engine ignition JAGUAR X308 1998 2.G Manual Online

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1208 of 2490

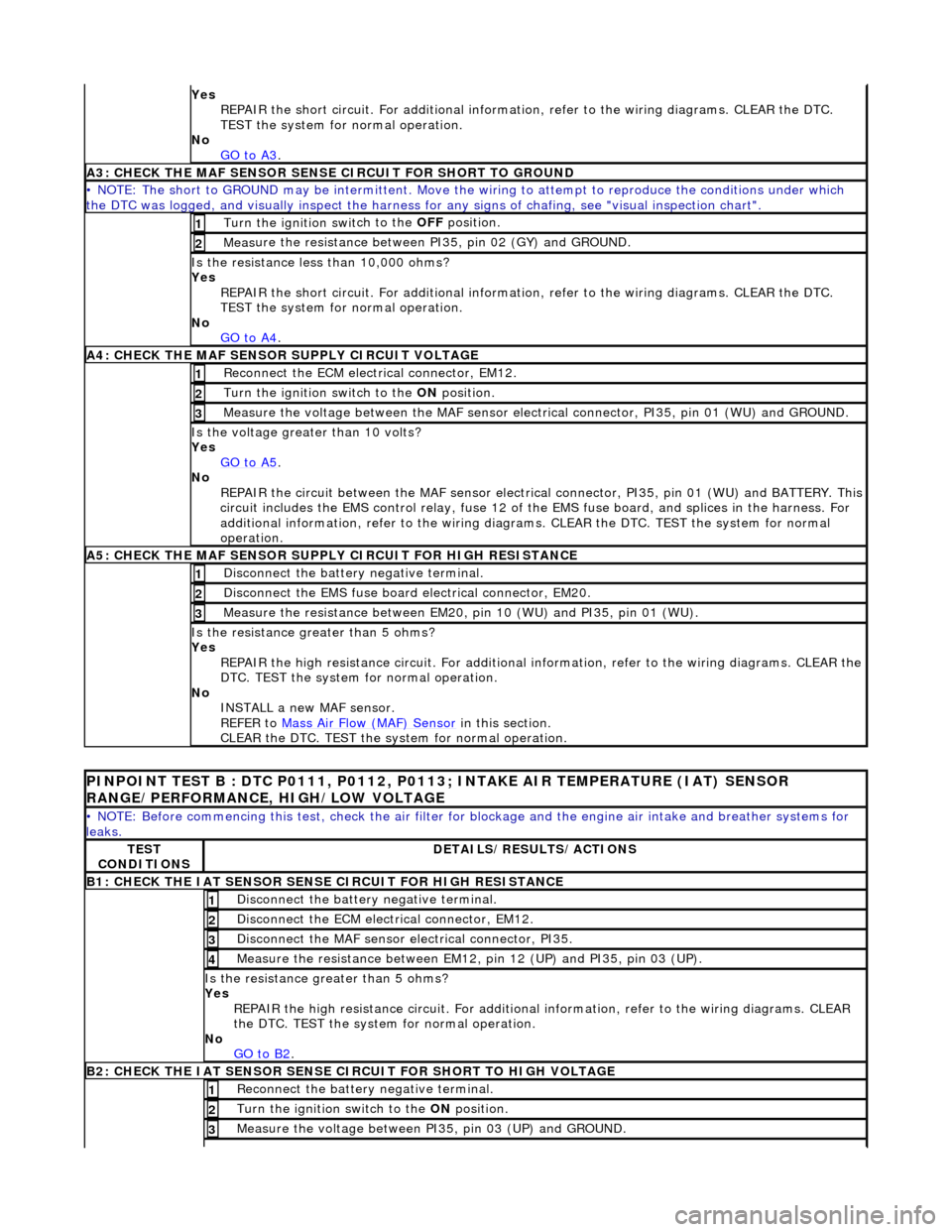

Yes

R

EPAIR the short circuit. For addi

tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to A3

.

A3: CHECK THE MAF SENSO

R SENS

E CIRCUIT FOR SHORT TO GROUND

• NO

TE: The short to GROUND may be intermittent. Move the

wiring to attempt to reproduce the conditions under which

the DTC was logged, and visually inspect the harness for any signs of chafing, see "visual inspection chart".

Turn the ignition swit

ch to the OFF

position.

1

Measure t

he resistance between PI35, pin 02 (GY) and GROUND.

2

Is t

he resistance less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to A4

.

A4: CHEC K THE MA

F SENSOR SUPPLY CIRCUIT VOLTAGE

Re

conn

ect the ECM electrical connector, EM12.

1

Turn the ignition swi

t

ch to the ON

position.

2

Me

asure the voltage between the MAF sensor electrical connector, PI35, pin 01 (WU) and GROUND.

3

Is the vol

t

age greater than 10 volts?

Yes GO to A5

.

No

REP

AIR the circuit between the MAF sensor electric

al connector, PI35, pin 01 (WU) and BATTERY. This

circuit includes the EMS control rela y, fuse 12 of the EMS fuse board, and splices in the harness. For

additional information, refer to the wiring diagrams. CLEAR the DT C. TEST the system for normal

operation.

A5: CHECK THE MAF SENSO

R SUPPLY CIRCUIT FOR HIGH RESISTANCE

Di

sc

onnect the battery negative terminal.

1

Di

sc

onnect the EMS fuse board electrical connector, EM20.

2

Meas

ure t

he resistance between EM20,

pin 10 (WU) and PI35, pin 01 (WU).

3

Is the res

istance greater than 5 ohms?

Yes REPAIR the high resistance circuit. For additional information, refer to the wiring diagrams. CLEAR the

DTC. TEST the system for normal operation.

No INSTALL a new MAF sensor.

REFER to Mass Air Flow (MAF) Sensor

in this

section.

CLEAR the DTC. TEST the system for normal operation.

P INPOINT TES

T B : DTC P0111, P0112, P0113;

INTAKE AIR TEMPERATURE (IAT) SENSOR

RANGE/PERFORMANCE, HIGH/LOW VOLTAGE

•

NOTE: Before commencing this

test, check the air filter for blockage and the engine air intake and breather systems for

leaks.

TE S

T

CONDITIONS

D E

TAILS/RESULTS/ACTIONS

B1: CHECK

THE IAT SENSOR

SENS

E CIRCUIT FOR HIGH RESISTANCE

Disc

onnect the battery negative terminal.

1

D

i

sconnect the ECM electrical connector, EM12.

2

Di

sc

onnect the MAF sensor electrical connector, PI35.

3

Me

asure

the resistance between EM12, pin 12 (UP) and PI35, pin 03 (UP).

4

Is th

e res

istance greater than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No GO to B2

.

B2: CHECK

THE IAT SENSOR SENSE CIRCUIT FOR SHORT TO HIGH VOLTAGE

R

e

connect the battery negative terminal.

1

Turn the ignition swi

t

ch to the ON

position.

2

Measure the voltage between PI 35,

pin 03 (UP) and GROUND.

3

Page 1209 of 2490

Is th

e voltage greater than 3 volts?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to B3

.

B3: CHECK

THE IAT SENSOR SENS

E CIRCUIT FOR SHORT TO GROUND

Turn the ignition swi

tch to the OFF

position.

1

Meas

ure the resistance between PI35, pin 03 (UP) and GROUND.

2

Is

the resistance less than 10,000 ohms?

Yes

REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No INSTALL a new MAF sensor.

REFER to Mass Air Flow (MAF) Sensor

in this section.

CLEAR the DTC. TEST the system for normal operation.

PI

NPOINT TEST C : DTC P0116, P0117, P0118

; ENGINE COOLANT TEMPERATURE (ECT) SENSOR

RANGE/PERFORMANCE, HIGH/LOW VOLTAGE

•

NOTE: Before commencing this

test, check the coolant level and condition, check the operation of the thermostat, rectify

as necessary.

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

C1: CHECK THE ECT SEN

SOR SENS

E CIRCUIT FOR HIGH RESISTANCE

Di

sconnect the battery negative terminal.

1

D

isconnect the ECM electrical connector, EM11.

2

D

isconnect the ECT sensor electrical connector, PI04.

3

Meas

ure the resistance between EM11, pin 09 (UY) and PI04, pin 02 (UY).

4

Is th

e resistance greater than 5 ohms?

Yes

REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No GO to C2

.

C2: CHECK THE ECT SEN

SOR SENSE CI

RCUIT FOR SHORT TO HIGH VOLTAGE

R

econnect the battery negative terminal.

1

Turn the ignition swi

tch to the ON

position.

2

Meas

ure the voltage between PI04, pin 02 (UY) and GROUND.

3

Is th

e voltage greater than 3 volts?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to C3

.

C3: CHECK THE ECT SEN

SOR SENSE CIRCUIT FOR SHORT TO GROUND

Turn the ignition swi

tch to the OFF

position.

1

Meas

ure the resistance between PI04, pin 02 (UY) and GROUND.

2

Is

the resistance less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No INSTALL a new ECT sensor. REFER to Section 303

-0

3A Engine Cooling

/

30

3

-0

3B Supercharger

Coo

ling

. CLEA

R the DTC. TEST the sy

stem for normal operation.

P

INPOINT TEST D : DTC P0121, P0122,

P0123; THROTTLE POSITION (TP) SENSOR

RANGE/PERFORMANCE, HIGH/LOW VOLTAGE

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

D1: CHECK

THE TP SENSOR SENS

E CIRCUIT FOR HIGH RESISTANCE

Di

sconnect the battery negative terminal.

1

Page 1210 of 2490

Di

sconnect the ECM electrical connector, EM11.

2

Disc

onne

ct the TP sensor electrical connector, PI06.

3

Meas

ure t

he resistance between EM11, pin 11 (U) and PI06, pin 03 (U).

4

Is th

e res

istance greater than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No GO to D2

.

D2

: CHECK THE TP SENSOR SENSE CIRCUIT FOR SHORT TO HIGH VOLTAGE

Re

connect the battery negative terminal.

1

Turn the ignition swit

ch to the ON

position.

2

Me

asure the voltage between PI06, pin 03 (U) and GROUND.

3

Is the volt

age greater than 5 volts?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to D3

.

D3: CH

ECK THE TP SENSOR SENSE CIRCUIT FOR SHORT TO GROUND

Turn the ignition swi

t

ch to the OFF

position.

1

Measure t

he resistance between PI06, pin 03 (U) and GROUND.

2

Is

t

he resistance less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No INSTALL a new TP sensor.

REFER to Throttle Position (TP) Sensor

in this

section.

CLEAR the DTC. TEST the syst em for normal operation.

PI

NPOINT TEST E : DTC P0131, P0132, P0133; RIGHT-HAND H02S LOW/HIGH VOLTAGE, SLOW

RESPONSE

•

NOTE: Before commencing this test, check the sensor connect

ions and harness, check for exhaust leaks, engine misfire,

etc. See 'visual inspection ch art' and 'possible causes'.

TES

T

CONDITIONS

D E

TAILS/RESULTS/ACTIONS

E1

: CHECK THE H02S

SENSE CI

RCUIT FOR HIGH RESISTANCE

Disc

onnect the battery negative terminal.

1

D

is

connect the H02S electrical connector, EM21.

2

Disc

onne

ct the ECM electrical connector, EM12

3

Meas

ure t

he resistance between EM21, pin 03 (R) and EM12, pin 15 (R).

4

Is th

e res

istance greater than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No GO to E2

.

E2: CHECK THE H02S

SENSE CIRCUI

T FOR SHORT TO HIGH VOLTAGE

Re

connect the battery negative terminal.

1

Turn the ignition swi

t

ch to the ON

position.

2

Measure t

he voltage between EM12, pin 15 (R) and GROUND.

3

Is th

e volt

age greater than 3 volts?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to E3

.

E3: CHECK THE H02S

SENSE CI

RCUIT FOR SHORT TO GROUND

Turn the ignition swi t

ch to the OFF

position.

1

Measure t

he resistance between EM12, pin 15 (R) and GROUND.

2

Page 1212 of 2490

CLEAR th

e DTC. TEST the syst

em for normal operation.

PINPOINT TES

T G : DTC P0137, P0138; RIGH

T-HAND CATALYST MONITOR SENSOR LOW/HIGH

VOLTAGE, NO ACTIVITY

TE S

T

CONDITIONS

D E

TAILS/RESULTS/ACTIONS

G1

: C

HECK THE CATALYST MONITOR SENSOR SENSE CIRCUIT FOR HIGH RESISTANCE

Di

sc

onnect the battery negative terminal.

1

Di

sc

onnect the catalyst monitor sensor electrical connector, EM22.

2

Disc

onne

ct the ECM electrical connector, EM12.

3

Meas

ure t

he resistance between EM22, pin 02 (U) and EM12, pin 17 (U).

4

Is th

e res

istance greater than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No GO to G2

.

G2: CHECK

THE CATALYST MONITOR SENSOR SE

NSE CIRCUIT FOR SHORT TO HIGH VOLTAGE

Re

connect the battery negative terminal.

1

Turn the ignition swi

t

ch to the ON

position.

2

Measure t

he voltage between EM12, pin 17 (U) and GROUND.

3

Is th

e volt

age greater than 3 volts?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No

GO to G3

.

G3: CHECK

THE CATALYST MONITOR SENSOR

SENSE CIRCUIT FOR SHORT TO GROUND

Turn the ignition swit

ch to the OFF

position.

1

Measure t

he resistance between EM12, pin 17 (U) and GROUND.

2

Is t

he resistance less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to G4

.

G4: CHECK

THE CATALYST MONITOR SENSOR

GROUND CIRCUIT FOR OPEN CIRCUIT

Reconn

ect the ECM electrical connector, EM12.

1

Meas

ure t

he resistance between EM22, pin 01 (BRD) and GROUND.

2

Is th

e res

istance greater than 5 ohms?

Yes REPAIR the circuit (this is a braide d lead which would require different repair techniques to standard

wiring). For additional information, refer to the wiring diagrams. CL EAR the DTC. TEST the system for

normal operation.

No INSTALL a new catalyst monitor sensor.

REFER to Catalyst Monitor Sensor RH

in this

section.

CLEAR the DTC. TEST the syst em for normal operation.

PINPOINT TES

T H : DTC P0151, P0152, P0153;

LEFT-HAND H02S LOW/HIGH VOLTAGE, SLOW

RESPONSE

•

NOTE: Before commencing this test, check the sensor connect

ions and harness, check for exhaust leaks, engine misfire,

etc. See 'visual inspection ch art' and 'possible causes'.

TES

T

CONDITIONS

D E

TAILS/RESULTS/ACTIONS

H1:

C

HECK THE H02S SENSE CIRCUIT FOR HIGH RESISTANCE

Di

sc

onnect the battery negative terminal.

1

D

is

connect the H02S electrical connector, EM23.

2

Disc

onne

ct the ECM electrical connector, EM12.

3

Meas

ure t

he resistance between EM23, pin 03 (G) and EM12, pin 14 (G).

4

Is th

e res

istance greater than 5 ohms?

Page 1220 of 2490

the DT

C. TEST the system for normal operation.

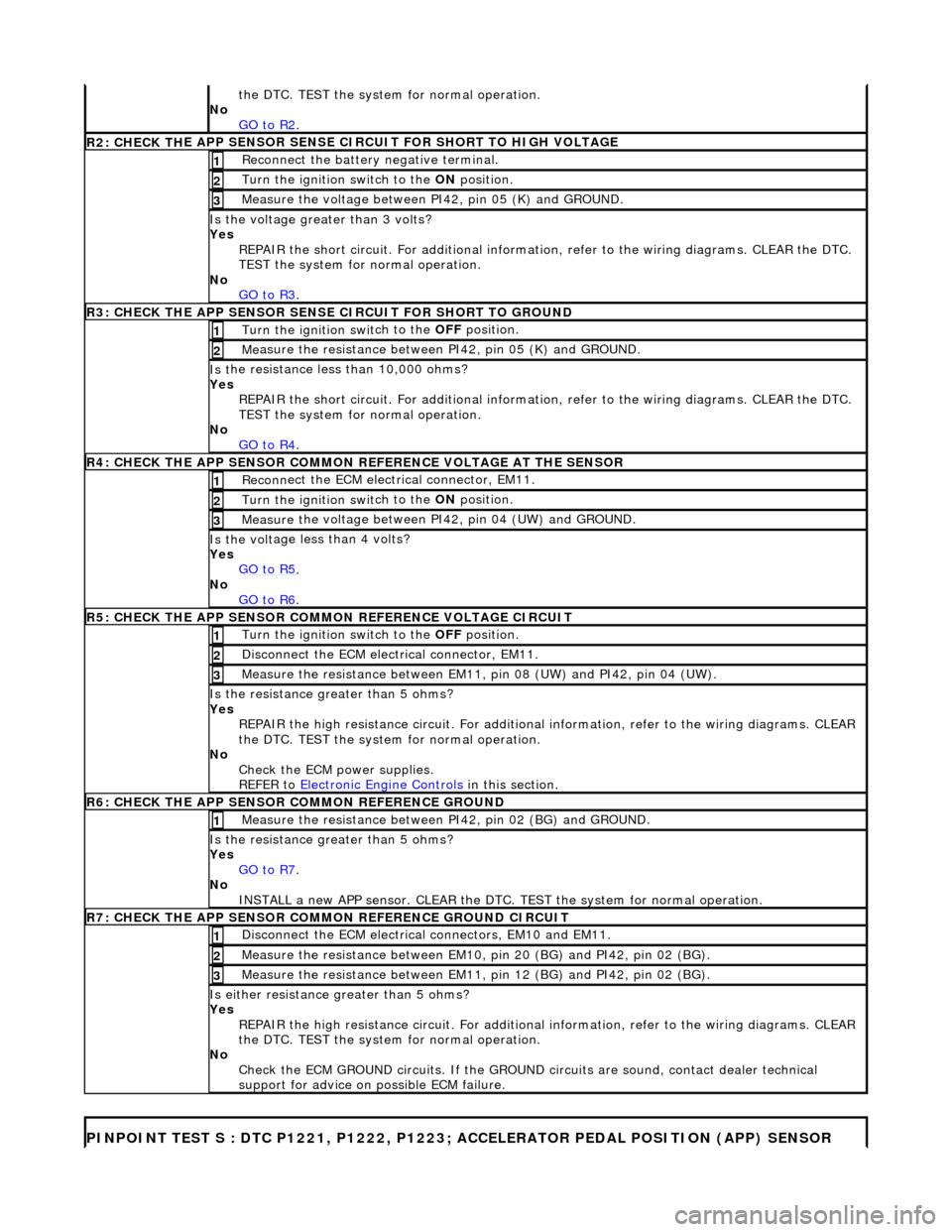

No GO to R2

.

R2: CHECK TH

E APP SENSOR SENSE CIRCUIT FOR SHORT TO HIGH VOLTAGE

R

e

connect the battery negative terminal.

1

Turn the ignition swi

t

ch to the ON

position.

2

Me

asure the voltage between PI42, pin 05 (K) and GROUND.

3

Is th

e volt

age greater than 3 volts?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to R3

.

R3: CHECK THE APP SENSOR SENS

E CIRCUIT FOR SHORT TO GROUND

Turn the ignition swi

t

ch to the OFF

position.

1

Me

asure the resistance between PI42, pin 05 (K) and GROUND.

2

Is

t

he resistance less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to R4

.

R4: CHECK THE APP SENSOR COM

MON

REFERENCE VOLTAGE AT THE SENSOR

Reconn

ect the ECM electrical connector, EM11.

1

Turn the ignition swi

t

ch to the ON

position.

2

Measure t

he voltage between PI42, pin 04 (UW) and GROUND.

3

Is th

e volt

age less than 4 volts?

Yes GO to R5

.

No

GO to R6

.

R5: CHECK THE APP SENSOR COM

M

ON REFERENCE VOLTAGE CIRCUIT

Turn the ignition swit

ch to the OFF

position.

1

Di

sconnect the ECM electrical connector, EM11.

2

Measure t

he resistance between EM11,

pin 08 (UW) and PI42, pin 04 (UW).

3

Is the res

istance greater than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No Check the ECM power supplies.

REFER to Electronic Engine Controls

in this

section.

R6: CHECK THE APP

SENSOR COM

MON REFERENCE GROUND

Meas

ure t

he resistance between PI42, pin 02 (BG) and GROUND.

1

Is th

e res

istance greater than 5 ohms?

Yes GO to R7

.

No

INST

ALL a new APP sensor. CLEAR the DTC.

TEST the system for normal operation.

R7: CHECK THE APP SENSOR COM

MON REFERENCE GROUND CIRCUIT

D

i

sconnect the ECM electrical connectors, EM10 and EM11.

1

Measure t

he resistance between EM10,

pin 20 (BG) and PI42, pin 02 (BG).

2

Measure t

he resistance between EM11,

pin 12 (BG) and PI42, pin 02 (BG).

3

Is either resistance greater

than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No Check the ECM GROUND circuits. If the GROUND circuits are sound, contact dealer technical

support for advice on possible ECM failure.

PINPO

INT TEST S : DTC P1221, P1222, P1223;

ACCELERATOR PEDAL POSITION (APP) SENSOR

Page 1221 of 2490

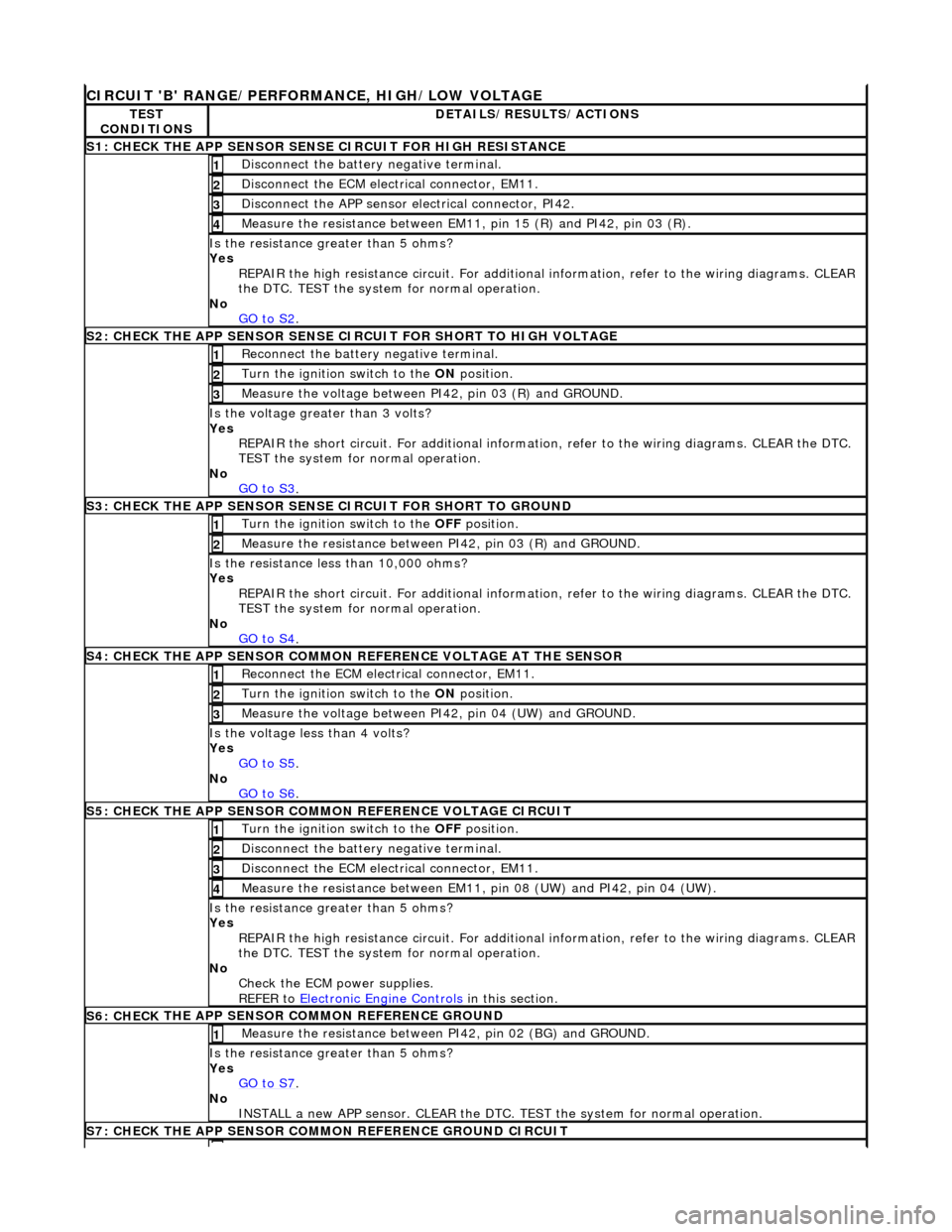

CIRCUI

T 'B' RANGE/PERFORMANCE, HIGH/LOW VOLTAGE

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

S1: CHECK

THE APP SENSOR SENSE CIRCUIT FOR HIGH RESISTANCE

Di

sconnect the battery negative terminal.

1

D

isconnect the ECM electrical connector, EM11.

2

Di

sconnect the APP sensor electrical connector, PI42.

3

Meas

ure the resistance between EM11, pin 15 (R) and PI42, pin 03 (R).

4

Is th

e resistance greater than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No GO to S2

.

S

2: CHECK THE APP SENSOR SENSE CIRCUIT FOR SHORT TO HIGH VOLTAGE

R

econnect the battery negative terminal.

1

Turn the ignition swi

tch to the ON

position.

2

M

easure the voltage between PI42, pin 03 (R) and GROUND.

3

Is th

e voltage greater than 3 volts?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to S3

.

S

3: CHECK THE APP SENSOR SENSE CIRCUIT FOR SHORT TO GROUND

Turn the ignition swi

tch to the OFF

position.

1

Meas

ure the resistance between PI42, pin 03 (R) and GROUND.

2

Is

the resistance less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to S4

.

S4:

CHECK THE APP SENSOR COMMON REFERENCE VOLTAGE AT THE SENSOR

Re

connect the ECM electrical connector, EM11.

1

Turn the ignition swi

tch to the ON

position.

2

Meas

ure the voltage between PI42, pin 04 (UW) and GROUND.

3

Is th

e voltage less than 4 volts?

Yes GO to S5

.

No

GO to S6

.

S5: CHECK

THE APP SENSOR COMM

ON REFERENCE VOLTAGE CIRCUIT

Turn the ignition swi

tch to the OFF

position.

1

Di

sconnect the battery negative terminal.

2

D

isconnect the ECM electrical connector, EM11.

3

Meas

ure the resistance between EM11,

pin 08 (UW) and PI42, pin 04 (UW).

4

Is th

e resistance greater than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No Check the ECM power supplies.

REFER to Electronic Engine Controls

in this section.

S6: CHECK

THE APP SENSOR COMMON REFERENCE GROUND

Meas

ure the resistance between PI42, pin 02 (BG) and GROUND.

1

Is th

e resistance greater than 5 ohms?

Yes GO to S7

.

No

INSTALL a new APP sensor. CLEAR the DTC. TEST the system for normal operation.

S7: CHECK

THE APP SENSOR COMM

ON REFERENCE GROUND CIRCUIT

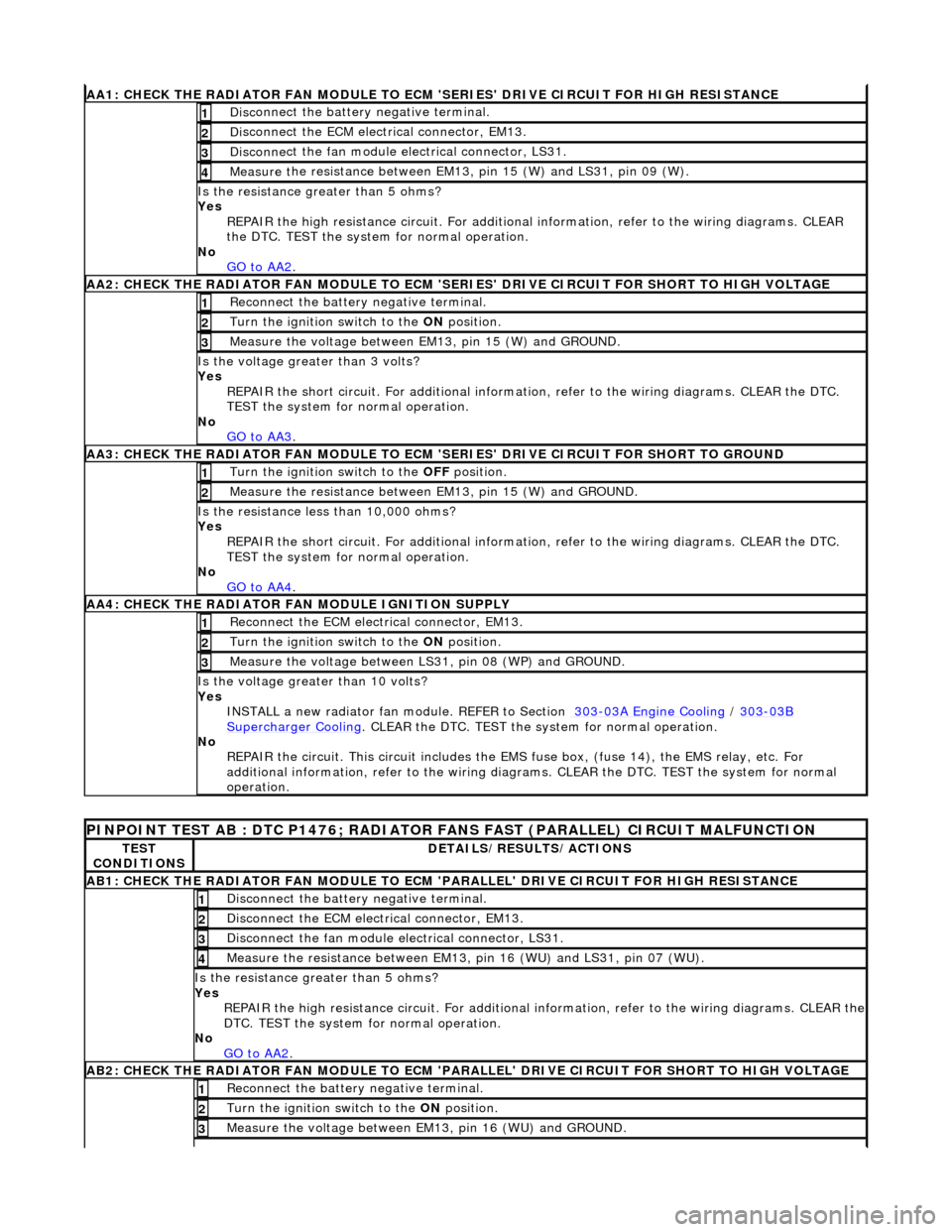

Page 1230 of 2490

AA1: CHECK THE RA

DIATOR FAN MODULE TO ECM

'SERIES' DRIVE CIRCUIT FOR HIGH RESISTANCE

Disc

onnect the battery negative terminal.

1

D

i

sconnect the ECM electrical connector, EM13.

2

Disc

onne

ct the fan module electrical connector, LS31.

3

Meas

ure t

he resistance between EM13, pin 15 (W) and LS31, pin 09 (W).

4

Is th

e res

istance greater than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No GO to AA2

.

AA2: CHECK THE RA

DIATOR FAN MODULE TO ECM 'SER

IES' DRIVE CIRCUIT FOR SHORT TO HIGH VOLTAGE

Re

connect the battery negative terminal.

1

Turn the ignition swit

ch to the

ON position.

2

Measure t

he voltage between EM13, pin 15 (W) and GROUND.

3

Is the volt

age greater than 3 volts?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to AA3

.

AA3: CHECK THE R A

DIATOR FAN MODULE TO ECM

'SERIES' DRIVE CIRCUIT FOR SHORT TO GROUND

Turn the ignition swit

ch to the

OFF position.

1

Meas ure t

he resistance between EM13, pin 15 (W) and GROUND.

2

Is

t

he resistance less than 10,000 ohms?

Yes

REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to AA4

.

AA4:

CHECK THE RADIATOR FAN MODULE IGNITION SUPPLY

Reconn

ect the ECM electrical connector, EM13.

1

Turn the ignition swit

ch to the

ON position.

2

Measure the voltage between LS 31,

pin 08 (WP) and GROUND.

3

Is the vol

t

age greater than 10 volts?

Yes INSTALL a new radiator fan module. REFER to Section 303

-03

A Engine Cooling

/

303-03B Supercharger Cooli

ng

. CLEA

R the DTC. TEST the sy stem f

or normal operation.

No REPAIR the circuit. This circui t includes the EMS fuse box, (f use 14), the EMS relay, etc. For

additional information, refer to the wiring diagrams. CLEAR the DT C. TEST the system for normal

operation.

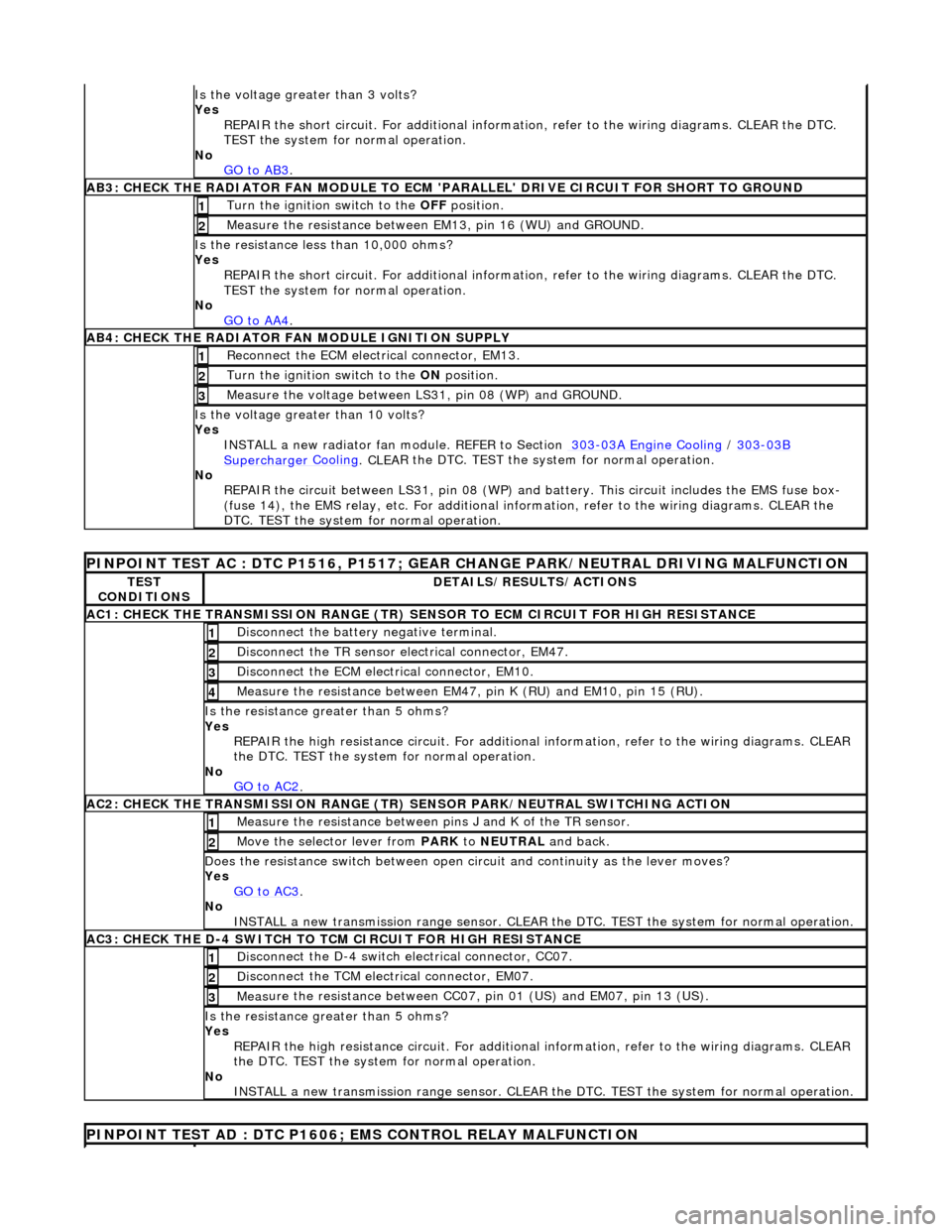

PINPOINT TE ST

AB : DTC P1476; RADIATOR

FANS FAST (PARALLEL) CIRCUIT MALFUNCTION

TES

T

CONDITIONS

D E

TAILS/RESULTS/ACTIONS

AB1

:

CHECK THE RADIATOR FAN MODULE TO ECM

'PARALLEL' DRIVE CIRCUIT FOR HIGH RESISTANCE

Disc

onnect the battery negative terminal.

1

D

i

sconnect the ECM electrical connector, EM13.

2

Disc

onne

ct the fan module electrical connector, LS31.

3

Meas

ure t

he resistance between EM13, pin 16 (WU) and LS31, pin 07 (WU).

4

Is th

e res

istance greater than 5 ohms?

Yes REPAIR the high resistance circuit. For additional information, refer to the wiring diagrams. CLEAR the

DTC. TEST the system for normal operation.

No GO to AA2

.

AB2:

CHECK THE RADIATOR FAN MODULE TO ECM 'PARALLEL' DRIVE CIRCUIT FOR SHORT TO HIGH VOLTAGE

R

e

connect the battery negative terminal.

1

Turn the ignition swi

t

ch to the ON

position.

2

Measure t

he voltage between EM13, pin 16 (WU) and GROUND.

3

Page 1231 of 2490

Is th

e voltage greater than 3 volts?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to AB3

.

AB3

: CHECK THE RADIATOR FAN MODULE TO ECM

'PARALLEL' DRIVE CIRCUIT FOR SHORT TO GROUND

Turn the ignition swi

tch to the OFF

position.

1

Meas

ure the resistance between EM13, pin 16 (WU) and GROUND.

2

Is

the resistance less than 10,000 ohms?

Yes

REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to AA4

.

AB4

: CHECK THE RADIATOR FAN MODULE IGNITION SUPPLY

Re

connect the ECM electrical connector, EM13.

1

Turn the ignition swi

tch to the ON

position.

2

Measure the

voltage between LS

31, pin 08 (WP) and GROUND.

3

Is the vol

tage greater than 10 volts?

Yes INSTALL a new radiator fan module. REFER to Section 303

-0

3A Engine Cooling

/

30

3

-03

B

Supercharger

Cooling

. CLEA

R the DTC. TEST the sy

stem for normal operation.

No REPAIR the circuit between LS31, pin 08 (WP) and battery. This circuit includes the EMS fuse box-

(fuse 14), the EMS relay, etc. For additional information, refer to the wiring diagrams. CLEAR the

DTC. TEST the system for normal operation.

P

INPOINT TEST AC : DTC P1516, P1517; GEAR

CHANGE PARK/NEUTRAL DRIVING MALFUNCTION

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

AC1: CH

ECK THE TRANSMISSION RANGE (TR) SE

NSOR TO ECM CIRCUIT FOR HIGH RESISTANCE

Di

sconnect the battery negative terminal.

1

Di

sconnect the TR sensor el

ectrical connector, EM47.

2

D

isconnect the ECM electrical connector, EM10.

3

Meas

ure the resistance between EM47, pin K (RU) and EM10, pin 15 (RU).

4

Is th

e resistance greater than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No GO to AC2

.

AC2: CH

ECK THE TRANSMISSION RANGE (TR)

SENSOR PARK/NEUTRAL SWITCHING ACTION

Meas

ure the resistance between pi

ns J and K of the TR sensor.

1

Mo

ve the selector lever from

PARK to NEUTRAL and back.

2

D

oes the resistance switch between open ci

rcuit and continuity as the lever moves?

Yes GO to AC3

.

No

INSTALL a new transmission range sensor. CLEAR th e DTC. TEST the system for normal operation.

AC3: CH

ECK THE D-4 SWITCH TO

TCM CIRCUIT FOR HIGH RESISTANCE

Di

sconnect the D-4 switch electrical connector, CC07.

1

Di

sconnect the TCM electrical connector, EM07.

2

Meas

ure the resistance between CC07,

pin 01 (US) and EM07, pin 13 (US).

3

Is th

e resistance greater than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No INSTALL a new transmission range sensor. CLEAR th e DTC. TEST the system for normal operation.

P

INPOINT TEST AD : DTC P1606;

EMS CONTROL RELAY MALFUNCTION

Page 1241 of 2490

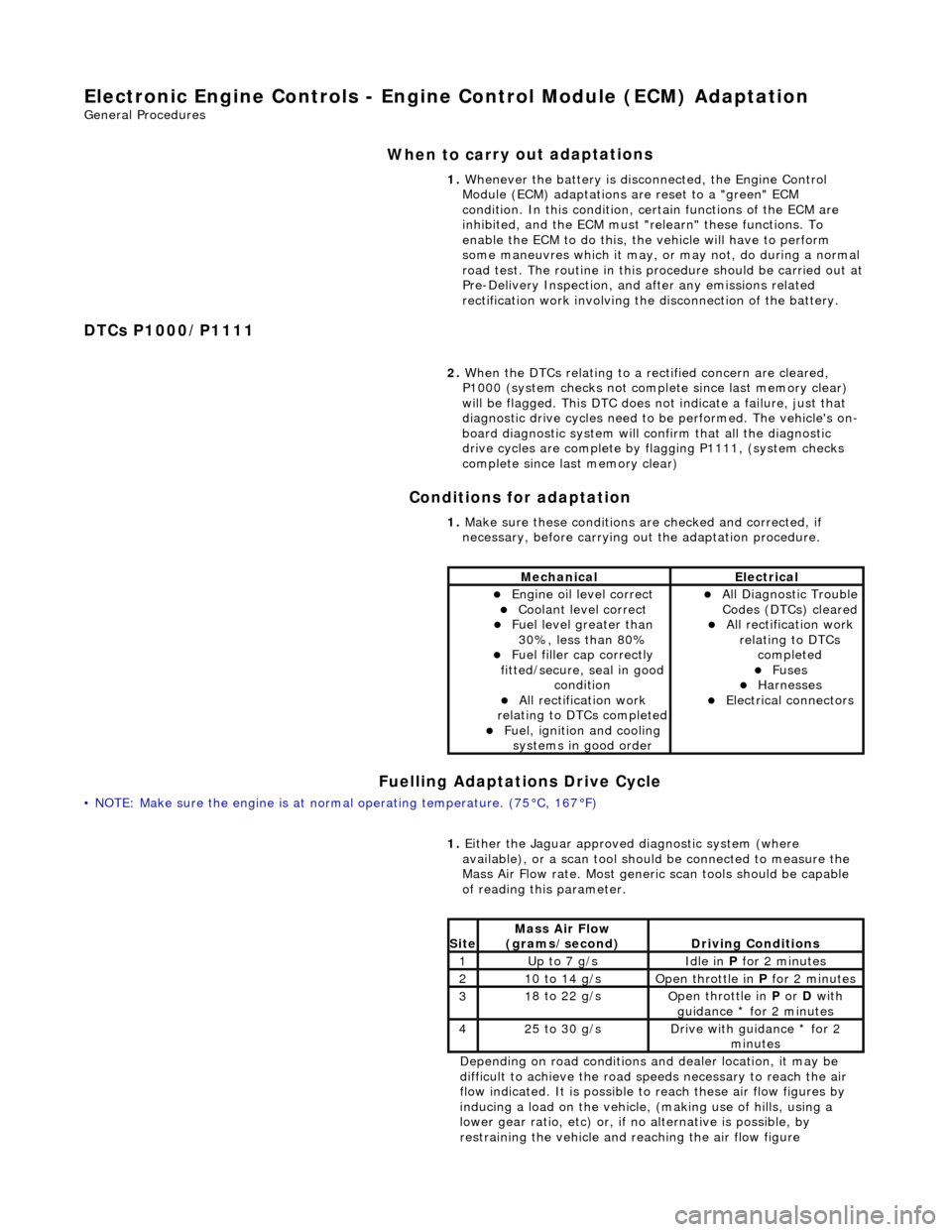

E

lectronic Engine Controls - Engine

Control Module (ECM) Adaptation

Gen

eral Procedures

When to car

ry out adaptations

DTCs P1000/P1111 Conditions for adaptation

Fuelling Adaptations Drive Cycle

•

NOTE: Make sure the engine is at normal operating

temperature. (75°C, 167°F) 1.

Whenever the battery is disconnected, the Engine Control

Module (ECM) adaptations are reset to a "green" ECM

condition. In this condition, certain functions of the ECM are

inhibited, and the ECM must "r elearn" these functions. To

enable the ECM to do this, the vehicle will have to perform

some maneuvres which it may, or may not, do during a normal

road test. The routine in this pr ocedure should be carried out at

Pre-Delivery Inspection, and after any emissions related

rectification work involving the disconnection of the battery.

2. When the DTCs relating to a rectified concern are cleared,

P1000 (system checks not complete since last memory clear)

will be flagged. This DTC does no t indicate a failure, just that

diagnostic drive cycles need to be performed. The vehicle's on-

board diagnostic system will confirm that all the diagnostic

drive cycles are complete by flagging P1111, (system checks

complete since last memory clear)

1. Make sure these conditions are checked and corrected, if

necessary, before carrying ou t the adaptation procedure.

MechanicalElectrical

Engi

ne oil level correct

Coo

lant level correct

F

uel level greater than

30%, less than 80%

F

uel filler cap correctly

fitted/secure, seal in good condition

Al

l rectification work

relating to DTCs completed

F

uel, ignition and cooling

systems in good order

Al

l Diagnostic Trouble

Codes (DTCs) cleared

Al

l rectification work

relating to DTCs completed

F

uses

Harnes

ses

E

lectrical connectors

1.

Either

the Jaguar approved diagnostic system (where

available), or a scan tool should be connected to measure the

Mass Air Flow rate. Most generi c scan tools should be capable

of reading this parameter.

Depending on road conditions and dealer location, it may be

difficult to achieve the road sp eeds necessary to reach the air

flow indicated. It is possible to reach these air flow figures by

inducing a load on the vehicle, (making use of hills, using a

lower gear ratio, etc) or, if no alternative is possible, by

restraining the vehicle and re aching the air flow figure

Si

te

Mass Air Flow

(gra

ms/second)

D

riving Conditions

1Up t

o 7 g/s

Idle

in

P for 2 minutes

21

0 to 14 g/s

O

pen throttle in

P for 2 minutes

31

8 to 22 g/s

O

pen throttle in

P or D with

guidance * for 2 minutes

42

5 to 30 g/s

D

rive with guidance * for 2

minutes

Page 1269 of 2490

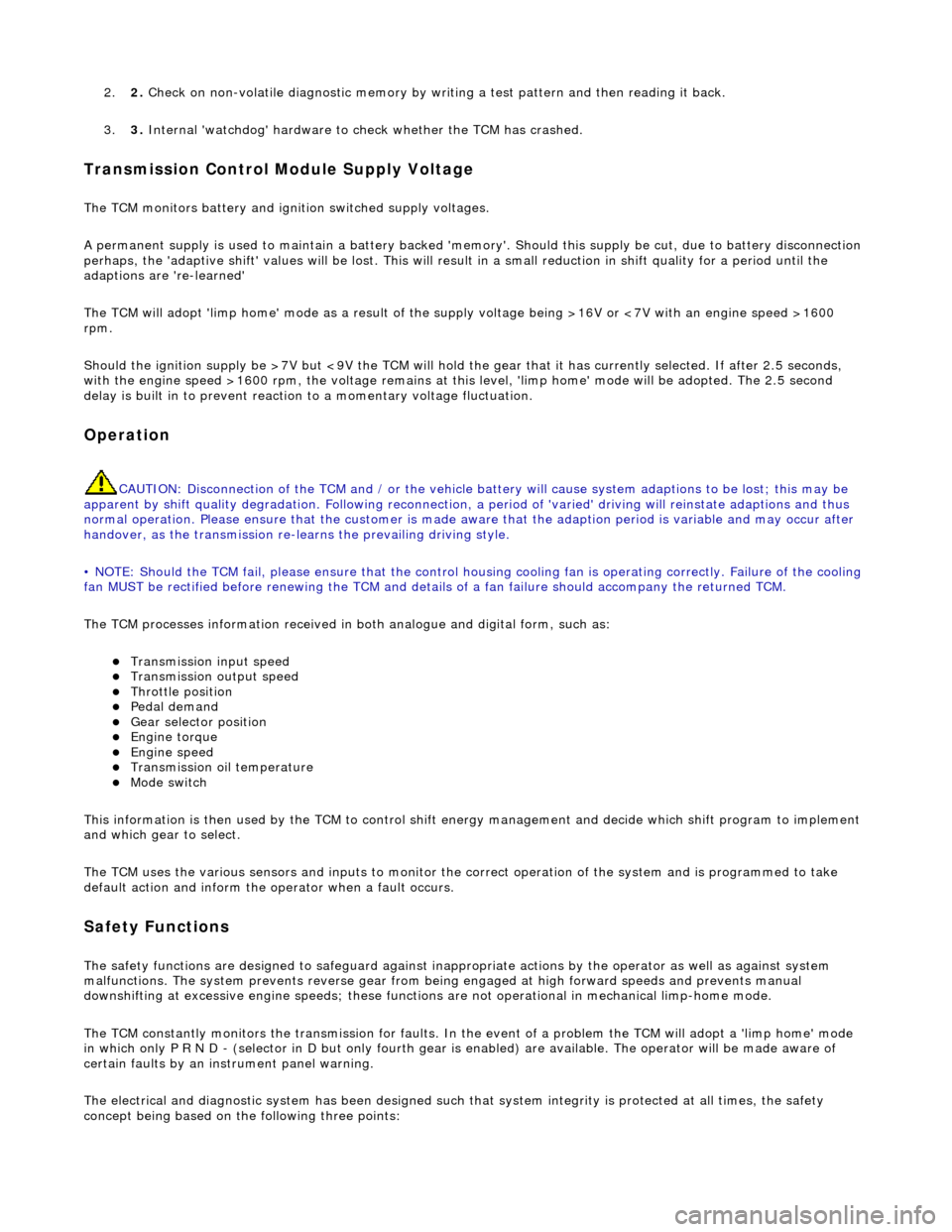

2.2. Check on non-volatile diagnostic memory by wr iting a test pattern and then reading it back.

3. 3. Internal 'watchdog' hardware to check whether the TCM has crashed.

Transmission Control Module Supply Voltage

The TCM monitors battery and igni tion switched supply voltages.

A permanent supply is used to maintain a battery backed 'memor y'. Should this supply be cut, due to battery disconnection

perhaps, the 'adaptive shift' valu es will be lost. This will result in a small reduction in shift quality for a period until th e

adaptions are 're-learned'

The TCM will adopt 'limp home' mode as a result of the supply voltage being >16V or <7V with an engine speed >1600

rpm.

Should the ignition supply be >7V but <9V the TCM will hold the gear that it has currently selected. If after 2.5 seconds,

with the engine speed >1600 rpm, the voltage remains at this level, 'limp home' mode will be adopted. The 2.5 second

delay is built in to prevent reaction to a momentary voltage fluctuation.

Operation

CAUTION: Disconnection of the TCM and / or the vehicle batt ery will cause system adaptions to be lost; this may be

apparent by shift quality degradation. Fo llowing reconnection, a period of 'varied' driving will reinstate adaptions and thus

normal operation. Please ensure that the customer is made aware that the adaption period is variable and may occur after

handover, as the transmission re-learns the prevailing driving style.

• NOTE: Should the TCM fail, please ensure that the control housing cooling fan is operating correctly. Failure of the cooling

fan MUST be rectified before renewing the TCM and details of a fan fa ilure should accompany the returned TCM.

The TCM processes information received in both analogue and digital form, such as:

Transmission input speed Transmission output speed Throttle position Pedal demand Gear selector position Engine torque Engine speed Transmission oil temperature Mode switch

This information is then used by the TC M to control shift energy management and decide which shift program to implement

and which gear to select.

The TCM uses the various sensors and inpu ts to monitor the correct operation of the system an d is programmed to take

default action and inform the operator when a fault occurs.

Safety Functions

The safety functions are designed to safeguard against inappr opriate actions by the operator as well as against system

malfunctions. The system prevents reve rse gear from being engaged at high forward speeds and prevents manual

downshifting at excessive engine speeds; these functions are not operational in mechanical limp-home mode.

The TCM constantly monitors the transmissi on for faults. In the event of a problem the TCM will adopt a 'limp home' mode

in which only P R N D - (selector in D but only fourth gear is enabled) are available. The operator will be made aware of

certain faults by an in strument panel warning.

The electrical and diagnostic system has been designed such that system integrity is protected at all times, the safety

concept being based on th e following three points: