vin JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1993 of 2490

Insulation Stripper

The moving jaw has an adjuster wheel which has a series of holes in it. Turning the wheel and placing the cable in the

matching size hole will automatically adjust the jaw to the correct pressure. Note that some wiring harness(s) may have a

harder insulation and slight adjustment of the wheel may be needed to make a clean strip but exercise care not to damage

the wire.

Insulation Stripper

Page 1995 of 2490

The crimping pliers have a moving jaw and a stationary jaw, with three different sized crimping enclosures. Each of the

enclosures is identified by a red, blue or yellow coloured dot which correspon ds to the three colours of the pre-terminated

wiring harness(s) and butt splice connector colors.

List of Parts

DescriptionPart NumberQuantity

Wiring Harness Repair Kit 418-S0651

Pre-Terminated Wiring Harness(s)418-066 to 418-103

inclusive 10 each

Glue Lined Heat Shrink Pack – small diameter418-10425 per

pack

Glue Lined Heat Shrink Pack – larger diameter418-10510 per pack

Case Assembly Comprising – carry case, li d, inner lid, base, insert, trays foam

spacers418-1061

Butt Splice Connector – Red 418-10750 per pack

Butt Splice Connector – Blue 418-10850 per

pack

Butt Splice Connector – Yellow 418-10920 per pack

Extraction Tool Handle 418-1101

Extraction Tip Pack consists of 2 spare screws plus 418-S1111

Tip A418-1181

Tip B418-1191

Tip C418-1201

Tip D418-1211

Tip E418-1221

Tip F418-1231

Page 1997 of 2490

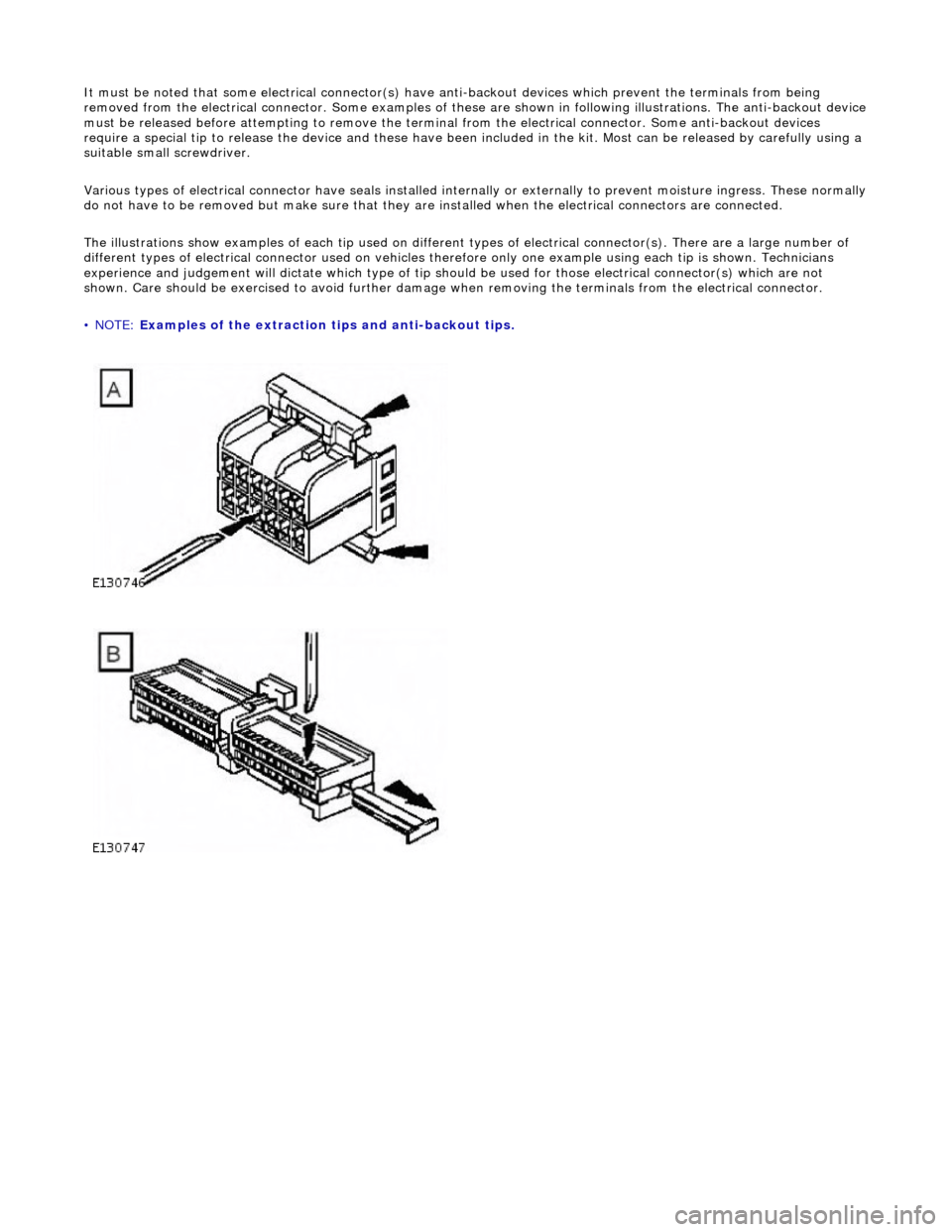

It must be noted that some electrical connector(s) have anti-backout devices which prevent the terminals from being

removed from the electrical connector. Some examples of thes e are shown in following illustrations. The anti-backout device must be released before attempting to remove the terminal from the electrical connector. Some anti-backout devices

require a special tip to release the device and these have been included in the kit. Most can be released by carefully using a

suitable small screwdriver.

Various types of electrical connector have seals installed intern ally or externally to prevent moisture ingress. These normally

do not have to be removed but make sure that they are installed when the electrical connectors are connected.

The illustrations show examples of each tip used on different types of electrical connector(s). There are a large number of

different types of electrical connector us ed on vehicles therefore only one example using each tip is shown. Technicians

experience and judgement will dictate whic h type of tip should be used for those electrical connector(s) which are not

shown. Care should be exercised to av oid further damage when removing the te rminals from the electrical connector.

• NOTE: Examples of the extraction tips and anti-backout tips.

Page 2013 of 2490

Multifunction Electronic Modules - Multifunction Electronic Module

Diagnosis and Testing

Tests Using the Portable Diagnostic Unit

Refer to PDU User Guide

The complexity of the electronics involved with the various Electronic Control Modules and the multiplexed communication

networks, preclude the use of workshop general electrical test equipment. Therefore, reference should be made to the PDU

User Guide for detailed instructions on test ing control modules.

The PDU systematically test s and analyses the control modules and th e associated electrical connections.

Where a fault involving a control module is indicated by the PDU, before replacing the component, some basic diagnostic

methods may be necessary to confirm that connecti ons are good and that wiring is not damaged.

Page 2023 of 2490

sliding roof finisher and clips. Carpet covered trims line the trunk and are secured by fir tree fasteners to the sides and fro nt inner panel.

Rear View Mirrors

The.interior rear view mirror is an electrochromic unit that automatically da rkens to prevent glare from following vehicle

lights. This automatic function is selected by pressing the switch at the bottom of the mirror. Pressing the switch again

cancels this function. An LED then illuminates when automatic dipping is operative. The light sensing unit for the Night

Sentinel automatic lamp operating system is also incorporated in the mirror casing.

The door mirrors are cheater mounted, colo r-keyed units, remote electrically adjustable and heated. Adjustment of both

mirrors is carried out from the driver's door switchpack.A slider switch selects the mirror to be adjusted, and a disc switch

adjusts the selected mirror to the required position. Mirror ad justment can only be made when the ignition switch is in

position I or II or the driver's door is open, and the selector switch is moved from the central position. The door mirrors also

automatically darken under control of the electrochromic interior rear view mirror. Mirror heating elements operate on

selection of backlight heating.

Automatic dipping of passenger door mirror for kerb view when reversing, is fitted as part of the memory pack. With the

ignition switch in position II, the mirror selector switch in the left or right position and reverse gear selected, automatic

dipping is initiated by moving the mirror toggle switch rearwards and releasing. On receipt of the dip signal, the passenger

door mirror is driven downwards either 7 degrees, bottom of travel, or 4,5 to 5,5 seconds, whichever occurs first.

Subsequent rearward movement of the toggle switch achieves further dipping of the mirror in the same increments and

sequence. The mirror can be manu ally returned to the normal memorised positi on by moving the toggle switch forward with

reverse gear selected. The mirror will auto matically return to memorised position on deselection of reverse gear, or moving

ignition switch from position II.

Door mirror fold-back where fitted, to facilitate parking in conf ined spaces, can be initiated when the ignition switch is in

position I or II, the mirror selector switch is in the centra l position and vehicle speed is below 19 km/h (12 mph). Mirror

fold-back is then initiated by moving the toggle switch rear wards and releasing it. The door mirrors are returned to the

normal driving position by agai n moving toggle switch rearwards. There is no speed constraint on this operation. In the

event of a fold-back mirror becoming 'out of position' due to acci dental impact, it must only be re-positioned by initiating

the fold-back sequence.

Loss of power supplies will result in loss of mirror fold-back memory. In the event of such a memory loss with mirrors in the

normal position, fold-back will operate on second movement of the toggle swit ch. On loss of memory with mirrors in the

fold-back position, they will return to the no rmal position on next fold-back operation.

Bumpers

Each bumper comprises a beam mounted to the body via two strut assemblies, and a moulded polypropylene cover

incorporating side armatures and chrome plated blades. Each strut is secured to the BIW by three bolts and supports the

beam on a single bolt/height adjuster. The front bumper cover which is moulded to form a lo wer air intake for the cooling

pack, also incorporates left and right handed twin fog lamps, brake coolin g ducts. Side marker lamps fitted for some

markets serve only as reflectors for UK and Europe. A plastic undertray secured to the lower edge of the front bumper,

improves airflow and minimises the ingres s of road grime in that area. Standard bumpers have glass mat thermoplastic

(GMT) beams mounted on GMT struts. For certain markets, aluminium bumper beams are installed on menasco energy

absorbing struts. Whilst both types of front bumper provide a fu lly integrated 'soft front end' that satisfies bumper impact

requirements, the energy absorbing front and rear bumpers are further designed to withstand 5mph (8kph) impacts with no

visible damage sustained. Side markers/re flectors, and direction indicators are designed for ease of ac cess from the outside

of the bumper. For adjustment and bulb change, the fog lamps are accessed from th e bumper interior. The bumper covers

are body coloured and matched. Replacement covers are supplied complete with side armatures and are finished in primer

Trunk

The trunk houses the spare wheel, the battery, an electrical carrier containing electrical fuses, relays and modules and a

compact disc auto-changer attached to body bracketry. The trun k is fitted with push-fit liners to the sides and front inner

panel.The carpet covered floor is in two removable sections, one covering the spare wheel and wheel changing equipment,

the other covering the battery and electrical carrier. The front and rear edges of the floor board loca te in blocks on the fuel

tank backboard and the rear of the body , which provide two height settings to accommodate the difference in thickness

between the space saver and full sized spare wheels. A moulded finisher covering the rear of the trunk below the sill is

secured to the rear panel by tabs and fir tree fasteners. Finisher panels fitted over the rear lamp units provide for access

from the trunk. Finisher panels fitted to the rear lamp units provide trunk inte rior access to the lamps. The trunk lid

underside is fitted with a removable mo ulded liner and two trunk illumination light s. Trunk locking is based on a central

latch and striker, operated electrically through the central lo cking system by an adjacent actuator or by key in a barrel lock

Page 2112 of 2490

Mirror adjustment can only be made when the ignition switch is in position I or II or the driver's door is open, and the

selector switch is moved from the central position.

When fitted, electrochromic door mirrors au tomatically darken under control of the interior rear view mirror. Mirror heating

elements operate on selection of backlight heating.

Automatic dipping of passenger door mirror for kerb view when reversing, is fitted as part of the memory pack. With the

ignition switch in position II, the mirror selector switch in the left or right position and reverse gear selected, automatic

dipping is initiated by moving the mirro r toggle switch rearwards and releasing.

On receipt of the dip signal, th e passenger door mirror is driven downwards eith er 7 degrees, bottom of travel, or 4,5 to 5,5

seconds, whichever occurs first. Subsequent rear ward movement of the toggle switch achieves further dipping of the mirror

in the same increments and sequence.

The mirror can be manually returned to the normal memorised position by moving the toggle switch forward with reverse

gear selected. The mirror will automatically return to memorised position on deselection of reverse gear, or moving ignition

switch from position II.

Door mirror fold-back where fitted, to facilitate parking in conf ined spaces, can be initiated when the ignition switch is in

position I or II, the mirror selector switch is in the centra l position and vehicle speed is below 19 km/h (12 mph). Mirror

fold-back is then initiated by moving the toggle switch rear wards and releasing it. The door mirrors are returned to the

normal driving position by ag ain moving toggle switch rearwards. There is no speed constraint on this operation.

In the event of a fold-back mirror becoming 'out of position' du e to accidental impact, it must only be re-positioned by

initiating the fold-back sequence.

Loss of power supplies will result in loss of mirror fold-back memory. In the event of such a memory loss with mirrors in the

normal position, fold-back will operate on second movement of the toggle swit ch. On loss of memory with mirrors in the

fold-back position, they will return to the no rmal position on next fold-back operation.

Page 2113 of 2490

Rear View Mirrors - Auto-Dimming Interior Mirror

Removal and Installation

Removal

Installation

1.

Remove roof console for access and disconnect interior mirror

harness multiplugs. Refer to 76.13.69.90.

2. Remove upper cover from mirror stem.

3. Remove rain sensor unit. Refer to Section 501.16.

4. CAUTION: When removing mirror from base, care must

be exercised to ensure that base is not detached from windshield.

Applying firm downward pre ssure, remove mirror assembly

from base.

1. Position mirror at bottom of base and apply firm upward

pressure to fully seat and secure in position.

2. Install upper cover to mirror stem.

3. Position roof console at head er and connect mirror harness

multiplugs.

4. Install rain sensor unit. Refer to Section 501.16.

5. Install roof console. Refer to 76.13.69.

Page 2118 of 2490

Rear View Mirrors - Interior Mirror

Removal and Installation

Removal

CAUTION: When removing mirror from base, care must be exercised to ensure that base is not detached from

windshield.

Installation

1. Remove upper cover from mirror stem.

2. Remove rain sensor unit. Refer to Section 501.16.

3. Applying firm downward pre ssure, remove mirror assembly

from base.

1. Position mirror at bottom of base and apply firm upward

pressure to fully seat and secure in position.

2. Install rain sensor unit. Refer to Section 501.16.

3. Install upper cover to mirror stem.

Page 2140 of 2490

Seating - Front Seat Head Restraint

Removal and Installation

Removal

Installation

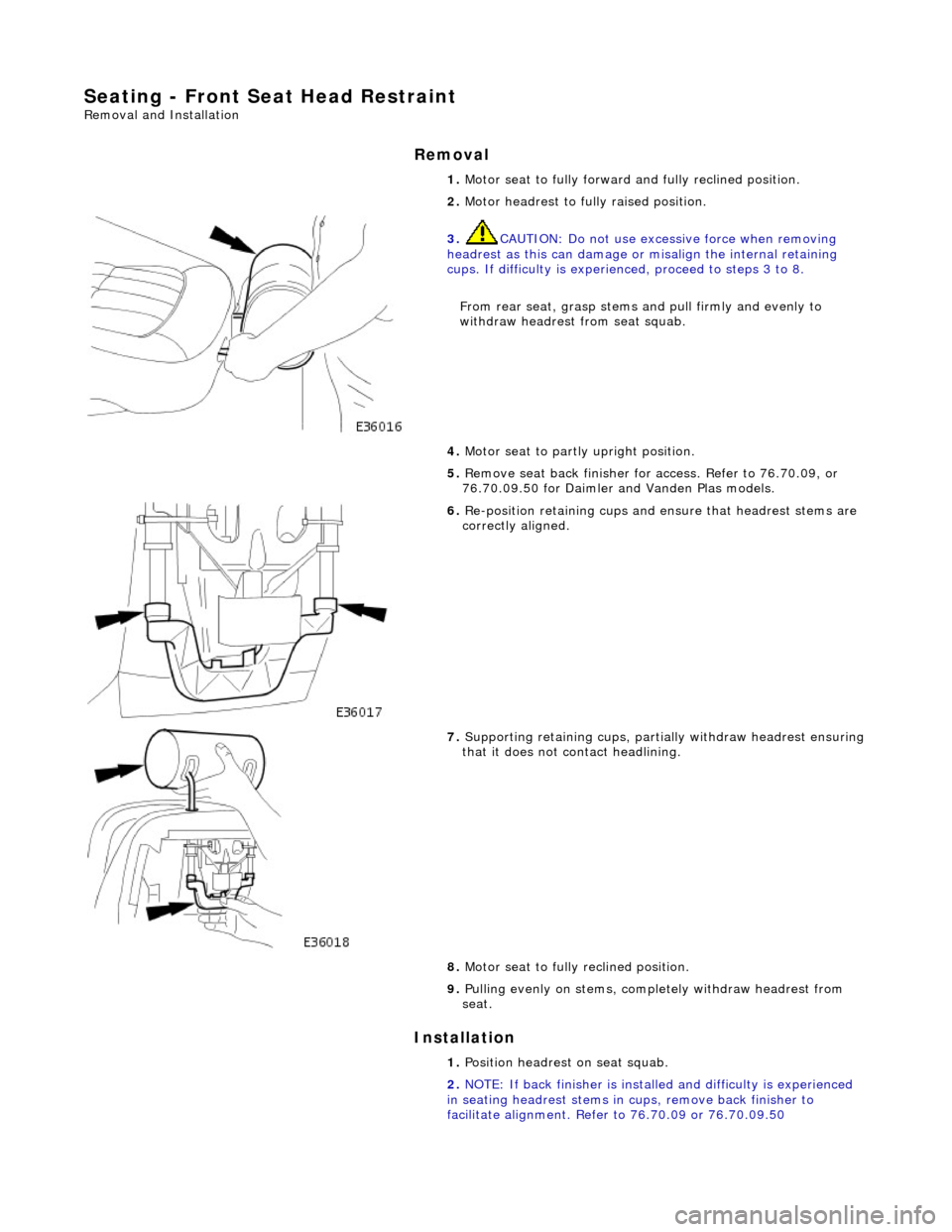

1. Motor seat to fully forward and fully reclined position.

2. Motor headrest to fully raised position.

3. CAUTION: Do not use excessive force when removing

headrest as this can damage or misalign the internal retaining

cups. If difficulty is experienced, proceed to steps 3 to 8.

From rear seat, gras p stems and pull firm ly and evenly to

withdraw headrest from seat squab.

4. Motor seat to partly upright position.

5. Remove seat back finisher for access. Refer to 76.70.09, or

76.70.09.50 for Daimler and Vanden Plas models.

6. Re-position retaining cups and en sure that headrest stems are

correctly aligned.

7. Supporting retaining cu ps, partially withdraw headrest ensuring that it does not contact headlining.

8. Motor seat to fully reclined position.

9. Pulling evenly on stems, comp letely withdraw headrest from

seat.

1. Position headrest on seat squab.

2. NOTE: If back finisher is instal led and difficulty is experienced

in seating headrest stems in cu ps, remove back finisher to

facilitate alignment. Refer to 76.70.09 or 76.70.09.50

Page 2201 of 2490

Installation

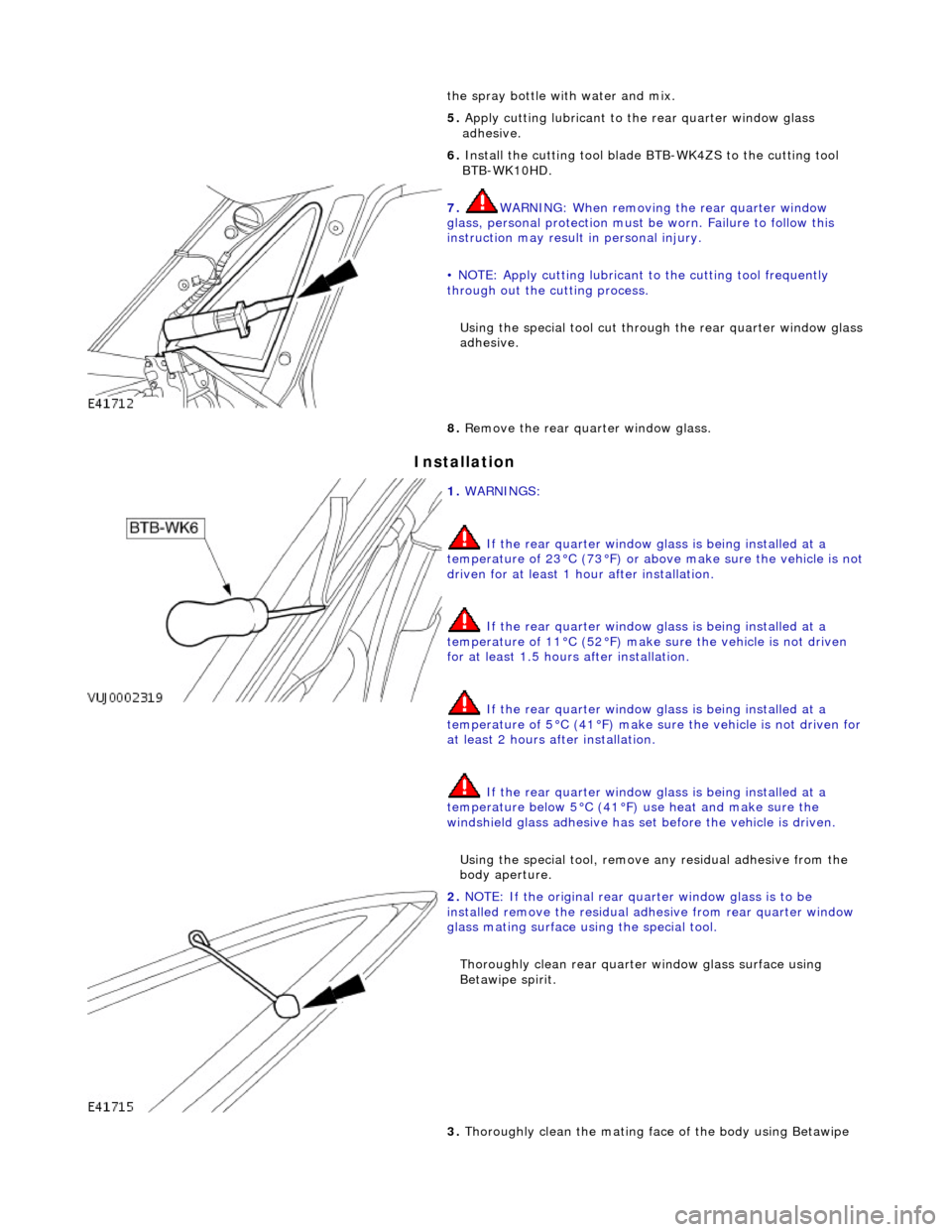

the spray bottle with water and mix.

5. Apply cutting lubricant to the rear quarter window glass

adhesive.

6. Install the cutting tool blade BTB-WK4ZS to the cutting tool

BTB-WK10HD.

7. WARNING: When removing the rear quarter window

glass, personal protec tion must be worn. Failure to follow this

instruction may result in personal injury.

• NOTE: Apply cutting lubricant to the cutting tool frequently

through out the cutting process.

Using the special tool cut throug h the rear quarter window glass

adhesive.

8. Remove the rear quarter window glass.

1. WARNINGS:

If the rear quarter window glass is being installed at a

temperature of 23°C (73°F) or abov e make sure the vehicle is not

driven for at least 1 hour after installation.

If the rear quarter window glass is being installed at a

temperature of 11°C (52°F) make sure the vehicle is not driven

for at least 1.5 hours after installation.

If the rear quarter window glass is being installed at a

temperature of 5°C (41°F) make su re the vehicle is not driven for

at least 2 hours after installation.

If the rear quarter window glass is being installed at a

temperature below 5°C (41°F) use heat and make sure the

windshield glass adhesive has set before the vehicle is driven.

Using the special tool, remove any residual adhe sive from the

body aperture.

2. NOTE: If the original rear qu arter window glass is to be

installed remove the residual ad hesive from rear quarter window

glass mating surface using the special tool.

Thoroughly clean rear quarte r window glass surface using

Betawipe spirit.

3. Thoroughly clean the mating face of the body using Betawipe