vi number JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1697 of 2490

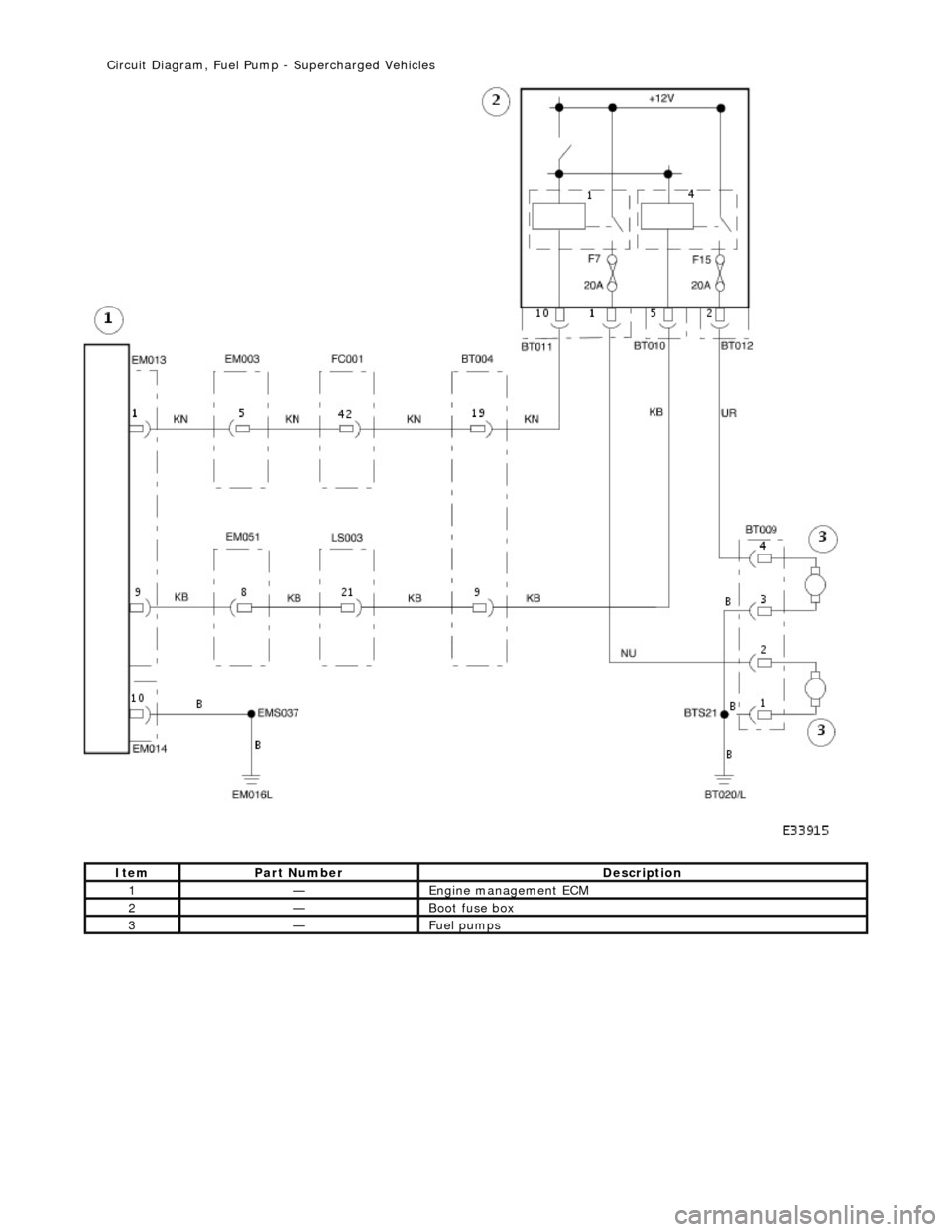

It

em

Par

t Number

De

scription

1—Engine

management ECM

2—Boot fuse box

3—Fue

l pumps

Ci

rcuit Diagram, Fuel Pump

- Supercharged Vehicles

Page 1783 of 2490

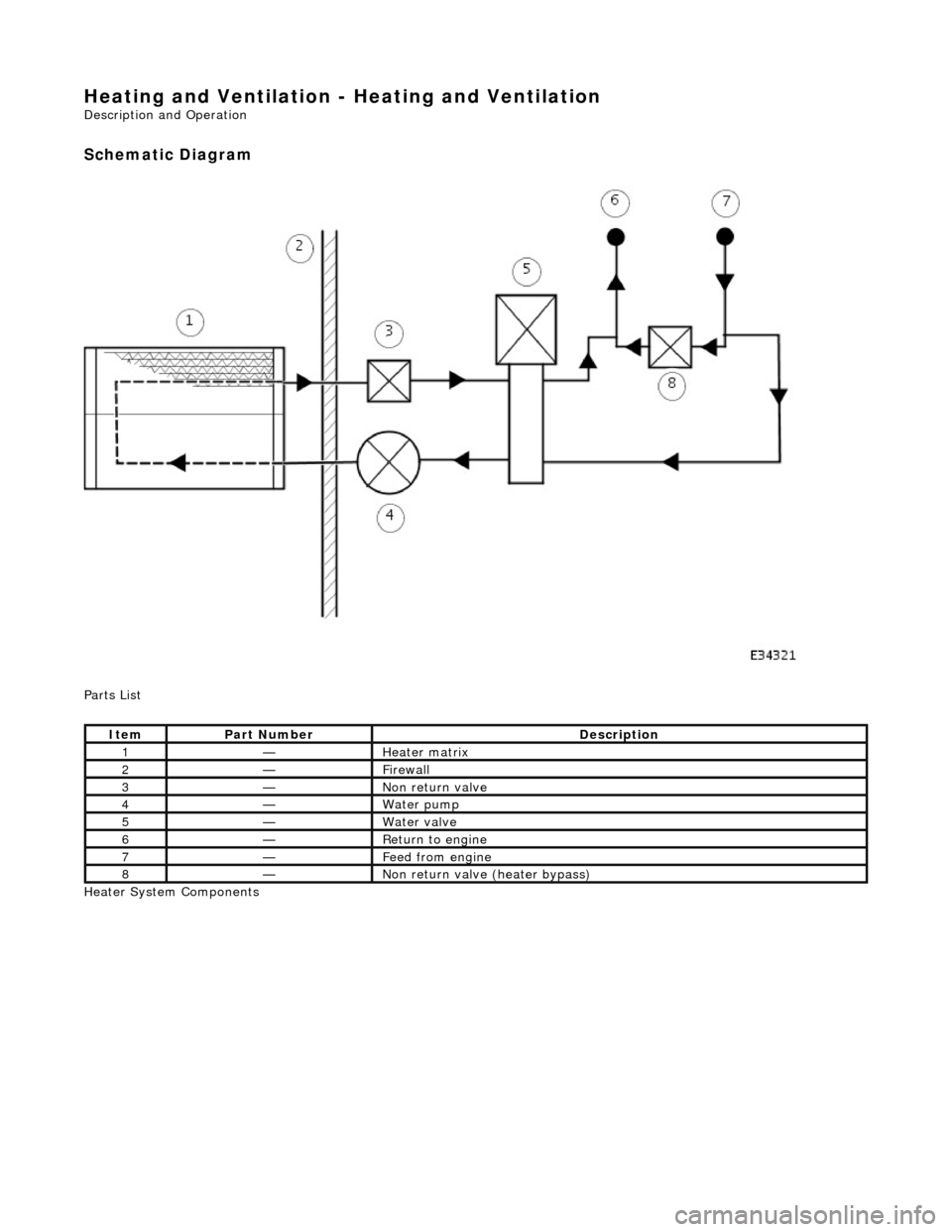

Heating and Ventilation - Heating and Ventilation

Description and Operation

Schematic Diagram

Parts List

Heater System Components

ItemPart NumberDescription

1—Heater matrix

2—Firewall

3—Non return valve

4—Water pump

5—Water valve

6—Return to engine

7—Feed from engine

8—Non return valve (heater bypass)

Page 1784 of 2490

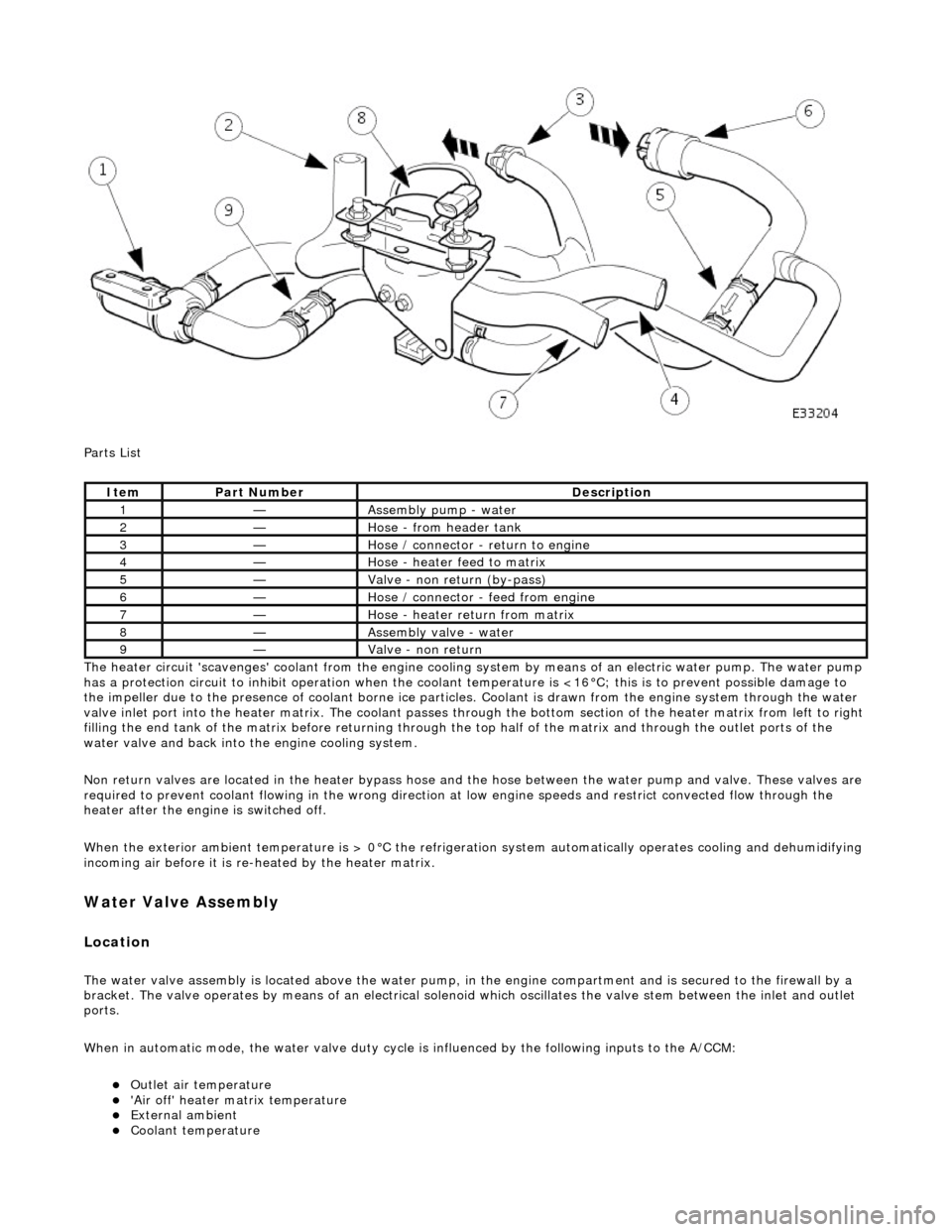

Parts List

The heater circuit 'scavenges' coolant from the engine cooling system by mean s of an electric water pump. The water pump

has a protection circuit to inhibit operation when the coolant temperature is <16°C; this is to prevent possible damage to

the impeller due to the presence of coolant borne ice particles. Coolant is drawn from the en gine system through the water

valve inlet port into the heater matrix. The coolant passes thro ugh the bottom section of the heater matrix from left to right

filling the end tank of the matrix before returning through the top half of the ma trix and through the outlet ports of the

water valve and back into the engine cooling system.

Non return valves are located in the heat er bypass hose and the hose between the water pump and valve. These valves are

required to prevent coolant flowing in th e wrong direction at low engine speeds and restrict convected flow through the

heater after the engine is switched off.

When the exterior ambient temperature is > 0°C the refrigerat ion system automatically operates cooling and dehumidifying

incoming air before it is re -heated by the heater matrix.

Water Valve Assembly

Location

The water valve assembly is located above the water pump, in the engine compartmen t and is secured to the firewall by a

bracket. The valve operates by means of an electrical solenoid which oscillates the valve stem between the inlet and outlet

ports.

When in automatic mode, the water valve duty cycle is influenced by the following inputs to the A/CCM:

Outlet air temperature 'Air off' heater matrix temperature External ambient Coolant temperature

ItemPart NumberDescription

1—Assembly pump - water

2—Hose - from header tank

3—Hose / connector - return to engine

4—Hose - heater feed to matrix

5—Valve - non return (by-pass)

6—Hose / connector - feed from engine

7—Hose - heater return from matrix

8—Assembly valve - water

9—Valve - non return

Page 1786 of 2490

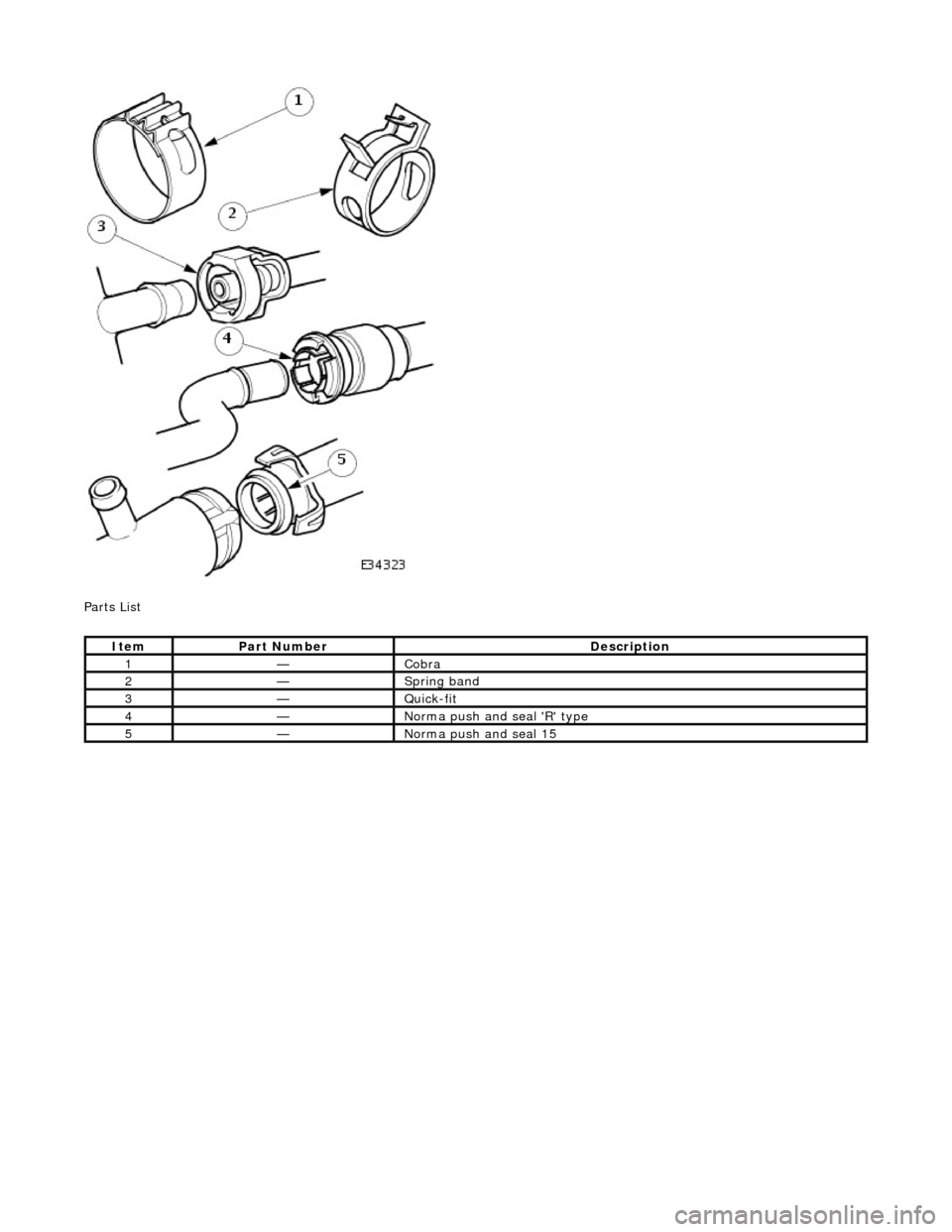

Parts List

ItemPart NumberDescription

1—Cobra

2—Spring band

3—Quick-fit

4—Norma push and seal 'R' type

5—Norma push and seal 15

Page 1798 of 2490

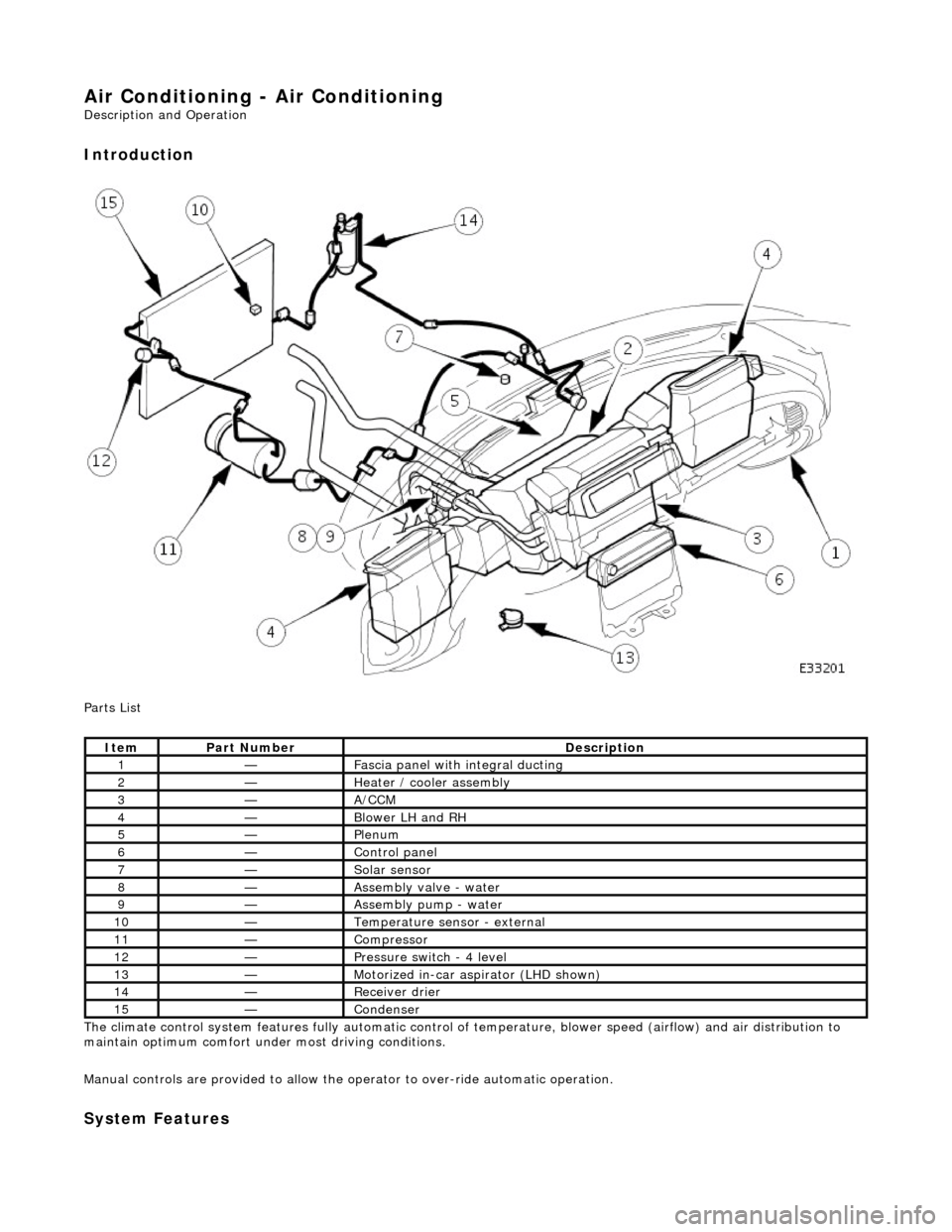

Air Conditioning - Air Conditioning

Description and Operation

Introduction

Parts List

The climate control system features fully automatic control of temperature, blower speed (airflow) and air distribution to

maintain optimum comfort under most driving conditions.

Manual controls are provided to allow the operator to over-ride automatic operation.

System Features

ItemPart NumberDescription

1—Fascia panel with integral ducting

2—Heater / cooler assembly

3—A/CCM

4—Blower LH and RH

5—Plenum

6—Control panel

7—Solar sensor

8—Assembly valve - water

9—Assembly pump - water

10—Temperature sensor - external

11—Compressor

12—Pressure switch - 4 level

13—Motorized in-car aspirator (LHD shown)

14—Receiver drier

15—Condenser

Page 1800 of 2490

Compressor:

Features

Engine mounted, driven by the accessory drive belt. Fixed displacement type. High-pressure relief valve, to avoid system over-pressure. ECM controlled clutch energized via a relay.

Receiver drier:

Vertically mounted on the ri ght-hand side of the engine compartment next to the engine coolant radiator. Fitted with the high-side charge port. Includes a fluorescent tracer dye me chanism to aid leak detection.

ItemPart NumberDescription

1—Compressor assembly

2—Condenser

3—Evaporator and heater matrix (internal)

4—Receiver drier

5—4-level pressure switch

6—Expansion valve (internal)

7—High-side charge port

8—Low-side charge port

9—Suction muffler

10—Discharge hose

11—Discharge pipe

12—Suction hose

13—Suction pipe

14—Liquid line

15—Jumper hose (condenser hose)

Page 1801 of 2490

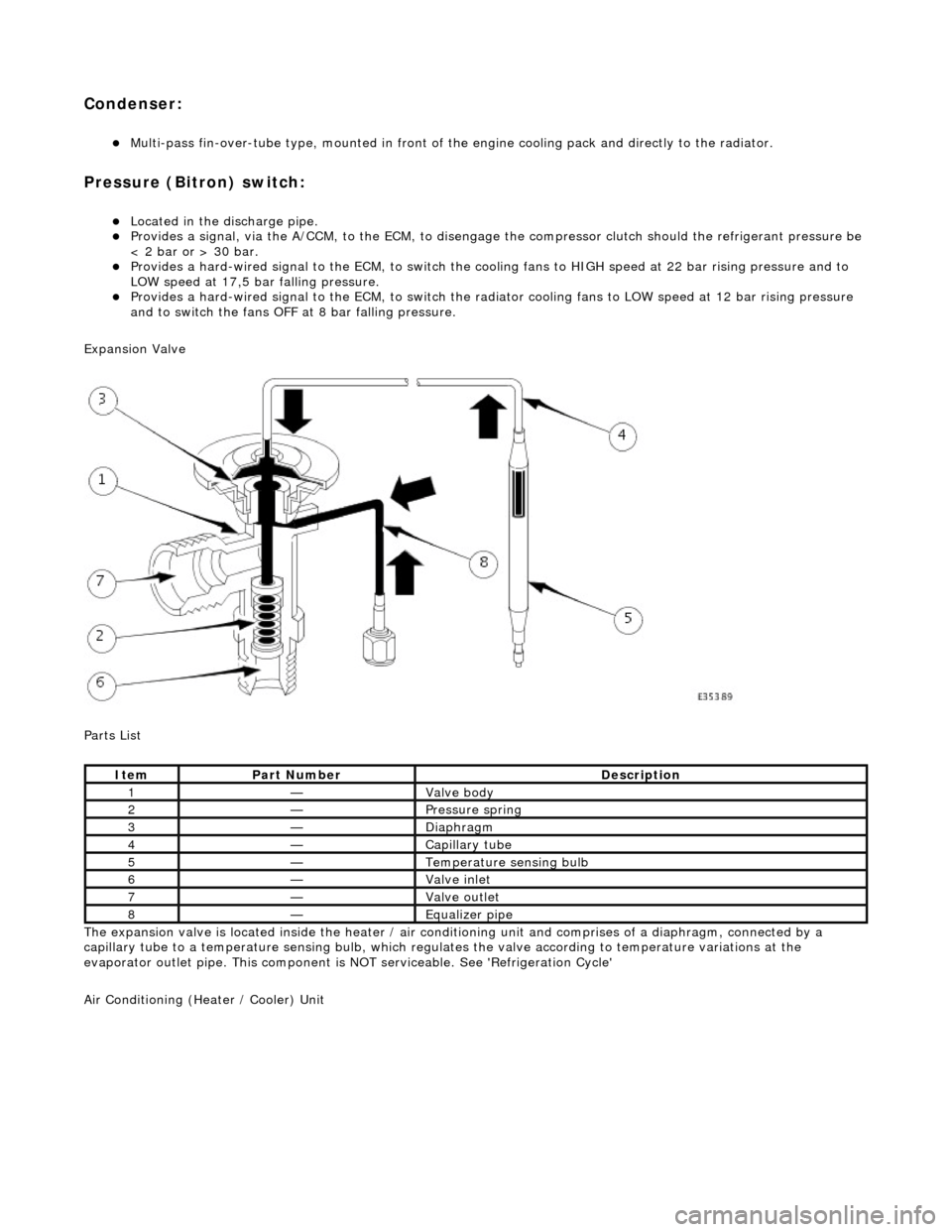

Condenser:

Multi-pass fin-over-tube type, mounted in front of the engine cooling pack and directly to the radiator.

Pressure (Bitron) switch:

Located in the discharge pipe. Provides a signal, via the A/CCM, to th e ECM, to disengage the compressor clut ch should the refrigerant pressure be

< 2 bar or > 30 bar.

Provides a hard-wired signal to the ECM, to switch the cool ing fans to HIGH speed at 22 bar rising pressure and to

LOW speed at 17,5 bar falling pressure.

Provides a hard-wired signal to the ECM, to switch the radiator cooling fans to LOW speed at 12 bar rising pressure

and to switch the fans OFF at 8 bar falling pressure.

Expansion Valve

Parts List

The expansion valve is located inside the heater / air conditioning unit and comprises of a diaphragm, connected by a

capillary tube to a temperat ure sensing bulb, which regulates the valve according to temperature variations at the

evaporator outlet pipe. This component is NOT serviceable. See 'Refrigeration Cycle'

Air Conditioning (Heater / Cooler) Unit

ItemPart NumberDescription

1—Valve body

2—Pressure spring

3—Diaphragm

4—Capillary tube

5—Temperature sensing bulb

6—Valve inlet

7—Valve outlet

8—Equalizer pipe

Page 1802 of 2490

Parts List

The air conditioning unit houses the evap orator, heater matrix and their temperatur e sensors. The unit also incorporates

two servo motor operated air distribution flaps which regulate airflow to the front and rear footwells and the quantity of

airflow through the cool air bypass (air which by-passes he ater matrix) up to the upper air distribution box (ADB).

When the footwell flap is open, air is du cted to the front and rear footwell areas via the lower air distribution duct (LADD)

and appropriate ducts. The LADD is clipped to the bottom of the air conditioning unit case an d the front foot ducts clipped

onto the outlets of the LADD.

Condensate (water) which forms on the evaporator fins is drained out of the unit case through two drains, located either

side of the unit underneath the evaporator. The liquid is routed to the vehicle exterior via flexible tubes which are located

behind the firewa ll heatshield.

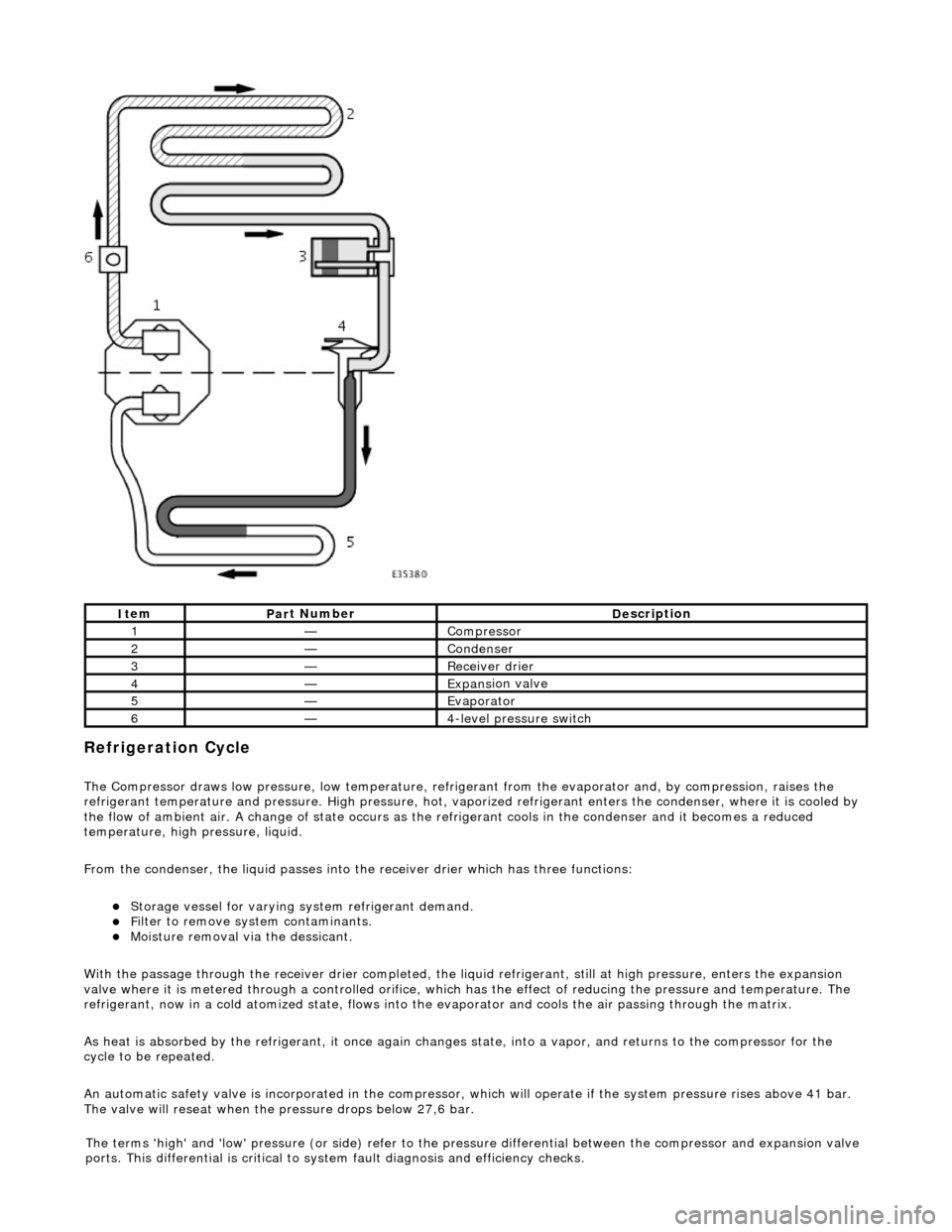

Refrigeration Cycle

ItemPart NumberDescription

1—Air inlet - LH (RH opposite, not shown)

2—Servomotor - cool air bypass

3—Servomotor - footwell outlet

4—Air outlet - footwell

5—Air outlet - ADB (with foam seal)

Page 1803 of 2490

Refrigeration Cycle

The Compressor draws low pressure, lo

w te

mperature, refrigerant from the evaporat or and, by compression, raises the

refrigerant temperature and pressure. High pressure, hot, vaporized refr igerant enters the condenser, where it is cooled by

the flow of ambient air. A change of state occurs as the refrigerant cools in the condense r and it becomes a reduced

temperature, high pressure, liquid.

From the condenser, the liquid passes into the receiver drier which has three functions:

Storage vessel

for varying sy

stem refrigerant demand.

F

ilter to remove sy

stem contaminants.

Mo

isture removal via the dessicant.

With the passage through the receiver drie r completed, the liquid refrigerant, still at high pressure, enters the expansion

valve where it is metered through a contro lled orifice, which has the effect of reducing the pres sure and temperature. The

refrigerant, now in a cold atomized st ate, flows into the evaporator and cools the air passing through the matrix.

As heat is absorbed by the refrigerant, it once again changes state, into a vapor, and returns to the compressor for the

cycle to be repeated.

An automatic safety valve is incorporated in the compressor, which will operate if the system pressure rises above 41 bar.

The valve will reseat when the pressure drops below 27,6 bar.

It

em

Par

t Number

De

scription

1—Compre

ssor

2—Conden

ser

3—Re

ceiver drier

4—Expans

ion valve

5—Evaporator

6—4

-level pressure switch

The terms 'high' and 'low'

pressure (or si

de) refer to the pres sure differential betw een the compressor and expansion valve

ports. This differential is critical to sy stem fault diagnosis and efficiency checks.

Page 1822 of 2490

Ref #12 DEF (resumes the system on at the previous temperature setting).

Button (switch) logic

All buttons with an integral LED state lamp conform to the following operating logic.

When the state lamp is lit the relevant func tion is operational. From this condition, pressing the button will de-activate the

function, confirmed by the LED being de-energized and the pres ence of a single audible 'beep'. A single 'beep' will

accompany the state lamp to confirm function re-selection.

1. 1. ON / OFF and manual fan speed.

Pressing this knob activates the system ON at the last settin g or switches the system OFF. Rotate the knob clockwise to

increase and anti-clockwise to decrease fan speed and thus airflow.

With the system OFF, ram air is available by the selected air di stribution mode (indicated by state lamp). Air flow will NOT

occur unless a manual air distribution mo de is selected, this air being unconditioned and flow dependent upon vehicle

speed.

• NOTE: The blowers are inhibited until the engine coolant te mperature is > 35°C, unless DEFROST, FACE or DEMIST modes

are selected.

2. 2. Manual Air Recirculation

Closes the outside air intakes of the blower asse mblies and recirculates air within the vehicle.

Two options of control are available :

Timed Recirculation. Pressing the button for less than 1.5 seconds lights up the LED (confirmed by a single bleep).

This provides recirculation of interior air for a period of approximately 5 minutes. Pressing the button within five

minutes returns the system to fresh air intake mode.

Continuous Recirculation. Pressing and holding the button for more than 1.5 seconds lights up the LED (confirmed by two beeps). This provides continuous reci rculation of interior air. Pressing the button returns the system to fresh air

intake mode.

• NOTE: Avoid using manual air recirculatio n for prolonged periods in cold weather, this may result in interior misting of

glass.

3. 3. Temperature Scale Selection

Press the appropriate button to display temperatures in degrees Celsius or Fahrenheit.

4. 4. Manual Fan Speed

Rotating the fan speed control knob (to vary fan speed) will di splay a proportional number of horizontal bars on the LCD.

There are total of eleven manual fan speeds available.

5. 5. Temperature Display

Indicator of internal demand temperatur e or external ambient temperature. The external ambient is updated every 4

seconds when the road speed > 25 km / h.

6. 6. Scale

Selected temperature scale, Celsius or Fahrenheit.

7. 7. External temperature

Symbol indicates when this option is selected