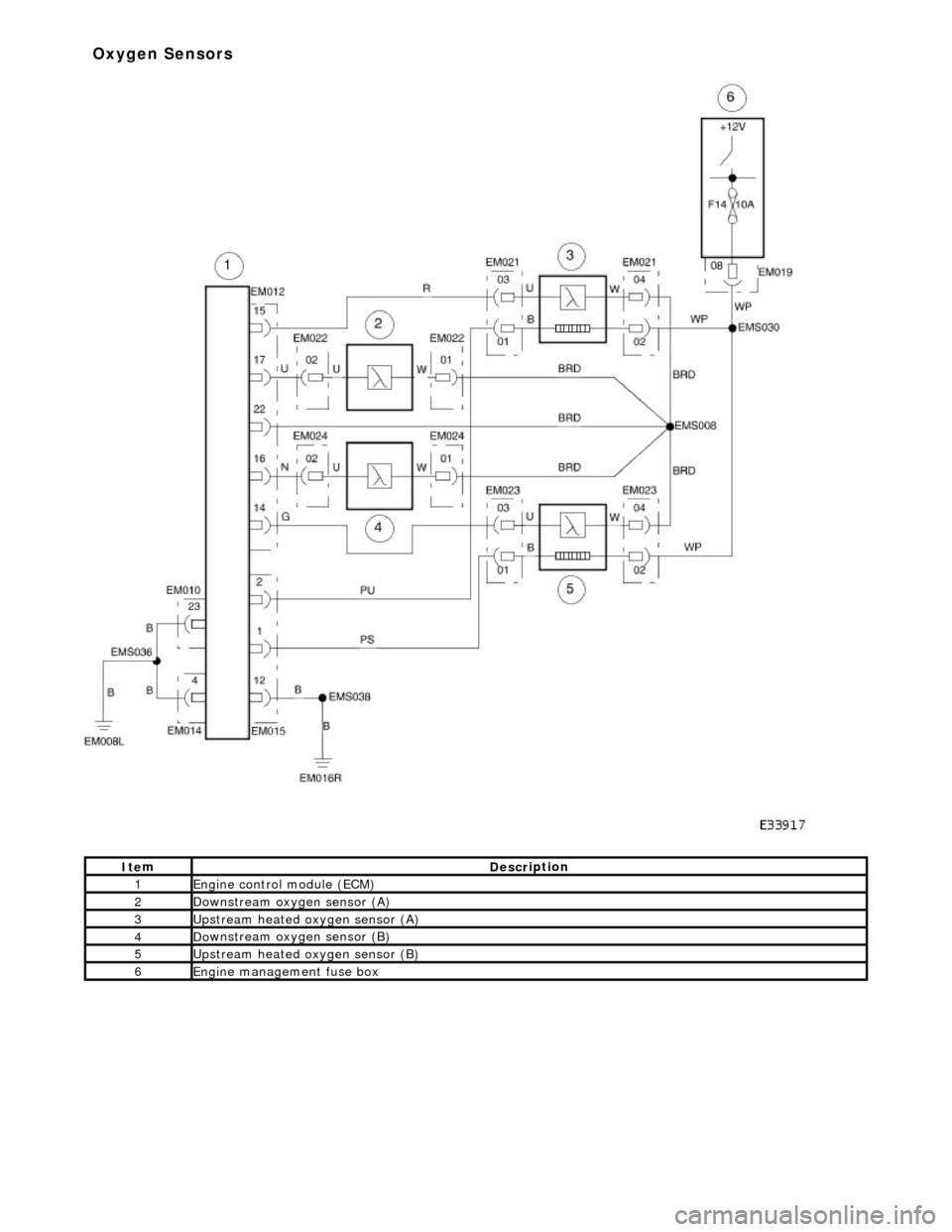

Oxygen Sensor JAGUAR X308 1998 2.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1188 of 2490

It e

m

De

scr

iption

1Engine

c

ontrol

module (ECM)

2Do

wnstream oxygen sensor (A)

3Upstream heated ox

ygen sensor

(A)

4D

o

wnstream oxygen sensor (B)

5Upstream heated ox

ygen sensor (B)

6Engine

management fuse box

Ox

yg

en Sensors

Page 1211 of 2490

Is

the resistance less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to E4

.

E4

: CHECK THE H02S GROUND

CIRCUIT FOR OPEN CIRCUIT

Re

connect the ECM electrical connector, EM12.

1

Meas

ure the resistance between EM21, pin 04 (BRD) and GROUND.

2

Is th

e resistance greater than 5 ohms?

Yes

REPAIR the circuit (this is a braide d lead which would require different repair techniques to standard

wiring). For additional information, refer to the wiring diagrams. CL EAR the DTC. TEST the system for

normal operation.

No INSTALL a new H02S.

REFER to Heated Oxygen Sensor (HO2S) RH

in this section.

CLEAR the DTC. TEST the syst em for normal operation.

PI

NPOINT TEST F : DTC P0133, P0135; RIGHT-HAND H02S HEATER CIRCUIT MALFUNCTION

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

F1:

CHECK THE H02S HEATER POWER SUPPLY CIRCUIT

D

isconnect the H02S electrical connector, EM21.

1

Turn the ignition swi

tch to the ON

position.

2

Meas

ure the voltage between EM21, pin 02 (WP) and GROUND.

3

Is the vol

tage greater than 10 volts?

Yes GO to F2

.

No

REPAIR the circuit. This circuit in cludes the EMS control relay and fu se 14 of the EMS fuse board. For

additional information, refer to the wiring diagrams. CLEAR the DT C. TEST the system for normal

operation.

F2: CHECK THE H02

S HEATER CONTROL CI

RCUIT FROM ECM FOR HIGH RESISTANCE

Di

sconnect the battery negative terminal.

1

D

isconnect the ECM electrical connector, EM15.

2

Me

asure the resistance between EM15, pin 02 (PU) and EM21, pin 01 (PU).

3

Is th

e resistance greater than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No GO to F3

.

F3: CHECK THE H02

S HEATER CONTROL CIRCUI

T FROM ECM FOR SHORT TO HIGH VOLTAGE

R

econnect the battery negative terminal.

1

Turn the ignition swi

tch to the ON

position.

2

Meas

ure the voltage between EM21, pin 01 (PU) and GROUND.

3

Is th

e voltage greater than 3 volts?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to F4

.

F4: CHECK THE H02

S HEATER CONTROL CI

RCUIT FROM ECM FOR SHORT TO GROUND

Turn the ignition swi

tch to the OFF

position.

1

Meas

ure the resistance between EM21, pin 01 (PU) and GROUND.

2

Is

the resistance less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No INSTALL a new H02S.

REFER to Heated Oxygen Sensor (HO2S) RH

in this section.

Page 1213 of 2490

Yes

REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No GO to H2

.

H

2: CHECK THE H02S SENSE CIRCUIT FOR SHORT TO HIGH VOLTAGE

R

econnect the battery negative terminal.

1

Turn the ignition swi

tch to the ON

position.

2

M

easure the voltage between EM12, pin 14 (G) and GROUND.

3

Is th

e voltage greater than 3 volts?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to H3

.

H

3: CHECK THE H02S SENSE CIRCUIT FOR SHORT TO GROUND

Turn the ignition swi

tch to the OFF

position.

1

Meas

ure the resistance between EM12, pin 14 (G) and GROUND.

2

Is

the resistance less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to H4

.

H4:

CHECK THE H02S GROUND CIRCUIT FOR OPEN CIRCUIT

Re

connect the ECM electrical connector, EM12.

1

Meas

ure the resistance between EM23, pin 04 (BRD) and GROUND.

2

Is th

e resistance greater than 5 ohms?

Yes REPAIR the circuit (this is a braide d lead which would require different repair techniques to standard

wiring). For additional information, refer to the wiring diagrams. CL EAR the DTC. TEST the system for

normal operation.

No INSTALL a new H02S.

REFER to Heated Oxygen Sensor (HO2S) RH

in this section.

CLEAR the DTC. TEST the syst em for normal operation.

P

INPOINT TEST I : DTC P0153, P0155; LEFT-HAND H02S HEATER CIRCUIT MALFUNCTION

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

I

1: CHECK H02S HEATER POWER SUPPLY CIRCUIT

D

isconnect the H02S electrical connector, EM23.

1

Turn the ignition swi

tch to the

ON position.

2

Meas

ure the voltage between EM23, pin 02 (WP) and GROUND.

3

Is the vol

tage greater than 10 volts?

Yes GO to I2

.

No

REPAIR the power supply circuit to the H02S heater. This circuit includes the EMS control relay and

fuse 14 of the EMS fuse board. For additional info rmation, refer to the wiring diagrams. CLEAR the

DTC. TEST the system for normal operation.

I

2: CHECK H02S HEATER CONTROL CIRC

UIT FROM ECM FOR HIGH RESISTANCE

Di

sconnect the battery negative terminal.

1

D

isconnect the ECM electrical connector, EM15.

2

Meas

ure the resistance between EM15,

pin 01 (PS) and EM23, pin 01 (PS).

3

Is th

e resistance greater than 5 ohms?

Yes REPAIR the high resistance circuit. For additional information, refer to the wiring diagrams. CLEAR the

DTC. TEST the system for normal operation.

No GO to I3

.

I

3: CHECK H02S HEATER CONTROL CIRCUIT

FROM ECM FOR SHORT TO HIGH VOLTAGE

R

econnect the battery negative terminal.

Page 1214 of 2490

1

Turn the ignition swit

ch to the

ON position.

2

Meas ure t

he voltage between EM23, pin 01 (PS) and GROUND.

3

Is th

e volt

age greater than 3 volts?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to I4

.

I4

: CHECK H02S HEATER CONTROL CIRCUIT FROM ECM FOR SHORT TO GROUND

Turn the ignition swit

ch to the

OFF position.

1

Measure t

he resistance between EM23, pin 01 (PS) and GROUND.

2

Is t

he resistance less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No INSTALL a new H02S.

REFER to Heated Oxygen Sensor (HO2S) LH

in this

section.

CLEAR the DTC. TEST the system for normal operation.

P INPOINT TES

T J : DTC P0157, P0158; LEFT-H

AND CATALYST MONITOR SENSOR LOW/HIGH

VOLTAGE, NO ACTIVITY

TE S

T

CONDITIONS

D E

TAILS/RESULTS/ACTIONS

J

1

: CHECK THE CATALYST MONITOR SENSOR

SENSE CIRCUIT FOR HIGH RESISTANCE

Disc

onnect the battery negative terminal.

1

Di

sc

onnect the catalyst monitor sensor electrical connector, EM24.

2

Disc

onne

ct the ECM electrical connector, EM12.

3

Meas

ure t

he resistance between EM24, pin 02 (N) and EM12, pin 16 (N).

4

Is th

e res

istance greater than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No GO to J2

.

J2

: CHECK THE CATALYST MONITOR SENSOR SENSE CIRCUIT FOR SHORT TO HIGH VOLTAGE

R

e

connect the battery negative terminal.

1

Turn the ignition swi

t

ch to the ON

position.

2

Measure t

he voltage between EM12, pin 16 (N) and GROUND.

3

Is th

e volt

age greater than 3 volts?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to J3

.

J3

: CHECK THE CATALYST MONITOR SENSOR

SENSE CIRCUIT FOR SHORT TO GROUND

Turn the ignition swit

ch to the OFF

position.

1

Measure t

he resistance between EM12, pin 16 (N) and GROUND.

2

Is t

he resistance less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to J4

.

J4

: CHECK THE CATALYST MONITOR SENSOR

GROUND CIRCUIT FOR OPEN CIRCUIT

Reconn

ect the ECM electrical connector, EM12.

1

Meas

ure t

he resistance between EM24, pin 01 (BRD) and GROUND.

2

Is th

e res

istance greater than 5 ohms?

Yes REPAIR the circuit (this is a braide d lead which would require different repair techniques to standard

wiring). For additional information, refer to the wiring diagrams. CL EAR the DTC. TEST the system for

Page 1249 of 2490

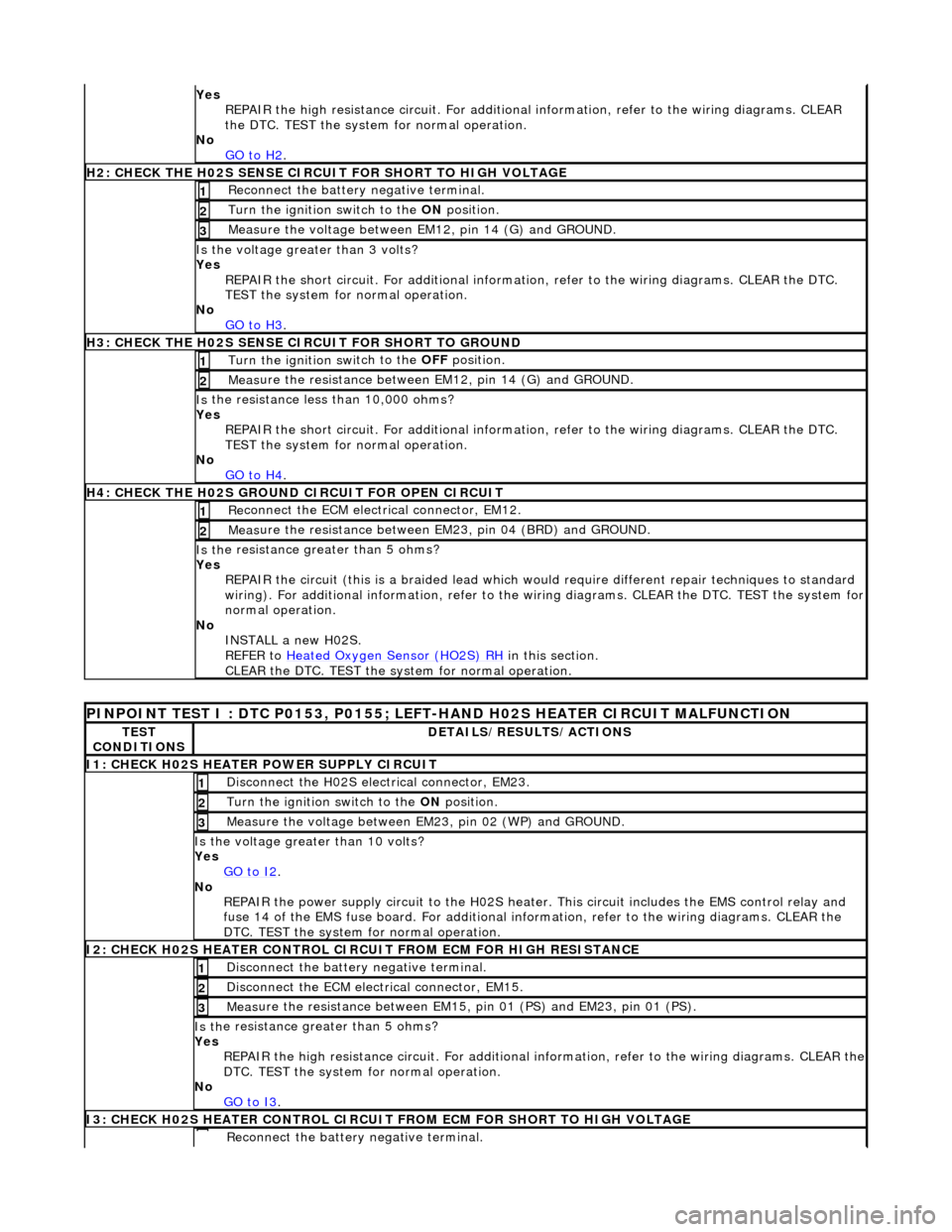

Electron

ic Engine Controls -

Heated Oxygen Sensor (HO2S) LH

Rem

oval and Installation

General Equipment

Remov

al

Installation

Snap

-on tool S6176

1. WARNING: ENSURE THAT TH E EXHAUST AND CATALYST

ARE COLD BEFORE COMMENCING WORK

Disconnect the battery ground lead.

2.

CAUTION: Make sure the wiring harness is not twisted or

damaged on removal. Failure to follow this instruction may result in

damage to the vehicle.

From inside the engine compartm ent, release the relevant sensor

(s) multiplug from its mounting bracket and disconnect the plug.

3.

To gain access to the sensor(s) the front muffler assembly must

be displaced for clearance; refer to 30.10.18.

4.

CAUTION: Make sure the wiring harness is not twisted or

damaged on removal. Failure to follow this instruction may result in

damage to the vehicle.

• NOTE: Right-hand shown, left-hand similar.

Using the Snap-on tool S6176, remove the sensor.

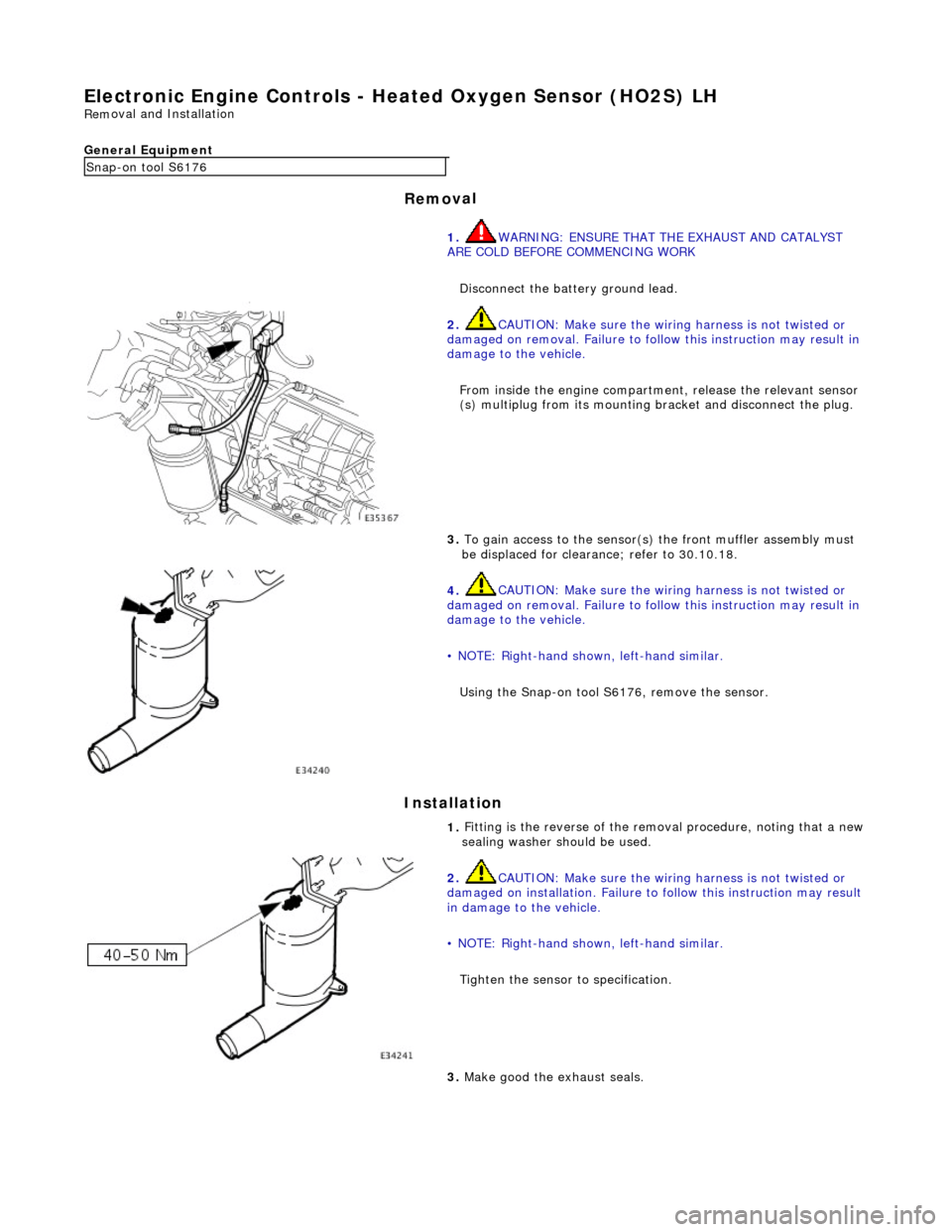

1.

Fitting is the reverse of the remo val procedure, noting that a new

sealing washer should be used.

2.

CAUTION: Make sure the wiring harness is not twisted or

damaged on installation. Failure to follow this instruction may result

in damage to the vehicle.

• NOTE: Right-hand shown, left-hand similar.

Tighten the sensor to specification.

3.

Make good the exhaust seals.

Page 1250 of 2490

Electronic

Engine Controls -

Heated Oxygen Sensor (HO2S) RH

Remo

val and Installation

General Equipment

Remov a

l

Installation

Snap -on to

ol S6176

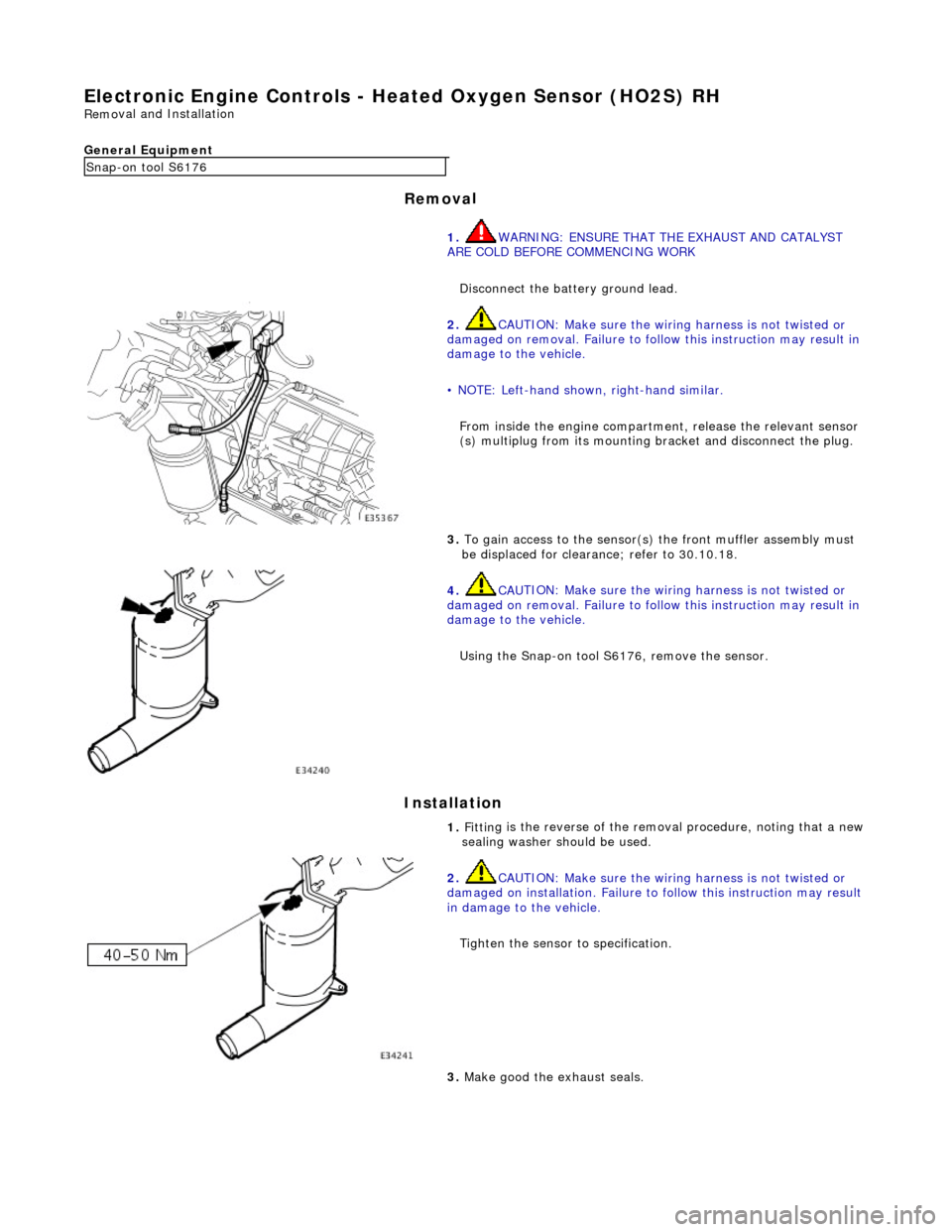

1. WARNING: ENSURE THAT TH E EXHAUST AND CATALYST

ARE COLD BEFORE COMMENCING WORK

Disconnect the battery ground lead.

2. CAU

TION: Make sure the wiring harness is not twisted or

damaged on removal. Failure to follow this instruction may result in

damage to the vehicle.

• NOTE: Left-hand shown, right-hand similar.

From inside the engine compartm ent, release the relevant sensor

(s) multiplug from its mounting bracket and disconnect the plug.

3. To

gain access to the sensor(s)

the front muffler assembly must

be displaced for clearance; refer to 30.10.18.

4. CAU

TION: Make sure the wiring harness is not twisted or

damaged on removal. Failure to follow this instruction may result in

damage to the vehicle.

Using the Snap-on tool S6176, remove the sensor.

1. Fittin

g is the reverse of the remo

val procedure, noting that a new

sealing washer should be used.

2. CAU

TION: Make sure the wiring harness is not twisted or

damaged on installation. Failure to follow this instruction may result

in damage to the vehicle.

Tighten the sensor to specification.

3. M

ake good the exhaust seals.

Page 1522 of 2490

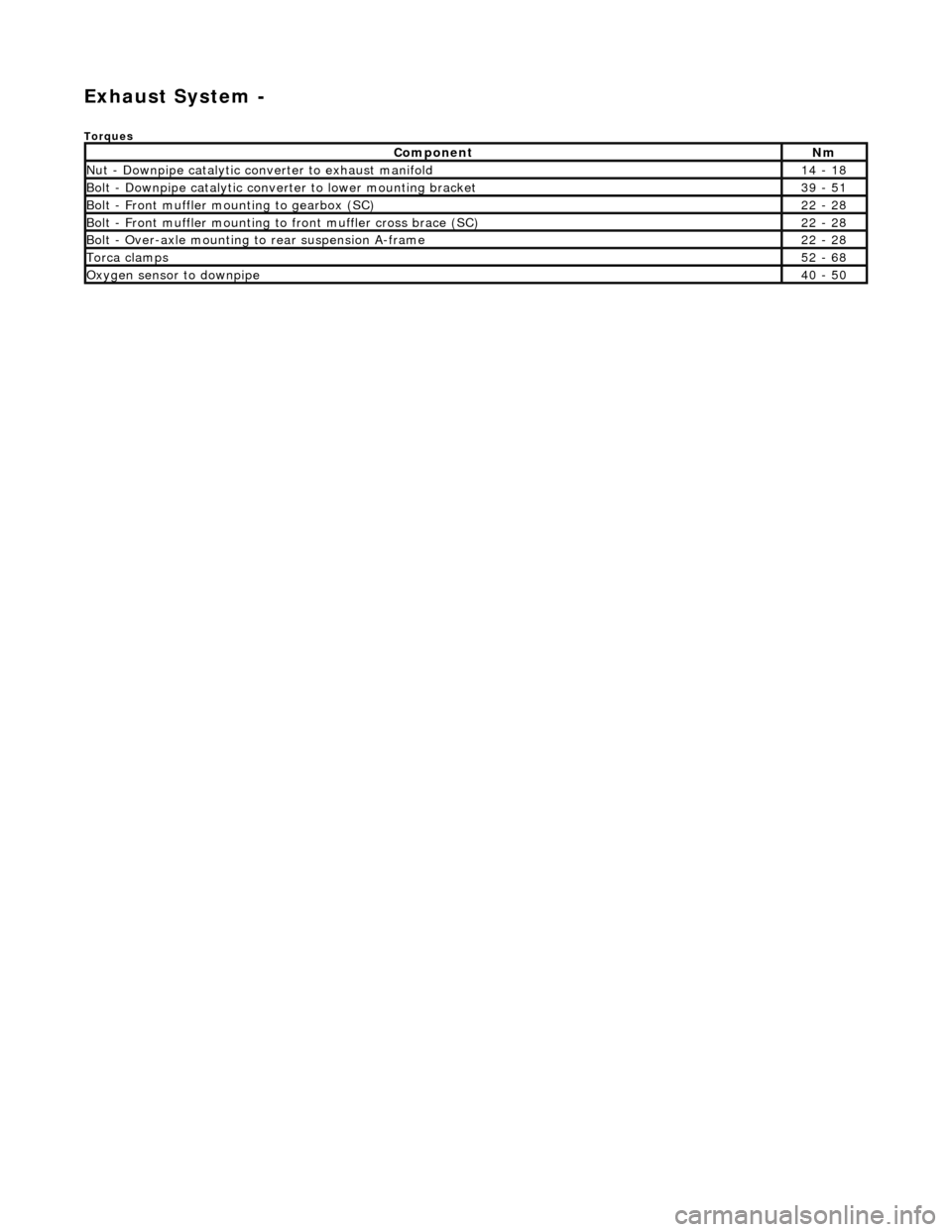

Exhaust System -

Torques

ComponentNm

Nut - Downpipe catalytic converter to exhaust manifold14 - 18

Bolt - Downpipe catalytic converter to lower mounting bracket39 - 51

Bolt - Front muffler mounting to gearbox (SC)22 - 28

Bolt - Front muffler mounting to front muffler cross brace (SC)22 - 28

Bolt - Over-axle mounting to rear suspension A-frame22 - 28

Torca clamps52 - 68

Oxygen sensor to downpipe40 - 50

Page 1525 of 2490

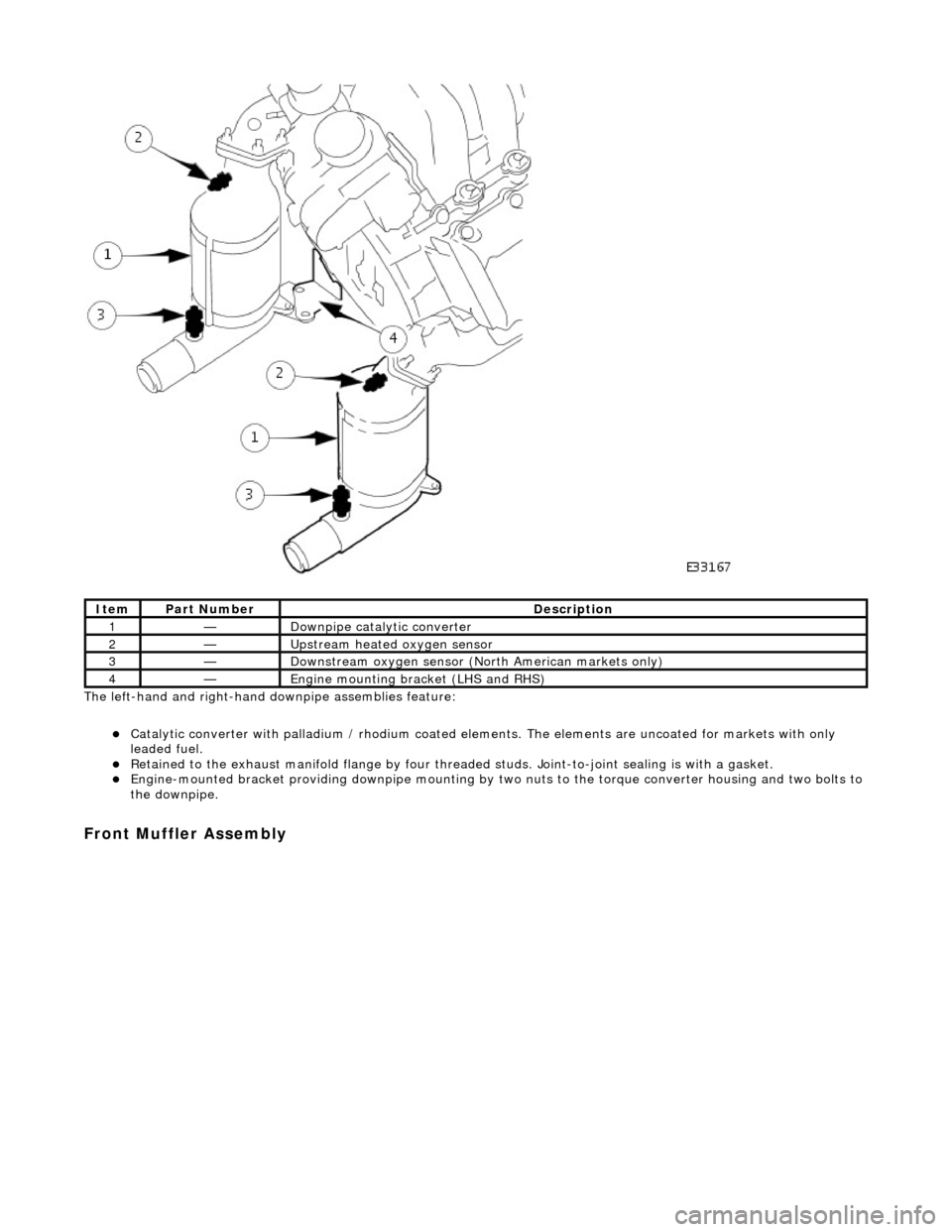

The left-hand and right-hand do wnpipe assemblies feature:

Catalytic converter with palladium / rhodium coated elem ents. The elements are uncoated for markets with only

leaded fuel.

Retained to the exhaust manifold flange by four thread ed studs. Joint-to-joint sealing is with a gasket. Engine-mounted bracket providing downpipe mounting by two nuts to the torque converter housing and two bolts to

the downpipe.

Front Muffler Assembly

ItemPart NumberDescription

1—Downpipe catalytic converter

2—Upstream heated oxygen sensor

3—Downstream oxygen sensor (North American markets only)

4—Engine mounting bracket (LHS and RHS)

Page 1528 of 2490

Joints and Clamps

Pipe-to-pipe joints which are slip joints, feature:

Clamping by Torca strap clamp. Indicator rings providing Maximum, Mini mum and Nominal engagement marks.

Oxygen Sensor (O2)

Location

Page 1529 of 2490

Parts List

Operation

ItemPart NumberDescription

1—Heated oxygen sensor (upstream)

2—Oxygen sensor (downstream)

3—Catalytic converter