check engine JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1405 of 2490

Pinpoint test C: P0702, P0753, P0758, P0763

Connect the scan tool 1

Have the DTC(s) and freeze frame data been recorded?

Yes GO to B2

B2: RENEW TORQUE CONVERTER

Renew the torque converter 1

Has the torque converter been renewed?

Yes GO to B3

B3: END

Drive the vehicle for a period from cold to include idle, brisk

acceleration and steady state cruising up to and including

normal engine temperature. Check for the presence of DTC 1

Has the fault code cleared?

Yes STOP

No Contact Jaguar Service

PINPOINT TEST C : P0702, P0753, P0758, P0763

TEST CONDITIONSDETAILS/RESULTS/ACTIONS

C1: RETRIEVE DTCS

• NOTE: Battery and or ECM disconnection prior to scanning wi ll erase all data, ensure that the correct DTC is present.

Connect the scan tool 1

Have the DTC(s) and freeze frame data been recorded?

Yes GO to C2

C2: CHECK HARNESS +VE CONTINUITY

Page 1412 of 2490

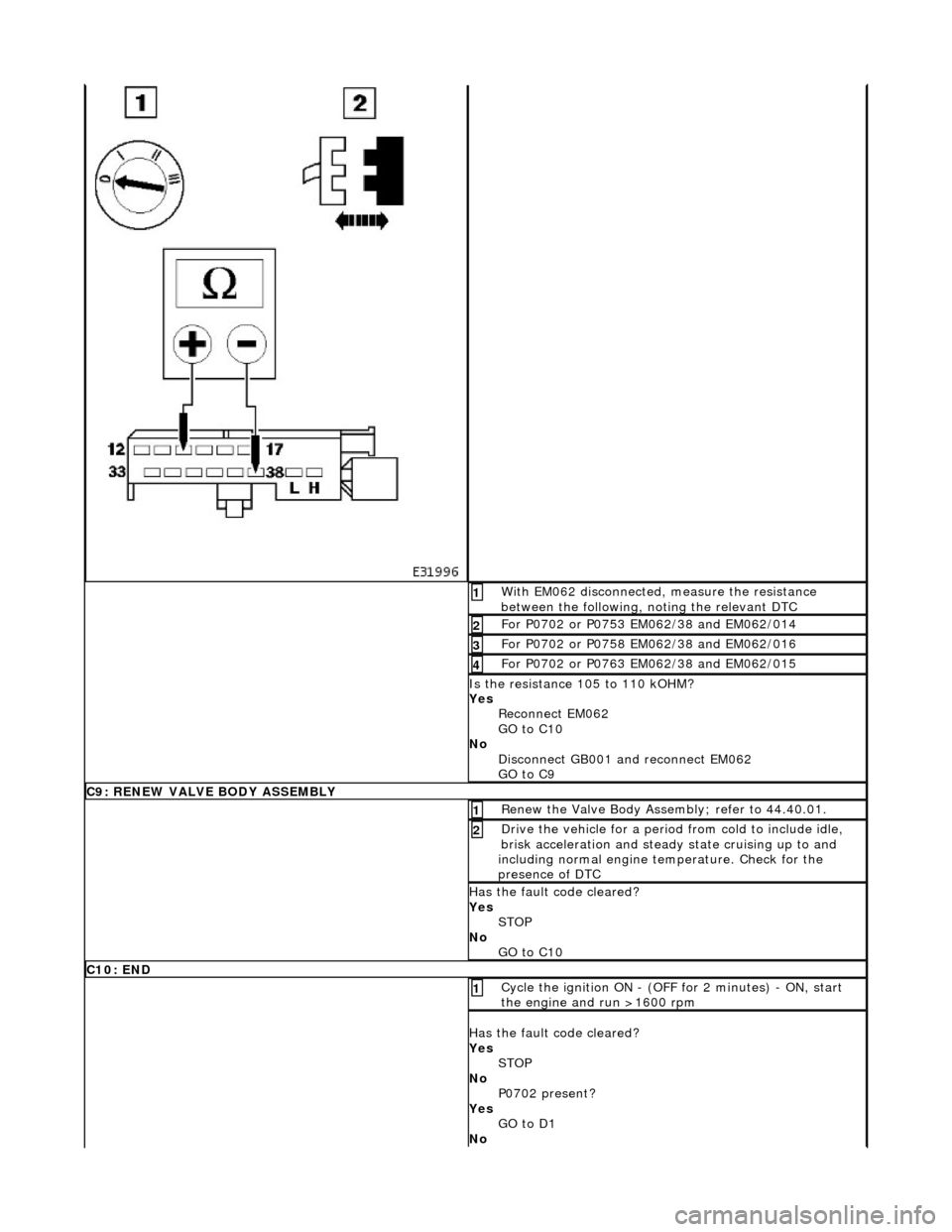

With EM062 disconnected, measure the resistance

between the following, noting the relevant DTC 1

For P0702 or P0753 EM062/38 and EM062/014 2

For P0702 or P0758 EM062/38 and EM062/016 3

For P0702 or P0763 EM062/38 and EM062/015 4

Is the resistance 105 to 110 kOHM?

Yes Reconnect EM062

GO to C10

No Disconnect GB001 and reconnect EM062

GO to C9

C9: RENEW VALVE BODY ASSEMBLY

Renew the Valve Body Assembly; refer to 44.40.01. 1

Drive the vehicle for a period from cold to include idle,

brisk acceleration and steady state cruising up to and

including normal engine temperature. Check for the

presence of DTC 2

Has the fault code cleared?

Yes STOP

No GO to C10

C10: END

Cycle the ignition ON - (OFF for 2 minutes) - ON, start

the engine and run >1600 rpm 1

Has the fault code cleared?

Yes STOP

No P0702 present?

Yes GO to D1

No

Page 1427 of 2490

Pinpoint test H: P0730, P0780

Connect the scan tool 1

Have the DTC(s) and freeze frame data been recorded?

Yes GO to G2

G2: RENEW TCM

Renew the TCM 1

Has the TCM been renewed?

Yes GO to G3

G3: END

• NOTE: The following step must be carried out in order that sy stem adaptions can take place.

Drive the vehicle for a period from cold to include idle, brisk

acceleration and steady state cruising up to and including

normal engine temperature. Check for the presence of DTC 1

Has the fault code cleared?

Yes STOP

No Contact Jaguar Service

PINPOINT TEST H : P0730, P0780

TEST CONDITIONSDETAILS/RESULTS/ACTIONS

H1: RETRIEVE DTCS

• NOTE: Battery and or ECM disconnection prior to scanning wi ll erase all data, ensure that the correct DTC is present.

Connect the scan tool 1

Have the DTC(s) and freeze frame data been recorded?

Yes GO to H2

H2: RENEW VALVE BODY ASSEMBLY

Renew the valve body assembly 1

Drive the vehicle for a period from cold to include idle, brisk

acceleration and steady state cruising up to and including

normal engine temperature. Check for the presence of DTC 2

Has the fault code cleared?

Page 1431 of 2490

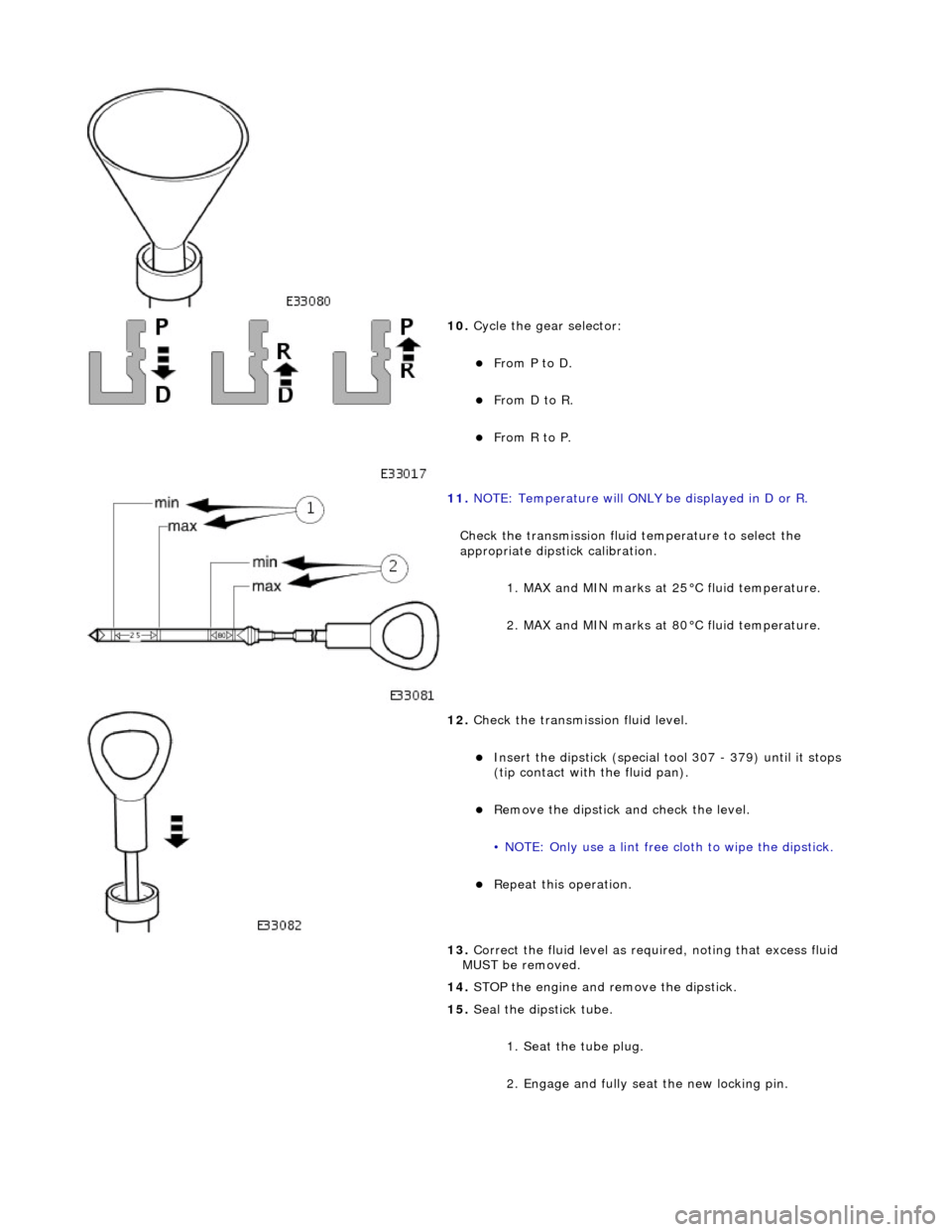

10. Cycle the gear selector:

From P to D.

From D to R.

From R to P.

11. NOTE: Temperature will ONLY be displayed in D or R.

Check the transmission fluid temperature to select the

appropriate dipstick calibration. 1. MAX and MIN marks at 25°C fluid temperature.

2. MAX and MIN marks at 80°C fluid temperature.

12. Check the transmission fluid level.

Insert the dipstick (special tool 307 - 379) until it stops

(tip contact with the fluid pan).

Remove the dipstick an d check the level.

• NOTE: Only use a lint free cloth to wipe the dipstick.

Repeat this operation.

13. Correct the fluid leve l as required, noting that excess fluid

MUST be removed.

14. STOP the engine and remove the dipstick.

15. Seal the dipstick tube.

1. Seat the tube plug.

2. Engage and fully seat the new locking pin.

Page 1504 of 2490

Automatic Transmission/Transaxle External Controls - 4.0L SC V8 - AJ26 -

External Controls

Diagnosis and Testing

Problem Solving - Transmission Shift

Quick Reference Fault Chart

Special Tool(s)

Digital multimeter

Generic scan tool

SymptomPossible SourcesAction

Shift stuck in P Selector cable seized

*GO to 44.15.08

*

Interlock solenoid not operating

*GO to PDU

*

Interlock latch seized

Transmission faulty

*

*Mechanical check

*

Operator sequence error

*Correct the sequence

*

Vehicle rolls on P Incorrect cable adjustment

*GO 44.15.07

*

Faulty parking pawl (transmission internal)

*Mechanical check

*

R does not engageIncorrect cable adjustment

*GO to 44.15.07

*

Transmission fluid level incorrect

*GO to 44.24.02

*

N not achievedIncorrect cable adjustment

Transmission faulty

*

*GO to 44.15.07

*

D does not engageIncorrect cable adjustment *GO to 44.15.07

*

Transmission fluid level incorrect

*GO to 44.24.02

*

Transmission faulty

*Mechanical check

*

Lower ratios will not holdExcessive engine temperature

DLS fault

*

*GO to PDU

*

Shift lever position not visually correctIncorrect DLS adjustment

*GO to 44.15.07

*

Shift lever has no effect upon the

transmission and resistance cannot be

feltCable disconnected or broken

Transmission selector problem

Shift lever drive pin adrift

*

*

*Mechanical check

*

Shift lever position not align correctly

following manual selection of lower

ratiosSliding block drive pin displaced - following road debris contact

*Mechanical check. Renew the selector if

damaged, or re-align the drive pin and

sliding block

*

Shift lever detent indistinct in 3

causing poor locationDLS detent fault

*GO to Renew the DLS

*

Shift may be moved from P without

brake pedal operationInterlock latch fault

*Mechanical check

*

Solenoid permanently activated

*GO to PDU

*

Engine may be started in positions

other than P or N Incorrect cable adjustment

DLS fault

*

*GO to 44.15.07

*

Shift lever vibrationLoose selector assembly

Cable isolation fault

*

*Mechanical check

*

Noise / rattle from 'J' gateDebris in the mechanism

*Clean

*

Worn 'J' gate track gasket

allowing lever and moulding to

contact

*GO to 44.15.05

*

Page 1520 of 2490

moving the set position of either the gear selector lever or the selector lever on the transmission casing.

3. Tighten to 22-28 Nm.

4. Verify the 'N' setting.

6. Check that all released connec tors are safely insulated and

connect the vehicle battery.

7. Switch ON the ignition.

8. Adjust the position of the linear switch so that the selector 'N'

position graphic illuminates. Ti ghten the four screws to 0,7-1

Nm.

9. Move the gear selector to 'R' to confirm that the 'R' position

graphic illuminates.

10. Check that the engine will start when the gear selector is in

the 'N' and 'P' positions, bu t not in any other position.

11. Move the gear selector to 'N'.

12. Switch OFF the ignition.

13. Disconnect the battery.

14. Install the console assembly, operation 76.25.01.

15. Install the console finisher veneer panel, operation 76.47.26.

16. Install the J-gate surround, operation 76.25.24.

17. Perform the Battery Reconnection Procedure described in

Operation 86.15.15.

Page 1531 of 2490

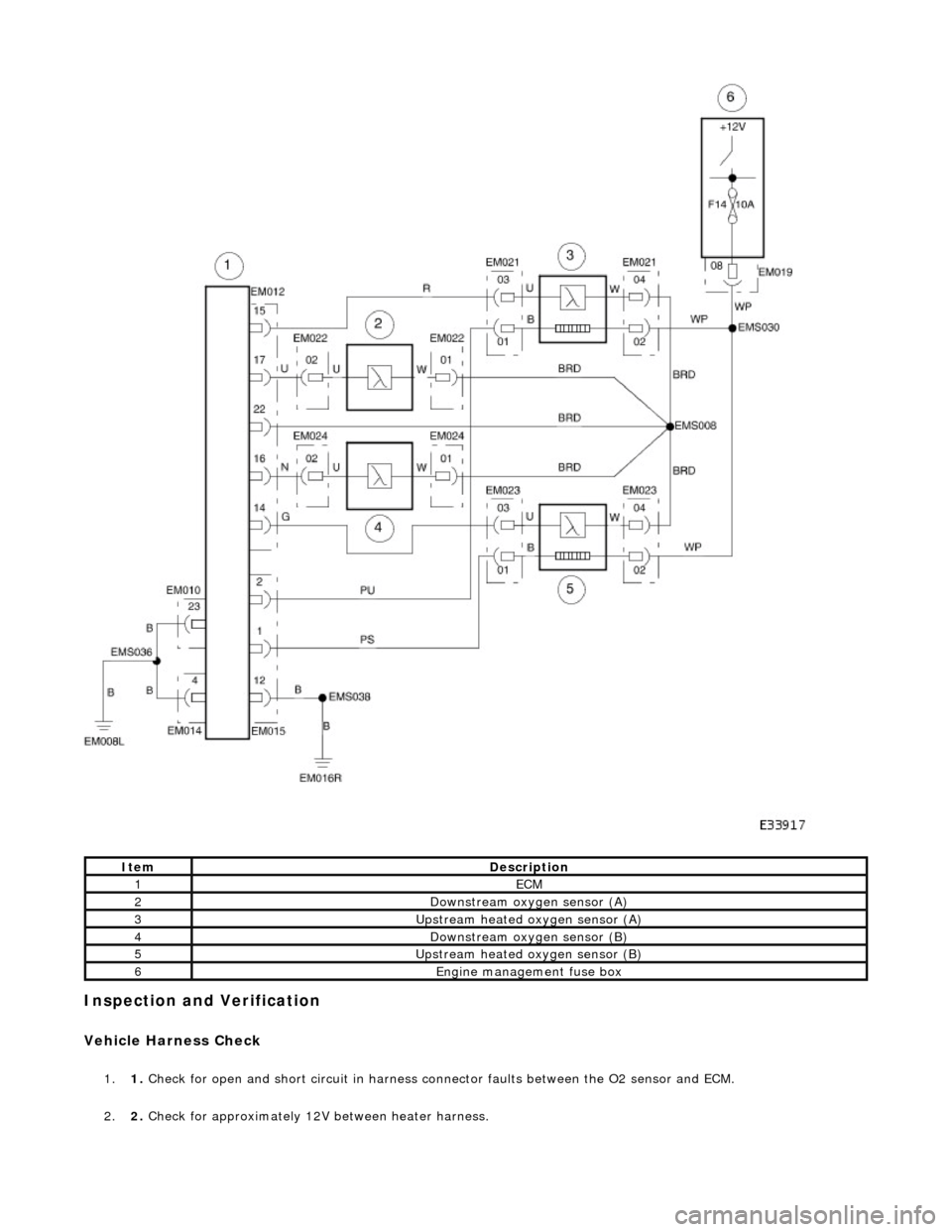

Inspection and Verification

Vehicle Harness Check

1.1. Check for open and short circuit in harness conn ector faults between the O2 sensor and ECM.

2. 2. Check for approximately 12V between heater harness.

ItemDescription

1ECM

2Downstream oxygen sensor (A)

3Upstream heated oxygen sensor (A)

4Downstream oxygen sensor (B)

5Upstream heated oxygen sensor (B)

6Engine management fuse box

Page 1532 of 2490

Heater Resistance Check

1.1. Verify that the resistance between the heater term inals is between 4OHM and 10OHM at -20°C to 100°C.

Performance Check

1.1. Run the engine at 2500 RPM for two minutes, to heat up the O2 sensor.

2. 2. Check the voltage of the sensor output: Alternates between less than 0.4V at feed back engine conditions and in

excess of 0.5V, see graph.

These voltages are for reference only.

3. 3. Check that cycle of the upstream se nsor output is in accordance with the appropriate pinpoint test.

4. 4. Check that cycle of the downstream sensor output is in accordance with the appropriate pinpoint test.

Page 1535 of 2490

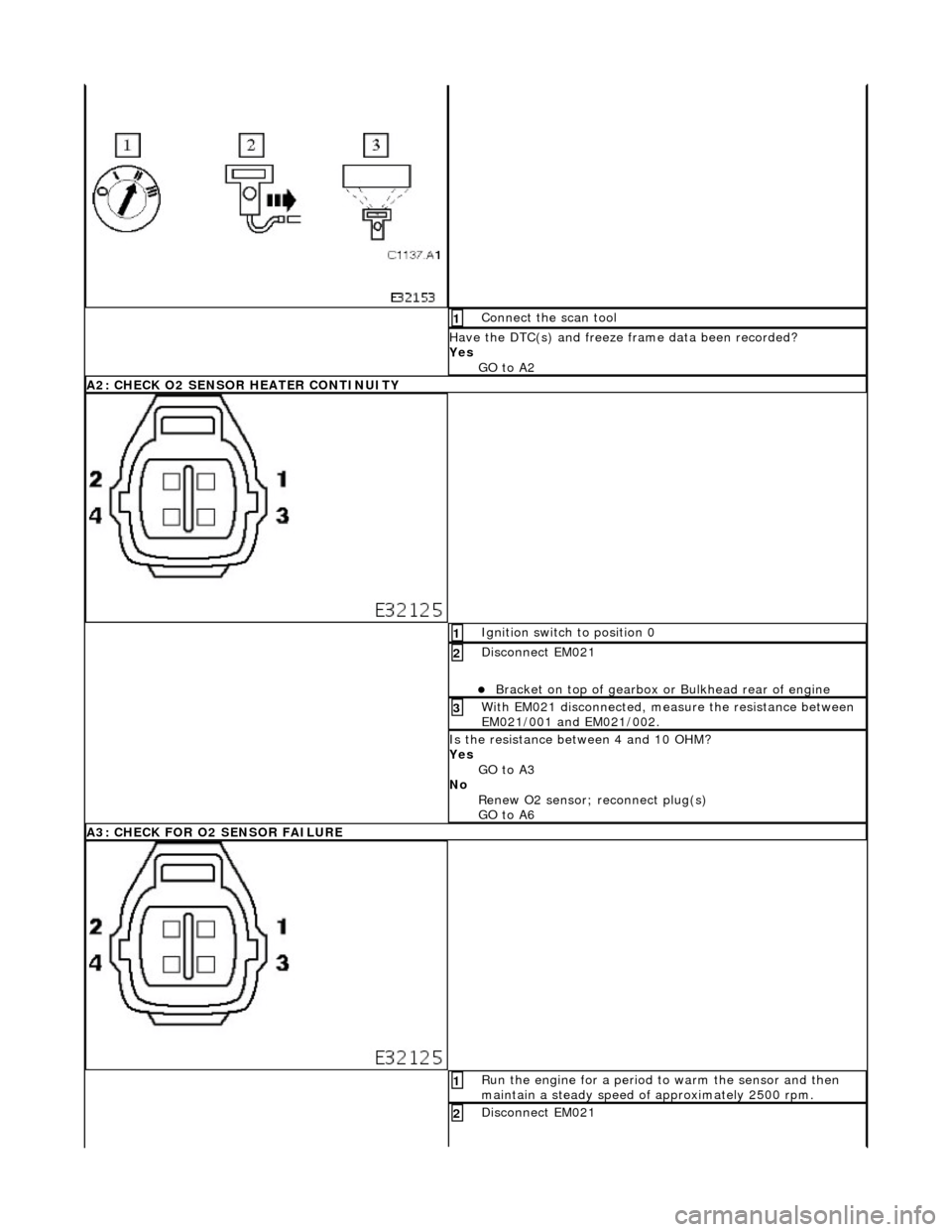

Connect the scan tool 1

Have the DTC(s) and freeze frame data been recorded?

Yes GO to A2

A2: CHECK O2 SENSOR HEATER CONTINUITY

Ignition switch to position 0 1

Disconnect EM021

Bracket on top of gearbox or Bulkhead rear of engine

2

With EM021 disconnected, measure the resistance between

EM021/001 and EM021/002. 3

Is the resistance between 4 and 10 OHM?

Yes

GO to A3

No Renew O2 sensor; reconnect plug(s)

GO to A6

A3: CHECK FOR O2 SENSOR FAILURE

Run the engine for a period to warm the sensor and then

maintain a steady speed of approximately 2500 rpm. 1

Disconnect EM021 2

Page 1536 of 2490

Bracket on top of gearbox or Bulkhead rear of engine

With EM021 disconnected, measure the voltage between

EM021/003 and EM021/004. 3

Is the voltage between 600mV and 1.0 Volt?

Yes

GO to A4

No Renew O2 sensor; reconnect plug(s)

GO to A6

A4: CHECK FOR O2 SENSOR FAILURE

With the conditions held as A3, suddenly decelerate to idle. 1

Has the voltage dropped to 400mV or less ?

Yes GO to A5

No Renew O2 sensor; reconnect plug(s)

GO to A6

A5: CHECK FOR O2 SENSOR FAILURE

With the conditions held as A4, suddenly accelerate to

approximately 2500 rpm. 1

Has the voltage risen to between 600mV and 1 volt?

Yes GO to A7

No Renew O2 sensor; reconnect plug(s)

GO to A6

A6: STOP

Perform appropriate service drive cycle and check for the

presence of DTC 1

Has the fault code cleared?

Yes STOP

No Contact Jaguar Service

A7: HEATED O2 SENSOR SHORT CIRCUIT TO GROUND