JAGUAR X308 1998 2.G Workshop Manual

X308 1998 2.G

JAGUAR

JAGUAR

https://www.carmanualsonline.info/img/21/7640/w960_7640-0.png

JAGUAR X308 1998 2.G Workshop Manual

Trending: remove oxygen sensor, seat motor fuse, sensor, transmission fluid, glove box, vent solenoid, p0335

Page 1411 of 2490

With EM062 and GB001 disconnected, measure the

resistance between EM062/014 and EM008R 1

Repeat for EM062/015 and EM008R 2

EM062/016 and EM008R 3

Is the resistance > 10 MOHM?

Yes GO to C8

No Inspect EM062 for corrosion, bent / pushed back pins or

locate harness. Repair as necessary and test the system

for normal operation.

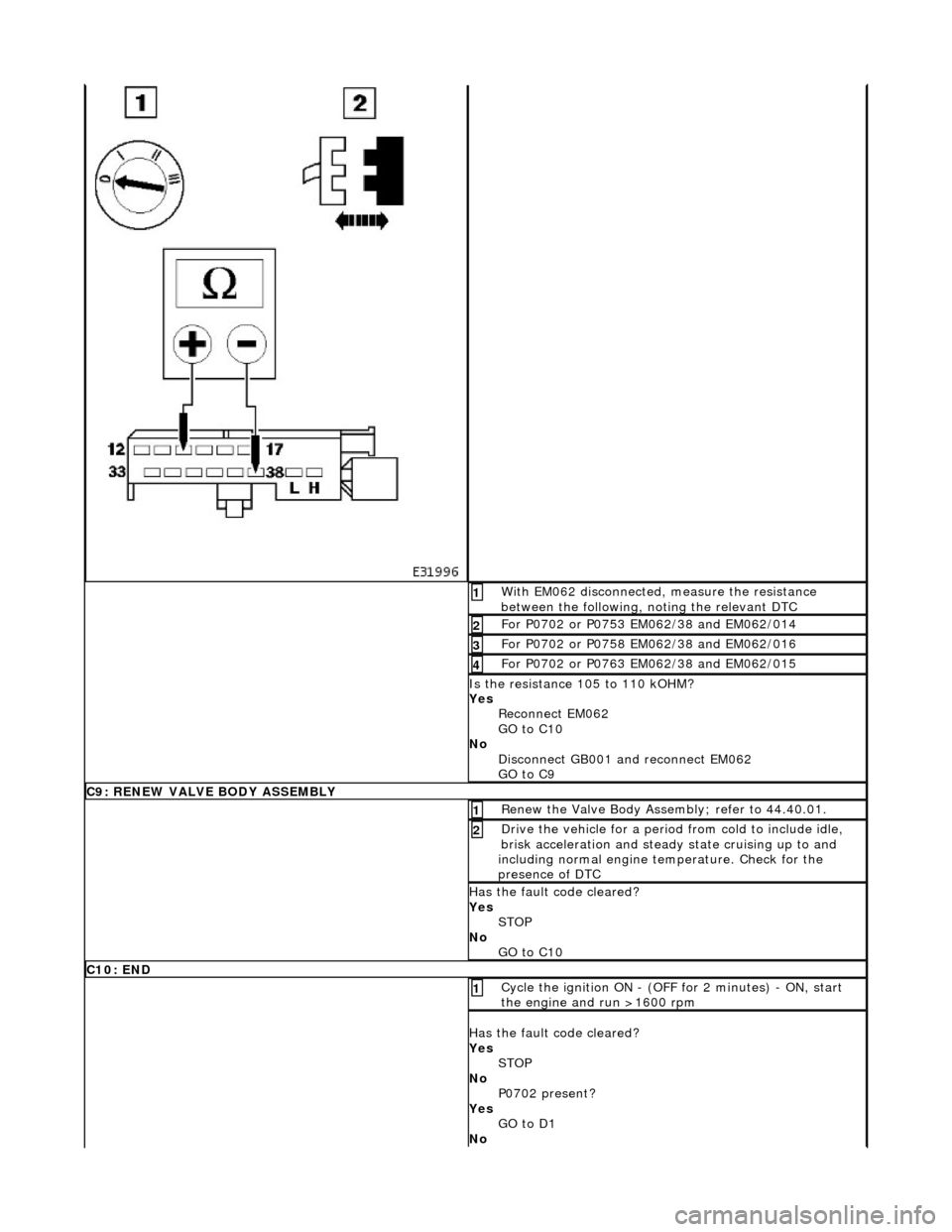

C8: CHECK INTERNAL HARNESS AND CO MPONENT CONTINUITY - SOLENOIDS

Page 1412 of 2490

With EM062 disconnected, measure the resistance

between the following, noting the relevant DTC 1

For P0702 or P0753 EM062/38 and EM062/014 2

For P0702 or P0758 EM062/38 and EM062/016 3

For P0702 or P0763 EM062/38 and EM062/015 4

Is the resistance 105 to 110 kOHM?

Yes Reconnect EM062

GO to C10

No Disconnect GB001 and reconnect EM062

GO to C9

C9: RENEW VALVE BODY ASSEMBLY

Renew the Valve Body Assembly; refer to 44.40.01. 1

Drive the vehicle for a period from cold to include idle,

brisk acceleration and steady state cruising up to and

including normal engine temperature. Check for the

presence of DTC 2

Has the fault code cleared?

Yes STOP

No GO to C10

C10: END

Cycle the ignition ON - (OFF for 2 minutes) - ON, start

the engine and run >1600 rpm 1

Has the fault code cleared?

Yes STOP

No P0702 present?

Yes GO to D1

No

Page 1413 of 2490

Pinpoint test D: P0702, P0748, P1748

P0753, P0758, P0763 present?

Yes Contact Jaguar Service

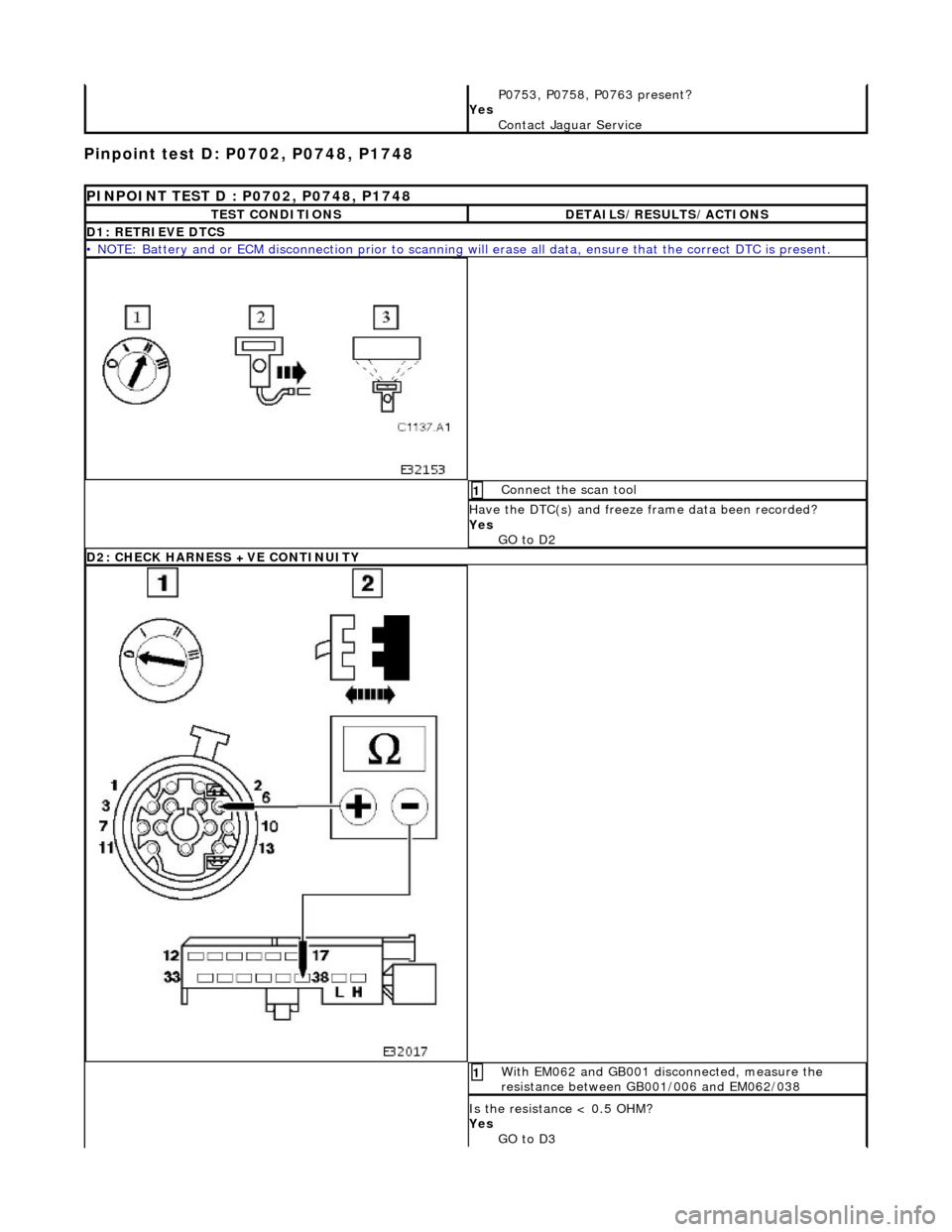

PINPOINT TEST D : P0702, P0748, P1748

TEST CONDITIONSDETAILS/RESULTS/ACTIONS

D1: RETRIEVE DTCS

• NOTE: Battery and or ECM disconnection prior to scanning wi ll erase all data, ensure that the correct DTC is present.

Connect the scan tool 1

Have the DTC(s) and freeze frame data been recorded?

Yes GO to D2

D2: CHECK HARNESS +VE CONTINUITY

With EM062 and GB001 disconnected, measure the

resistance between GB001/006 and EM062/038 1

Is the resistance < 0.5 OHM?

Yes GO to D3

Page 1414 of 2490

No Inspect EM062, EM044 and GB001 for corrosion, bent /

pushed back pins or locate harness. Repair as necessary

and test the system for normal operation.

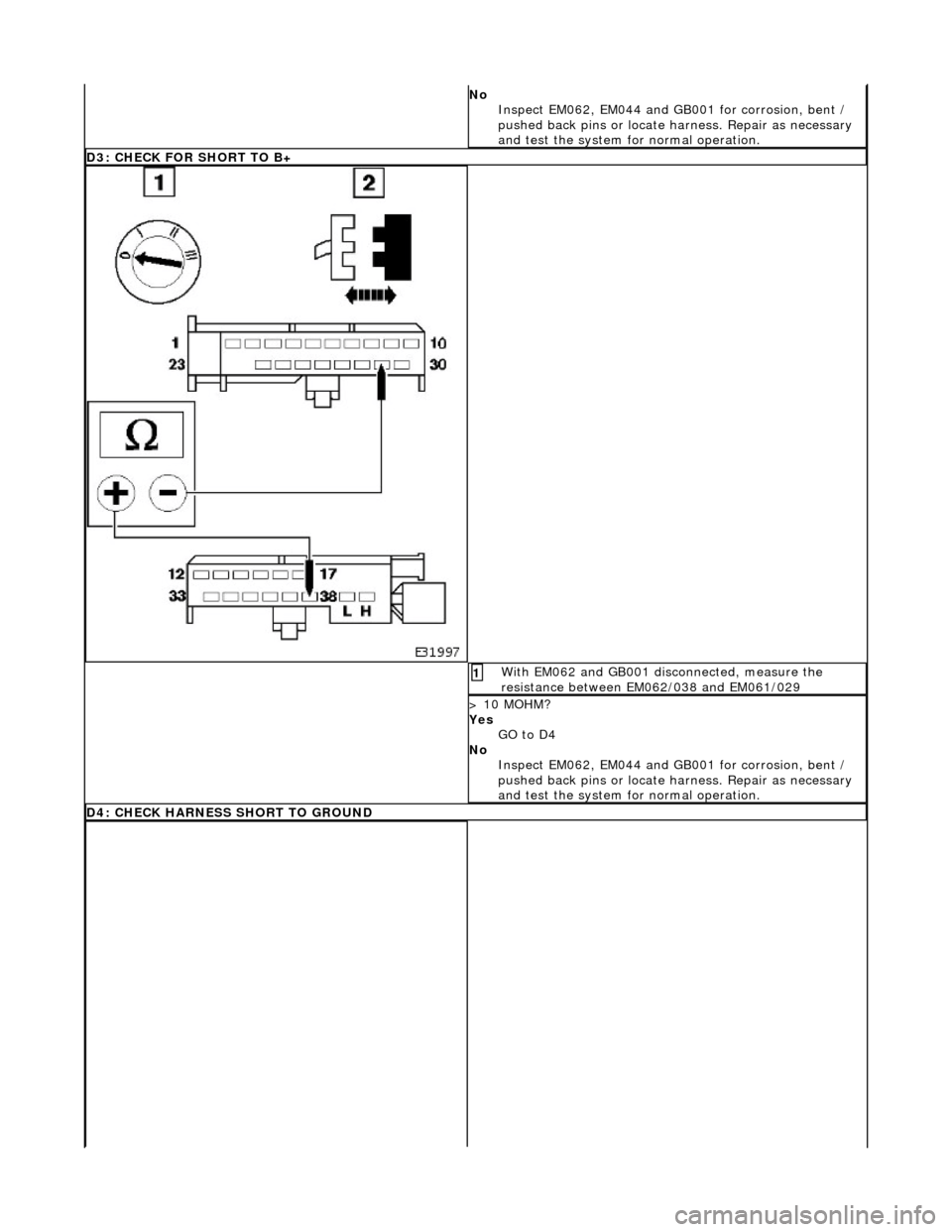

D3: CHECK FOR SHORT TO B+

With EM062 and GB001 disconnected, measure the

resistance between EM062/038 and EM061/029 1

> 10 MOHM?

Yes GO to D4

No Inspect EM062, EM044 and GB001 for corrosion, bent /

pushed back pins or locate harness. Repair as necessary

and test the system for normal operation.

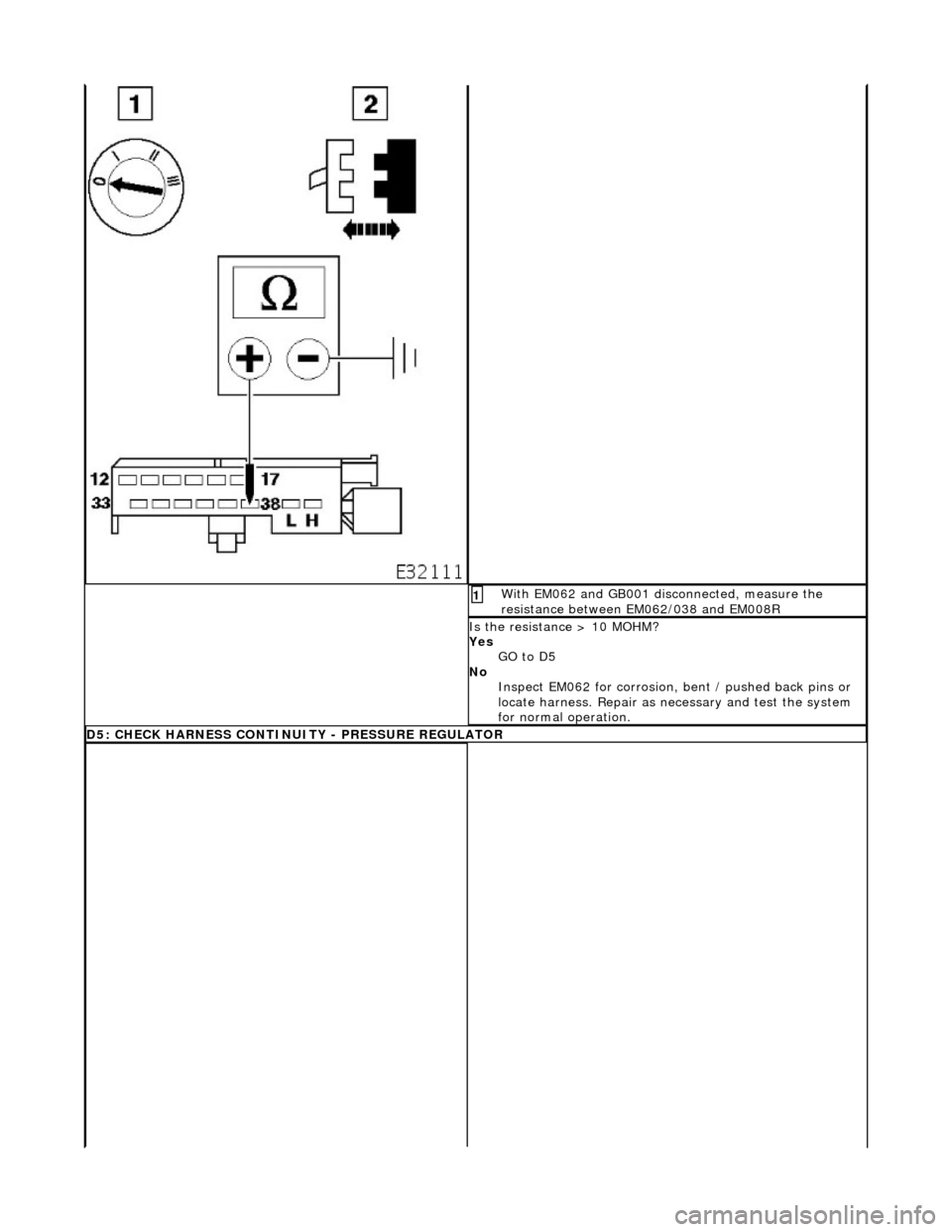

D4: CHECK HARNESS SHORT TO GROUND

Page 1415 of 2490

With EM062 and GB001 disconnected, measure the

resistance between EM062/038 and EM008R 1

Is the resistance > 10 MOHM?

Yes GO to D5

No Inspect EM062 for corrosion, bent / pushed back pins or

locate harness. Repair as necessary and test the system

for normal operation.

D5: CHECK HARNESS CONTINUI TY - PRESSURE REGULATOR

Page 1416 of 2490

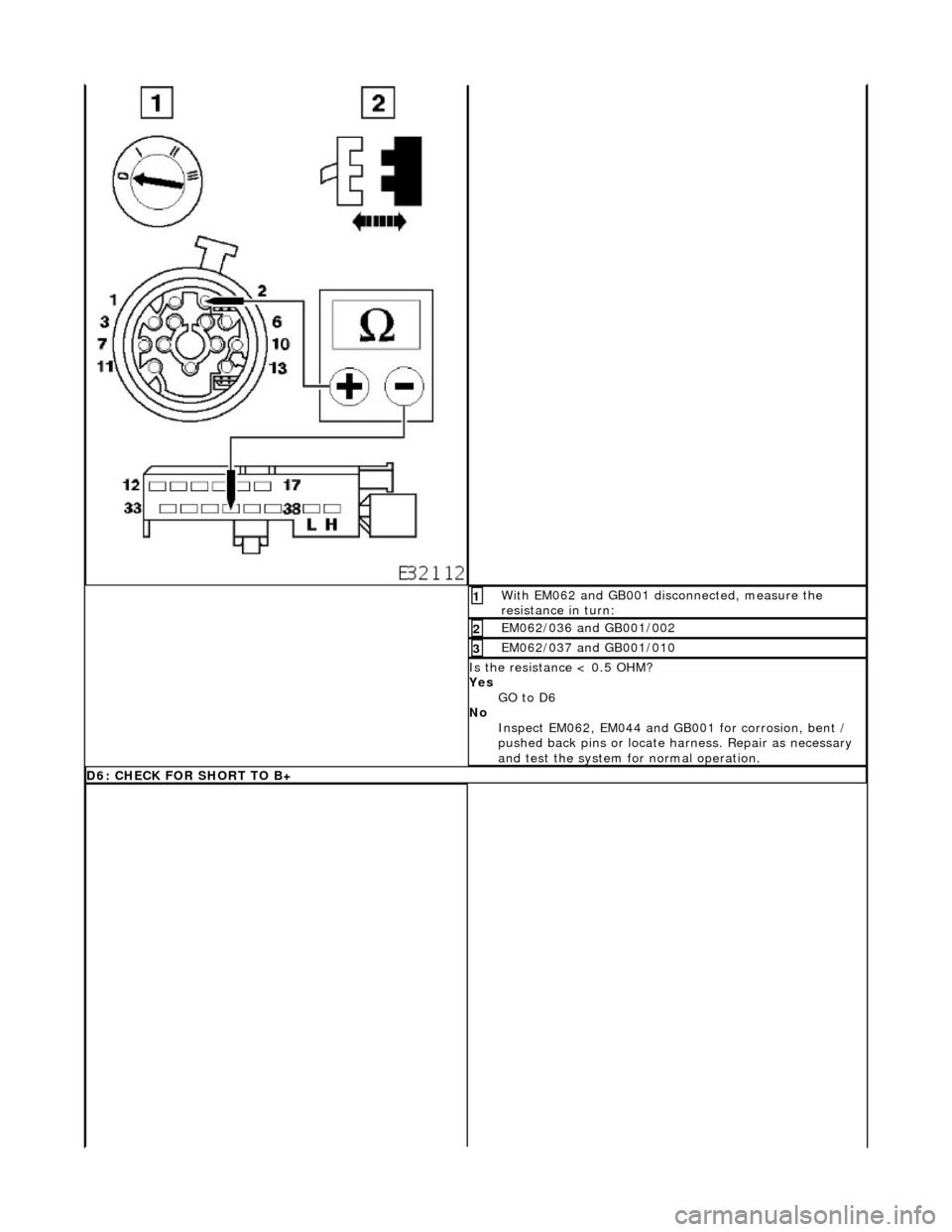

With EM062 and GB001 disconnected, measure the

resistance in turn: 1

EM062/036 and GB001/002 2

EM062/037 and GB001/010 3

Is the resistance < 0.5 OHM?

Yes GO to D6

No Inspect EM062, EM044 and GB001 for corrosion, bent /

pushed back pins or locate harness. Repair as necessary

and test the system for normal operation.

D6: CHECK FOR SHORT TO B+

Page 1417 of 2490

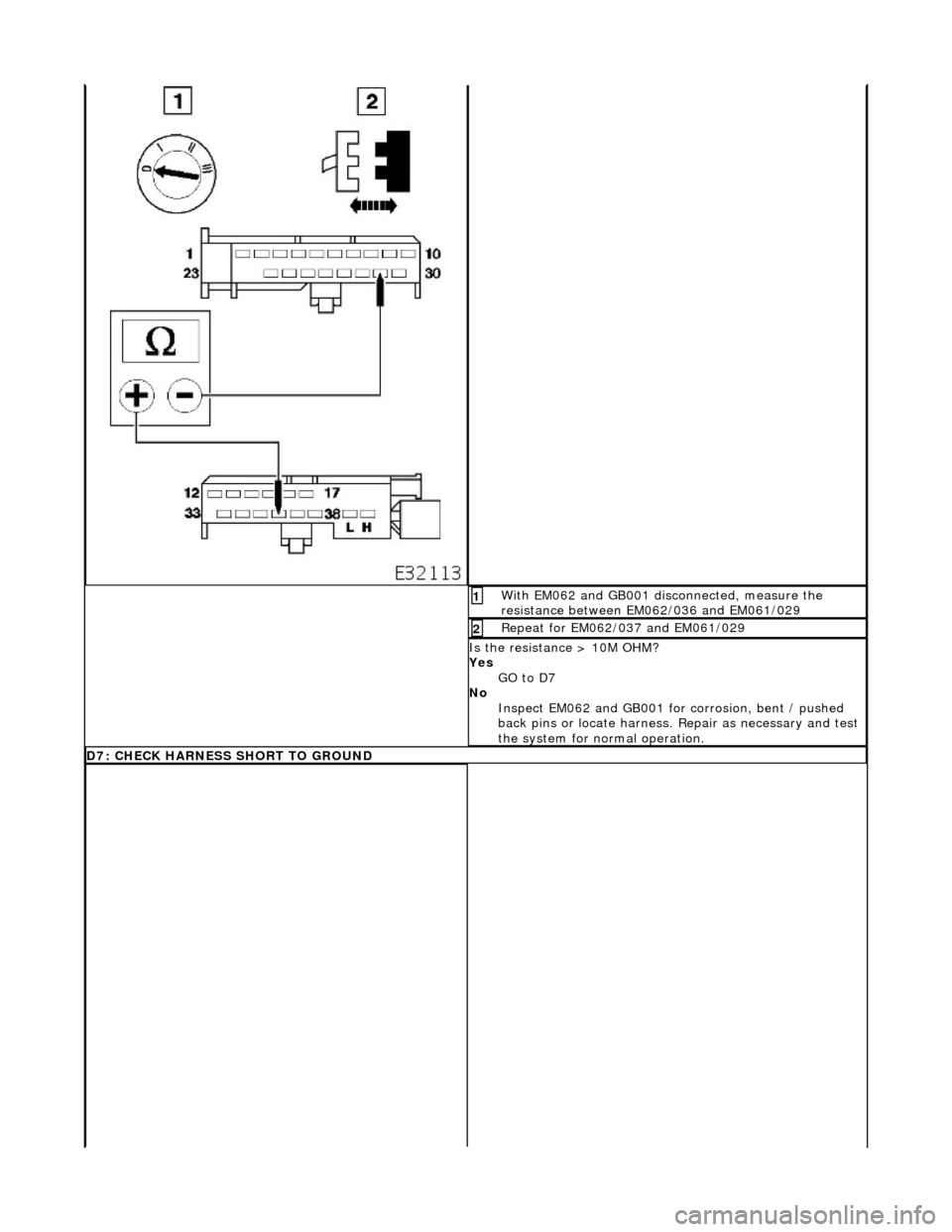

With EM062 and GB001 disconnected, measure the

resistance between EM062/036 and EM061/029 1

Repeat for EM062/037 and EM061/029 2

Is the resistance > 10M OHM?

Yes GO to D7

No Inspect EM062 and GB001 for corrosion, bent / pushed

back pins or locate harness. Repair as necessary and test

the system for normal operation.

D7: CHECK HARNESS SHORT TO GROUND

Page 1418 of 2490

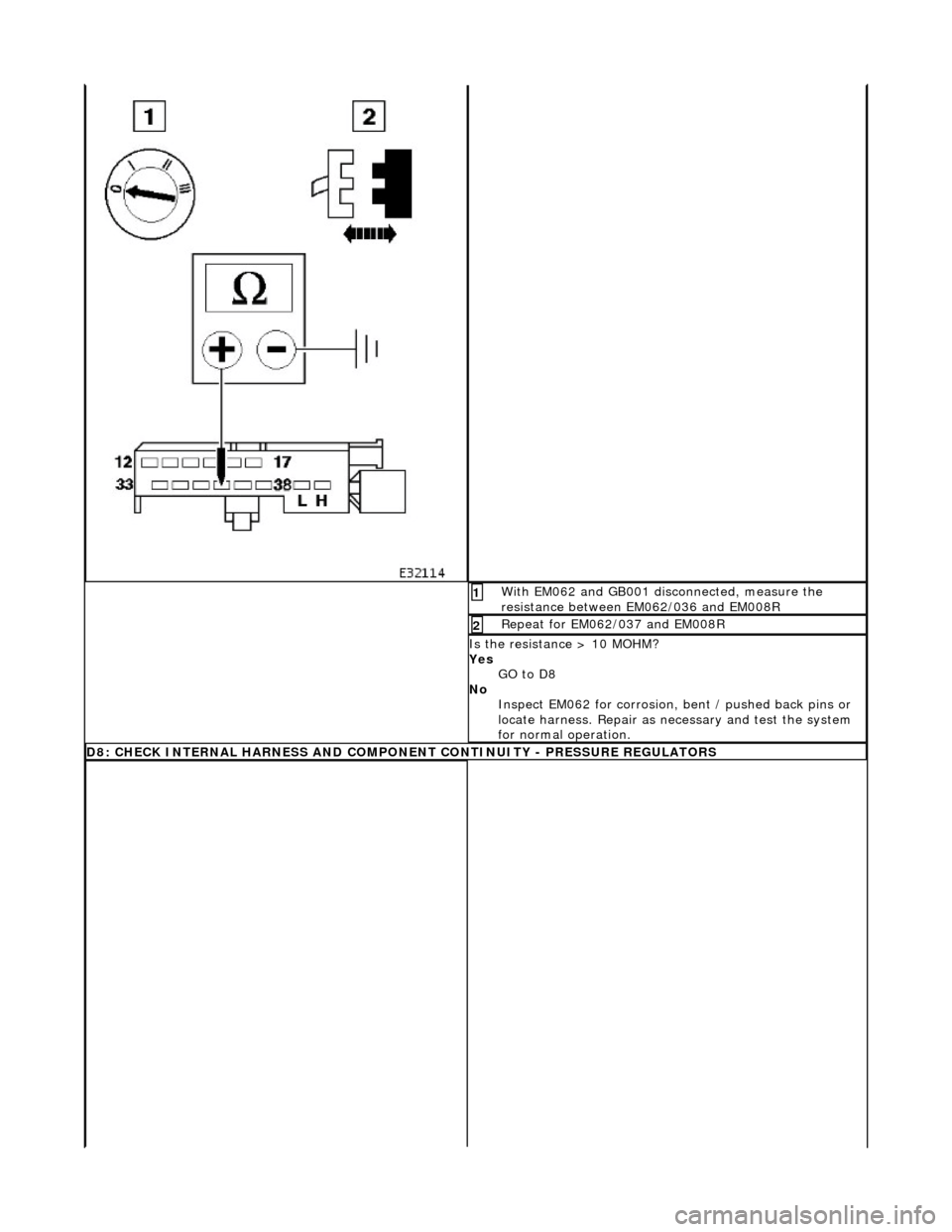

With EM062 and GB001 disconnected, measure the

resistance between EM062/036 and EM008R 1

Repeat for EM062/037 and EM008R 2

Is the resistance > 10 MOHM?

Yes GO to D8

No Inspect EM062 for corrosion, bent / pushed back pins or

locate harness. Repair as necessary and test the system

for normal operation.

D8: CHECK INTERNAL HARNESS AND COMPON ENT CONTINUITY - PRESSURE REGULATORS

Page 1419 of 2490

Pinpoint test E: P0702

With EM062 disconnected, measure the resistance

between the following, noting the relevant DTC 1

For P0702 or P0748 EM062/38 and EM062/036 2

For P0702 or P1748 EM062/38 and EM062/037 3

Is the resistance 16 to 18 kOHM?

Yes Reconnect EM062

GO to D9

No Renew the Valve Body Assembly; refer to 44.40.01.

Drive the vehicle for a period from cold to include idle,

brisk acceleration and steady state cruising up to and

including normal engine temperature.

GO to D9

D9: END

Cycle the ignition ON - (OFF for 2 minutes) - ON, start

the engine and run >1600 rpm 1

Has the fault code cleared?

Yes STOP

No Contact Jaguar Service

PINPOINT TEST E : P0702

TEST CONDITIONSDETAILS/RESULTS/ACTIONS

E1: RETRIEVE DTCS

• NOTE: Battery and or ECM disconnection prior to scanning wi ll erase all data, ensure that the correct DTC is present.

Page 1420 of 2490

Connect the scan tool 1

Have the DTC(s) and freeze frame data been recorded?

Yes GO to E2

E2: CHECK SENSOR SUPPLY VOLTAGE

With GB001 disconnected, measure the voltage between

GB001/007 and GB001/012 1

Is voltage B+?

Yes Reconnect GB001

GO to E5

No GO to E3

E3: CHECK HARNESS +VE CONTINUITY

Trending: torque specification, electrical, cooling system, P1260, maintenance, refrigerant type, charger