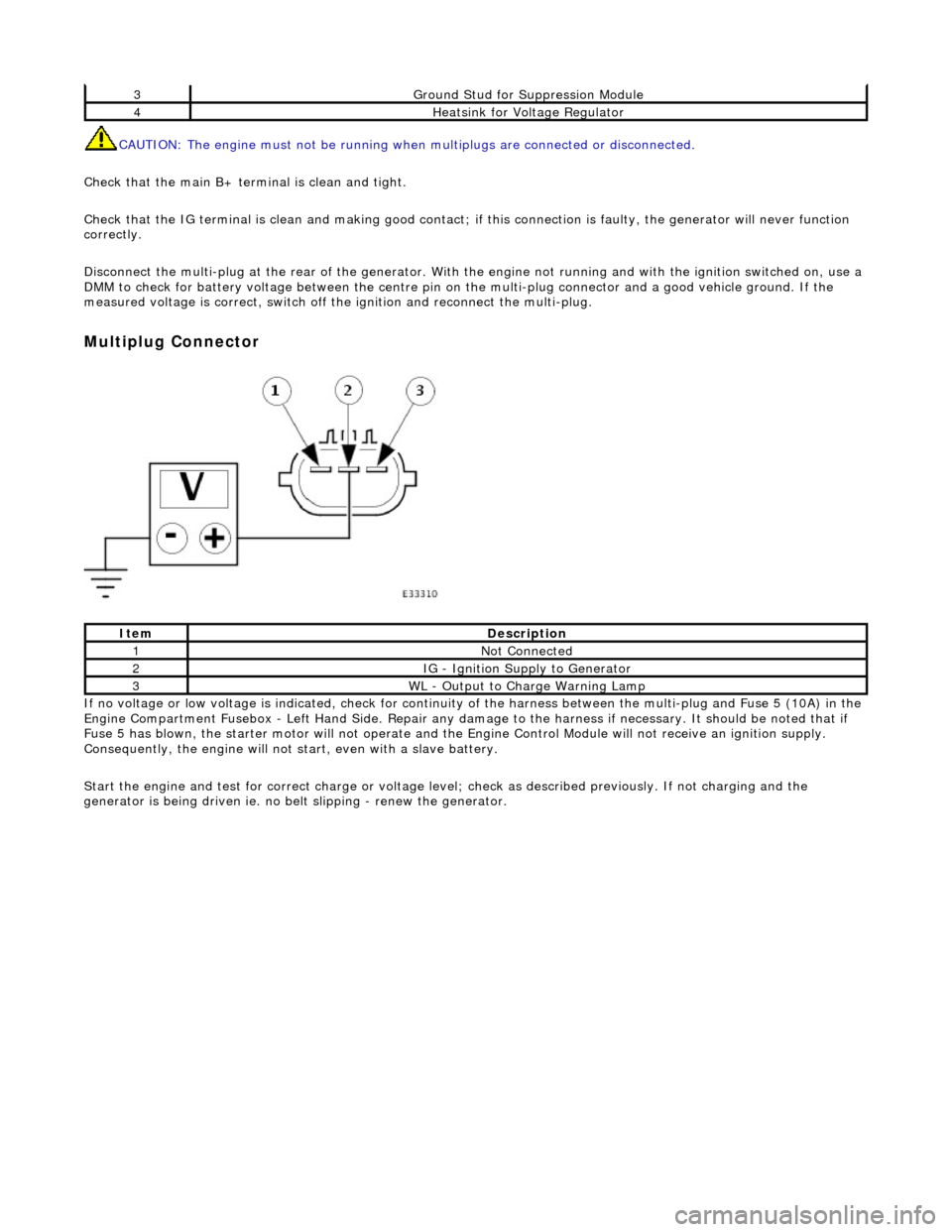

CAUTION: The engine must not be running when multiplugs are connected or disconnected.

Check that the main B+ terminal is clean and tight.

Check that the IG terminal is clean and ma king good contact; if this connection is faulty, the generator will never function

correctly.

Disconnect the multi-plug at th e rear of the generator. With the engine not running and with the ignition switched on, use a

DMM to check for battery voltage between the centre pin on the multi-plug connector and a good vehicle ground. If the

measured voltage is correct, switch off the ignition and reconnect the multi-plug.

Multiplug Connector

If no voltage or low voltage is indicated, check for continuity of the harness between the multi-plug and Fuse 5 (10A) in the

Engine Compartment Fusebox - Left Hand Si de. Repair any damage to the harness if necessary. It should be noted that if

Fuse 5 has blown, the starter motor will not operate and the Engine Control Module will not receive an ignition supply.

Consequently, the engine will not st art, even with a slave battery.

Start the engine and test for correct ch arge or voltage level; check as described previously. If not charging and the

generator is being driven ie. no be lt slipping - renew the generator.

3Ground Stud for Suppression Module

4Heatsink for Voltage Regulator

ItemDescription

1Not Connected

2IG - Ignition Supply to Generator

3WL - Output to Charge Warning Lamp

Page 1975 of 2490

Location of J1962 socket

The J1962 socket is located at the driver side inboard footwell.

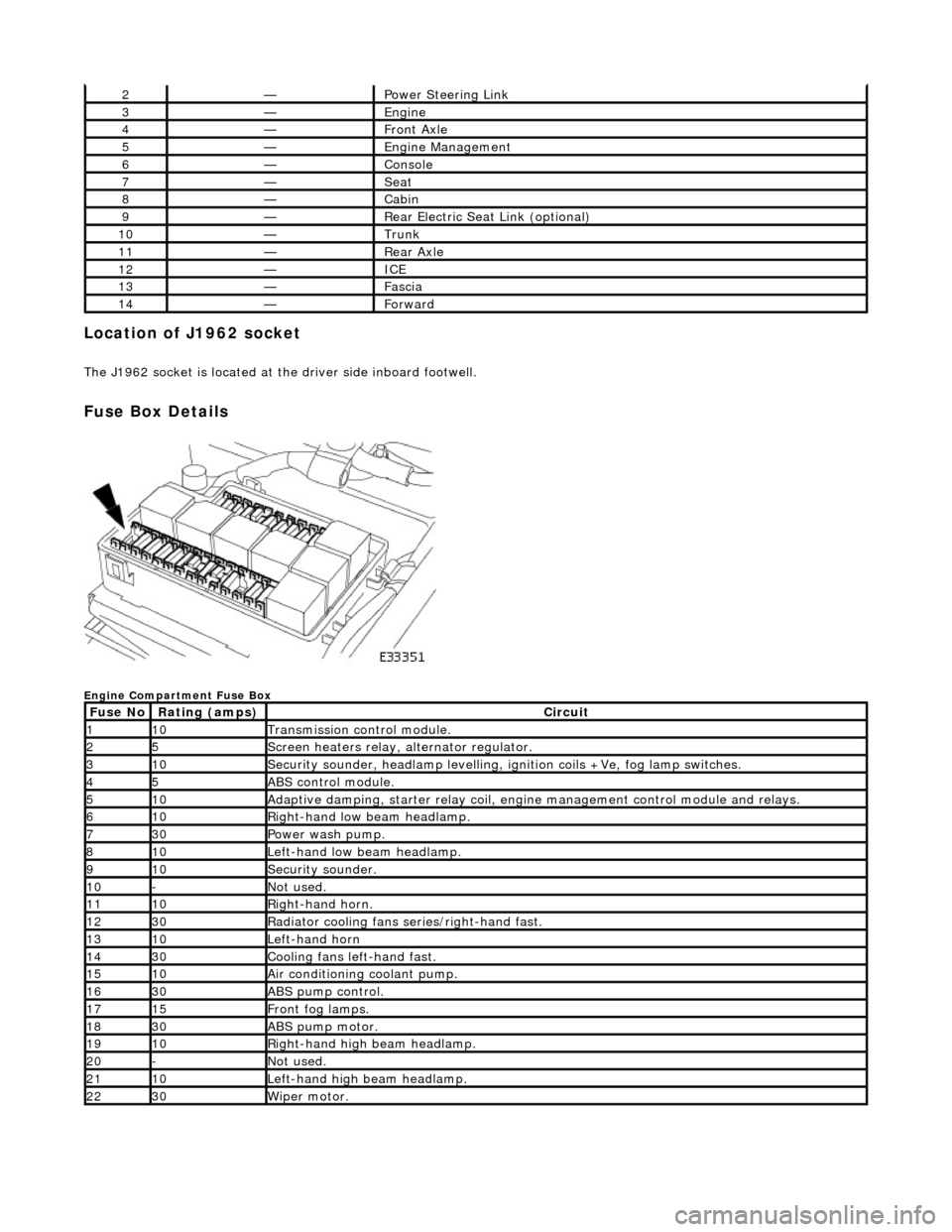

Fuse Box Details

Engine Compartment Fuse Box

2—Power Steering Link

3—Engine

4—Front Axle

5—Engine Management

6—Console

7—Seat

8—Cabin

9—Rear Electric Seat Link (optional)

10—Trunk

11—Rear Axle

12—ICE

13—Fascia

14—Forward

Fuse NoRating (amps)Circuit

110Transmission control module.

25Screen heaters relay, alternator regulator.

310Security sounder, headlamp levelling, ignition coils +Ve, fog lamp switches.

45ABS control module.

510Adaptive damping, starter relay coil, engine management control module and relays.

610Right-hand low beam headlamp.

730Power wash pump.

810Left-hand low beam headlamp.

910Security sounder.

10-Not used.

1110Right-hand horn.

1230Radiator cooling fans series/right-hand fast.

1310Left-hand horn

1430Cooling fans left-hand fast.

1510Air conditioning coolant pump.

1630ABS pump control.

1715Front fog lamps.

1830ABS pump motor.

1910Right-hand high beam headlamp.

20-Not used.

2110Left-hand high beam headlamp.

2230Wiper motor.

Page 1976 of 2490

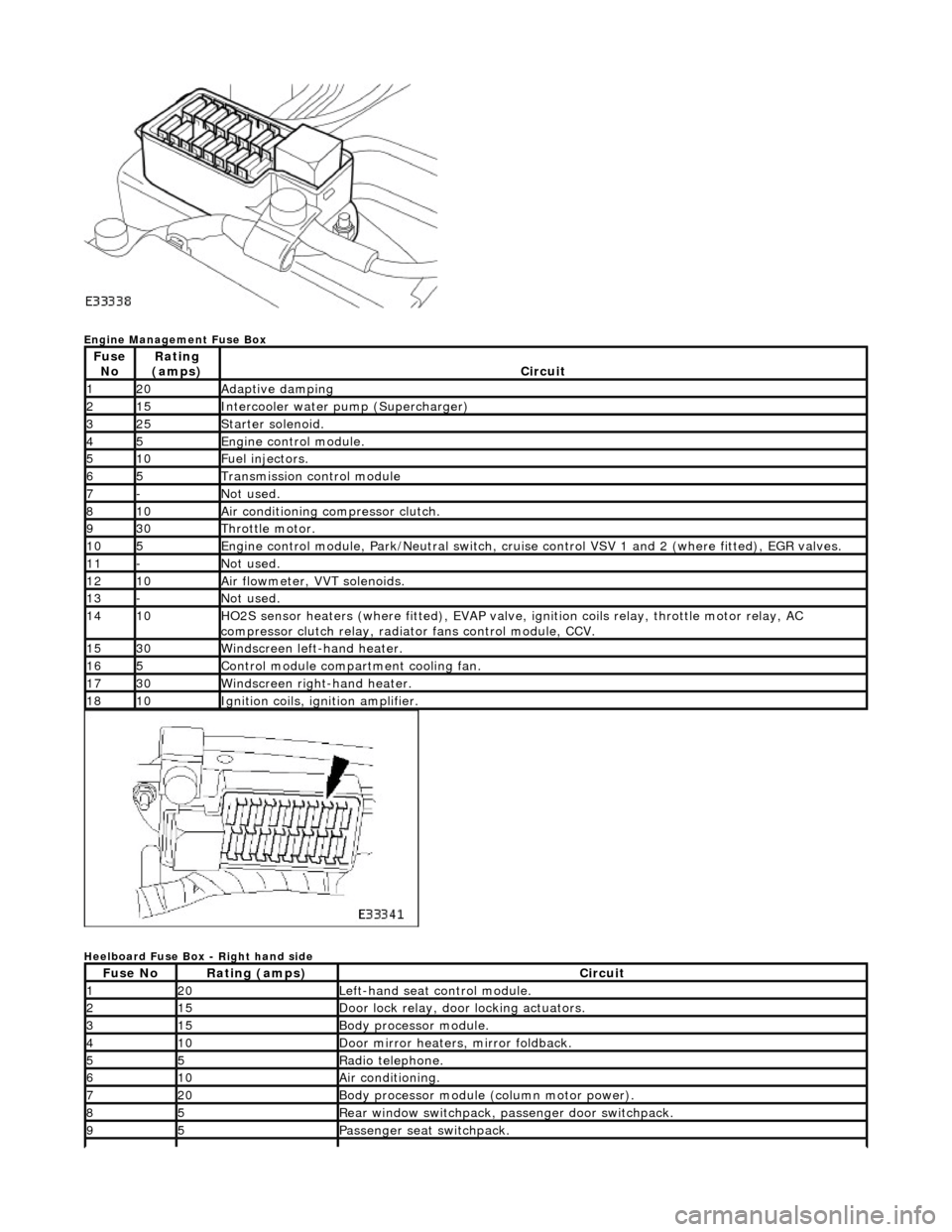

Engine Management Fuse Box

Heelboard Fuse Box - Right hand side

Fuse NoRating

(amps)Circuit

120Adaptive damping

215Intercooler water pump (Supercharger)

325Starter solenoid.

45Engine control module.

510Fuel injectors.

65Transmission control module

7-Not used.

810Air conditioning compressor clutch.

930Throttle motor.

105Engine control module, Park/Neutr al switch, cruise control VSV 1 and 2 (where fitted), EGR valves.

11-Not used.

1210Air flowmeter, VVT solenoids.

13-Not used.

1410HO2S sensor heaters (where fitted ), EVAP valve, ignition coils relay, throttle motor relay, AC

compressor clutch relay, radi ator fans control module, CCV.

1530Windscreen left-hand heater.

165Control module compartment cooling fan.

1730Windscreen right-hand heater.

1810Ignition coils, ignition amplifier.

Fuse NoRating (amps)Circuit

120Left-hand seat control module.

215Door lock relay, door locking actuators.

315Body processor module.

410Door mirror heaters, mirror foldback.

55Radio telephone.

610Air conditioning.

720Body processor module (column motor power).

85Rear window switchpack, passenger door switchpack.

95Passenger seat switchpack.

Page 1978 of 2490

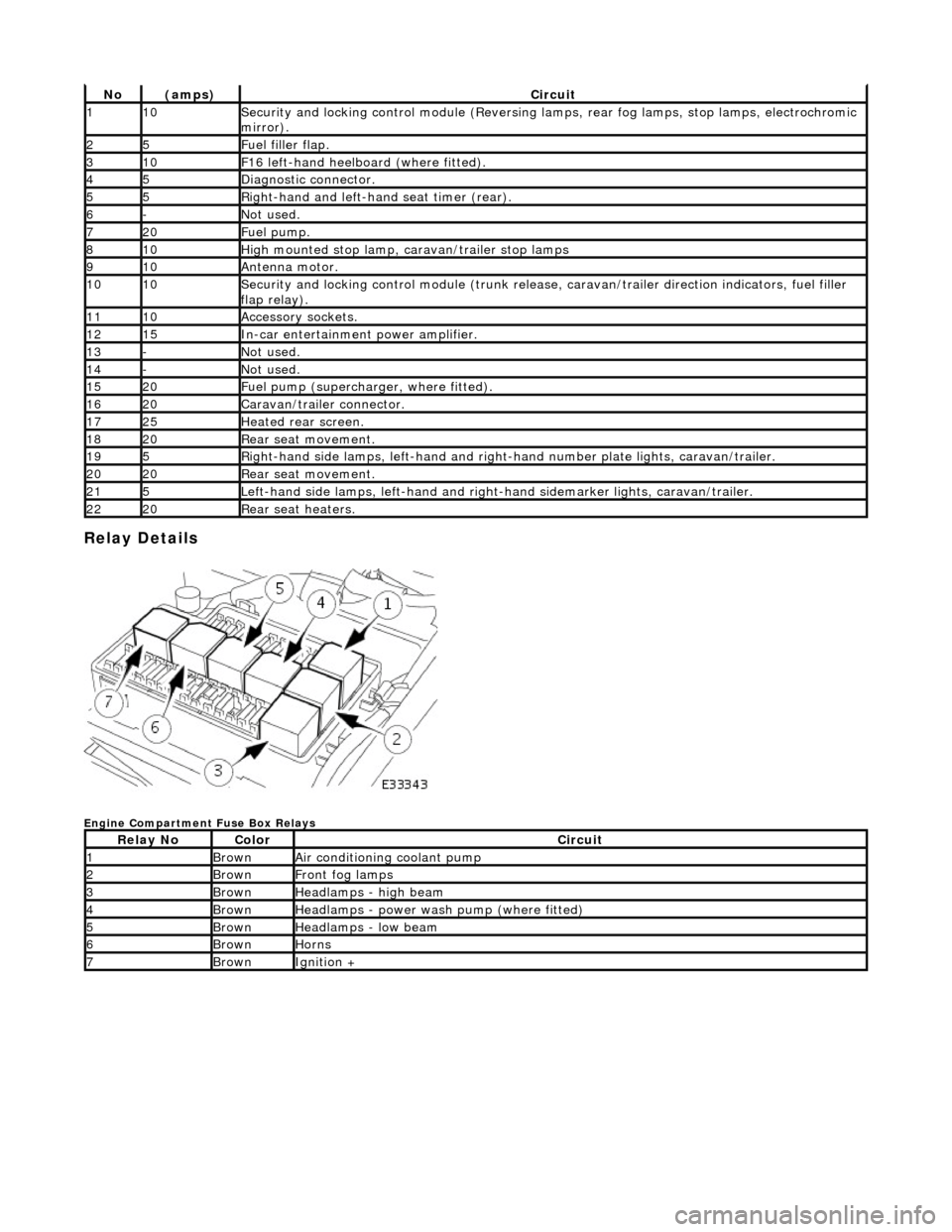

Relay Details

Engine Compartment Fuse Box Relays

No(amps)Circuit

110Security and locking control module (Reversing lamps, rear fog lamps, stop lamps, electrochromic

mirror).

25Fuel filler flap.

310F16 left-hand heelboard (where fitted).

45Diagnostic connector.

55Right-hand and left-han d seat timer (rear).

6-Not used.

720Fuel pump.

810High mounted stop lamp, caravan/trailer stop lamps

910Antenna motor.

1010Security and locking control module (trunk release, caravan/trailer direction indicators, fuel filler

flap relay).

1110Accessory sockets.

1215In-car entertainment power amplifier.

13-Not used.

14-Not used.

1520Fuel pump (supercharger, where fitted).

1620Caravan/trailer connector.

1725Heated rear screen.

1820Rear seat movement.

195Right-hand side lamps, left-h and and right-hand number pl ate lights, caravan/trailer.

2020Rear seat movement.

215Left-hand side lamps, left-hand and right-hand sidemarker lights, caravan/trailer.

2220Rear seat heaters.

Relay NoColorCircuit

1BrownAir conditioning coolant pump

2BrownFront fog lamps

3BrownHeadlamps - high beam

4BrownHeadlamps - power wash pump (where fitted)

5BrownHeadlamps - low beam

6BrownHorns

7BrownIgnition +

Page 1979 of 2490

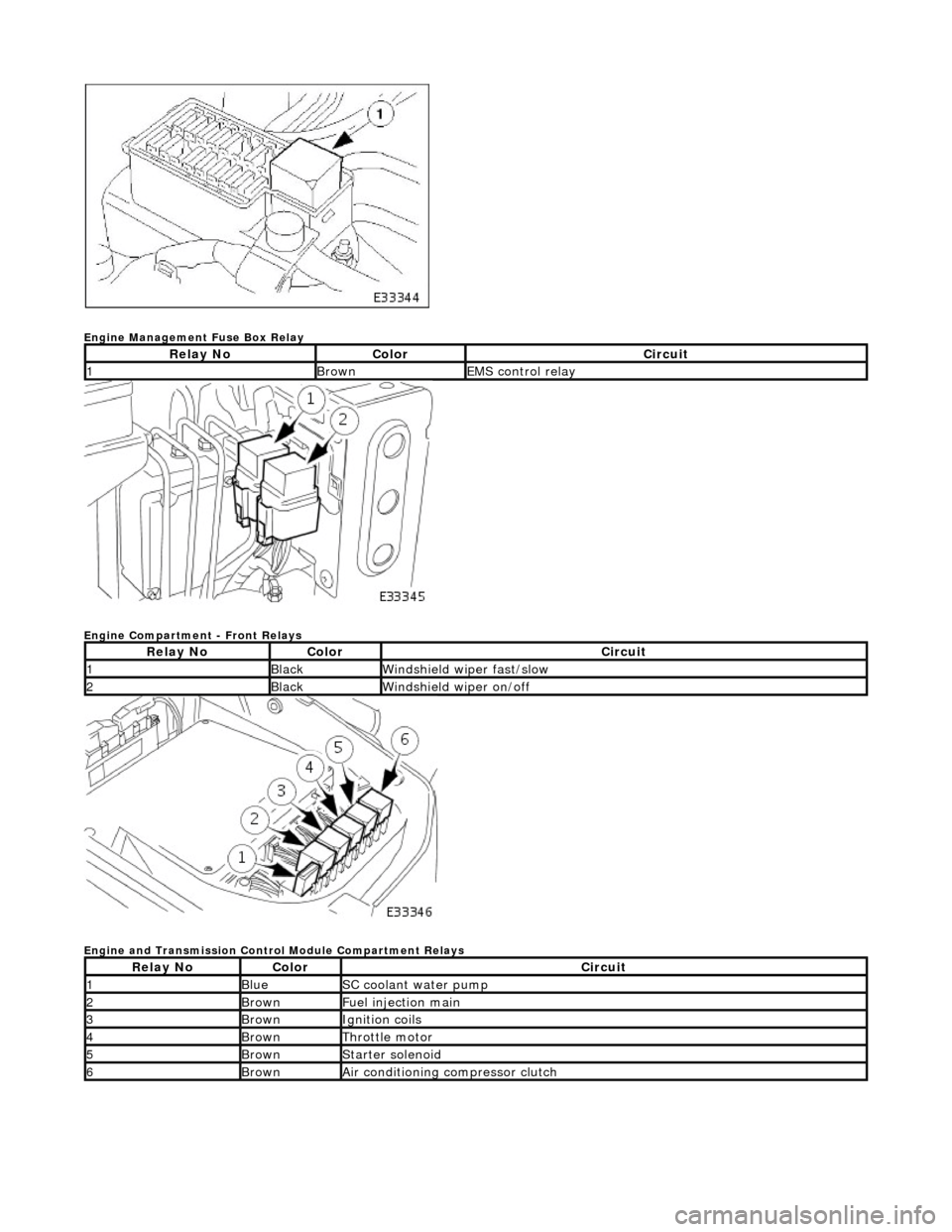

Engine Management Fuse Box Relay

Engine Compartment - Front Relays

Engine and Transmission Control Module Compartment Relays

Relay NoColorCircuit

1BrownEMS control relay

Relay NoColorCircuit

1BlackWindshield wiper fast/slow

2BlackWindshield wiper on/off

Relay NoColorCircuit

1BlueSC coolant water pump

2BrownFuel injection main

3BrownIgnition coils

4BrownThrottle motor

5BrownStarter solenoid

6BrownAir conditioning compressor clutch