fuel JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1235 of 2490

3. Conne

ct CMP sensor connector.

4. Connect

fuel feed pipe to inlet manifold.

R

emove blanking plugs.

Install and lubricate new O-r

ing.

5. Install

bolts securing fuel feed

pipe to the inlet manifold.

6. Install coolant expansion tank.

Page 1241 of 2490

E

lectronic Engine Controls - Engine

Control Module (ECM) Adaptation

Gen

eral Procedures

When to car

ry out adaptations

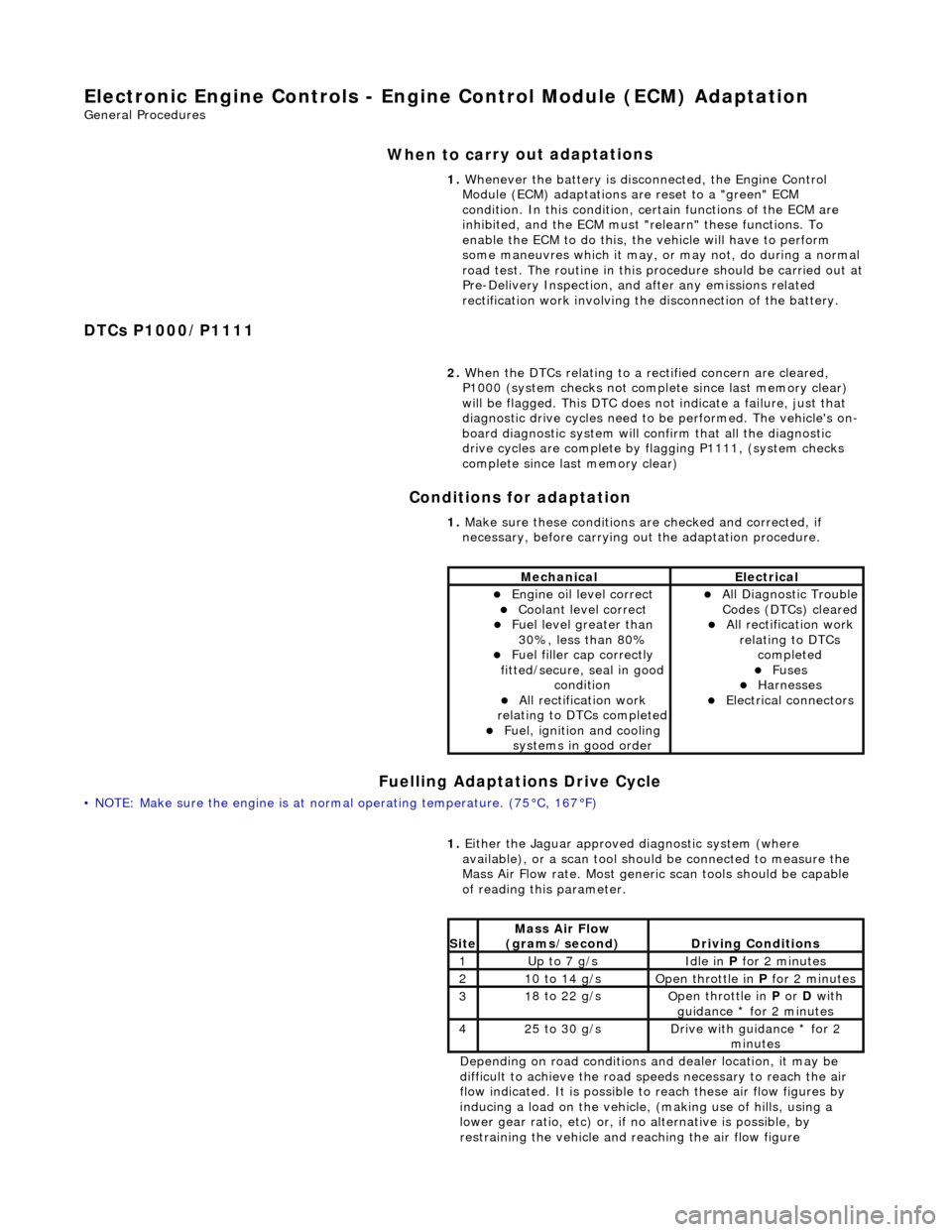

DTCs P1000/P1111 Conditions for adaptation

Fuelling Adaptations Drive Cycle

•

NOTE: Make sure the engine is at normal operating

temperature. (75°C, 167°F) 1.

Whenever the battery is disconnected, the Engine Control

Module (ECM) adaptations are reset to a "green" ECM

condition. In this condition, certain functions of the ECM are

inhibited, and the ECM must "r elearn" these functions. To

enable the ECM to do this, the vehicle will have to perform

some maneuvres which it may, or may not, do during a normal

road test. The routine in this pr ocedure should be carried out at

Pre-Delivery Inspection, and after any emissions related

rectification work involving the disconnection of the battery.

2. When the DTCs relating to a rectified concern are cleared,

P1000 (system checks not complete since last memory clear)

will be flagged. This DTC does no t indicate a failure, just that

diagnostic drive cycles need to be performed. The vehicle's on-

board diagnostic system will confirm that all the diagnostic

drive cycles are complete by flagging P1111, (system checks

complete since last memory clear)

1. Make sure these conditions are checked and corrected, if

necessary, before carrying ou t the adaptation procedure.

MechanicalElectrical

Engi

ne oil level correct

Coo

lant level correct

F

uel level greater than

30%, less than 80%

F

uel filler cap correctly

fitted/secure, seal in good condition

Al

l rectification work

relating to DTCs completed

F

uel, ignition and cooling

systems in good order

Al

l Diagnostic Trouble

Codes (DTCs) cleared

Al

l rectification work

relating to DTCs completed

F

uses

Harnes

ses

E

lectrical connectors

1.

Either

the Jaguar approved diagnostic system (where

available), or a scan tool should be connected to measure the

Mass Air Flow rate. Most generi c scan tools should be capable

of reading this parameter.

Depending on road conditions and dealer location, it may be

difficult to achieve the road sp eeds necessary to reach the air

flow indicated. It is possible to reach these air flow figures by

inducing a load on the vehicle, (making use of hills, using a

lower gear ratio, etc) or, if no alternative is possible, by

restraining the vehicle and re aching the air flow figure

Si

te

Mass Air Flow

(gra

ms/second)

D

riving Conditions

1Up t

o 7 g/s

Idle

in

P for 2 minutes

21

0 to 14 g/s

O

pen throttle in

P for 2 minutes

31

8 to 22 g/s

O

pen throttle in

P or D with

guidance * for 2 minutes

42

5 to 30 g/s

D

rive with guidance * for 2

minutes

Page 1242 of 2490

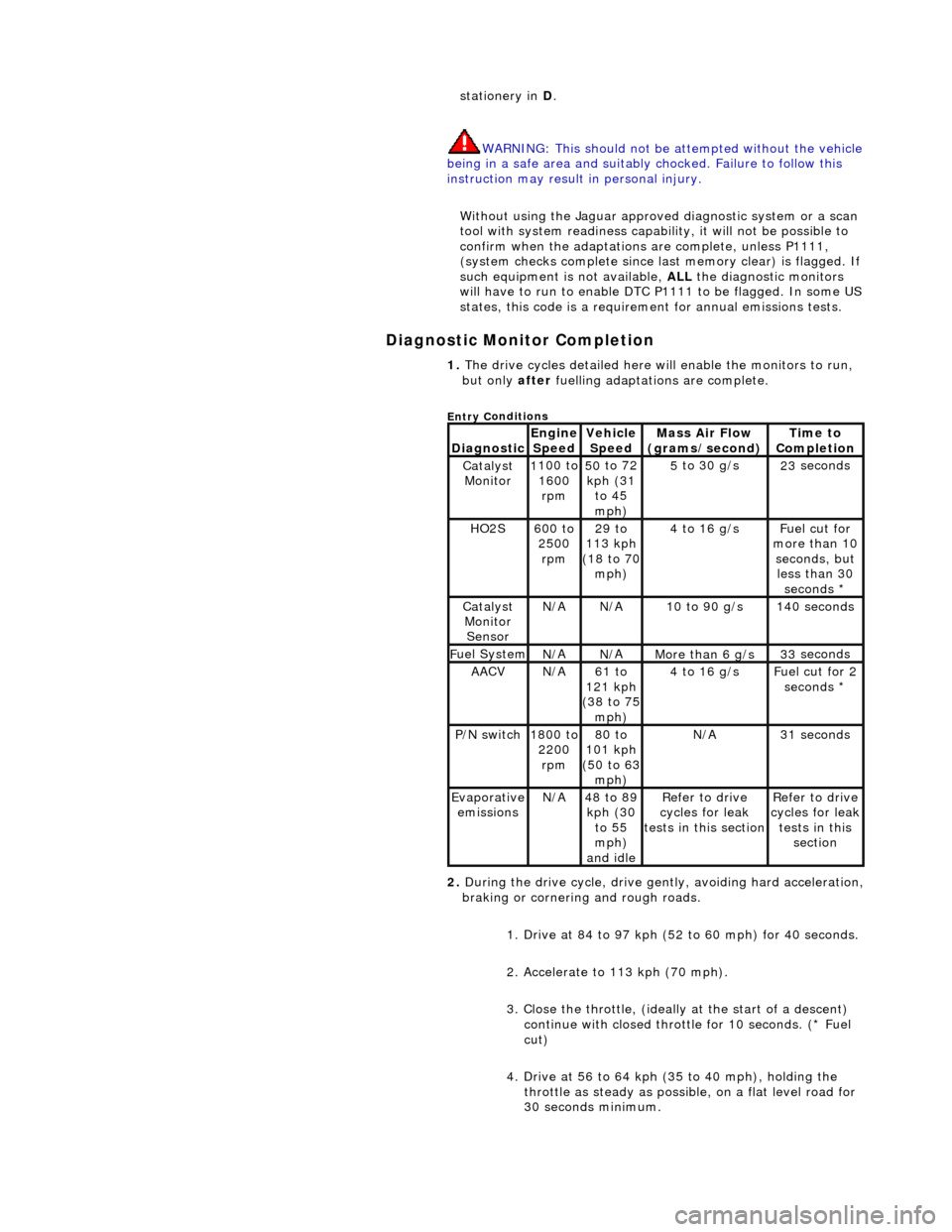

Diagnostic Monitor Comp

letion

stat

ionery in

D.

WARNING: This should not be attempted without the vehicle

being in a safe area and suitably chocked. Failure to follow this

instruction may result in personal injury.

Without using the Jaguar approved diagnostic system or a scan

tool with system readiness capability, it will not be possible to

confirm when the adaptations are complete, unless P1111,

(system checks complete since last memory clear) is flagged. If

such equipment is not available, ALL the diagnostic monitors

will have to run to enable DTC P1111 to be flagged. In some US

states, this code is a requirem ent for annual emissions tests.

1. The dri v

e cycles detailed here w

ill enable the monitors to run,

but only after fuelling adaptations are complete.

Entry C

onditions

Di

agno

stic

Engine

S p

eed

Ve

h

icle

Speed

Mass Air Flow

(gra ms/sec

ond)

Ti

m

e to

Completion

Catalyst Monitor1 100

to

1600 rpm

50 to

72

kph (31 to 45

mph)

5 to

30 g/s

23

se

conds

HO2S6

00 t

o

2500 rpm

29 to

113 kph

(18 to 70

mph)

4 to

16 g/s

F

u

el cut for

more than 10 seconds, but less than 30 seconds *

Catalyst Monitor SensorN/ AN/A10

to 90 g/s

14

0

seconds

F

u

el System

N/

AN/AMore than 6 g/s33 se

conds

AACVN/

A61 to

121 kph

(38 to 75

mph)

4 to

16 g/s

F

u

el cut for 2

seconds *

P /

N switch

1

800

to

2200 rpm

80 to

101 kph

(50 to 63

mph)

N/ A31 se

conds

Evaporative

em is

sions

N/

A48 to

89

kph (30 to 55

mph)

and idle

R e

fer to drive

cycles for leak

tests in this section

Re

fer to drive

cycles for leak

tests in this section

2. During the drive cycle, drive gent ly, avoiding hard acceleration,

braking or cornering and rough roads.

1. Drive at 84 to 97 kph (52 to 60 mph) for 40 seconds.

2. Accelerate to 113 kph (70 mph).

3. Close the throttle, (ideally at the start of a descent)

continue with closed throttle for 10 seconds. (* Fuel

cut)

4. Drive at 56 to 64 kph (35 to 40 mph), holding the throttle as steady as possib le, on a flat level road for

30 seconds minimum.

Page 1243 of 2490

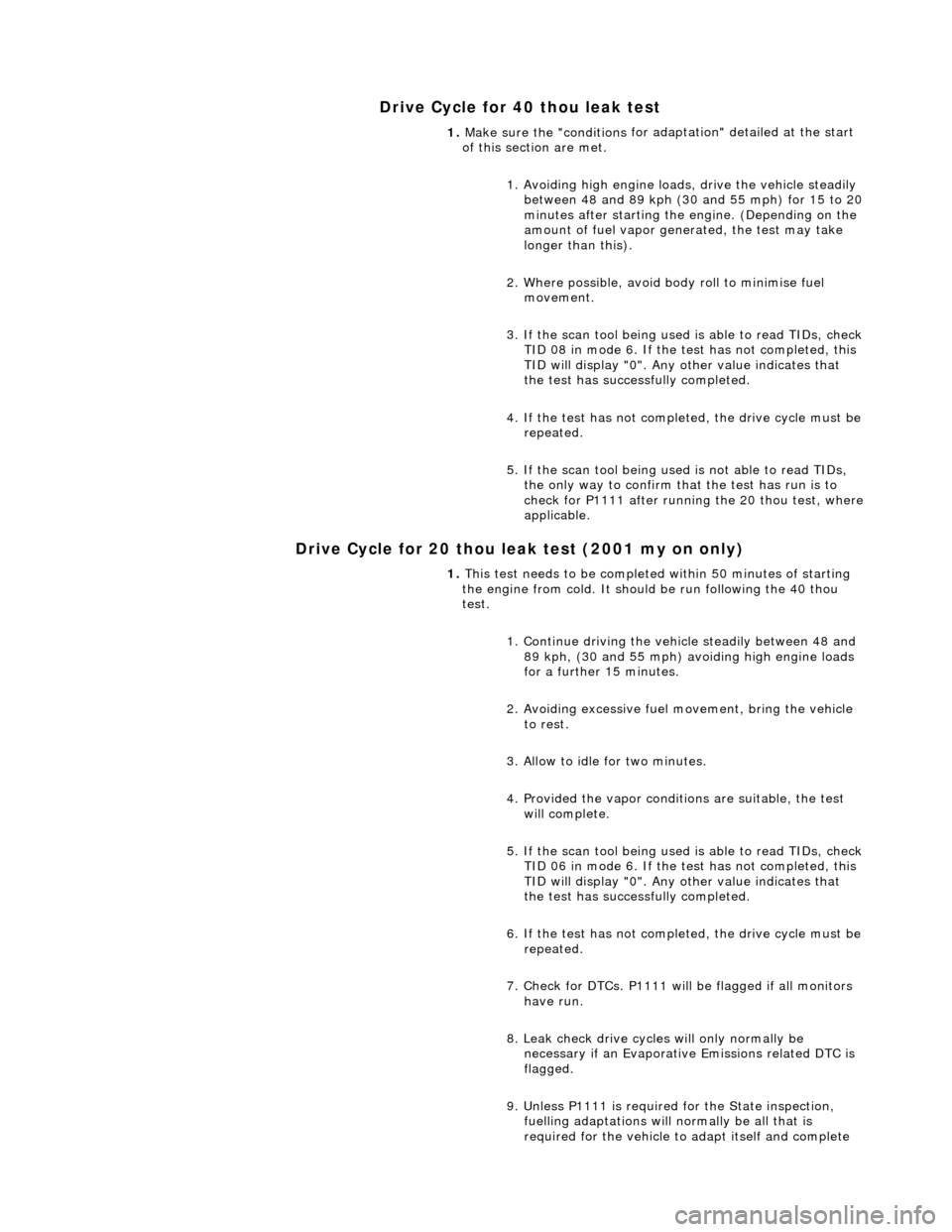

Drive Cycle for 40 thou leak test

Drive Cycle for 20 thou leak test (2001 my on only)

1. Make sure the "conditions

for ad

aptation" detailed at the start

of this section are met.

1. Avoiding high engine load s, drive the vehicle steadily

between 48 and 89 kph (30 and 55 mph) for 15 to 20

minutes after starting the engine. (Depending on the

amount of fuel vapor gene rated, the test may take

longer than this).

2. Where possible, avoid body roll to minimise fuel movement.

3. If the scan tool being used is able to read TIDs, check

TID 08 in mode 6. If the test has not completed, this

TID will display "0". Any other value indicates that

the test has successfully completed.

4. If the test has not completed, the drive cycle must be repeated.

5. If the scan tool being used is not able to read TIDs, the only way to confirm that the test has run is to

check for P1111 after running the 20 thou test, where

applicable.

1. This test needs to be completed within 50 minutes of starting

the engine from cold. It should be run following the 40 thou

test.

1. Continue driving the vehi cle steadily between 48 and

89 kph, (30 and 55 mph) avoiding high engine loads

for a further 15 minutes.

2. Avoiding excessive fuel movement, bring the vehicle to rest.

3. Allow to idle for two minutes.

4. Provided the vapor conditions are suitable, the test will complete.

5. If the scan tool being used is able to read TIDs, check

TID 06 in mode 6. If the test has not completed, this

TID will display "0". Any other value indicates that

the test has successfully completed.

6. If the test has not completed, the drive cycle must be repeated.

7. Check for DTCs. P1111 will be flagged if all monitors have run.

8. Leak check drive cycles will only normally be necessary if an Evaporative Emissions related DTC is

flagged.

9. Unless P1111 is required for the State inspection, fuelling adaptations will normally be all that is

required for the vehicle to adapt itself and complete

Page 1524 of 2490

All vehicles are fitted with a stainless steel exhaust system which features:

Low back-pressure gas flow. Catalytic converters for mark ets having unleaded fuel. Front muffler common to the left-hand and right-hand engine cylinder banks.

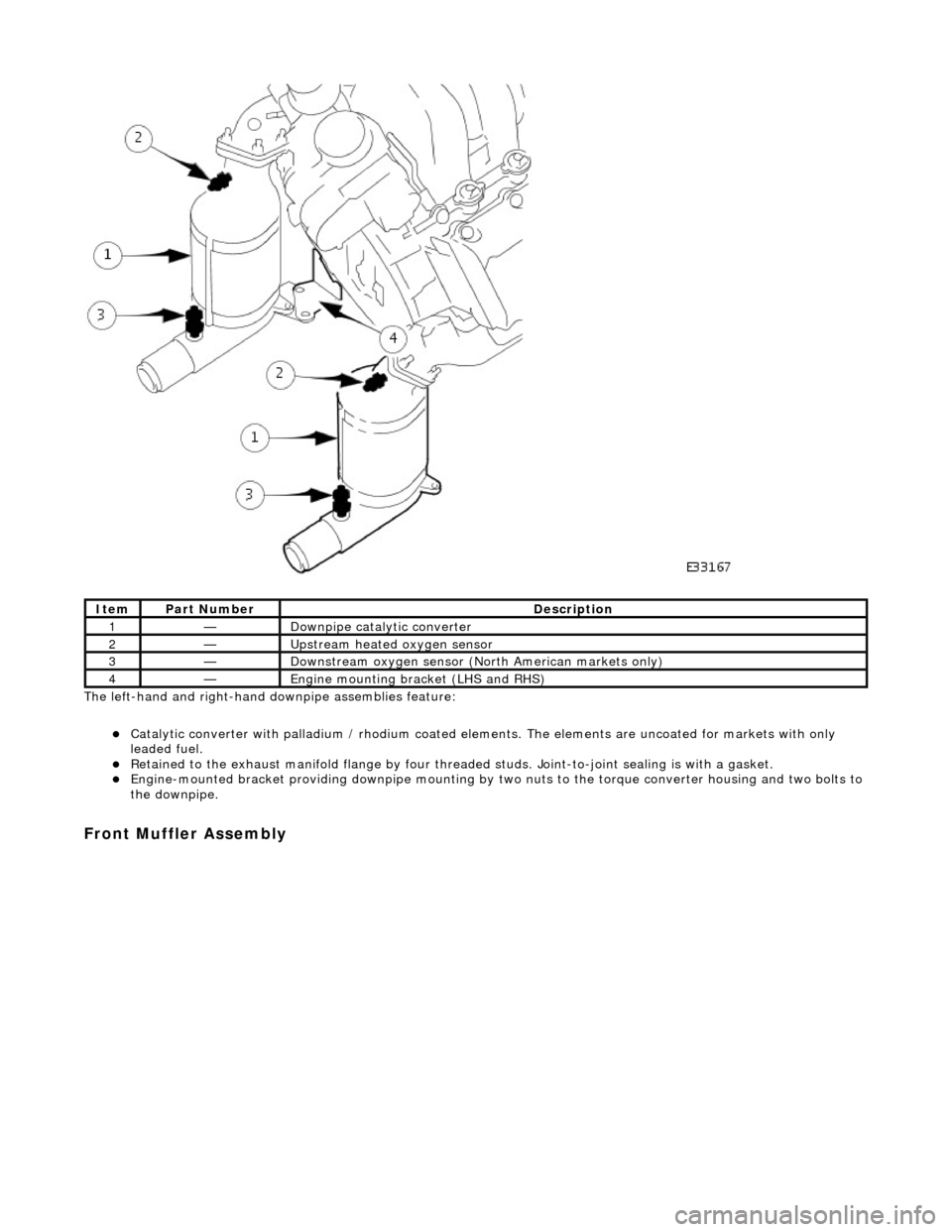

Downpipe Catalytic Converter Assembly

Page 1525 of 2490

The left-hand and right-hand do wnpipe assemblies feature:

Catalytic converter with palladium / rhodium coated elem ents. The elements are uncoated for markets with only

leaded fuel.

Retained to the exhaust manifold flange by four thread ed studs. Joint-to-joint sealing is with a gasket. Engine-mounted bracket providing downpipe mounting by two nuts to the torque converter housing and two bolts to

the downpipe.

Front Muffler Assembly

ItemPart NumberDescription

1—Downpipe catalytic converter

2—Upstream heated oxygen sensor

3—Downstream oxygen sensor (North American markets only)

4—Engine mounting bracket (LHS and RHS)

Page 1530 of 2490

The upstream heated oxygen sensor is located at the catalytic converter inlet and detects the concentration of oxygen in the

raw exhaust gases; an internal heater reduces the warm up time of the sensor output.

An oxygen sensor (without heater) is located at the converter outlet.

The ECM receives input signals from the se nsors and varies the fuel injector duration (mixture) to provide optimum gas

emissions.

Circuit Diagram, O2 Sensors / ECM

Page 1688 of 2490

Fuel System - General Inform

ation - Fuel System

Description an

d Operation

The fuel tank is mounted across the vehicle behind the passenger compartment bulkhead.

Fuel is drawn by the fuel pump from the tank and then supplied to the two fuel rails, via a filter.

Fuel injectors are installed in the fuel ra ils on each side of the intake manifold.

The amount of fuel injected into th e engine is controlled by the ECM.

A cross-over pipe connects the two fuel ra ils together at the front of the manifold.

A test valve in the cross-over pipe allo ws the fuel rail to be pressurized and de-pressurized during the servicing and

troubleshooting procedures.

A pressure regulator on the rear of the right fuel rail controls the pressure in the fuel rails.

A return line directs excess fuel from the pressure regulator back to the fuel tank.

Operation and service procedures

The fuel injector

s, rails, pres

sure regulator and, wher e fitted, supercharger are described in greater detail in Section 303-04

together with servicing procedures.

The fuel tank, pump, fuel level senders and fuel lines are similarly covered in Section 310-01.

Page 1689 of 2490

Fuel System - General Information - Fuel System Pre

ssure Check

Gen

eral Procedures

WARNING: Working on the fuel system re sults in fuel and fuel vapor being present in the atmosphere. Fuel vapor is

extremely flammable, hence great care must be taken whilst working on the fuel system. Adhere strictly to the following

precautions:

D

o not smoke in the work area

Di

splay

NO SMOKING signs around the work area

D

isconnect the battery before

working on the fuel system

Av

oid sparks

Make sure sui

table fire ex

tinguishers are at hand

Make sure absor

bent material is at

hand to soak up any spillage

Make sure the work area is

well ventilated

M

ake sure that the gauge is correctly conn

ected, and that all connections are secure BEFORE starting the engine

DO N

OT

disconnect the gauge from the schrader valve while the engine is running

Make su

re the schrader valve reseals once the gauge is disconnected

• NOTE: Depending on the design of the ga uge set, there may be a drain valve and tube. Make sure this valve is closed, and

the drain tube placed in a suitable container BEFORE connecting the gauge to the schrader valve.

1. Make sure the vehi

cle is in

Park for vehicles with automatic

transmission, Neutral for vehicles with manual transmission.

2. Apply the parking brake.

3. Place suitable absorbent material around the schrader valve to

absorb any spillage when connecting the gauge set.

4. Remove the protective cap from the schrader valve.

5. Connect the gauge, using adaptors if required.

6. Remove the absorbent material and dispose of safely.

7. Disconnect and plug the vacuum hose from the pressure

regulator.

8. Start the engine and record the fuel pressure reading.

As a gui

de, the fuel pressu

re should be approximately 3.0

bar (44.1 psi) with the regulator disconnected.

9. With the engine still running, reconnect the vacuum hose to

the pressure regulator an d record the reading.

Th

e pressure should dr

op to approximately 2.6 bar (38

psi) when the vacuum hose is reconnected.

10. Switch off the engine.

11. Place more absorbent material around the schrader valve.

12. Where fitted, open the drain valve and allow the fuel from the

gauge and line to flow into the container to depressurize the

system.

13. Disconnect and remove the gauge set and any adaptors.

14. Clean up any fuel which may have been spilt and remove the

absorbent material. Dispose of safely.

15. Refit and secure the protective cap to the schrader valve.

16. Reconnect the fuel pressure regulator vacuum hose.

17. Start the engine and make sure there are no leaks.

Page 1690 of 2490

Fuel System - General Information - Fuel System Pressure Rele

ase

Gen

e

ral Procedures

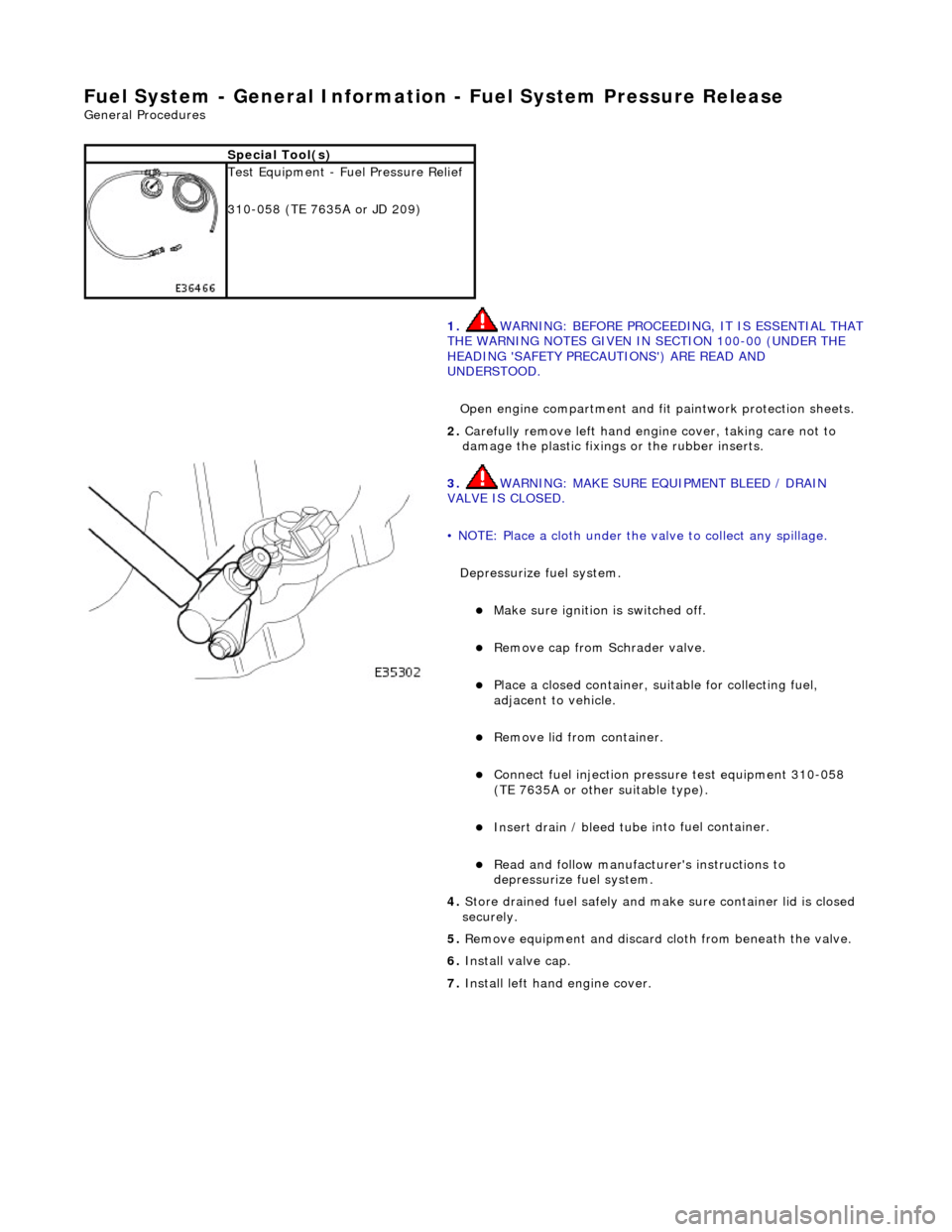

S p

ecial Tool(s)

Tes

t

Equipment - Fuel Pressure Relief

310-058 (TE 7635A or JD 209)

1. WARNING: BEFORE PROCEEDING, IT IS ESSENTIAL THAT

THE WARNING NOTES GIVEN IN SECTION 100-00 (UNDER THE

HEADING 'SAFETY PRECAUTIONS') ARE READ AND

UNDERSTOOD.

Open engine compartment and fi t paintwork protection sheets.

2. Carefull

y remove left

hand engine cover, taking care not to

damage the plasti c fixings or the rubber inserts.

3. WA

RNING: MAKE SURE EQUIPMENT BLEED / DRAIN

VALVE IS CLOSED.

• NOTE: Place a cloth under the valve to collect any spillage.

Depressurize fuel system.

Make sure ignition i s

switched off.

R

e

move cap from Schrader valve.

Pla

c

e a closed container, su

itable for collecting fuel,

adjacent to vehicle.

R e

move lid from container.

Conne

ct

fuel injection pressu

re test equipment 310-058

(TE 7635A or other suitable type).

Insert drain / bleed tu be i

nto fuel container.

R

e

ad and follow manufacturer's instructions to

depressurize fuel system.

4. Store drained f u

el safely and make

sure container lid is closed

securely.

5. Remove equipment and discard cloth from beneath the valve.

6. Install valve cap.

7. Install left hand engine cover.