Ground JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1036 of 2490

Fuel Char

ging and Controls - Fuel

Injection Supply Manifold Pipe

Remo

val and Installation

Remov

a

l

WARNING: B

E

FORE PROCEEDING, IT IS ESSENTIAL THAT

THE WARNING NOTES GIVEN IN SECTION 100-00 (UNDER

THE HEADING 'SAFETY PRECAUTION S') ARE READ AND UNDERSTOOD.

In

stallation

1.

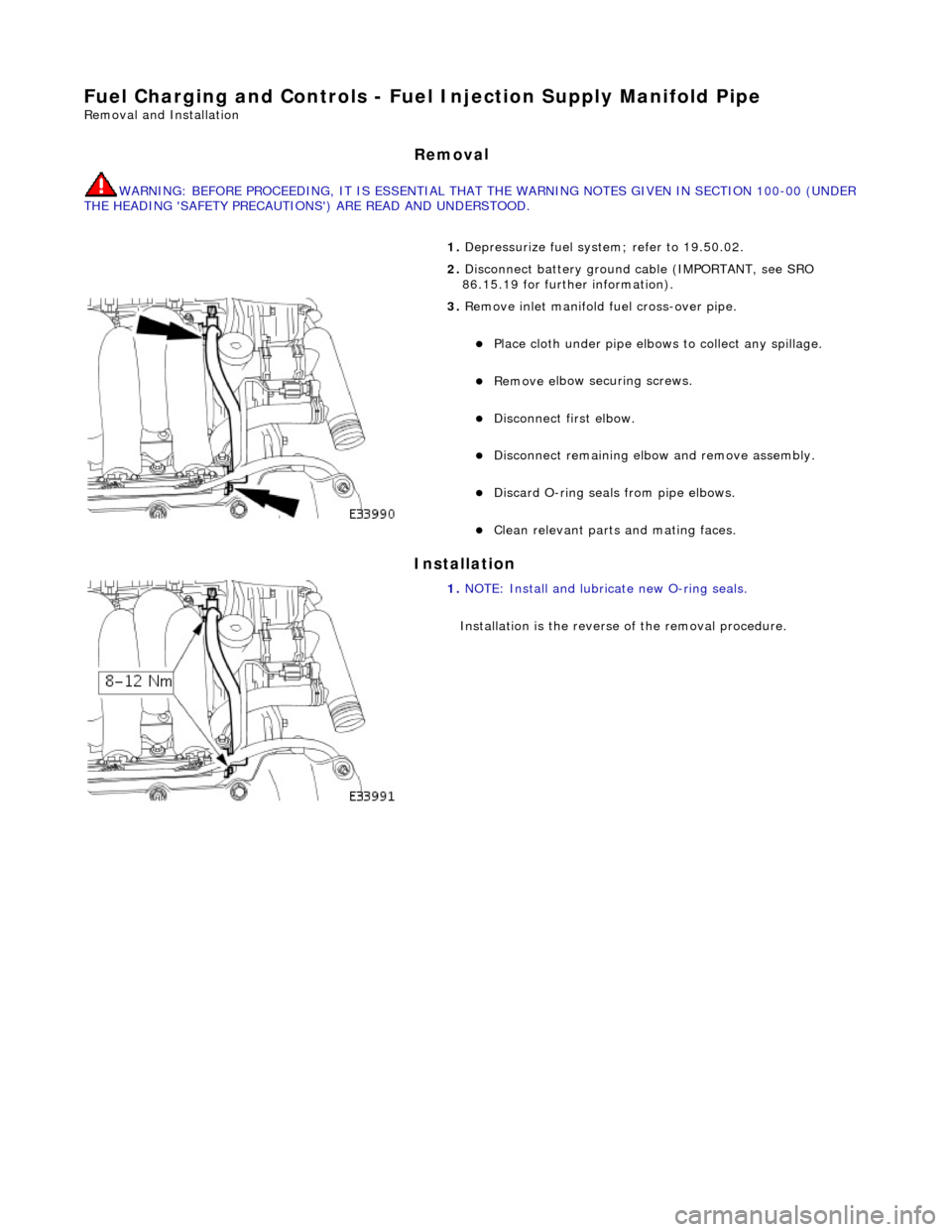

De

pressurize fuel syst

em; refer to 19.50.02.

2. Disconnect battery ground cable (IMPORTANT, see SRO

86.15.19 for further information).

3. Re

move inlet manifold

fuel cross-over pipe.

пЃ¬Plac

e cloth under pipe elbows

to collect any spillage.

пЃ¬Remove e

lbow securing screws.

пЃ¬Di

sc

onnect first elbow.

пЃ¬Disc

onnect remaining elbow and remove assembly.

пЃ¬Discard O

-

ring seals

from pipe elbows.

пЃ¬Clean relevant parts and mating faces.

1. NOTE : Install

and lubricate new O-ring seals.

Installation is th e reverse of the removal procedure.

Page 1037 of 2490

Fuel Ch

arging and Controls

- Fuel Injector4.0L NA V8 - AJ27/3.2L NA V8 -

AJ26

Re

moval and Installation

Remov

al

S

pecial Tool(s)

R

emover - Fuel Injector

303-539 (JD 231)

1. Disconnect battery ground cable (IMPORTANT, see SRO

86.15.19 for further information).

2. WARNING: BEFORE PROCEEDING, IT IS ESSENTIAL THAT

THE WARNING NOTES GIVEN IN SECTION 100-00 (UNDER THE

HEADING 'SAFETY PRECAUTIONS') ARE READ AND

UNDERSTOOD.

Depressurize the fuel sy stem; refer to 19.50.02.

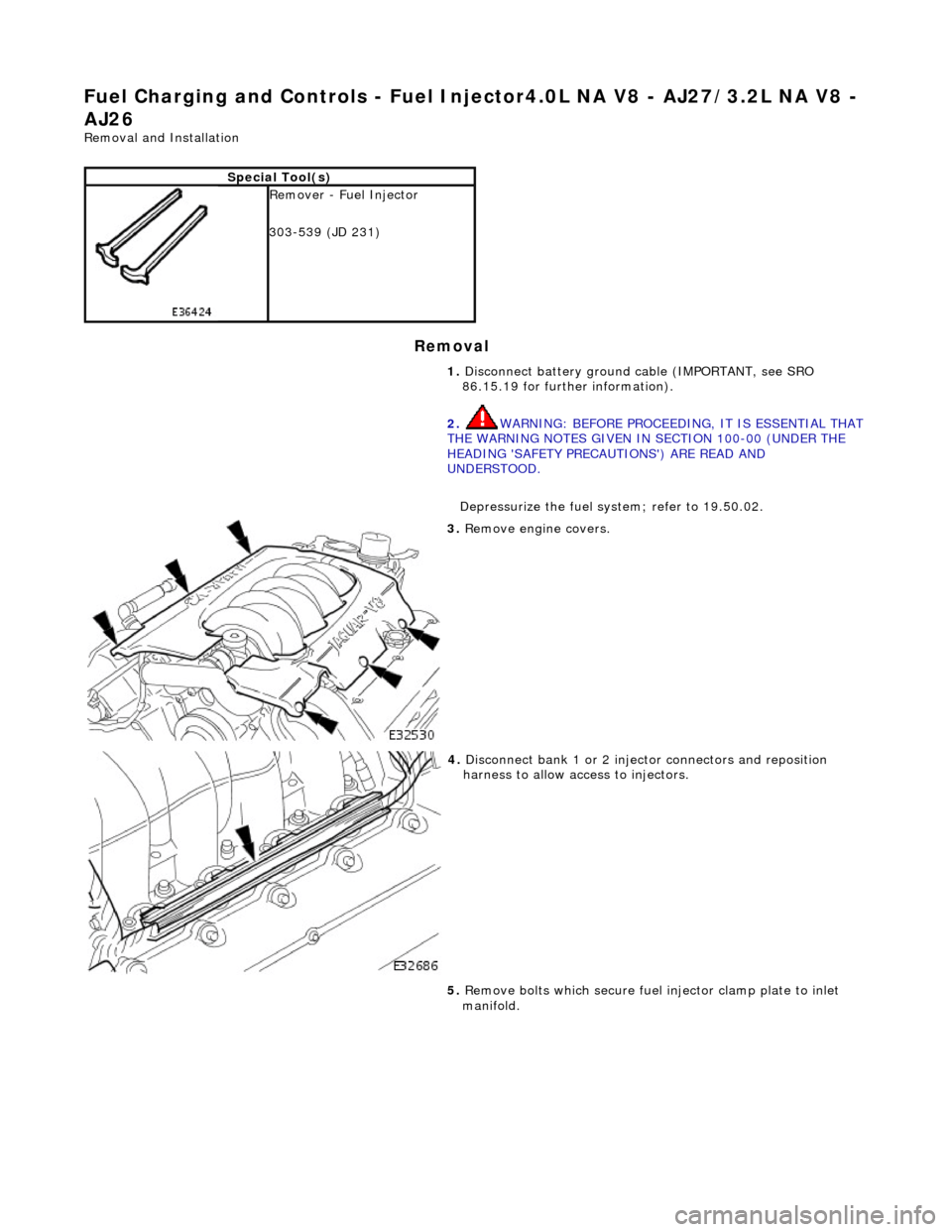

3. R

emove engine covers.

4. Di

sconnect bank 1 or 2 inject

or connectors and reposition

harness to allow access to injectors.

5. Remove bolts which secure fuel injector clamp plate to inlet

manifold.

Page 1039 of 2490

Fuel Charging and Controls

- Fuel Injector4.0L SC V8 - AJ26

Rem

oval and Installation

Remov

al

Installation

1.

Disconnect battery ground cabl e (IMPORTANT, see SRO 86.15.19

for further information).

2. WARNING: BEFORE PROCEEDING, IT IS ESSENTIAL THAT

THE WARNING NOTES GIVEN IN SECTION 100-00 (UNDER THE

HEADING 'SAFETY PRECAUTIONS') ARE READ AND UNDERSTOOD.

Depressurize fuel system; refer to 19.50.02.

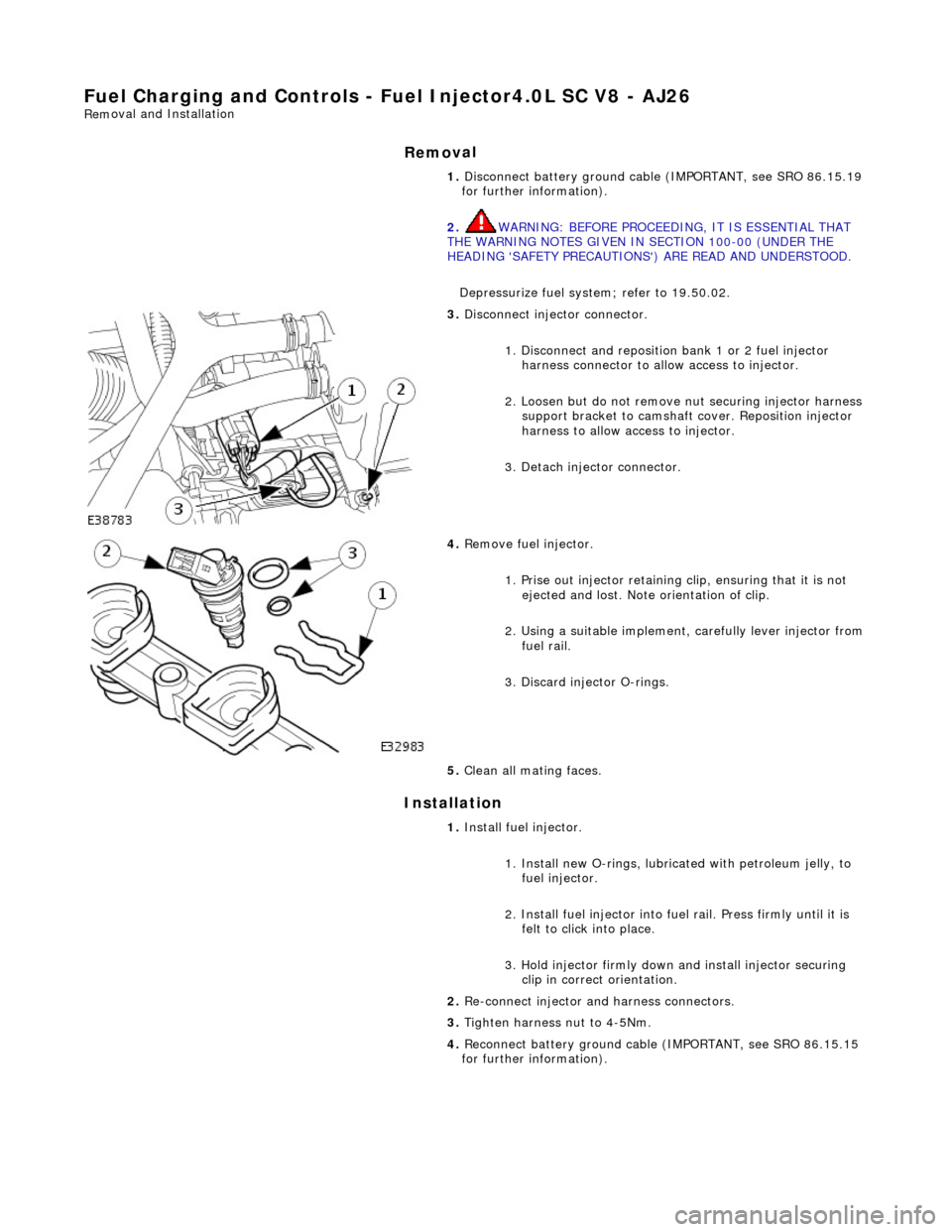

3.

Disconnect injector connector.

1. Disconnect and reposition bank 1 or 2 fuel injector harness connector to allow access to injector.

2. Loosen but do not remove nut securing injector harness support bracket to camshaft cover. Reposition injector

harness to allow access to injector.

3. Detach injector connector.

4.

Remove fuel injector.

1. Prise out injector retaining clip, ensuring that it is not ejected and lost. Note orientation of clip.

2. Using a suitable implement, carefully lever injector from

fuel rail.

3. Discard injector O-rings.

5. Clean all mating faces.

1. Install fuel injector.

1. Install new O-rings, lubricat ed with petroleum jelly, to

fuel injector.

2. Install fuel injector into fuel rail. Press firmly until it is felt to click into place.

3. Hold injector firmly down and install injector securing clip in correct orientation.

2. Re-connect injector and harness connectors.

3. Tighten harness nut to 4-5Nm.

4. Reconnect battery ground cable (IMPORTANT, see SRO 86.15.15

for further information).

Page 1040 of 2490

Fuel Char

ging and Controls - Fu

el Injectors4.0L SC V8 - AJ26

Remo

val and Installation

Remov

a

l

Installation

1. Disc onne

ct battery ground cable (IMPORTANT, see SRO

86.15.19 for further information).

2. WARNING: BEFORE PROCEEDING, IT IS ESSENTIAL THAT

THE WARNING NOTES GIVEN IN SECTION 100-00 (UNDER THE

HEADING 'SAFETY PRECAUTIONS') ARE READ AND

UNDERSTOOD.

Depressurize fuel syst em; refer to 19.50.02.

3. Drain radiator coolant; refer to 2

6.10.01.

4. Remove air cleaner cover / inta ke assembly; refer 19.10.30.

5. Remove throttle body; refer to 19.70.04.

6. Remove throttle induction elbo w; refer to (SC) 19.70.28.

7. Remove exhaust gas re-circulation valve (EGR) if fitted; refer

to 17.45.01.

8. Remove supercharger outlet duct and gasket; refer to

18.50.16.

9. Remove coolant outlet pipe; refer to (SC) 26.31.08 .

10. Remove supercharger drive belt; refer to 18.50.08.

11. Remove supercharger assembly; refer to 18.50.15.

12. Remove bank 1 or 2 charge air cooler as required; refer to

18.50.18 and / or 18.50.19.

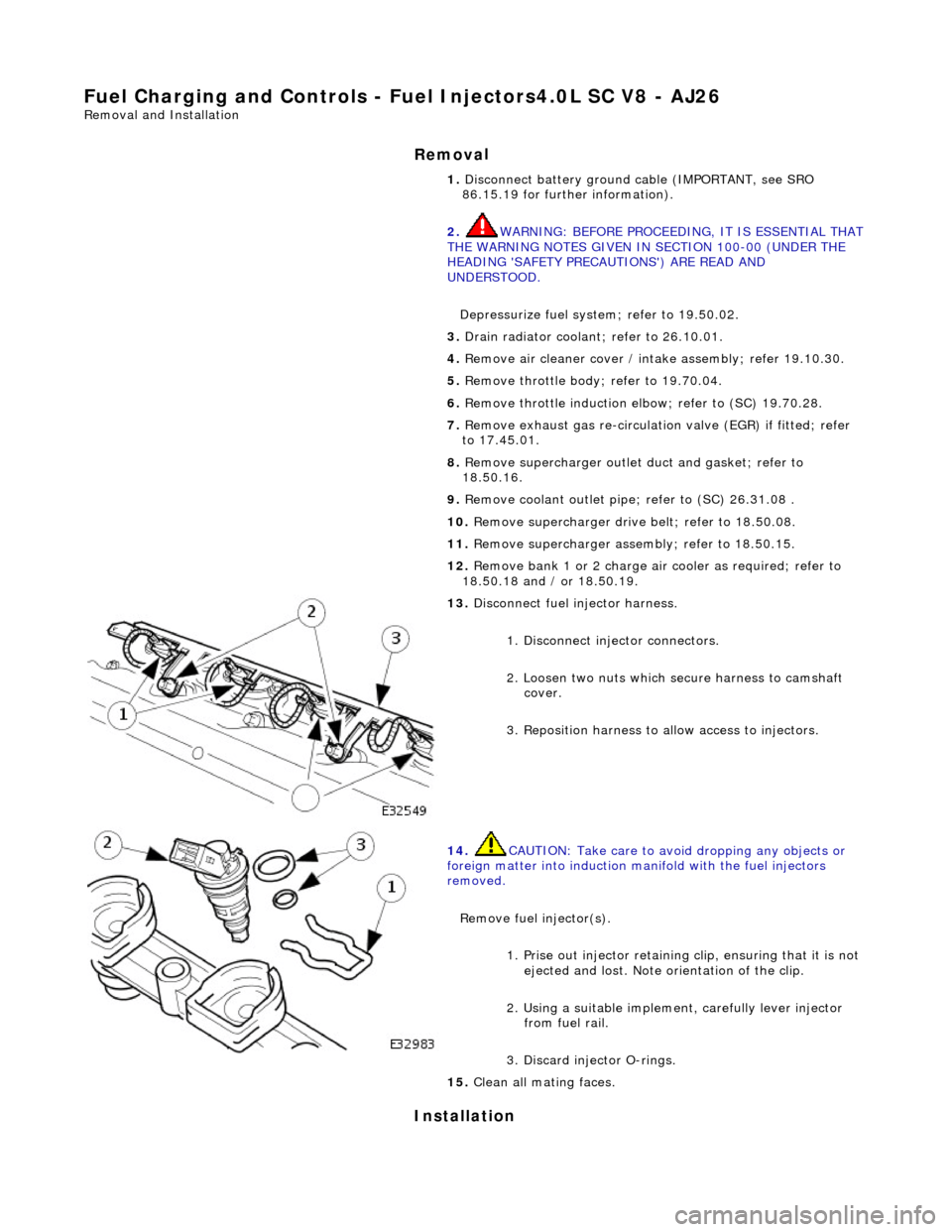

13 . Di

sconnect fuel injector harness.

1. Disconnect injector connectors.

2. Loosen two nuts which se cure harness to camshaft

cover.

3. Reposition harness to al low access to injectors.

14. CAUTI

ON: Take care to avoi

d dropping any objects or

foreign matter into induction ma nifold with the fuel injectors

removed.

Remove fuel injector(s). 1. Prise out injector retaining clip, ensuring that it is not

ejected and lost. Note orientation of the clip.

2. Using a suitable implemen t, carefully lever injector

from fuel rail.

3. Discard injector O-rings.

15 . Cle

an all mating faces.

Page 1041 of 2490

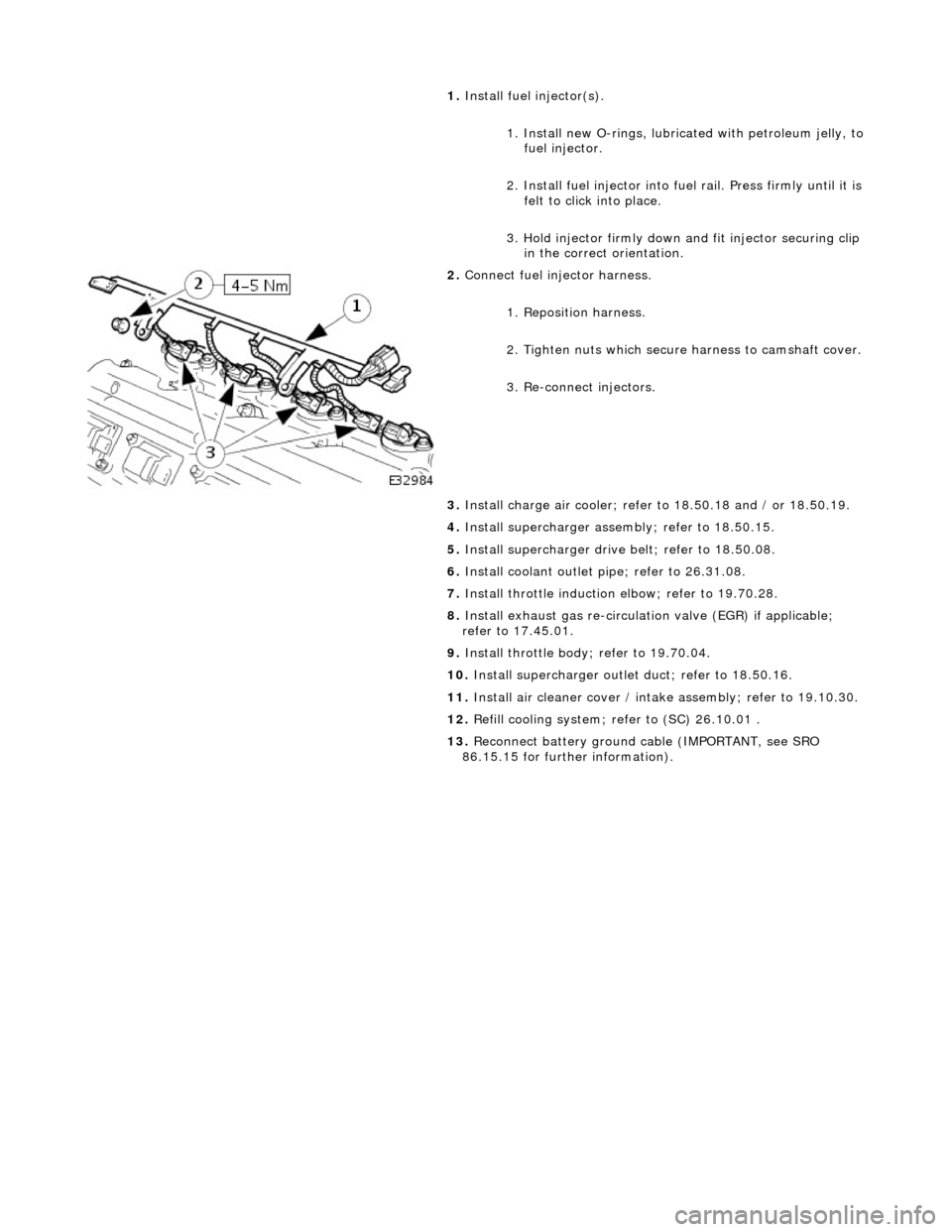

1.

Install

fuel injector(s).

1. Install new O-rings, lubricated with petroleum jelly, to

fuel injector.

2. Install fuel in jector into fuel rail. Press firmly until it is

felt to click into place.

3. Hold injector firmly down and fit injector securing clip

in the correct orientation.

2. Conne

ct fuel injector harness.

1. Reposition harness.

2. Tighten nuts which secure harness to camshaft cover.

3. Re-connect injectors.

3. Install charge air c ooler; refer to 18.50.18 and / or 18.50.19.

4. Install supercharger asse mbly; refer to 18.50.15.

5. Install supercharger driv e belt; refer to 18.50.08.

6. Install coolant outlet pi pe; refer to 26.31.08.

7. Install throttle induction elbow; refer to 19.70.28.

8. Install exhaust gas re-circulation valve (EGR) if applicable;

refer to 17.45.01.

9. Install throttle body ; refer to 19.70.04.

10. Install supercharger outlet duct; refer to 18.50.16.

11. Install air cleaner cover / intake assembly; re fer to 19.10.30.

12. Refill cooling system; refer to (SC) 26.10.01 .

13. Reconnect battery ground cable (IMPORTANT, see SRO

86.15.15 for further information).

Page 1042 of 2490

Fuel Char

ging and Controls - Throttle Body

Re

mo

val and Installation

Remov

a

l

• C

A

UTIONS:

When the throttle body is being replaced by a unit with the part number suffix ' BA', and carrying a sticker such as the

illustration below, then the usual cleaning procedure is NOT to be carried out. These thro ttle bodies have a molykote

coating which will be damaged by normal cleaning procedures. Refer to the latest service action s for further information.

This process assumes the use of the original throttle ca ble. The cable setting procedure in this instance is NOT

appropriate for a new cable; see 19.20.06.

1. Disc onne

ct battery ground cable (IMPORTANT, see SRO

86.15.19 for further information).

2. Remove air cleaner cover / in take assembly; refer 19.10.30

3. Disc

onnect connectors and vacuum pipe.

4. Ro

tate throttle quadrant to allow disconnection of inner cable.

5. NOTE: Do not disturb adjusting nut

Release throttle cable locking nut and displace outer cable from

Page 1047 of 2490

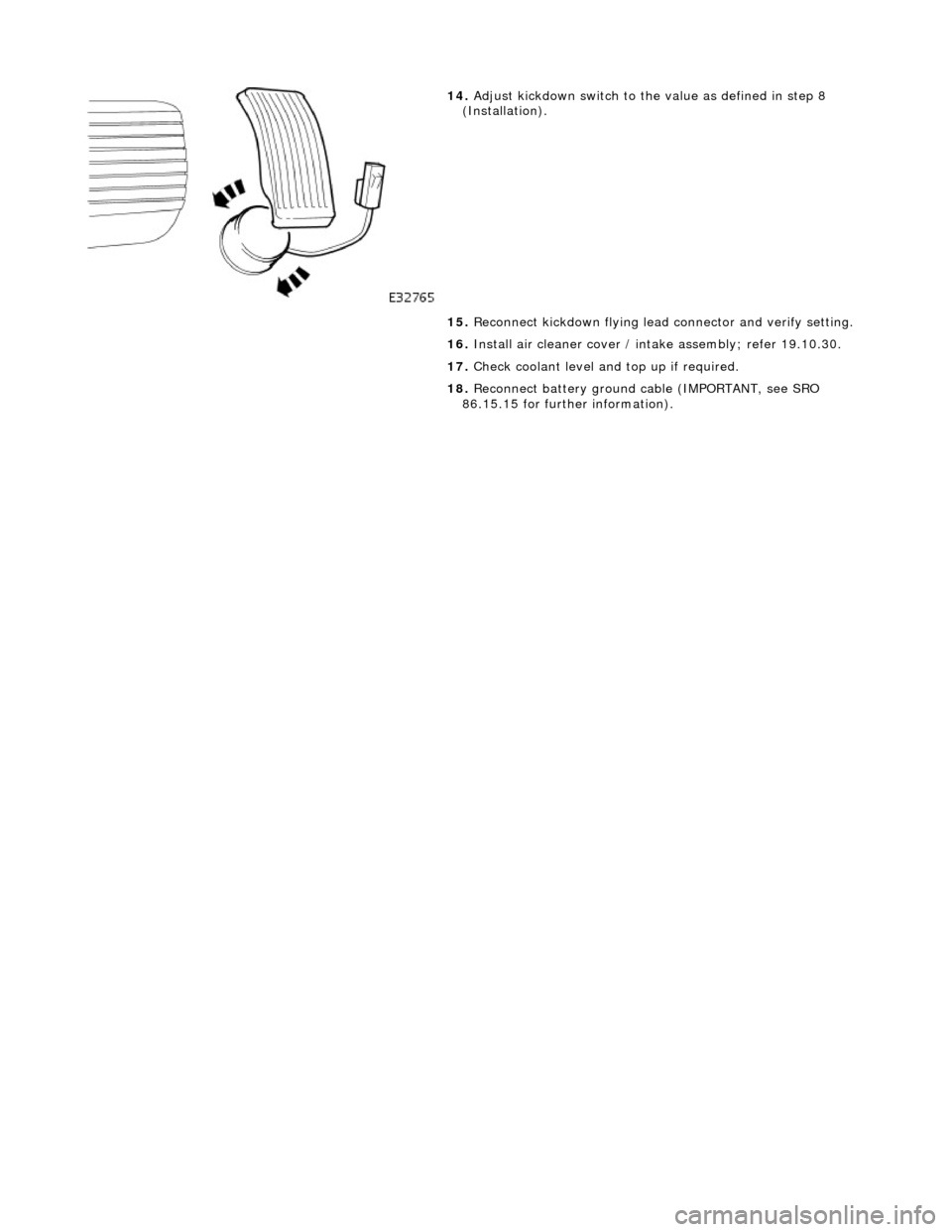

14

.

Adjust kickdown switch to th e value as defined in step 8

(Installation).

15. Reconnect kickdown flying lead connector and verify setting.

16. Install air cleaner cover / intake assembly; refer 19.10.30.

17. Check coolant level and top up if required.

18. Reconnect battery ground cable (IMPORTANT, see SRO

86.15.15 for further information).

Page 1065 of 2490

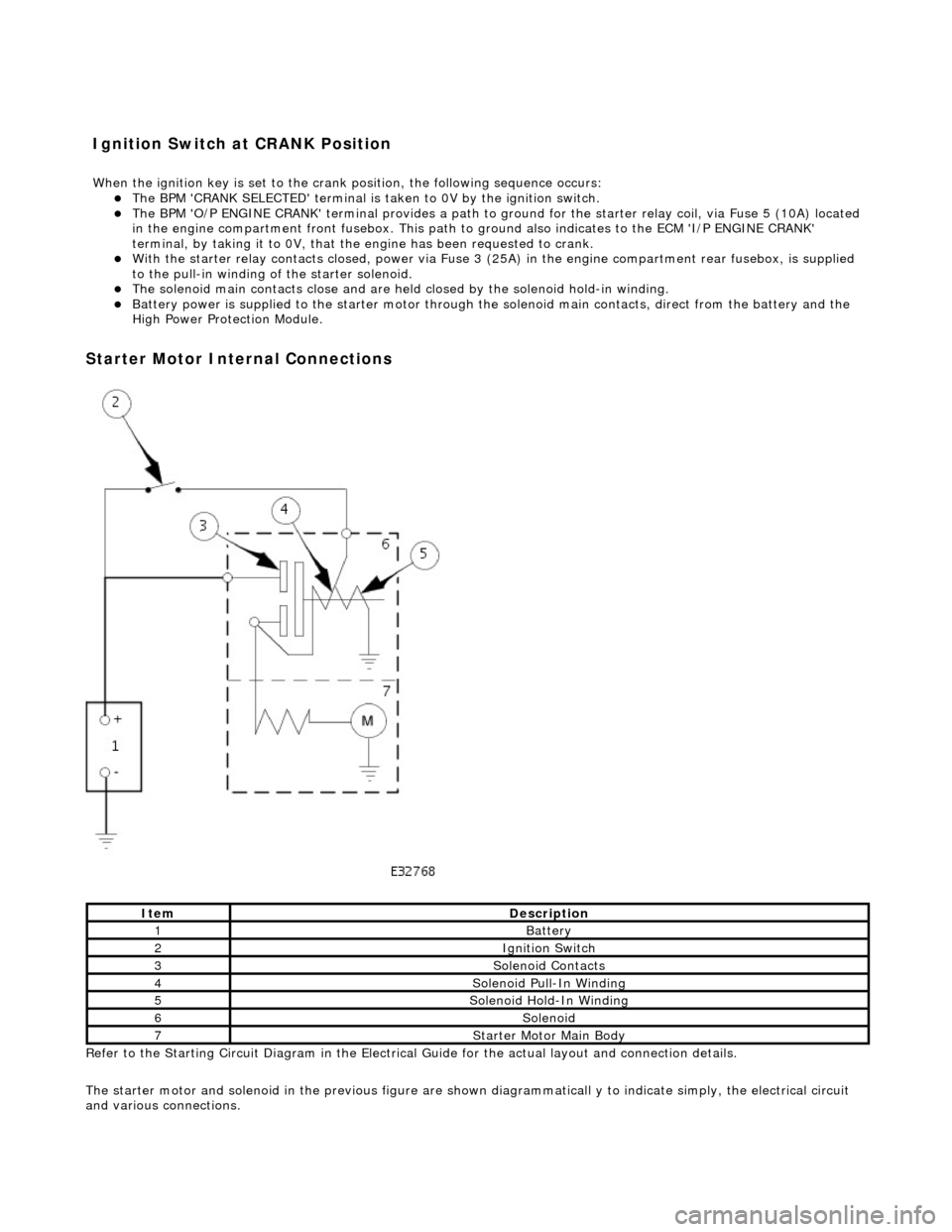

пЃ¬The BPM

'CRANK SELECTED' terminal is ta

ken to 0V by the ignition switch.

пЃ¬The BPM

'O/P ENGINE CRANK' terminal pr

ovides a path to ground for the starte r relay coil, via Fuse 5 (10A) located

in the engine compartment front fusebo x. This path to ground also indicates to the ECM 'I/P ENGINE CRANK'

terminal, by taking it to 0V, that the engine has been requested to crank.

пЃ¬Wi

th the starter relay contacts closed,

power via Fuse 3 (25A) in the engine compartment rear fusebox, is supplied

to the pull-in winding of the starter solenoid.

пЃ¬The s

olenoid main contacts close and are held

closed by the solenoid hold-in winding.

пЃ¬Battery power is supplied

to

the starter motor through the solenoid main contacts, direct from the battery and the

High Power Protection Module.

Starter

Motor Internal Connections

Re

fer to the Starting Circuit Diagram in the Electrical

Guide for the actual layout and connection details.

The starter motor and solenoid in the previous figure are shown diagrammaticall y to indicate simply, the electrical circuit

and various connections.

It

em

De

scription

1Batt

ery

2Ignition Switch

3So

lenoid Contacts

4So

lenoid Pull-In Winding

5So

lenoid Hold-In Winding

6So

lenoid

7St

arter Motor Main Body

I

gnition Switch at CRANK Position

W

hen the ignition key is set to the crank position, the following sequence occurs:

Page 1067 of 2490

Pinpoint Tests

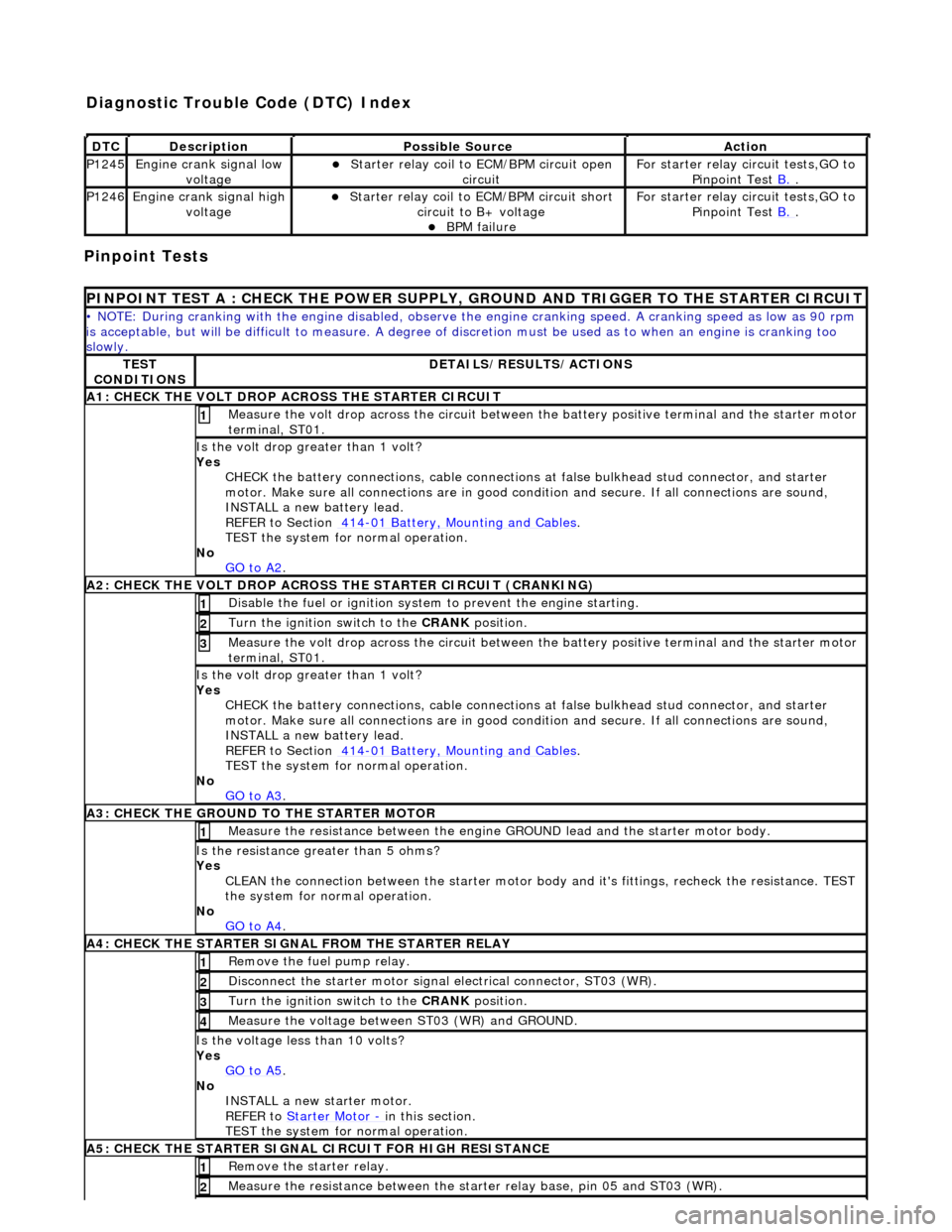

DT

C

De

scription

Possib

le Source

Acti

on

P1245Engine

crank signal low

voltage

пЃ¬Starter relay

coil to

ECM/BPM circuit open

circuit

F

or starter relay circuit tests,GO to

Pinpoint Test B.

.

P1246Engine

crank signal high

voltage

пЃ¬Starter relay

coil to ECM/BPM circuit short

circuit to B+ voltage

пЃ¬B

PM failure

F

or starter relay circuit tests,GO to

Pinpoint Test B.

.

P

INPOINT TEST A : CHECK THE

POWER SUPPLY, GROUND AND TRI GGER TO THE STARTER CIRCUIT

•

NOTE: During cranking with the engine disabled, observe the engine cranking speed. A cranking speed as low as 90 rpm

is acceptable, but will be difficult to measure. A degree of discretion must be used as to when an engine is cranking too

slowly.

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

A1: CHECK

THE VOLT DROP AC

ROSS THE STARTER CIRCUIT

M

easure the volt drop across the circuit between the battery positive terminal and the starter motor

terminal, ST01.

1

Is the vol

t drop greater than 1 volt?

Yes CHECK the battery connections, cable connections at false bulkhead stud connector, and starter

motor. Make sure all connections are in good co ndition and secure. If all connections are sound,

INSTALL a new battery lead.

REFER to Section 414

-0

1 Battery, Mounting and Cables

.

TEST the system

for normal operation.

No GO to A2

.

A2: CHECK

THE VOLT DROP ACROSS

THE STARTER CIRCUIT (CRANKING)

Di

sable the fuel or ignition system to prevent the engine starting.

1

Turn the ignition swi

tch to the CRANK

position.

2

M

easure the volt drop across the circuit between the battery positive terminal and the starter motor

terminal, ST01.

3

Is the vol

t drop greater than 1 volt?

Yes CHECK the battery connections, cable connections at false bulkhead stud connector, and starter

motor. Make sure all connections are in good co ndition and secure. If all connections are sound,

INSTALL a new battery lead.

REFER to Section 414

-0

1 Battery, Mounting and Cables

.

TEST the system

for normal operation.

No GO to A3

.

A3:

CHECK THE GROUND TO THE STARTER MOTOR

Meas

ure the resistance between the engine GROUND lead and the starter motor body.

1

Is th

e resistance greater than 5 ohms?

Yes CLEAN the connection between the starter motor body and it's fittings, recheck the resistance. TEST

the system for normal operation.

No GO to A4

.

A4

: CHECK THE STARTER SIGNAL FROM THE STARTER RELAY

R

emove the fuel pump relay.

1

Di

sconnect the starter motor signal

electrical connector, ST03 (WR).

2

Turn the ignition swi

tch to the CRANK

position.

3

M

easure the voltage between ST03 (WR) and GROUND.

4

Is th

e voltage less than 10 volts?

Yes GO to A5

.

No

INSTALL a new starter motor.

REFER to Starter Motor

-

in t

his section.

TEST the system for normal operation.

A5

: CHECK THE STARTER SIGNAL CIRCUIT FOR HIGH RESISTANCE

R

emove the starter relay.

1

Meas

ure the resistance between the st

arter relay base, pin 05 and ST03 (WR).

2

Diagnostic Trouble Code (D

TC) Index

Page 1068 of 2490

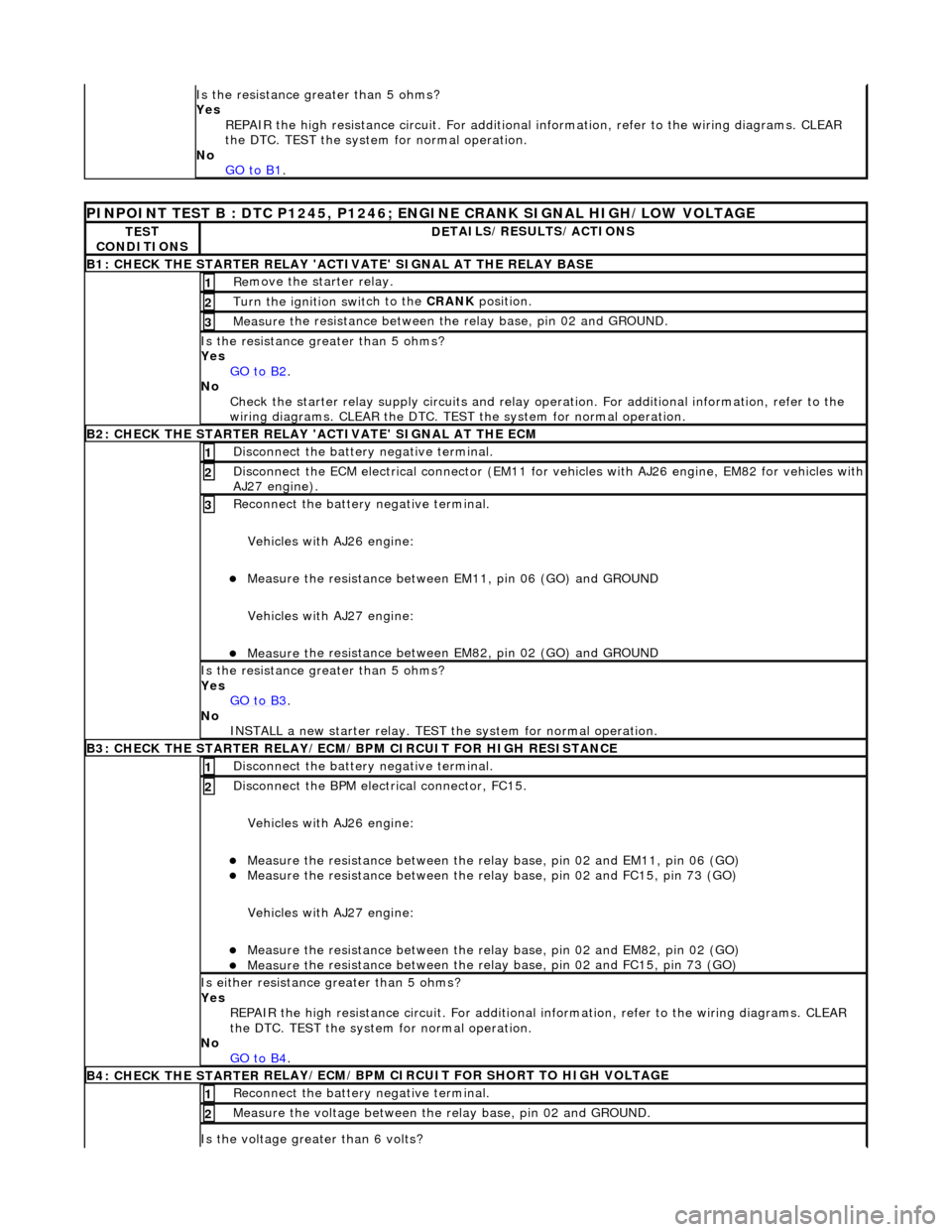

Is the res

istance greater than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No GO to B1

.

PINPOINT TES

T B : DTC P1245, P1246; ENGINE CRANK SIGNAL HIGH/LOW VOLTAGE

TE

S

T

CONDITIONS

D E

TAILS/RESULTS/ACTIONS

B1: CHECK

THE STARTER

RELAY 'ACTIV

ATE' SIGNAL AT THE RELAY BASE

Re

move the starter relay.

1

Turn the ignition swi

t

ch to the CRANK

position.

2

Measure t

he resistance between th

e relay base, pin 02 and GROUND.

3

Is the res

istance greater than 5 ohms?

Yes GO to B2

.

No Check t

he starter relay supply circui

ts and relay operation. For additi onal information, refer to the

wiring diagrams. CLEAR the DTC. TEST the system for normal operation.

B2: CHECK THE STARTER

RELAY 'A

CTIVATE' SIGNAL AT THE ECM

Disc

onnect the battery negative terminal.

1

D

i

sconnect the ECM electrical connector (EM11 for vehicles with AJ26 engine

, EM82 for vehicles with

AJ27 engine).

2

R e

connect the battery negative terminal.

Vehicles with AJ26 engine:

пЃ¬Meas ure t

he resistance between EM11, pin 06 (GO) and GROUND

Vehicles with AJ27 engine:

пЃ¬Meas ure t

he resistance between EM82, pin 02 (GO) and GROUND

3

Is th

e res

istance greater than 5 ohms?

Yes GO to B3

.

No

IN

STALL a new starter relay. TEST

the system for normal operation.

B3: CHECK THE STARTER

RELAY/ECM/BPM CIRCUIT FOR HIGH RESISTANCE

Di sc

onnect the battery negative terminal.

1

Disc

onne

ct the BPM electrical connector, FC15.

Vehicles with AJ26 engine:

пЃ¬Meas ure t

he resistance between the relay

base, pin 02 and EM11, pin 06 (GO)

пЃ¬Measure t

he resistance between the relay

base, pin 02 and FC15, pin 73 (GO)

Vehicles with AJ27 engine:

пЃ¬Meas ure t

he resistance between the relay

base, pin 02 and EM82, pin 02 (GO)

пЃ¬Measure t

he resistance between the relay

base, pin 02 and FC15, pin 73 (GO)

2

Is either resistance greater

than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No GO to B4

.

B4: CHECK THE STARTER

RE

LAY/ECM/BPM CIRCUIT FOR SHORT TO HIGH VOLTAGE

Re

connect the battery negative terminal.

1

Meas

ure t

he voltage between the

relay base, pin 02 and GROUND.

2

Is the volt

age greater than 6 volts?