ECU JAGUAR X308 1998 2.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 76 of 2490

5. Re

move wire temporarily securing

vertical link to road spring.

6. Remove and discard plasti c cover from ball joint.

7. Position wishb

o

ne to engage ball joint taper in vertical link.

8. In

stall nut securing ball joint to vertical link and tighten nut to

60-80Nm.

9. Reposition wheel speed sensor harness on wishbone and

secure with two tiestraps.

Page 79 of 2490

1

11 and support on stands. Refer to Section 100-02.

5. Ins

tall Special Tool 204-111 in road spring.

Sl

acken tool adjuster to suit spring length.

Install adaptor

and thrust collar.

Posit

ion stem of tool in center of spring passing dowel

through slot in su spension turret.

6. R

otate stem of Special Tool to

position dowel across slot.

7. W

ARNING: WHEN TURNING TOOL ADJUSTER, ENSURE

THAT TOOL STEM DOES NOT ROTATE AND DISTURB POSITION

OF DOWEL IN SUSPENSION TURRET.

Rotate adjuster of Special Tool to tension spring.

8. R

emove spring pan to lower

wishbone securing bolts.

9. Rotate adjuster of Special Tool to release tension from spring.

Page 80 of 2490

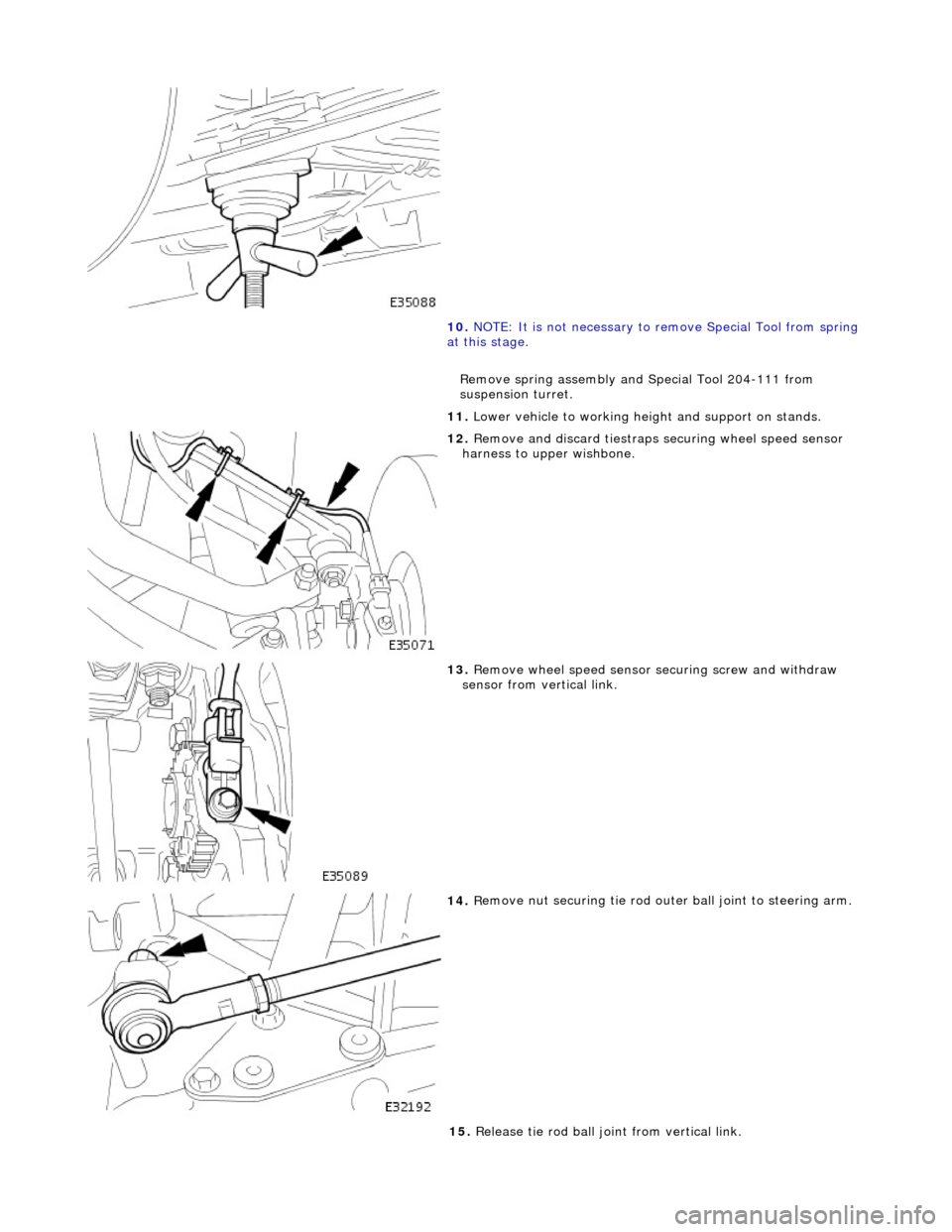

10. NOTE

: It is not necessary to re

move Special Tool from spring

at this stage.

Remove spring assembly and Special Tool 204-111 from

suspension turret.

11. Lower vehicle to working heig ht and support on stands.

12 . Remove an

d discard tiestraps

securing wheel speed sensor

harness to upper wishbone.

13 . R

emove wheel speed sensor se

curing screw and withdraw

sensor from vertical link.

14 . R

emove nut securing tie rod oute

r ball joint to steering arm.

15. Release tie rod ball joint from vertical link.

Page 81 of 2490

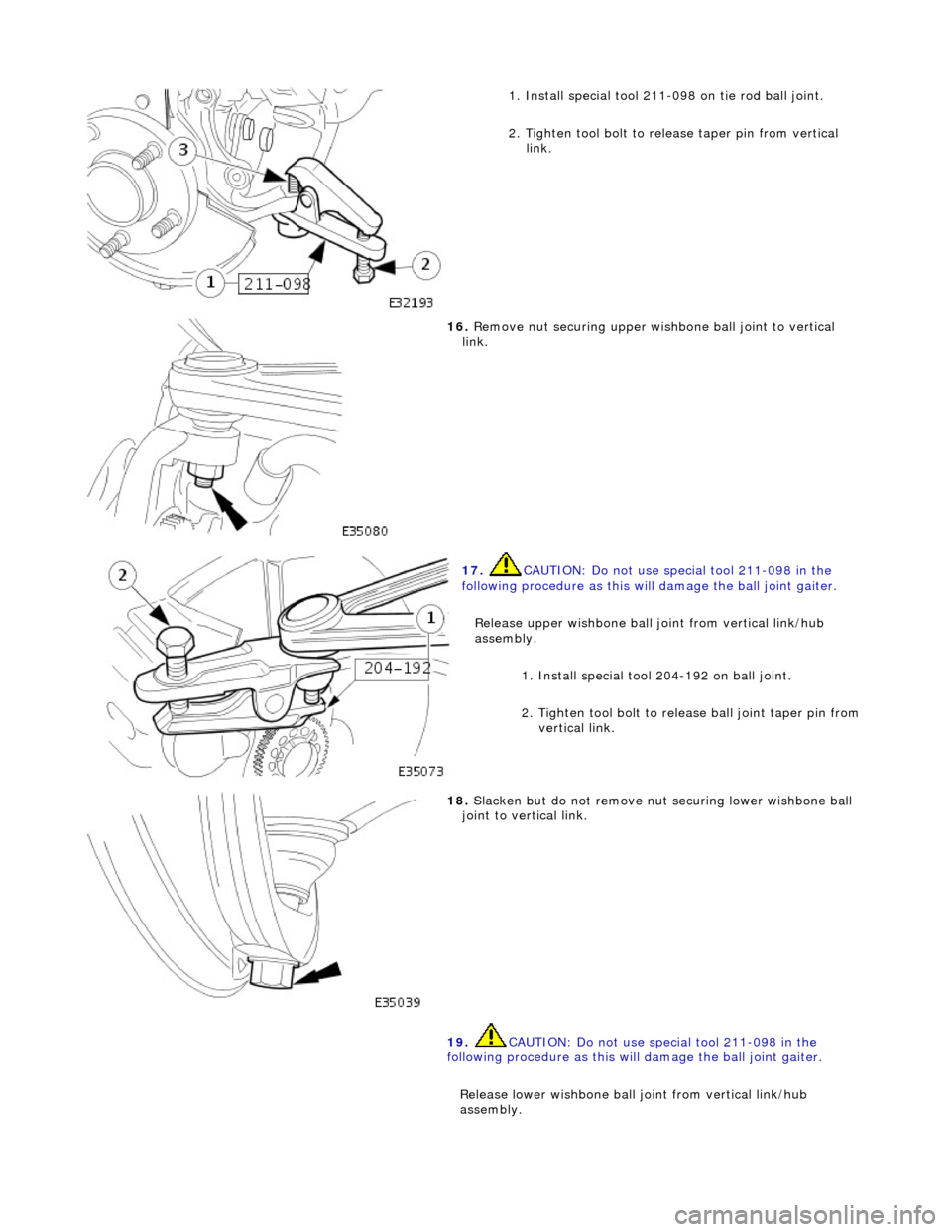

1

. Install special tool 211-098 on tie rod ball joint.

2. Tighten tool bolt to rele ase taper pin from vertical

link.

16

.

Remove nut securing upper wish bone ball joint to vertical

link.

17

.

CAUTION: Do not use special tool 211-098 in the

following procedure as this will damage the ball joint gaiter.

Release upper wishbone ball joint from vertical link/hub

assembly.

1. Install special tool 204-192 on ball joint.

2. Tighten tool bolt to rele ase ball joint taper pin from

vertical link.

18

.

Slacken but do not remove nut securing lower wishbone ball

joint to vertical link.

19. CAUTION: Do not use special tool 211-098 in the

following procedure as this will damage the ball joint gaiter.

Release lower wishbone ball joint from vertical link/hub

assembly.

Page 82 of 2490

1.

Install special tool 204-293 on ball joint.

2. Tighten tool bolt to rele ase ball joint taper pin from

vertical link.

20. Remove special tool 204-293 from ball joint.

21 . R

emove vertical link/hub assembly.

Support

ing ver

tical link/ hu

b assembly, remove lower

wishbone ball joint nut.

R e

move vertical link /hub assembly.

22 . R

emove stabilizer bar link to

wishbone securing nut and bolt.

23 . R

emove wishbone front arm to

rear arm securing bolt .

24. Slacken but do not remove shock absorber lower nut and

bolt.

Page 83 of 2490

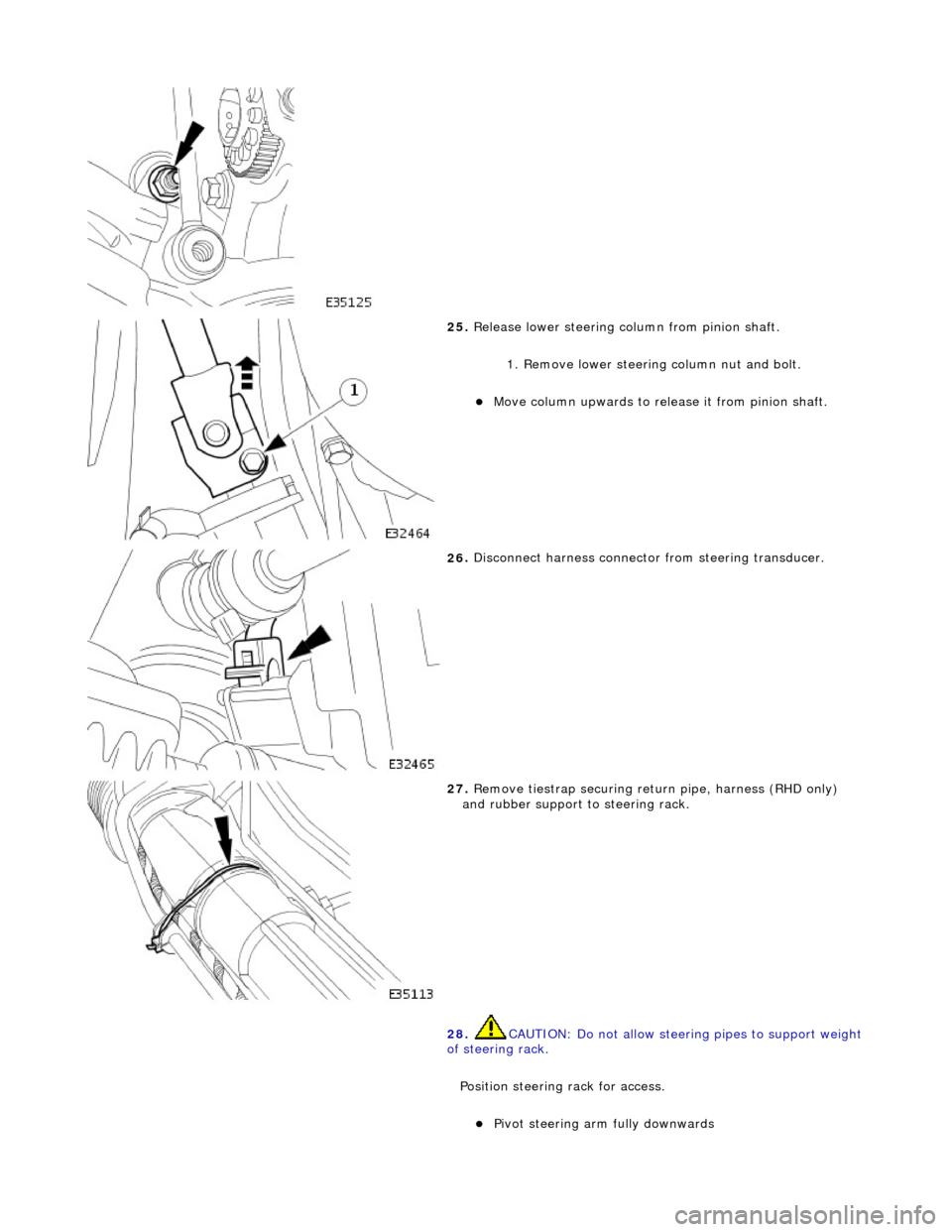

25

.

Release lower steering column from pinion shaft.

1. Remove lower steering column nut and bolt.

Move column up

wards to release it from pinion shaft.

26

.

Disconnect harness connector from steering transducer.

27

.

Remove tiestrap securing retu rn pipe, harness (RHD only)

and rubber support to steering rack.

28. CAUTION: Do not allow steerin g pipes to support weight

of steering rack.

Position steering rack for access.

Pi

vot steering arm fully downwards

Page 84 of 2490

In

stallation

Re

move steering rack securing bolts.

Carefully move steer

ing rack

downwards for access to

wishbone eccentric bolt.

29 . R

emove lower wishbone rear

arm eccentric bolt and nut.

Mark position of eccentri

c bo

lt large graduation mark on

crossbeam.

R e

move wishbone rear ec

centric bolt and nut.

30. Remove lower wishbone rear arm/ball joint assembly from

crossbeam.

1. Positi

on wishbone rear arm on crossbeam and install but do

not tighten eccentric bolt.

2. Install steeri

ng rack on crossbeam.

Ensure

that b

ushes are correct

ly positioned on steering

rack.

Posi ti

on steering rack on crossbeam.

Position support brac

kets over bus

hes.

Install mountin

g bracket bolts an

d tighten to 41-54Nm.

3. Install lower steering column on pinion shaft.

Move col u

mn downwards to engage coupling splines on

pinion shaft.

Page 85 of 2490

1

. Install nut and bolt and tighten to 22-28Nm.

4. Position an

d connect harnes

s to steering transducer.

RHD

vehicles. Position steeri

ng harness behind return

pipe.

Conne

ct harness to transducer.

5. Secure return pipe on steering

rack.

1. Position pipe rubber support on steering rack.

2. Position pipe on support .

3. RHD vehicles. Position harness on pipe support rubber.

4. Secure pipe and harness to support with new tiestrap.

6. Inst

all shock absorber

and mounting bracket.

Posit

ion shock absorber moun

ting bracket on wishbone

rear arm.

Install

wishbone front arm to

rear arm bolt and tighten to

77-103Nm.

7. Tighten shock absorber lower bolt and nut to 43-57Nm.

Page 86 of 2490

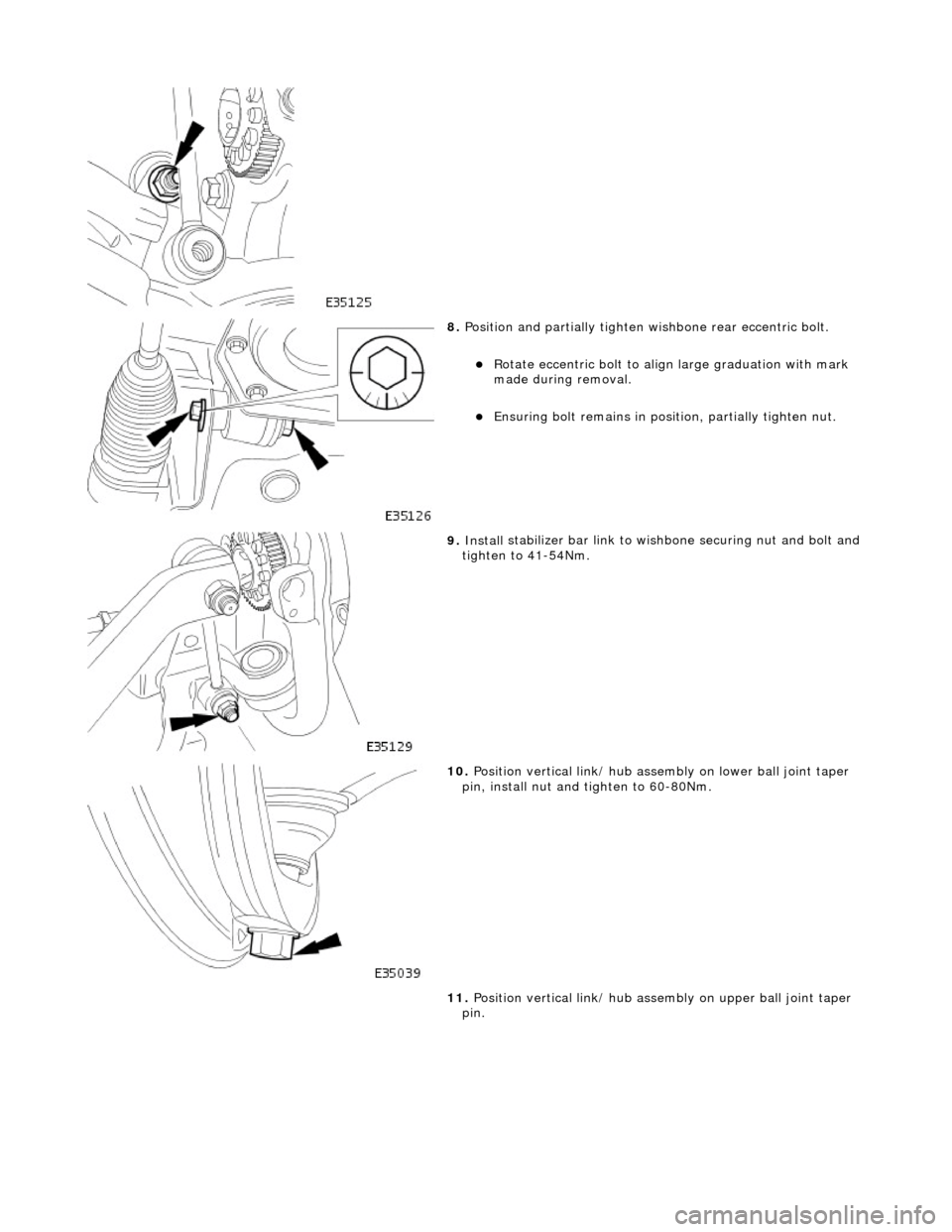

8. Position an

d partially tighten

wishbone rear eccentric bolt.

Rotate

eccentric bolt to align large graduation with mark

made during removal.

Ens u

ring bolt remains in position, partially tighten nut.

9. Install stabil

izer bar link to wi

shbone securing nut and bolt and

tighten to 41-54Nm.

10 . Position verti

cal link/ hub asse

mbly on lower ball joint taper

pin, install nut and tighten to 60-80Nm.

11. Position vertical link/ hub asse mbly on upper ball joint taper

pin.

Page 87 of 2490

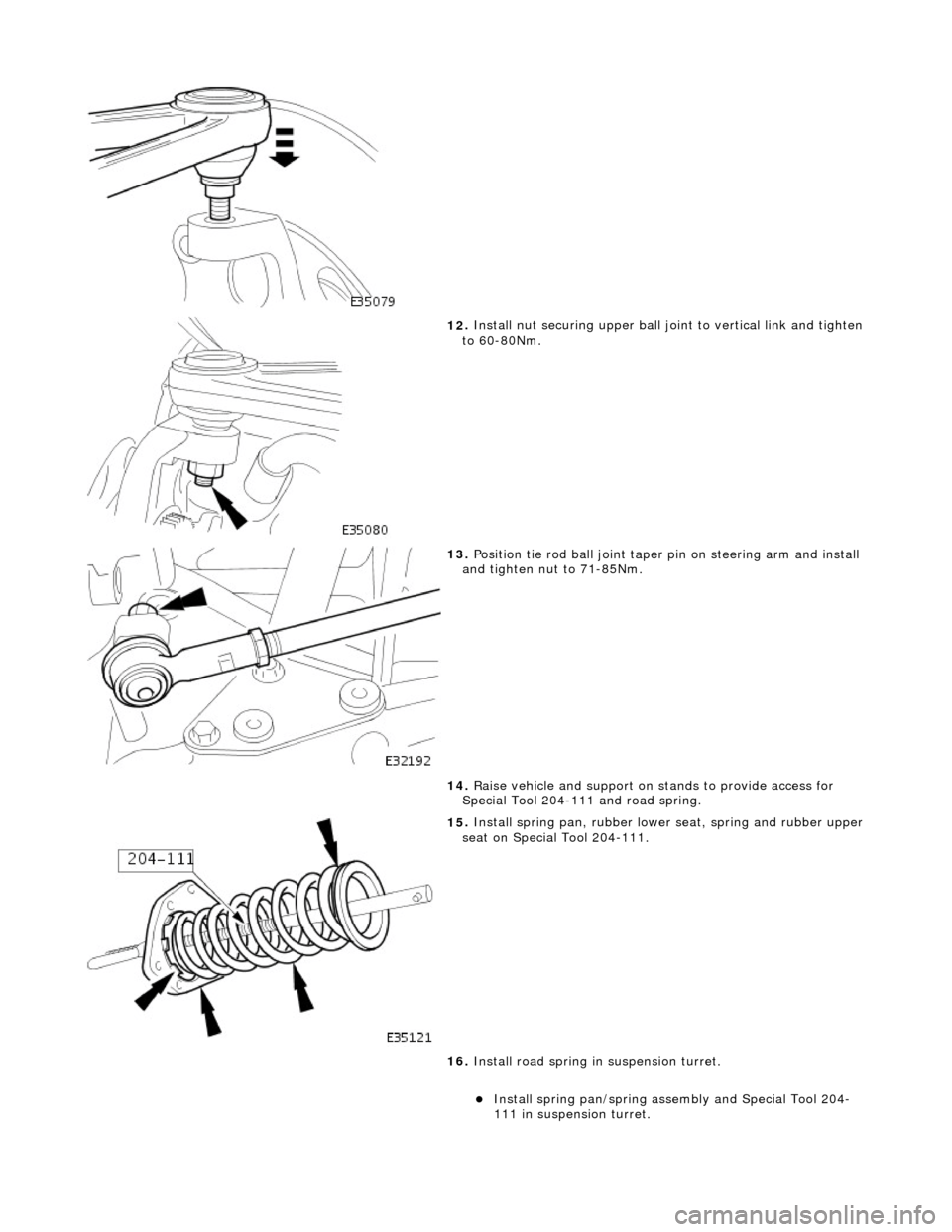

12

.

Install nut securing upper ball jo int to vertical link and tighten

to 60-80Nm.

13

.

Position tie rod ball joint taper pin on steering arm and install

and tighten nut to 71-85Nm.

14. Raise vehicle and support on st ands to provide access for

Special Tool 204-111 and road spring.

15

.

Install spring pan, rubber lowe r seat, spring and rubber upper

seat on Special Tool 204-111.

16. Install road spring in suspension turret.

Install

spring pan/spring as

sembly and Special Tool 204-

111 in suspension turret.