JAGUAR X308 1998 2.G Workshop Manual

X308 1998 2.G

JAGUAR

JAGUAR

https://www.carmanualsonline.info/img/21/7640/w960_7640-0.png

JAGUAR X308 1998 2.G Workshop Manual

Page 1399 of 2490

Pin NumberCircuitCircuit Function

001n3 speed signal

002Pressure regulator MD signal

003n2 speed signal

004Temperature sensor

005Solenoid 1 <-> 2, 4 <-> 5

006Solenoid and pressure regulator +ve

007Speed sensor +ve

008Solenoid 2 <-> 3

009Solenoid 3 <-> 4

010Pressure regulator SD signal

011Torque converter solenoid

012Speed and temperature sensor ground

Page 1462 of 2490

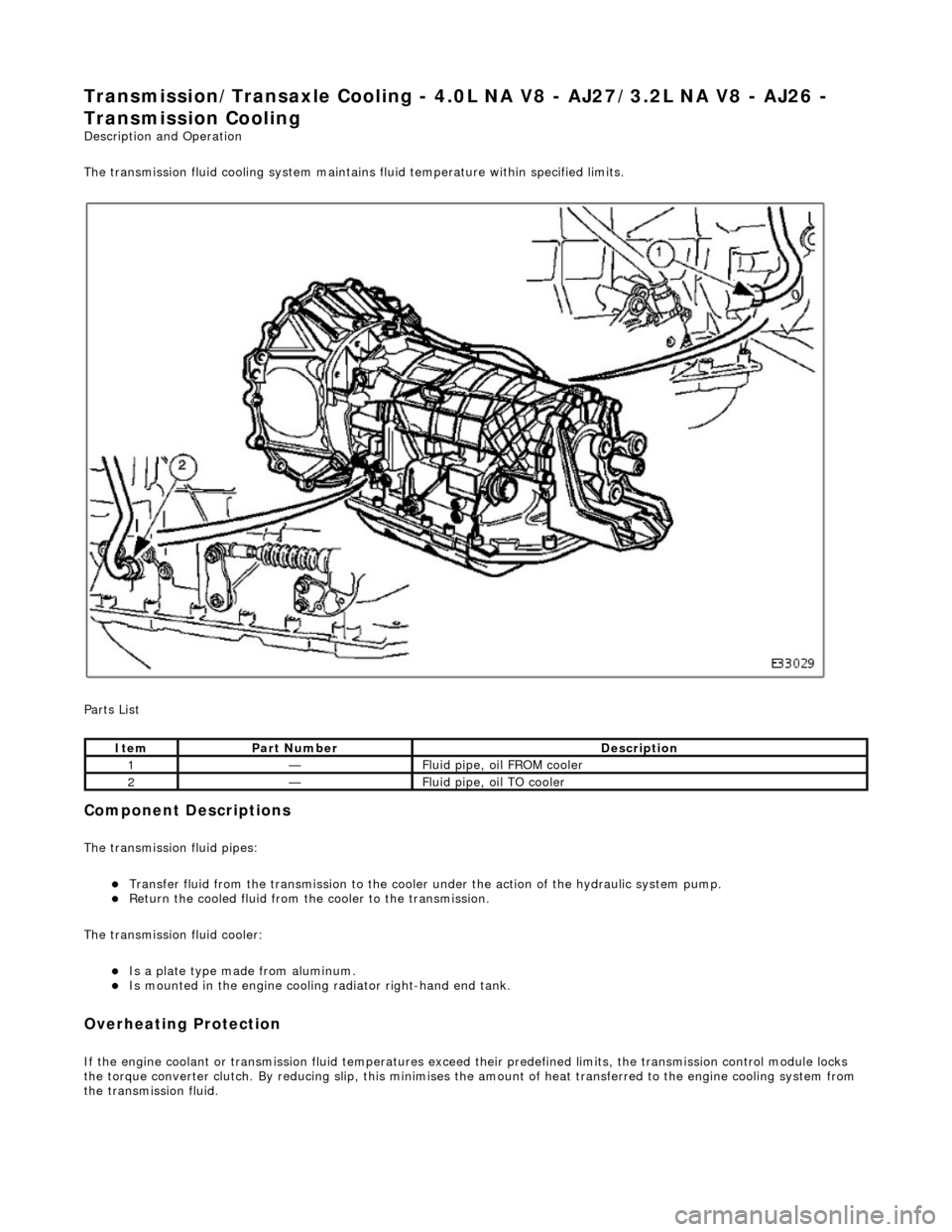

Transmission/Transaxle Cooling - 4.0L NA V8 - AJ27/3.2L NA V8 - AJ26 -

Transmission Cooling

Description and Operation

The transmission fluid cooling system maintains fluid temperature within specified limits.

Parts List

Component Descriptions

The transmission fluid pipes:

Transfer fluid from the transmission to the cooler under the action of the hydraulic system pump. Return the cooled fluid from th e cooler to the transmission.

The transmission fluid cooler:

Is a plate type made from aluminum. Is mounted in the engi ne cooling radiator right-hand end tank.

Overheating Protection

If the engine coolant or transm ission fluid temperatures exceed their predefined limits, th e transmission control module locks

the torque converter clutch. By reducing slip, this minimises th e amount of heat transferred to the engine cooling system from

the transmission fluid.

ItemPart NumberDescription

1—Fluid pipe, oil FROM cooler

2—Fluid pipe, oil TO cooler

Page 1464 of 2490

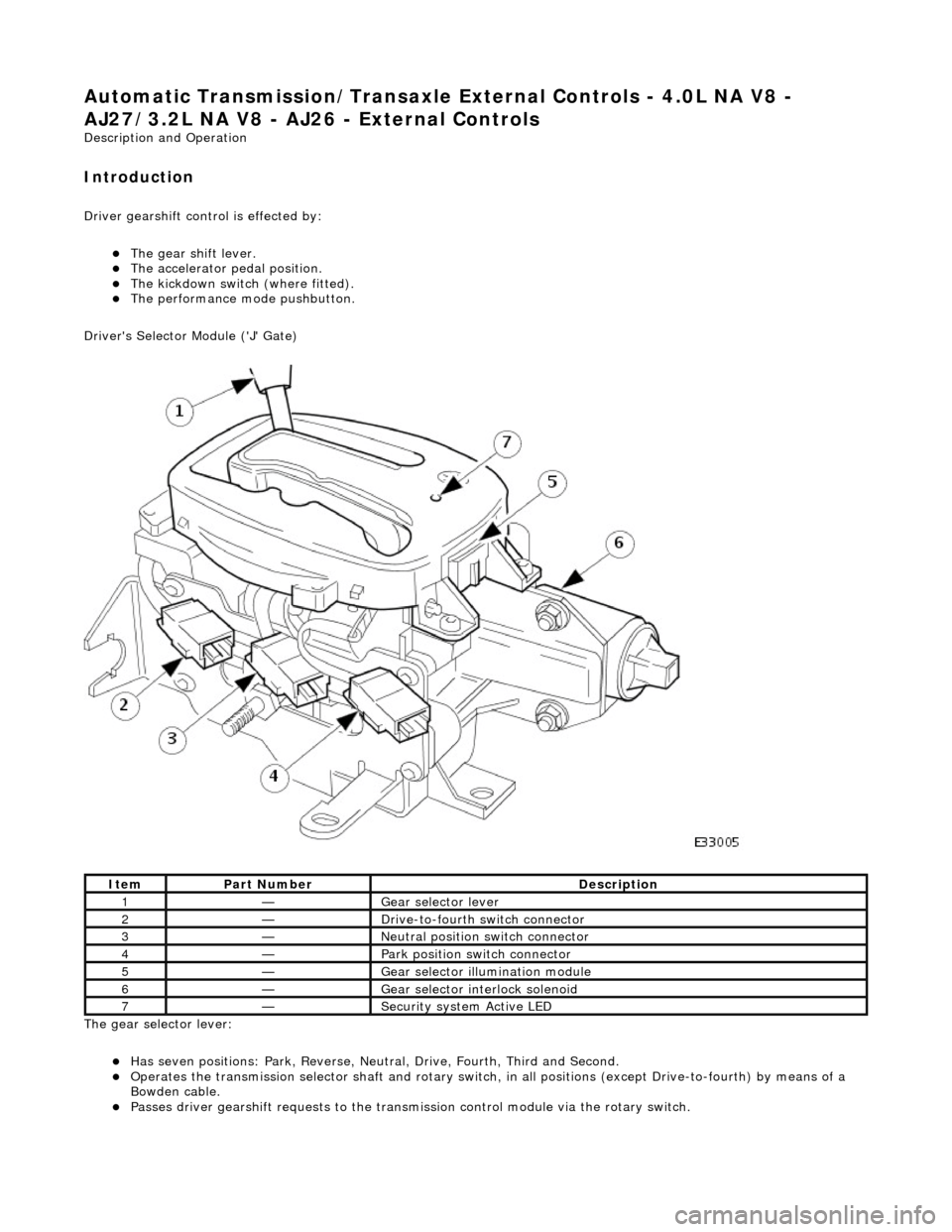

Automatic Transmission/Transaxle External Controls - 4.0L NA V8 -

AJ27/3.2L NA V8 - AJ26 - External Controls

Description and Operation

Introduction

Driver gearshift control is effected by:

The gear shift lever. The accelerator pedal position. The kickdown switch (where fitted). The performance mode pushbutton.

Driver's Selector Module ('J' Gate)

The gear selector lever:

Has seven positions: Park, Reverse, Neutral, Drive, Fourth, Third and Second. Operates the transmission selector shaft and rotary switch, in all positions (except Drive-to-fourth) by means of a

Bowden cable.

Passes driver gearshift requests to the transm ission control module via the rotary switch.

ItemPart NumberDescription

1—Gear selector lever

2—Drive-to-fourth switch connector

3—Neutral position switch connector

4—Park position switch connector

5—Gear selector illumination module

6—Gear selector interlock solenoid

7—Security system Active LED

Page 1500 of 2490

ItemPart NumberDescription

1—Gear selector lever

2—Access blank - Gear-shift interlock solenoid

3—Connector - DLS

4—Dual Linear Switch (DLS)

5—Connector - Park position switch

6—Connector - Illumination module

Page 1525 of 2490

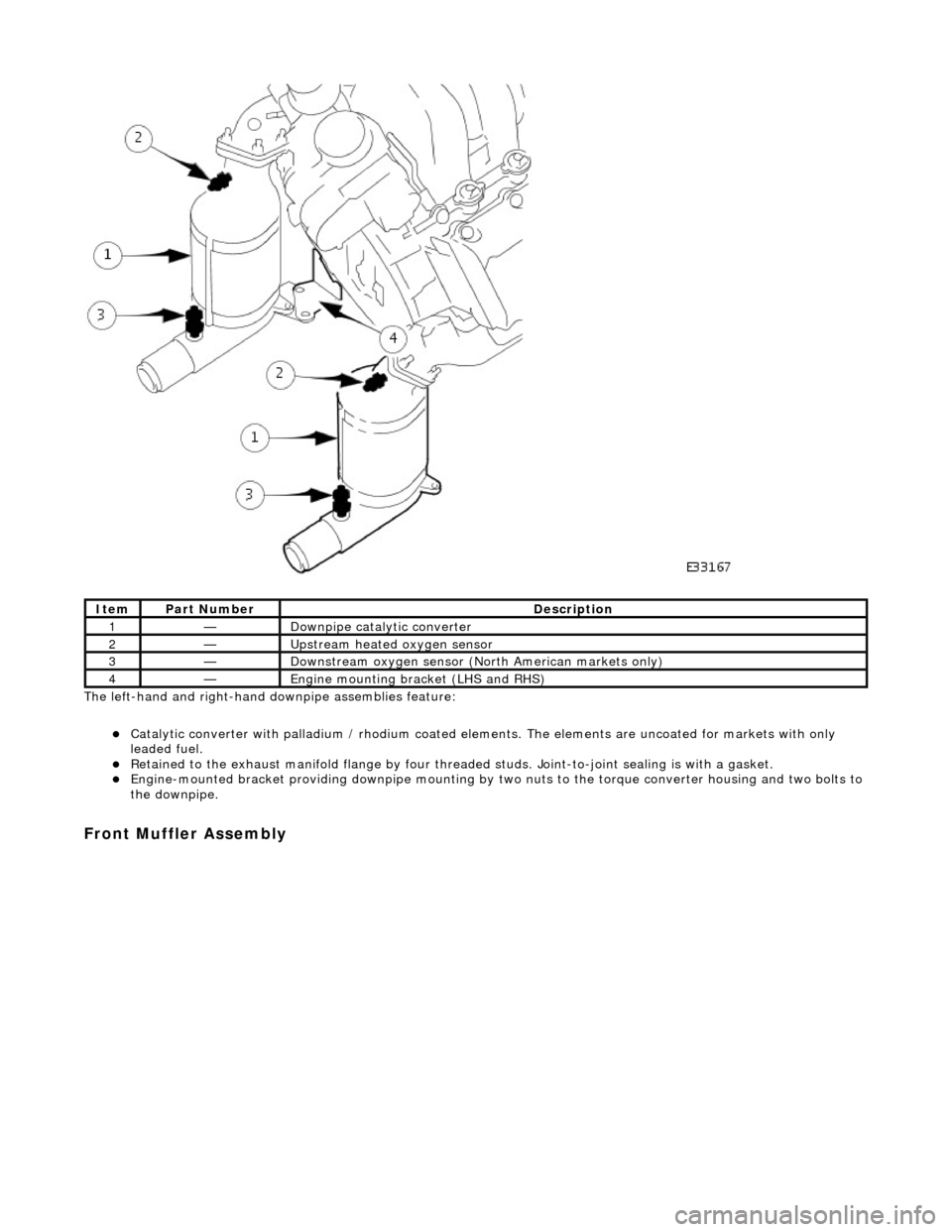

The left-hand and right-hand do wnpipe assemblies feature:

Catalytic converter with palladium / rhodium coated elem ents. The elements are uncoated for markets with only

leaded fuel.

Retained to the exhaust manifold flange by four thread ed studs. Joint-to-joint sealing is with a gasket. Engine-mounted bracket providing downpipe mounting by two nuts to the torque converter housing and two bolts to

the downpipe.

Front Muffler Assembly

ItemPart NumberDescription

1—Downpipe catalytic converter

2—Upstream heated oxygen sensor

3—Downstream oxygen sensor (North American markets only)

4—Engine mounting bracket (LHS and RHS)

Page 1529 of 2490

Parts List

Operation

ItemPart NumberDescription

1—Heated oxygen sensor (upstream)

2—Oxygen sensor (downstream)

3—Catalytic converter

Page 1692 of 2490

Fuel Tank and Lines - Fuel Tank and Li

nes

Description an

d Operation

Fuel Tank

Parts List

The steel fuel tank is located inside the trunk and mounted across the vehicle behind the passenger compartment bulkhead.

The fuel tank is held in posi tion by two retaining straps fi tted to body-mounted brackets.

The fuel tank has an integral non-adjustable fill er pipe and integral breather and vapor pipework.

A single fuel pump is mounted inside the tank on vehicles with normally aspirated engines. For vehicles with supercharged

engines, two pumps are fitted in the tank. Fuel is drawn by the pump(s) from the fuel tank and supplied via the fuel lines

and 70 micron filter to the fuel rails.

The fuel lines run from front-to-rear down the vehicle's left-hand-side.

Ite

m

Part

Number

Descr

iption

1—Fu

el filler latch box

2—Pressure reli

ef pipe, ORVR

(shown) / tank breather pipe on non-ORVR systems

3—Tank grounding

cable

4—Evaporative flan

ge assembly

(ORVR type shown)

5—Trunk elec

trical harne

ss (part of)

6—Fue

l

level sensor

flange/connector

7—Fu

el tank retaining straps

8—F

u

el tank retaining stra

ps adjustable clamps

9—Fu

el tank retaining straps lower brackets

10—Tank vapor outlet pipe to un

derflo

or pipe quick-fit connector

11—F

u

el filler latch bo

x water drain pipe

Page 1694 of 2490

P a

rts List

The fuel level sensor is mounte d on the fuel tank vertical face and reacts to level changes via a float and pivot which is

connected to a potentiometer. As the fuel level drops the resistance increases.

The fuel level sensor can be serviced without removing the tank.

It e

m

Par

t

Number

De

scr

iption

1—Lockin

g rin

g

2—Fue

l

level sensor

3—Seal

Fuel

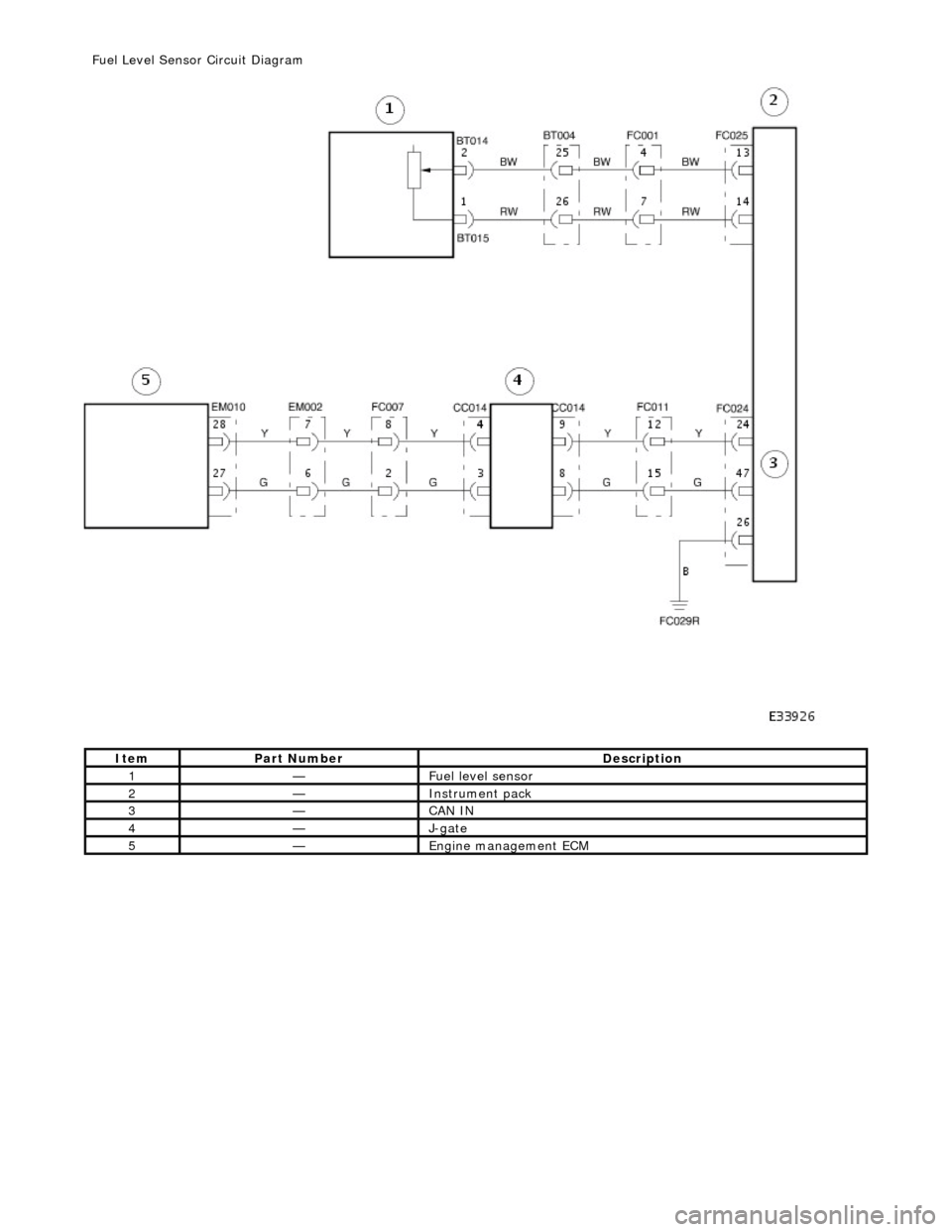

Level Sensor

Page 1695 of 2490

It

em

Par

t Number

De

scription

1—Fue

l level sensor

2—Instrument pack

3—CAN IN

4—J-

gate

5—Engine

management ECM

F

uel Level Sensor Circuit Diagram

Page 1696 of 2490

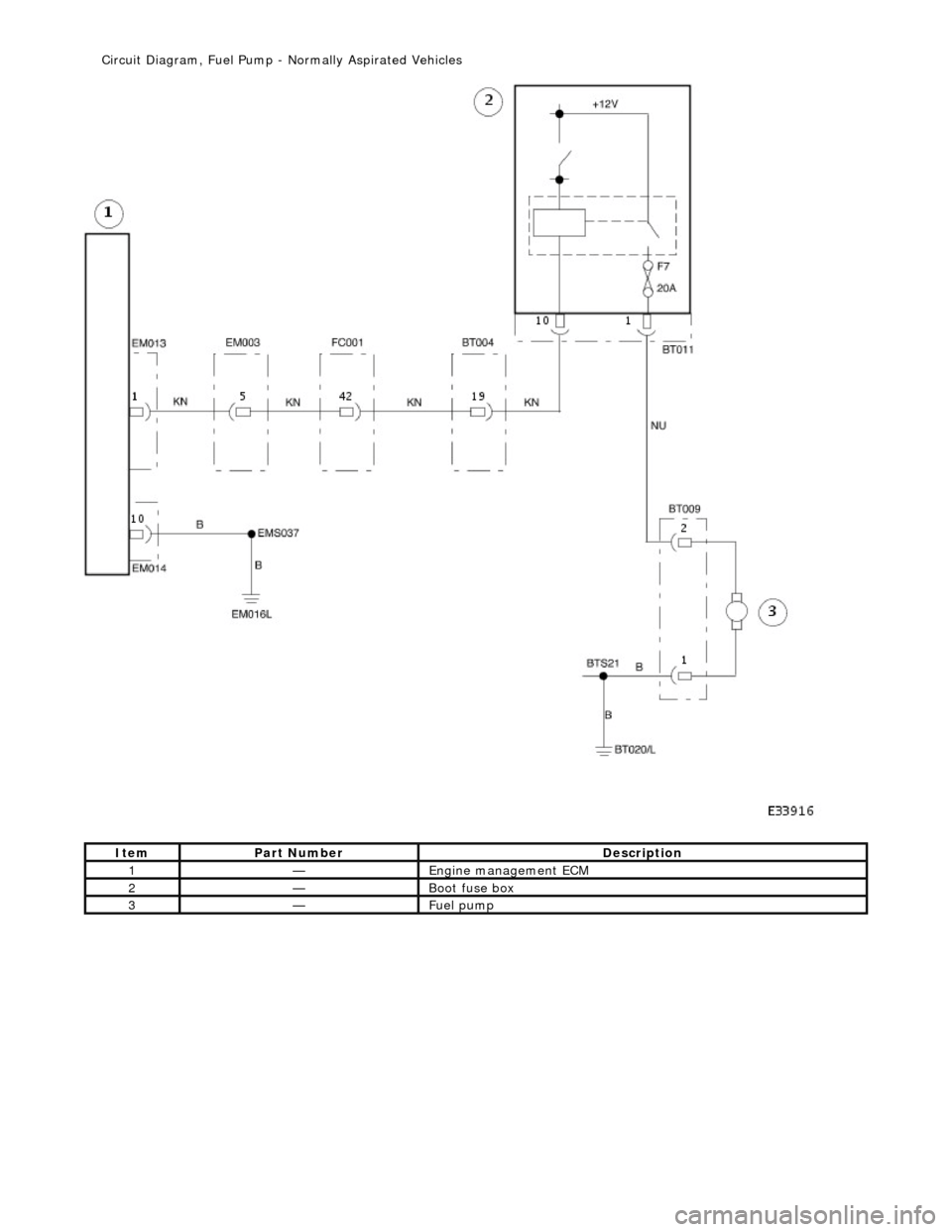

Ite

m

Par

t

Number

De

scr

iption

1—Engine

m

anagement ECM

2—Boot fuse box

3—Fue

l

pump

Ci

rcui

t Diagram, Fuel Pump -

Normally Aspirated Vehicles