height JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 33 of 2490

501‐17: Roof Open

ing

Panel

Description and Operation

Roof Opening Panel

General Procedures

Motor Synchronization (76.82.48)

Roof Opening Panel Alignment

Removal and Installation

Roof Opening Panel (76.82.05)

Roof Opening Panel Frame (76.82.01)

Roof Opening Panel Module (86.76.07)

Roof Opening Panel Motor (86.76.01)

Roof Opening Panel Shie

ld (76.82.06)

Roof Opening Panel Trim

Roof Opening Panel Weatherstrip (76.82.15)

501‐19: Bumpers

Specification

Description and Operation

Bumpers

Removal and Installation

Front Bumper (76.22.08)

Front Bumper and Bumper Cover (76.22.08)

Front Bumper Cover (76.22.78)

Front Bumper Isolator (76.22.31)

Rear Bumper (76.22.27) (76.22.52)

Rear Bumper Co

ver (76.22.74) (76.22.77)

Rear Bumper Isolator (76.22.70)

501‐20A : Safety Belt System

Specification

Description and Operation

Safety Belt System

Removal and Installation

Front Safety Belt Retractor (76.73.10)

Rear Safety Belt Retractor (76.73.18)

Safety Belt Shoulder Height Adjuster (76.73.12)

Page 58 of 2490

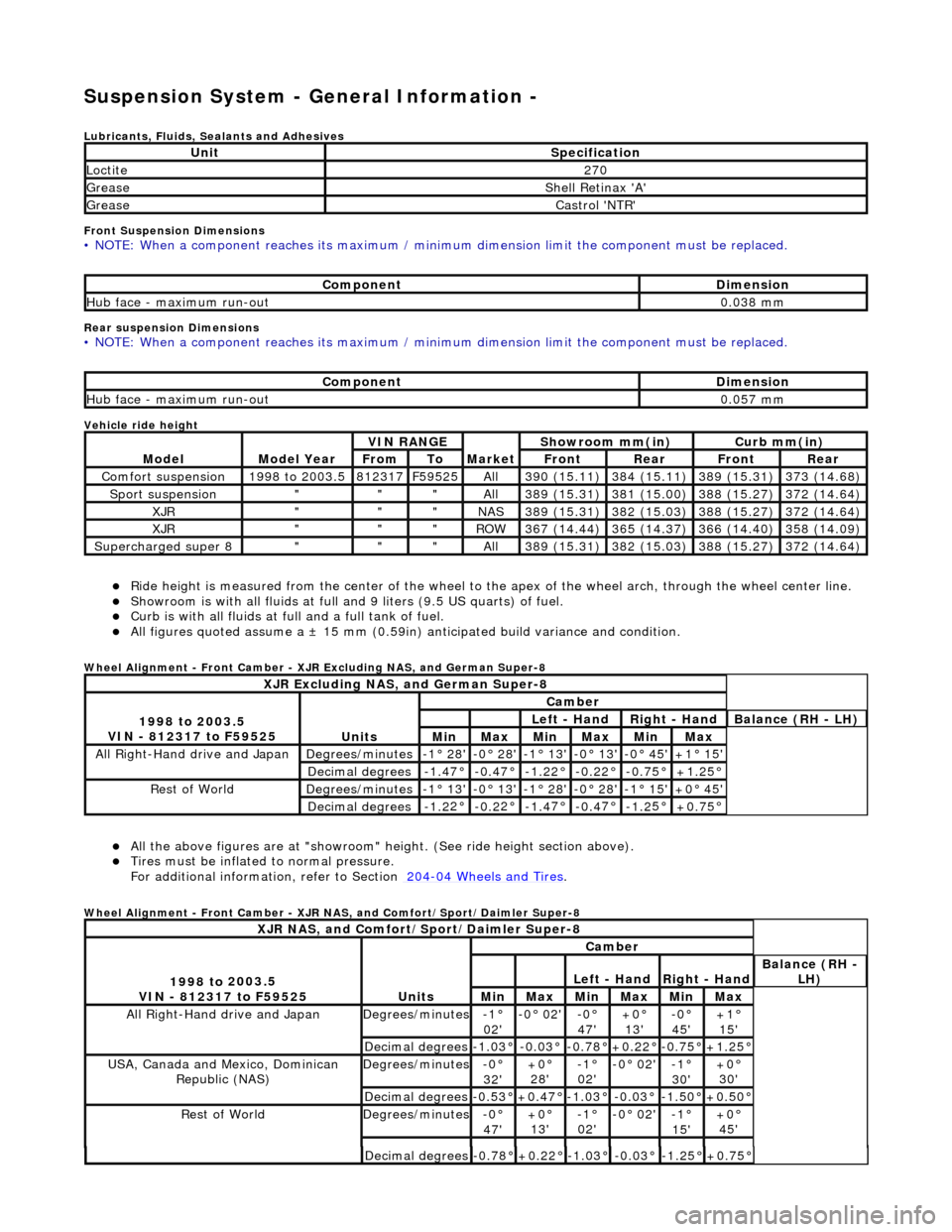

Suspension System - General Informatio

n -

Lubric

ants, Fluids, Sealants and Adhesives

Front Suspension Dimensions

• NO

TE: When a component reaches its maximum / minimum dimension limit the component must be replaced.

Rear sus

p

ension Dimensions

•

NO

TE: When a component reaches its maximum / minimum dimension limit the component must be replaced.

Vehicle ride

height

R i

de height is measured from

the center of the wheel to the apex of the wheel arch, through the wheel center line.

Showroom is with a

ll fluids at full an

d 9 liters (9.5 US quarts) of fuel.

Curb is

with all fluids at full and a full tank of fuel.

All f

i

gures quoted assume a ±

15 mm (0.59in) anticipated bu ild variance and condition.

Whee

l Alignment - Front Camber - XJR Excluding NAS, and German Super-8

Al l the above fi

gures

are at "showroom" height. (See ride height section above).

Tires must be infl

ated

to normal pressure.

For additional informat ion, refer to Section 204

-04

Wheels and Tires

.

Whe

e

l Alignment - Front Camber - XJR NAS, and Comfort/Sport/Daimler Super-8

UnitSp

ecification

Loctite27

0

Greas eShell Retin a

x 'A'

Greas

eCastro l 'NT

R'

Com

p

onent

Di

mensi

on

Hub face

-

maximum run-out

0.

03

8 mm

Com

p

onent

Di

mensi

on

Hub face

-

maximum run-out

0.

05

7 mm

Mod

e

l

Mod

e

l Year

V

I

N RANGE

Mark

et

Sh

owroom mm(in)

Curb mm(i

n)

FromToFron

t

RearFr

on

t

Rear

Com

f

ort suspension

1

998

to 2003.5

8

123

17

F

595

25

All3

90 (

15.11)

3

84 (

15.11)

3

89 (

15.31)

3

73 (

14.68)

Sport su

spe

nsion

"""All3

89 (

15.31)

3

81 (

15.00)

3

88 (

15.27)

3

72 (

14.64)

XJR"""NAS3

89 (

15.31)

3

82 (

15.03)

3

88 (

15.27)

3

72 (

14.64)

XJR"""RO

W367 (

14.44)

3

65 (

14.37)

3

66 (

14.40)

3

58 (

14.09)

Supercharged super 8"""All3

89 (

15.31)

3

82 (

15.03)

3

88 (

15.27)

3

72 (

14.64)

XJR

Excluding NAS, and German Super-8

1998 to

2003.5

VIN - 812317 to F59525

Units

Cambe r

Left

- Hand

Rig

h

t - Hand

Bal

a

nce (RH - LH)

MinMaxMinMaxMinMax

All Right-Hand driv

e and JapanDegrees

/minutes

-

1

° 28'

-0

°

28'

-

1

° 13'

-

0

° 13'

-0

° 45'+1 °

15'

Decimal degrees-1.

4

7°

-0

.4

7°

-1

.2

2°

-0.

2

2°

-0

.7

5°

+1

.25

°

R

e

st of World

De

grees

/minutes

-

1

° 13'

-0

°

13'

-

1

° 28'

-

0

° 28'

-1

° 15'+0 °

45'

Decimal degrees-1.

2

2°

-0

.2

2°

-1

.4

7°

-0.

4

7°

-1

.2

5°

+0

.75

°

XJR

NAS, and Comfort/Sport/Daimler Super-8

1

998 to

2003.5

VIN - 812317 to F59525

Units

Cambe r

Left

- Hand

Rig

h

t - Hand

Bal

a

nce (RH -

LH)

MinMaxMinMaxMinMax

All Right-Hand drive and JapanDegrees

/minutes

-1°

02'-0

° 02'

-0°

47'

+0°

13'

-0° 45'+1°

15'

Decimal degrees-1.0

3°

-0.0

3°

-0.7

8°

+0.22

°

-0.7

5°

+1.25

°

USA, Canada an

d Mexico,

Dominican

Republic (NAS)

De grees

/minutes

-0°

32 '+0 °

28'

-1 °

02'

-0 °

02'

-1°

30 '+0 °

30'

Decimal degrees-0. 5

3°

+0

.47

°

-1

.0

3°

-0

.0

3°

-1.

5

0°

+0

.50

°

R

e

st of World

De

grees

/minutes

-0°

47 '+0 °

13'

-1 °

02'

-0 °

02'

-1°

15 '+0 °

45'

Decimal degrees-0. 7

8°

+0

.22

°

-1

.0

3°

-0

.0

3°

-1.

2

5°

+0

.75

°

Page 59 of 2490

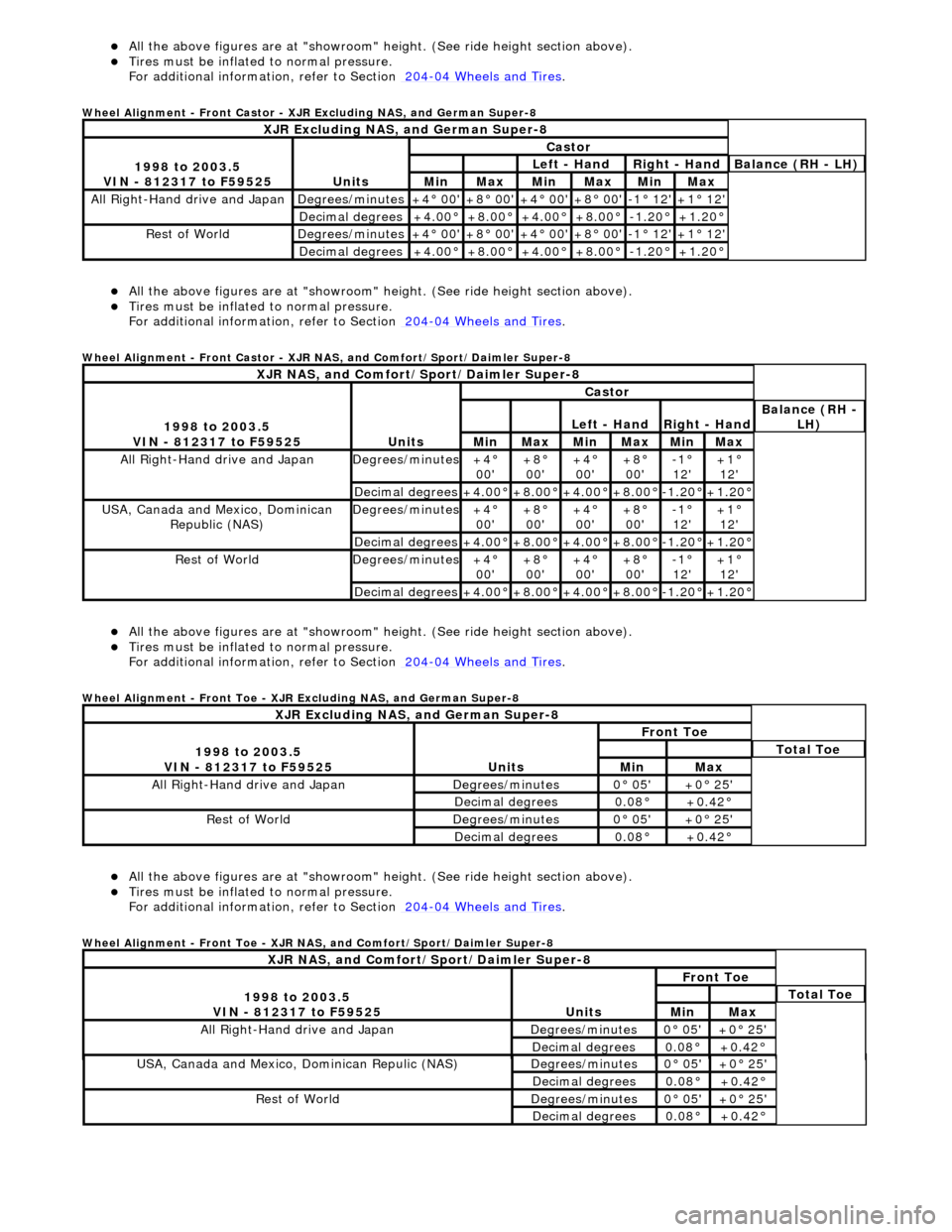

Al

l the above figures

are at "showroom" height. (See ride height section above).

Ti

res must be inflated

to normal pressure.

For additional informat ion, refer to Section 204

-0

4 Wheels and Tires

.

Whe

el Alignment - Front Castor - XJR Excluding NAS, and German Super-8

Al

l the above figures

are at "showroom" height. (See ride height section above).

Ti

res must be inflated

to normal pressure.

For additional informat ion, refer to Section 204

-0

4 Wheels and Tires

.

Whe

el Alignment - Front Castor - XJR NAS, and Comfort/Sport/Daimler Super-8

Al

l the above figures

are at "showroom" height. (See ride height section above).

Ti

res must be inflated

to normal pressure.

For additional informat ion, refer to Section 204

-0

4 Wheels and Tires

.

Whe

el Alignment - Front Toe - XJR Excluding NAS, and German Super-8

Al

l the above figures

are at "showroom" height. (See ride height section above).

Ti

res must be inflated

to normal pressure.

For additional informat ion, refer to Section 204

-0

4 Wheels and Tires

.

Whe

el Alignment - Front Toe - XJR NAS, and Comfort/Sport/Daimler Super-8

XJR

Excluding NAS, and German Super-8

1

998 to 2003.5

VIN - 812317 to F59525

Units

Castor

Le

ft - Hand

Rig

ht - Hand

Bal

ance (RH - LH)

MinMaxMinMaxMinMax

All Right

-Hand drive and Japan

De

grees/minutes

+4

° 00'

+8

° 00'

+4

° 00'

+8

° 00'

-1

° 12'

+1

° 12'

Decimal degrees+4

.00°

+8

.00°

+4

.00°

+8

.00°

-1.

20°

+1

.20°

R

est of World

De

grees/minutes

+4

° 00'

+8

° 00'

+4

° 00'

+8

° 00'

-1

° 12'

+1

° 12'

Decimal degrees+4

.00°

+8

.00°

+4

.00°

+8

.00°

-1.

20°

+1

.20°

XJR

NAS, and Comfort/Sport/Daimler Super-8

1

998 to 2003.5

VIN - 812317 to F59525

Units

Castor

Le

ft - Hand

Rig

ht - Hand

Bal

ance (RH -

LH)

MinMaxMinMaxMinMax

All Right

-Hand drive and Japan

De

grees/minutes

+4

°

00'

+8

°

00'

+4

°

00'

+8

°

00'

-1

°

12'

+1

°

12'

Decimal degrees+4

.00°

+8

.00°

+4

.00°

+8

.00°

-1.

20°

+1

.20°

USA, Canada an

d Mexico, Dominican

Republic (NAS)

De

grees/minutes

+4

°

00'

+8

°

00'

+4

°

00'

+8

°

00'

-1

°

12'

+1

°

12'

Decimal degrees+4

.00°

+8

.00°

+4

.00°

+8

.00°

-1.

20°

+1

.20°

R

est of World

De

grees/minutes

+4

°

00'

+8

°

00'

+4

°

00'

+8

°

00'

-1

°

12'

+1

°

12'

Decimal degrees+4

.00°

+8

.00°

+4

.00°

+8

.00°

-1.

20°

+1

.20°

XJR

Excluding NAS, and German Super-8

1

998 to 2003.5

VIN - 812317 to F59525

Units

Fr

ont Toe

To

tal Toe

MinMax

All Right-Hand driv

e and Japan

De

grees/minutes

0

° 05'

+0

° 25'

Decimal degrees0.

08°

+0

.42°

R

est of World

De

grees/minutes

0

° 05'

+0

° 25'

Decimal degrees0.

08°

+0

.42°

XJR

NAS, and Comfort/Sport/Daimler Super-8

1

998 to 2003.5

VIN - 812317 to F59525

Units

Fr

ont Toe

To

tal Toe

MinMax

All Right-Hand driv

e and Japan

De

grees/minutes

0

° 05'

+0

° 25'

Decimal degrees0.

08°

+0

.42°

USA, Canada an

d Mexico

, Dominican Repulic (NAS)

De

grees/minutes

0

° 05'

+0

° 25'

Decimal degrees0.

08°

+0

.42°

R

est of World

De

grees/minutes

0

° 05'

+0

° 25'

Decimal degrees0.

08°

+0

.42°

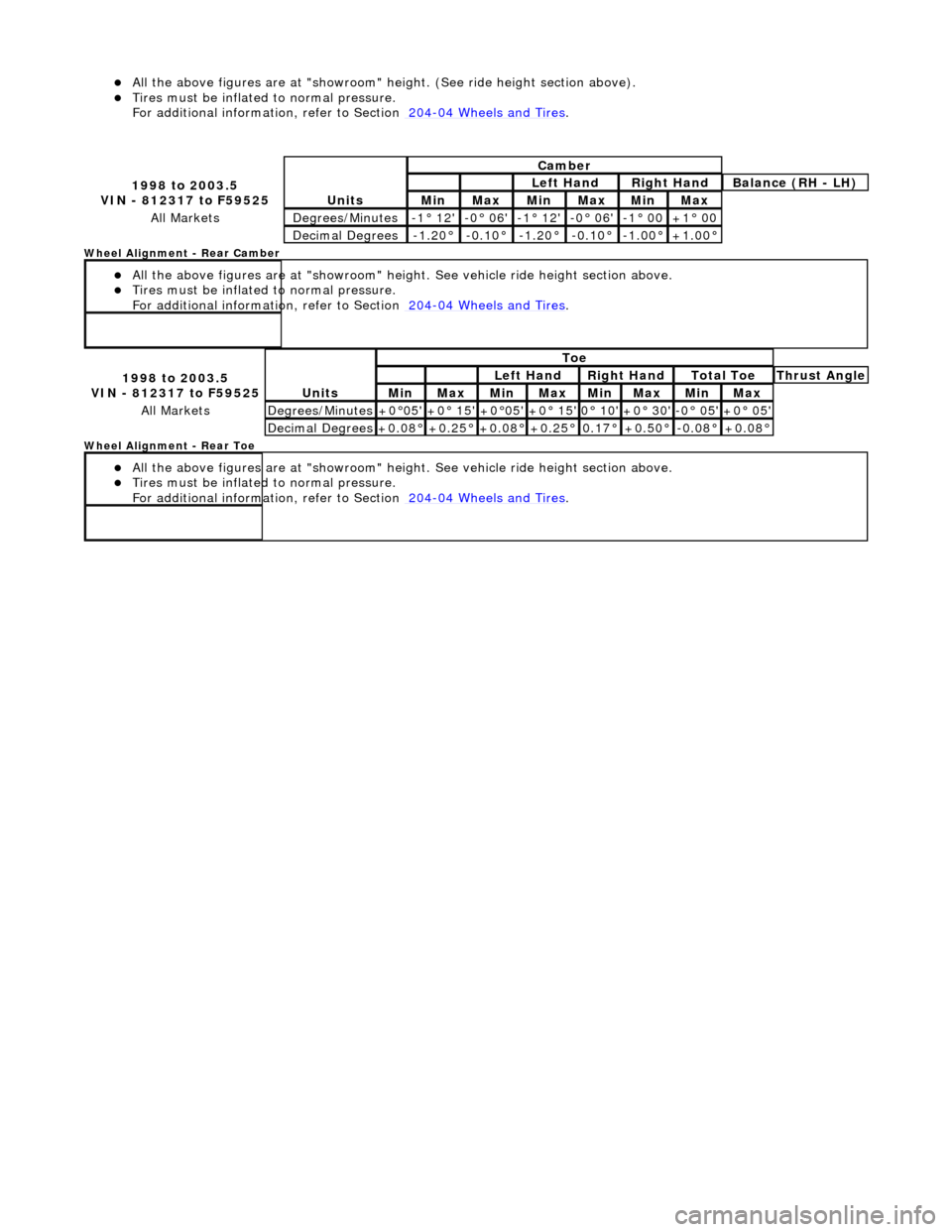

Page 60 of 2490

All the above fi

gures

are at "showroom" height. (See ride height section above).

Tires must be infl

ated

to normal pressure.

For additional informat ion, refer to Section 204

-04

Wheels and Tires

.

Wh

eel Alignment - Rear Camber

All the above figu res

are at "s

howroom" height. See vehicle ride height section above.

Tires must be infl

ated

to normal pressure.

For additional informat ion, refer to Section 204

-04

Wheels and Tires

.

W

h

eel Alignment - Rear Toe

All the above figu res

are at "s

howroom" height. See vehicle ride height section above.

Tires must be infl

ated

to normal pressure.

For additional informat ion, refer to Section 204

-04

Wheels and Tires

.

1 998 to

2003.5

VIN - 812317 to F59525

Units

Cambe r

Left

Hand

Rig

h

t Hand

Bal

a

nce (RH - LH)

Min MaxMin MaxMinMax

All MarketsDe

grees

/Minutes

-

1

° 12'

-0

° 06'-1° 12'-0

° 06'

-1

°

00

+1

°

00

De

ci

mal Degrees

-1.

2

0°

-0

.1

0°

-1.

2

0°

-0.

1

0°

-1.

0

0°

+1

.00

°

1

998 to

2003.5

VIN - 812317 to F59525

Units

To e

Left

Hand

Rig

h

t Hand

To

t

al Toe

Thr

u

st Angle

MinMaxMinMaxMin MaxMin Max

All MarketsDe

grees

/Minutes

+0

°

05'

+0

° 15'+0°

05'

+0

° 15'0°

10'

+0

° 30'-0° 05'+0 °

05'

De

ci

mal Degrees

+0

.08

°

+0

.25

°

+0

.08

°

+0

.25

°

0.

17

°

+0

.50

°

-0.

0

8°

+0

.08

°

Page 222 of 2490

Remova

l

2

05-2

34 (JD 550-1)

1. CAUTION: Replacement of nuts and bolts: Various

thread-locking devices are used on nuts and bolts throughout the

vehicle. These devices restrict the number of times a nut or bolt

can be used. See section 100-00 for information.

Release handbrake.

2. Ra

ise the vehicle on a four-post lift.

3. Fully slacken bu

t do not remove parking brake cable adjuster

nut.

4. Relea s

e appropriate side parkin

g brake cable from connecting

clip.

5. With draw parkin

g brake cable th

rough equalizer (LH side cable

only).

6. Lower four-post lift.

7. Raise rear of vehicle to workin g height and support on stands.

Refer to section 100-02.

8. Remove rear wheel. Refer to section 204-04.

Page 238 of 2490

clip

.

5. With draw parkin

g brake cable th

rough equalizer (LH side cable

only).

6. Lower four-post lift.

7. Raise rear of vehicle to workin g height and support on stands.

Refer to section 100-02.

8. Remove rear wheel. Refer to section 204-04.

9. Posit i

on special tool (204-1

95) on hub studs and install

securing nuts.

10 . Slac

ken but do not remove hub to axle shaft securing nut.

11. Remove nuts and withdraw special tool (204-195) from hub.

12. Remove rear brake disc. Refer to 70.10.13.

13. Remove parking brake shoe s. Refer to 70.40.05.

14. Remove wheel speed sensor.

Page 249 of 2490

cli

p.

5. With

draw parking brake cable th

rough equalizer (LH side cable

only).

6. Lower four-post lift.

7. Raise rear of vehicle to workin g height and support on stands.

Refer to section 100-02.

8. Remove rear wheel. Refer to section 204-04.

9. Posit

ion special tool (204-1

95) on hub studs and install

securing nuts.

10

.

Slacken but do not remove hub to axle shaft securing nut.

11. Remove securing nuts from stud s and withdraw special tool

(204-195) from hub.

12. Remove rear brake disc. Refer to 70.10.13.

13. Remove parking brake shoe s. Refer to 70.40.05.

14. Remove wheel speed sensor.

Page 273 of 2490

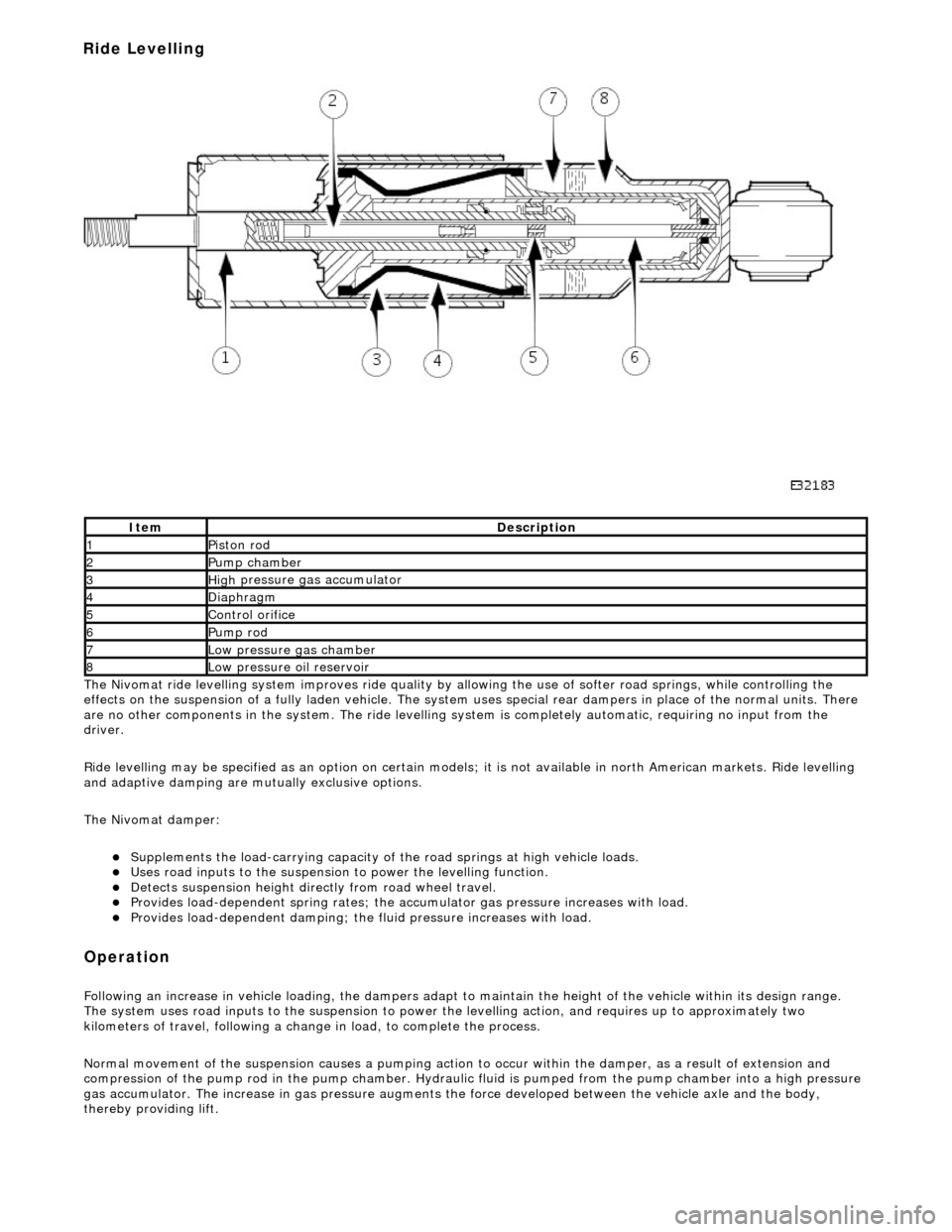

The

Nivomat ride levelling system improves ride quality by al

lowing the use of softer road springs, while controlling the

effects on the suspension of a fully laden vehicle. The system uses special rear dampers in place of the normal units. There

are no other components in th e system. The ride levelling system is comple tely automatic, requiring no input from the

driver.

Ride levelling may be specified as an opti on on certain models; it is not available in north American markets. Ride levelling

and adaptive damping are mu tually exclusive options.

The Nivomat damper:

Su

pplements the load-carrying capacity of th

e road springs at high vehicle loads.

Uses road inputs to the

suspension to power the levelling function.

De

tects suspension height dire

ctly from road wheel travel.

Provi

des load-dependent spring rates; the ac

cumulator gas pressure increases with load.

Pr

ovides load-dependent damping; the fluid pressure increases with load.

Op

eration

F

ollowing an increase in vehicle loading,

the dampers adapt to maintain the height of the vehicle within its design range.

The system uses road inputs to the suspension to power the levelling action, and requires up to approximately two

kilometers of travel, following a change in load, to complete the process.

Normal movement of the suspension caus es a pumping action to occur within the damper, as a result of extension and

compression of the pump rod in the pump chamber. Hydraulic fluid is pumped from the pump cham ber into a high pressure

gas accumulator. The increase in gas pressure augments the force developed between th e vehicle axle and the body,

thereby providing lift.

It

em

De

scription

1Pi

ston rod

2Pum

p chamber

3High

pressure

gas accumulator

4Diaphragm

5Co

ntrol orifice

6Pump rod

7Low pressure gas ch

amber

8Low pressure oil

reservoir

Ride Levelling

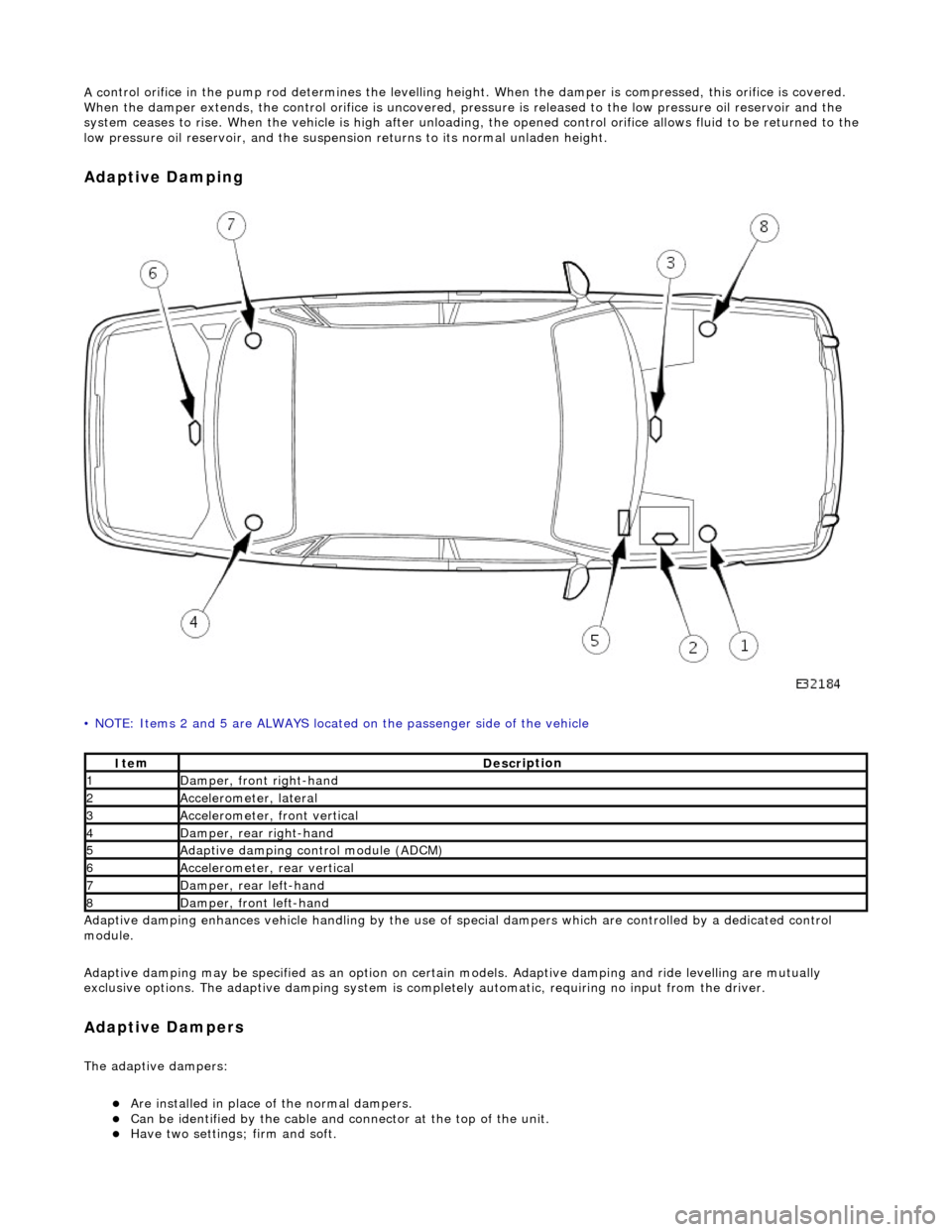

Page 274 of 2490

A c

ontrol orifice in the pump rod determines the levelling height. When the damper is compressed, this orifice is covered.

When the damper extends, the control orif ice is uncovered, pressure is released to the low pressure oil reservoir and the

system ceases to rise. When the vehicle is high after unloading, the opened control or ifice allows fluid to be returned to the

low pressure oil reservoir, and the suspensi on returns to its normal unladen height.

Ad

aptive Damping

•

NOTE: Items 2 and 5 are ALWAYS located

on the passenger side of the vehicle

Adaptive damping enhances vehicle handli ng by the use of special dampers which are controlled by a dedicated control

module.

Adaptive damping may be specified as an option on certai n models. Adaptive damping and ride levelling are mutually

exclusive options. The adaptive damping system is completely automatic, requiring no input from the driver.

A d

aptive Dampers

The adaptiv

e dampers:

Are inst

alled in place of the normal dampers.

Can be identified

by the cable and connector at the top of the unit.

Have two settings; fi

rm and so

ft.

It

e

m

De

scr

iption

1Dam

p

er, front right-hand

2Accel

e

rometer, lateral

3Accel

e

rometer,

front vertical

4D

a

mper, rear right-hand

5Adaptive dampin

g control module (A

DCM)

6Accel

e

rometer, rear vertical

7D

amper, rear l

eft-hand

8Dam

p

er, front left-hand

Page 908 of 2490

3. Disconnect the brake servo hose.

60. Fit engine rear lifting eyes (303 - 536).

61. Traverse the hoist to the engine compartment and lower it to

working height.

62. Fit lifting chains to the hoist and connect to each engine

lifting eye. Use longer chains to the rear lifting eyes to allow

the engine to tilt rearwards wh en removing from the vehicle.

63. Remove the engine front mounting nuts.

64. Raise the ramp.

65. Disconnect the transmission connector.

1. Release the lever lock on the transmission harness

multi-plug.

2. Disconnect the connector.

66. Disconnect the transmission selector cable.