vin JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 2383 of 2490

Paint

The inhalation of sprays, fumes, or dust during paint application or sanding processes should always be avoided. Ensure

that there is efficient ventilation / extrac tion at all times. Paint spraying should be confined as far as possible to spray

booths. Personnel with a history of asth ma should not be employed in any process involving the use of isocyanates.

Operators working in a spray booth where isocyanate material is present must use air-fed breathing equipment with air

supplied to the visor at the re commended pressure and filtered to remove oil, water, and fumes. Operators involved in

handling mixing or spraying should wear protective clothing including gloves and goggles, to avoid skin and eye contact.

Particle masks or canister type respir atosr should be worn when sanding.

Applied Heat

When welding, flame cutting, brazing etc, the operator shou ld use as appropriate, goggles, mask / fume extractor and

flameproof protective clothing. It is especially important when working with polyurethane compounds to use air-fed

breathing equipment. Appropriat e fire fighting equipment and personnel trai ned in its use must always be available.

Metal Repair

Appropriate eye and hand protection should be worn when sanding, drilling, cutting, chiselling, flatting or welding. Face

masks or air-fed visors should also be wo rn when sanding or flatting either body solder or fillers. On completion of a

soldering operation, swarf must be re moved from the work area and the operat or must wash his hands thoroughly.

GENERAL REPAIR NOTES

The following advice should be noted before any repair work is carried out.

Disconnect the vehicle battery gr ound lead (disconnect the alternator where electric welding is used) and take note of the

reconnection procedures as detailed in 86.15.15.

Where structural parts are straightened or renewed, a body alignment / straightening jig must be used. The application of

heat, especially excessive heat, reduces the strength of steels, where appropriate therefore, structural sections should be

straightened by cold processes.

Repairs may only be carried out successful ly, and any warranties protected, if genuine Jaguar replacement parts and Jaguar

approved materials are used.

The correct tools, procedures and facilities must always be us ed. The quality of the work must not be compromised by using

inappropriate methods or equipment.

All trim and electrical components in the locality of the repair must be removed or disconnected prior to panel removal /

replacement; this is especially important where hollow sectio ns may contain harnesses, tubes or foam, see section A4.3.5.

WARNING: DO NOT WORK IN THE VICINITY OF A LIVE AIR BAG, REMOVE IT COMPLETELY. READ WORKING

PRACTICES AIR BAG, SECTION 20. ANY SEAT BELT WHICH HAS BEEN WORN IN AN ACCIDENT MUST BE RENEWED.

CAUTION: Electric arc welding should not be used on Jaguar vehicles. The high voltages produced by this process will

cause irreparable damage to the electric al control and microprocessor systems.

The following welding and gas processes are the only ones recommended by Jaguar Cars Ltd.

Welding and Gas Processes

Resistance spot welding, MIG welding and all gas processes may only be carried out on bare, unpainted or unplated metal.

The flanges of panels to be welded toge ther, must be clean, corrosion free and tr eated as appropriate, with either weld-

through primer or inter-weld sealer. Only materials and processes specified in the 'Body Sealing and Preservation Manual'

should be used in the relevant application areas detailed in this section. Refer to 'Zinc Coated Panels' Section

Page 2384 of 2490

Generally, resistance spot welding equipment used in the motor vehicle repair industry does not produce welds of equivalent strength to those achieved during manufactu re. The expression 'single row of resistance spot welds' indicates that the spots

should be spaced on a pitch of 19mm to 25mm, which normally results in mo re spot welds than those produced in the

original factory joint.

Resistance spot welds should be removed using a resistance spot weld cutter. If the new joint is to be MIG plug welded, old

resistance spot welds should be cut from the panel to be reta ined and the resulting holes used for plug welding. Suitable

holes may also be drilled or punched; 8,0 mm dia for sect ions up to 1,6 mm, and 10,0 mm dia for thicker sections.

PLASTICS-EXPLANATORY NOTES

Plastic component and trim materials

This table, in conjunction with the illu strations on the following pages will enable rapid identification of the particular

material of any major plastic part.

• NOTE: Only those components suitable for economic reclamation are identified.

Plastics - Handling Notes

The exterior panel temperature of a vehicle must not exceed 95°C at any time and may only be held at this level for a

maximum of two hours. Similarly, interior vehicle temperatur e must be limited to 86°C for a maximum duration of two

hours. Exposure to temperatures above those specified may result in distorted or permanently damaged components. If

there is doubt concerning temperature limitations, components that may be adversel y affected by exposure to heat should

be removed from the vehicle.

Plastic components that become greasy may be clea ned with an 'SBP 3' spirit wipe, or equivalent.

Recycled Materials

Any of the materials listed in this section, may be recycled provided that they ar e not contaminated by other incompatible

plastics or metals. For instan ce, the air conditioning unit case, manufactur ed from PP (polypropylene), must be separated

from the heater matrix, evaporator, contro l devices (electronic and mechanical) and all fixings before it can be considered

for recycling. After removal, the case mu st only be placed for disposal with materials of the same generic type. Bumper

cover assemblies similarly have side arma tures of dissimilar materials rivetted to them, these together with their fixings

must be removed prior to recy cling. Components manufactured from 'blended' materials must not be recycled with pure

materials. For example do not mix PC/ABS (wheel trim) with ABS ('B' pillar upper trim).

Plastics, Component Location and Type - External

TermMaterial Name

absAcrylonitrile Butadiene Styrene

abs / paAcrylonitrile Butadiene Styrene and Polyamide (nylon) blend

abs / pcAcrylonitrile Butadiene Styrene and Polycarbonate blend

ABS / PBTAcrylonitrile Styrene Acrylate and Polybutylene Terephthalate

paPolyamide (nylon)

pcPolycarbonate

pePolyethylene

pmmaPolymethyl Methacrylate

pomPolyoxymethylene (acetal)

ppPolypropylene

ppoModified Polyphenylene Oxide

purPolyurethane

pvcPolyvinylchloride

SMAStyrene Maleic Anhydride

Page 2392 of 2490

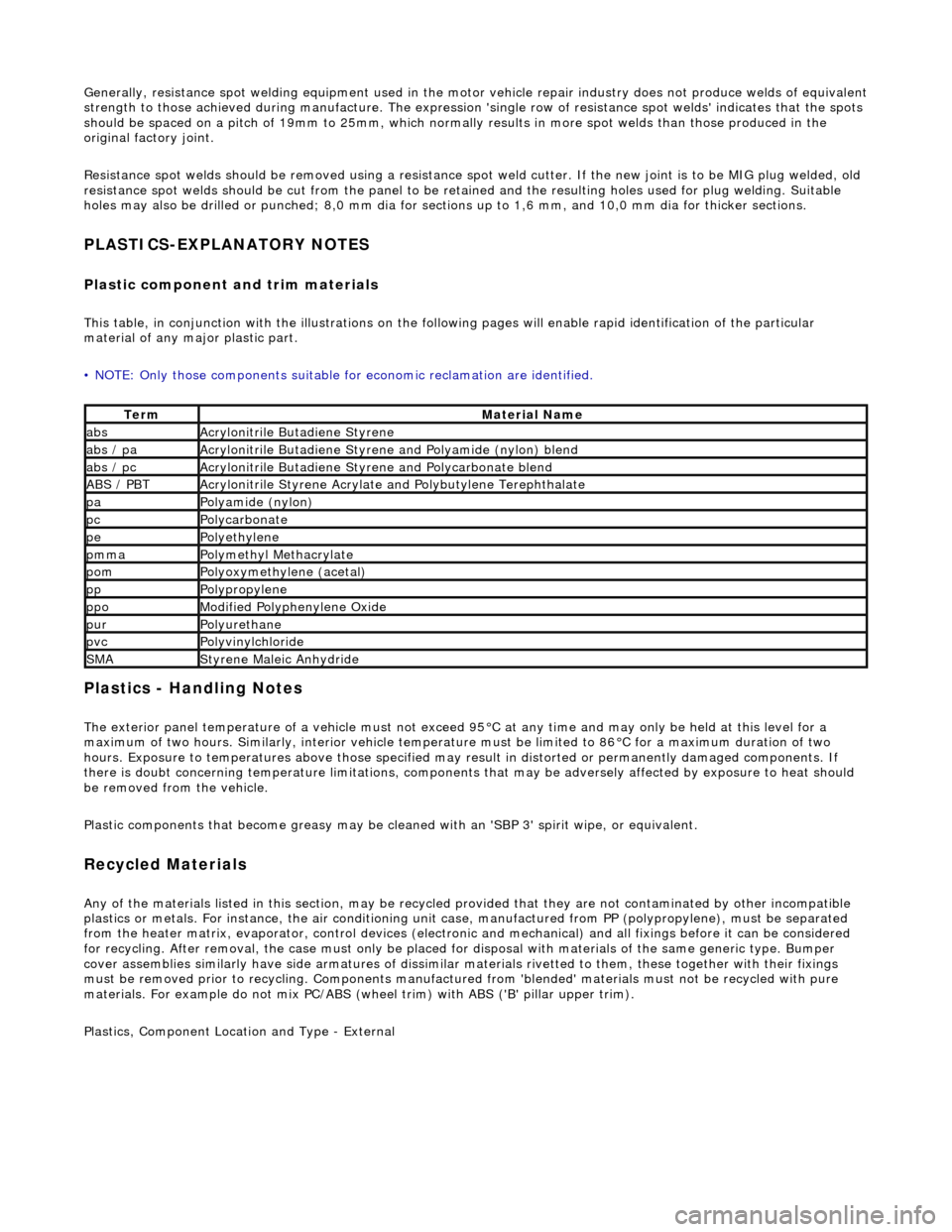

a pneumatic saw (3).

• NOTE: On some panels, before removing the bulk with a pneumatic saw, it may be necessary to remove brazed areas and

MIG welded seams. Separate spot welded joints and remove the panel remnants.

Removal of Panels and Welds

PREPARATION OF PANEL SURFACES

WARNING: DO NOT BURN UNDERSEAL OFF. USE A 'HOT KNIFE' OR SUITABLE SOLVENT.

• NOTE: Observe all appropriate safety procedures.

Remove weld nuggets with a sander and 36 gr it disc and clean all flanges to a bright smooth finish (1). Straighten existing

panel joint edges as required.

Mark off the area of new panel and cut to size leaving approxim ately two inches overlap on the existing panel. Offer up new

panel or section, align with associated pa rts, i.e. new rear fender aligned with door / luggage compartment lid / backlight

aperture and clamp the panel into positi on.Where necessary, cut the new and orig inal panels to form a butt joint.

Release all clamps and remove the new panel. If required, apply inner panel protection and or sound insulation.

Prepare the new panel joint edges, including interior and exterior, for welding by cleaning to bright metal (1).

Apply weld-through primer or in terweld sealer(2) to all surfaces to be resistance spot welded.

Where appropriate, apply metal- to-metal adhesive or sealer (3) in accordance with the manufacturer's instructions.

Page 2405 of 2490

On North American specification vehicles, the VIN is marked on all major external panels, certain structural members and

power / transmission units. The labels ca rrying this information are known as 'Label-Anti-theft VIN (USA body panel only)'

or 'Label-Anti-theft-Engine and Gearbo x (U.S.A. only),' drawing reference A .

Replacement Components

Only genuine Jaguar replacement parts must be used in the repair of a vehicle. Furthermore, any new parts replacing items

carrying a VIN label must have either 'Label-Anti-theft Replacement Part (USA body panel only)' or 'Label-Anti-theft

Replacement Part-Engine and Gearbox (U.S.A . only),' drawing reference B , fitted in a different location to the previous

label.

A protective mask used to prevent the replacement part la bel from being damaged or obscured during the refinishing /

protection processes, must be remo ved prior to customer hand-over.

Procurement

Anti-theft labels may only be ordered from Jaguar Cars through :

Product Compliance Dept.,

Jaguar Inc.,

555 MacArthur Blvd.,

Mahwah

NJ 07430

Label Fitting Process

CAUTION: It is a requirement of United States of America federal law th at the protective mask is removed from all

anti-theft labels after performing painting and rustproofing operations. Fail ure to comply with this requirement may render

both the manufacturer and the de aler in violation of the law.

• NOTE: Any attempt to remove an anti-t heft label will destroy that label. Ensure correct location before affixing.

Using a suitable solvent clean the area where the anti-theft label is to be affixed. Peel the backing from the label and

position on the panel. Carry out all refini shing / protection processes. Remove the anti-theft label protective mask prior to

vehicle handover to the customer.

Page 2407 of 2490

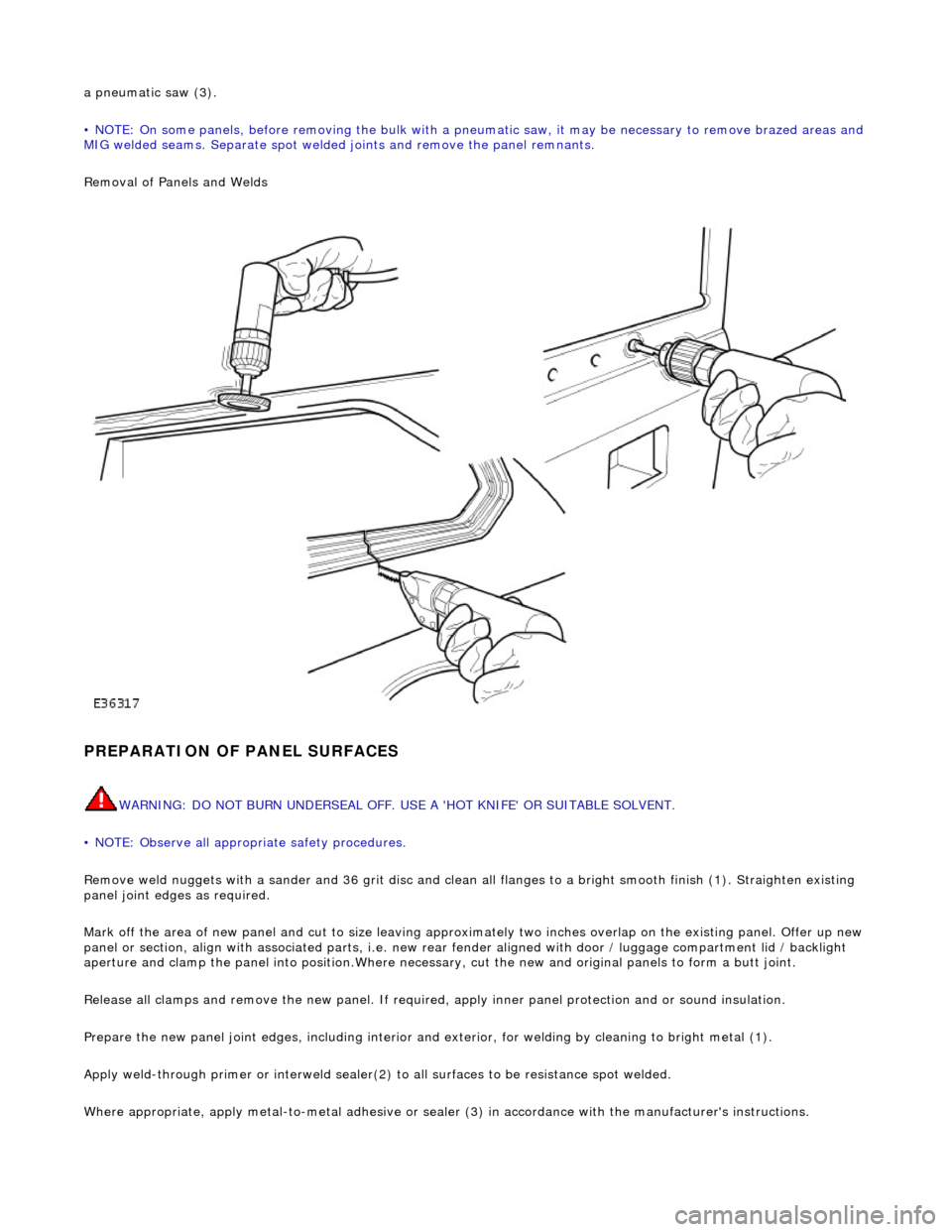

For coachline specifications, see page? .

Tape Application

Apply a suitable length of 3M "Fine Line Striping Tape" to the panel. Having suitably applied the tape, which is slit into 8

strips, each 3mm wide, the appr opriate strip may then be peeled away to expose the lacquer coat below (Refer to

Application of Striping Tape Drawing). The paint may then be applied by hand brush or a suitable air-brush. The remaining

tape provides masking during paint applicat ion and drying. Careful positioning of the masking tape is necessary, particularly

when the repair is confined to a single panel and the newly painted coachline mu st conform to coachlines on adjacent

panels.

Where it is necessary to match an existing 1.5mm coachline, two tec hniques are available:

Proceed as above, to expose a 3mm strip of lacquer coat. Using either a standard masking tape, or a 3M "Fine Line Masking

Tape" applied over the striping tape, reduce the width of the exposed strip to 1.5mm.

Use a suitable combination of standard mask ing tape, together with 3M "Fine Line Striping Tape" if desired, to achieve an

unmasked strip 1.5mm wide in the correct position on the panel.

After application of the tape, use a fine-g rit wet-and-dry paper to lightly 'flat' the exposed surface, before application of

paint.

Application of Striping Tape

Coachline Locations

The coachline locations on the side of XJ Sport and supercharged models are illustrated below, for all other models refer to

the drawing under 'Other Models'.

XJ Sport and XJR8

Page 2420 of 2490

lever mechanism driven by an electric motor. A sliding roof control module (SRCM) controls the motor in response to

selections made on the roof console switch , or input from the security system for automatic closing. Both the motor and the SRCM are accessed by removing the roof console.In the event of an electrical failure the sliding roof can be manually

operated. This is achieved by inserting a wide bladed screwdriver into a slot in the motor drive gear and turning clockwise to open or counter clockwise to close the sliding roof.

• NOTE: The drive gear becomes disengaged from the motor during manual operation. Before restoring electrical operation

the drive gear must be rotated one quarter turn in the reverse direction to re-engage the motor.

The SRCM is held in position by clips and has two electrical connectors in terfacing with the motor and the roof console

switch/security system. Prior to installing a new SRCM, the sun ro of must be in a neutral closed position. This provides the

SRCM with a sliding roof datum, to ensure accurate and consistent operation. Obstacle sensin g operates on closing in the

slide mode only. If the sliding roof lid encounters an ob struction between 4mm and 200mm from the closed position, the

SRCM detects increased motor load and reve rses the motor, driving the sliding roof to the fully open position. The sliding

roof lid surround seal has a metal inner sect ion which will deform on removal. If removed, this seal must be discarded and a

new seal must be installed on the lid using a Jaguar approved crimping tool.