ECU JAGUAR X308 1998 2.G Repair Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 131 of 2490

I

nstallation

14

.

To prevent damage to lower ball joint, secure vertical link to

road spring using strong wire.

15

.

Remove upper wishbone fulcrum nut and shaft and withdraw

wishbone from crossbeam.

16. Secure upper wishbone in a vise.

17

.

Remove bush assemblies from wishbone.

1. Using a drift, remove thru st washer and spacer tube

from each inner and outer half-bush.

2. Remove inner and outer half bushes from wishbone.

Repeat

procedure to remove

remaining bush assembly.

18. Clean wishbone paying particular attention to bush locations.

19. Check that ball joint gaiter is not punctured or deeply

abraded.

1. Install thrust washer and spacer tube in first wishbone half-

bush.

Page 132 of 2490

2. Apply a su

itable lubricant to exterior of each half-bush.

3. Install soft covers to vise jaws.

4. Install half-bush

/spacer tu

be assembly in wishbone.

1. Align half-bush/spacer tube assembly with wishbone bore.

2. Position wishbone and half bush/spacer tube assembly between vise jaws.

Cl

ose vise jaws until half-bush/tube assembly is fully

seated in wishbone.

5. Remove wishbone from vise.

6. Instal

l second half-bush in wishbone.

1. Align and engage second half-bush with installed

spacer tube.

2. Position wishbone and half bush assembly between vise jaws.

Close

vise jaws until second half-bush assembly is fully

seated.

7. Remove wishbone from vise.

8. Following steps 1 to 7, install final bush assembly to wishbone.

9. Inst al

l wishbone on crossbeam.

Posi

ti

on wishbone on crossbeam.

Install

fulcrum shaft with threaded end rearward.

Install nut an

d tighten to 60-80Nm.

10. Remove wire temporarily securing vertical link to road spring.

Page 133 of 2490

11

.

Position wishbone to engage ball joint taper in vertical link.

12

.

Install nut securing ball joint to vertical link and tighten nut to

60-80Nm.

13

.

Reposition wheel speed sensor harness on wishbone and

secure with two tiestraps.

14. Fit road wheel. Refer to Section 100-02

15. Raise vehicle, remove stands and fully lower vehicle.

16. Fully slacken nut on special tool.

Page 136 of 2490

Remova

l

CAUTI

O

N: Replacement of

nuts and bolts: Various thread-locking devises are used on nuts and bolts throughout the

vehicle. These devises restrict the number of times a nut or bolt can be used. See section 100-00 for information.

1 8

G 1004

1.

Re

move vertical link and hub as

sembly. Refer to 60.25.38.90.

2. Re

move brake disc shield from vertical link.

1. Remove screws.

2. Remove disc shield.

3. Us

ing special tool, secure vertical link and hub assembly in a

vise.

Secure special tool

in a vise.

Posit

i

on hub in tool.

Inst

al

l wheel nuts.

4. Re

move rotor nut spring-clip.

5. Remove rotor nut.

Us

ing special tool 206-066A remove rotor nut.

Page 139 of 2490

Inst

all inboard circli

p in vertical link.

5. U

sing a hydraulic press, install hub in vertical link.

1. Position special tool on press bed.

2. Position the vertical link on the tool, with the inboard-side face down.

3. Position hub on bearing.

4. Position a flat steel plate across the face of the hub,

DO NOT place plate ac ross wheel studs.

5. Operate press to install the hub, applying a three-ton

load to ensure hub is fully seated in bearing.

6. U

sing special tool, secure vertical link and hub assembly in a

vise.

Secure special

tool in a vise.

Posit

ion hub in tool.

Inst

all wheel nuts.

7. Install

rotor nut .

1. Install rotor nut on hub.

2. Using special tool tighten rotor nut.

8. CAUTION: Do not slacken the rotor nut to engage the

spring clip.

• NOTE: If the castellated slots of the rotor nut are not aligned,

tighten the rotor nut further unti l the spring clip engages the

Page 142 of 2490

Remova

l

CAUTI

O

N: Replacement of

nuts and bolts: Various thread-locking devises are used on nuts and bolts throughout the

vehicle. These devises restrict the number of times a nut or bolt can be used. Refer to Section 100-00 for further

information.

1 8

G 1004

1.

Ra

ise front of vehicle and support on stands. Refer to Section

100-02.

2. Remove appropriate road wheel. Refer to Section 100-02.

3. Remove front brake disc. Refer to 70.10.12.

4. Remove vertical link and hub assembly. Refer to operation

60.25.38.90.

5. Re

move brake-disc shield from vertical link.

1. Remove screws.

2. Remove disc shield.

6. Us

ing special tool, secure vertical link and hub assembly in a

vise.

Secu re spe

cial tool 204-195 in a vise.

Posit

i

on hub in tool.

Inst

al

l wheel nuts.

7. Remove rotor nut spring-clip.

Page 145 of 2490

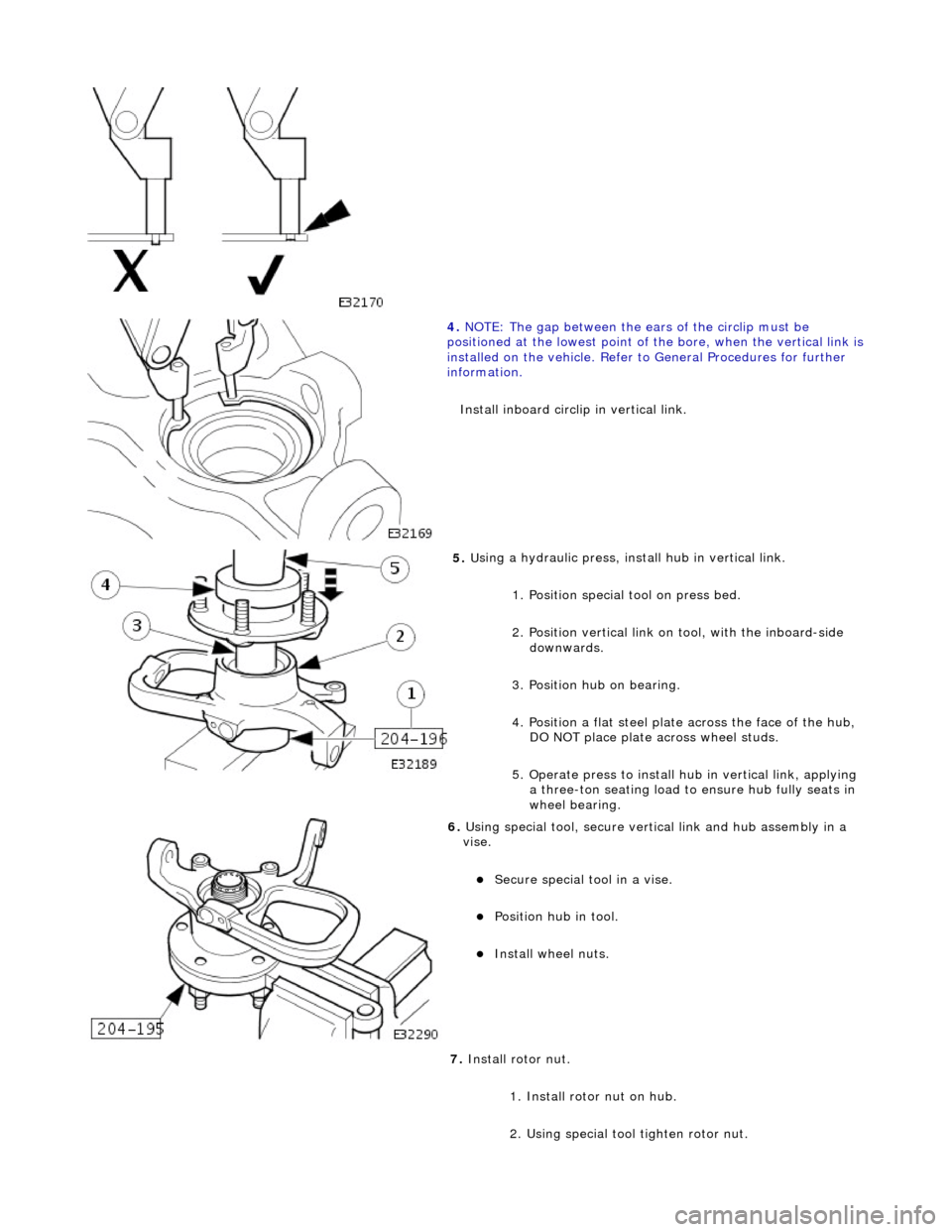

4. NOTE

: The gap between the ears of the circlip must be

positioned at the lowest point of the bore, when the vertical link is

installed on the vehicl e. Refer to General Procedures for further

information.

Install inboard circli p in vertical link.

5. U

sing a hydraulic press, install hub in vertical link.

1. Position special tool on press bed.

2. Position vertical link on tool, with the inboard-side downwards.

3. Position hub on bearing.

4. Position a flat steel plate across the face of the hub,

DO NOT place plate ac ross wheel studs.

5. Operate press to install hu b in vertical link, applying

a three-ton seating load to ensure hub fully seats in

wheel bearing.

6. U

sing special tool, secure vertical link and hub assembly in a

vise.

Secure special

tool in a vise.

Posit

ion hub in tool.

Inst

all wheel nuts.

7. Install rotor nut.

1. Install rotor nut on hub.

2. Using special tool tighten rotor nut.

Page 148 of 2490

Remova

l

CAUTI

O

N: Replacement of

nuts and bolts: Various thread-locking devises are used on nuts and bolts throughout the

vehicle. These devises restrict the number of times a nut or bolt can be used. See section 100-00 for information.

1 8

G 1004

1.

Ra

ise front of vehicle and support on stands. Refer to Section

100-02.

2. Remove appropriate road wheel. Refer to Section 100-02.

3. Remove front brake disc. Refer to 70.10.12.

4. Remove vertical link and hub assembly. Refer to operation

60.25.38.90.

5. Re

move brake-disc shield from vertical link.

1. Remove screws.

2. Remove disc shield.

6. Us

ing special tool, secure vertical link and hub assembly in a

vise.

Secure special tool

in a vise.

Posit

i

on hub in tool.

Inst

al

l wheel nuts.

7. Re

move rotor nut spring-clip.

Page 151 of 2490

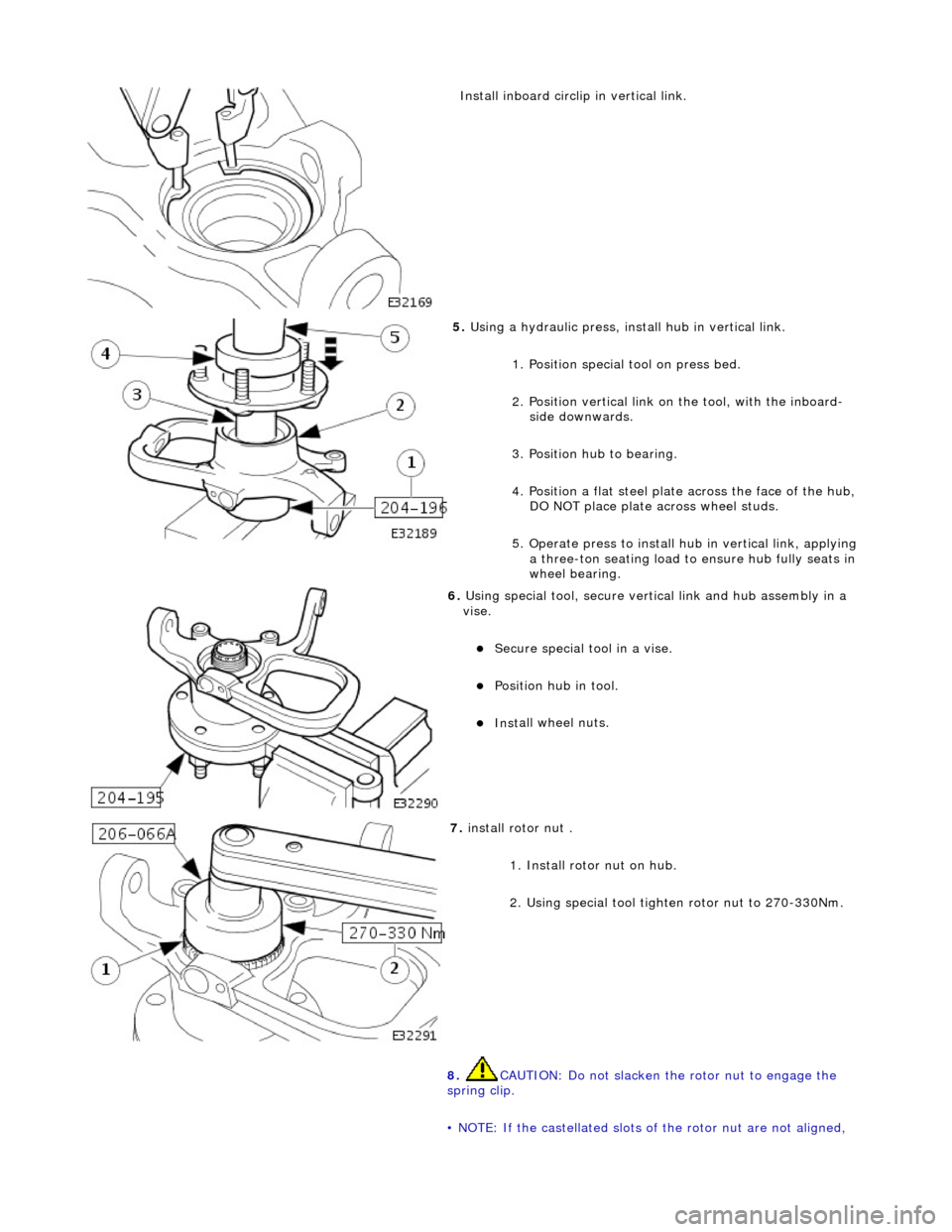

Inst

all inboard circli

p in vertical link.

5. U

sing a hydraulic press, install hub in vertical link.

1. Position special tool on press bed.

2. Position vertical link on the tool, with the inboard-side downwards.

3. Position hub to bearing.

4. Position a flat steel plate across the face of the hub,

DO NOT place plate ac ross wheel studs.

5. Operate press to install hu b in vertical link, applying

a three-ton seating load to ensure hub fully seats in

wheel bearing.

6. U

sing special tool, secure vertical link and hub assembly in a

vise.

Secure special

tool in a vise.

Posit

ion hub in tool.

Inst

all wheel nuts.

7. i

nstall rotor nut .

1. Install rotor nut on hub.

2. Using special tool tighten rotor nut to 270-330Nm.

8. CAUTION: Do not slacken the rotor nut to engage the

spring clip.

• NOTE: If the castellated slots of the rotor nut are not aligned,

Page 153 of 2490

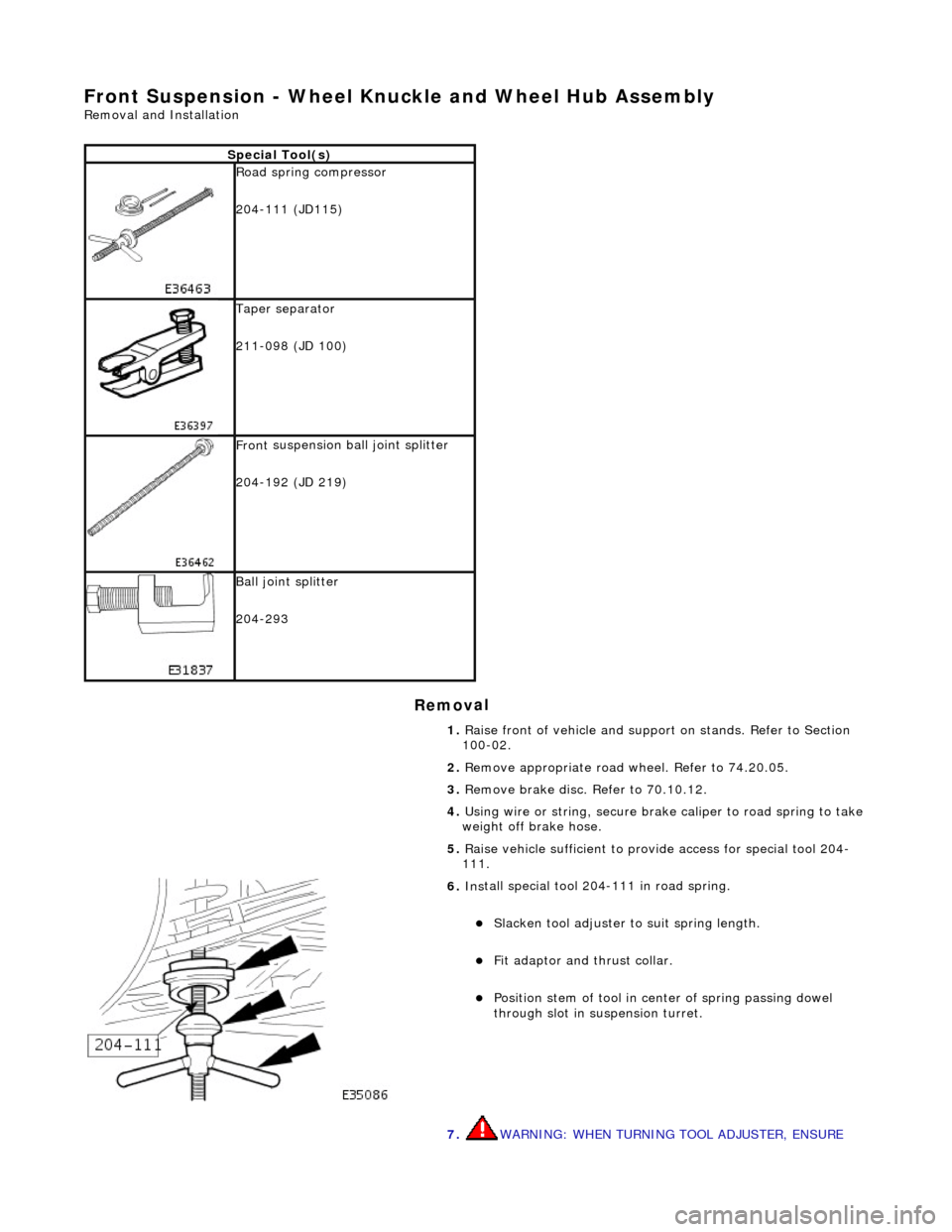

Front Susp

ension - Wheel Knuckle and Wheel Hub Assembly

Re

moval and Installation

Remov

al

S

pecial Tool(s)

R

oad spring compressor

204-111 (JD115)

Taper separator

211-098 (JD 100)

Front

suspension ball joint splitter

204-192 (JD 219)

Bal

l joint splitter

204-293

1. Raise front of vehicle and support on stands. Refer to Section

100-02.

2. Remove appropriate road wheel. Refer to 74.20.05.

3. Remove brake disc. Refer to 70.10.12.

4. Using wire or string, secure brak e caliper to road spring to take

weight off brake hose.

5. Raise vehicle sufficient to provide access for special tool 204-

111.

6. Ins

tall special tool 204-111 in road spring.

Sl

acken tool adjuster to suit spring length.

Fit adaptor and th

rust collar.

Posit

ion stem of tool in center of spring passing dowel

through slot in su spension turret.

7. WARNING: WHEN TURNING TOOL ADJUSTER, ENSURE