WIRING JAGUAR X308 1998 2.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1029 of 2490

ci

rcuit includes the EMS fuse box,

fuse 05, and the fuel injection relay. For additional information,

refer to the wiring diagrams. CLEAR DTC. TEST the system for normal operation.

A4: CHECK

THE INJECTOR GROUND

CIRCUIT FOR HIGH RESISTANCE

Turn the ignition swi

tch to the OFF

position.

1

Di

sconnect the battery negative terminal.

2

D

isconnect the ECM electrical connector, (EM15, vehi

cles with AJ26 engine, EM84, vehicles with AJ27

engine).

3

Meas

ure the resistance between the relevant injector harness electrical connector (IJ03 to IJ10,

vehicles with AJ26 engine, PI07 to PI14, vehicles with AJ27 engine), pin 01 and the ECM electrical

connector, pins as follows -

Vehicles with AJ26 engine:

пЃ¬Cy

l 1 IJ03, pin 01 (BU) and EM15, pin 07

пЃ¬Cy

l 2 IJ07, pin 01 (BU) and EM15, pin 18

пЃ¬Cy

l 3 IJ04, pin 01 (BN) and EM15, pin 17

пЃ¬Cy

l 4 IJ08, pin 01 (BN) and EM15, pin 05

пЃ¬Cy

l 5 IJ05, pin 01 (BG) and EM15, pin 16

пЃ¬Cy

l 6 IJ09, pin 01 (BG) and EM15, pin 04

пЃ¬Cy

l 7 IJ06, pin 01 (BW) and EM15, pin 06

пЃ¬Cy

l 8 IJ10, pin 01 (BW) and EM15, pin 15

Vehicles with AJ27 engine:

пЃ¬Cy

l 1 PI07, pin 01 (B

G) and EM84, pin 02

пЃ¬Cy

l 2 PI11, pin 01 (BW) and EM84, pin 06

пЃ¬Cy

l 3 PI08, pin 01 (BO) and EM84, pin 21

пЃ¬Cy

l 4 PI12, pin 01 (BW) and EM84, pin 04

пЃ¬Cy

l 5 PI09, pin 01 (B

G) and EM84, pin 14

пЃ¬Cy

l 6 PI13, pin 01 (BO) and EM84, pin 03

пЃ¬Cy

l 7 PI10, pin 01 (BW) and EM84, pin 05

пЃ¬Cy

l 8 PI14, pin 01 (BR) and EM84, pin 13

4

Is th

e resistance greater than 5 ohms?

Yes REPAIR the circuit between the relevant injector harness electrical connector pin 01 and the engine

control module electrical connecto r. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No GO to A5

.

A5: CHECK

THE INJECTOR GROUND CI

RCUIT FOR SHORT CIRCUIT TO BATTERY

R

econnect the battery negative terminal.

1

Meas

ure the voltage between the relevant injector harness electrical connector (IJ03 to IJ10, vehicles

with AJ26 engine, PI07 to PI14, vehicles with AJ27 engine), pin 01 and GROUND.

2

Is th

e voltage greater than 3 volts?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to A6

.

A6: CHECK

THE INJECTOR GROUND CI

RCUIT FOR SHORT CIRCUIT TO GROUND

Meas

ure the resistance between the relevant injector harness electrical connector (IJ03 to IJ10,

vehicles with AJ26 engine, PI07 to PI14, vehicles with AJ27 engine), pin 01 and GROUND.

1

Is

the resistance less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No Contact dealer technical support for advice on possible ECM failure.

P

INPOINT TEST B : DTC P0460; FUEL

LEVEL SENSE SIGNAL PERFORMANCE

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

B1: CHECK

THE FUEL LEVEL SENSOR REFERENCE GROUND

Di

sconnect the fuel level sensor electrical connector, BT15.

1

Page 1030 of 2490

Measure t

he resistance

between BT15 and GROUND.

2

Is the res

istance greater than 5 ohms?

Yes GO to B2

.

No

GO to B3

.

B2: CHECK THE FUEL

LEVEL SENSOR REFERE

NCE GROUND CIRCUIT FOR HIGH RESISTANCE

Disc

onnect the instrument cluster electrical connector, FC25.

1

Meas

ure t

he resistance between FC25, pin 14 (RW) and BT15 (RW).

2

Is the res

istance greater than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No GO to B3

.

B3: CHECK THE FUEL

LEVEL SENSOR (EMPTY)

Di

sc

onnect the fuel level sensor electrical connectors, BT14 and BT15.

1

Empty the fuel

tank. 2

Measure t

he resistance between the

fuel level sensor connections.

3

Is t

he resistance 900 ohms?

Yes GO to B4

.

No

INST

ALL a new fuel level sensor.

REFER to Section 310

-0 1

Fuel Tank and Lines

.

CLEAR t h

e DTC. TEST the system for normal operation.

B4:

CHECK

THE FUEL LEVEL SENSOR (FULL)

Fi

ll

the fuel tank.

1

Meas

ure t

he resistance between the

fuel level sensor connections.

2

Is

the resistance 80 ohms?

Yes GO to B5

.

No

INST

ALL a new fuel level sensor.

REFER to Section 310

-0 1

Fuel Tank and Lines

.

CLEAR t h

e DTC. TEST the system for normal operation.

B

5

: CHECK THE FUEL LEVEL SENSOR SIGNAL WIRE FOR HIGH RESISTANCE

Di

sc

onnect the instrument cluster electrical connector, FC25.

1

Meas

ure t

he resistance between FC25, pin 13 (BW) and BT14 (BW).

2

Is th

e res

istance greater than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No INSTALL a new instrument cluster.

REFER to Section 413

-01

Instrume

nt Cluster

.

CLEAR t h

e DTC. TEST the system for normal operation.

P

INPOINT TEST C : DTC P1646; FU

EL PUMP 2 (SC) RELAY MALFUNCTION

•

NO

TE: This DTC applies only to the

supercharged system fuel pump 2.

TES

T

CONDITIONS

D E

TAILS/RESULTS/ACTIONS

C

1

: CHECK THE FUEL PUMP 2 RELAY POWER SUPPLY

R

e

move the fuel pump 2 relay.

1

Turn the ignition swi

t

ch to the

ON position.

2

Meas

ure t

he voltage between the

relay base, pin 01 and GROUND.

3

Is the volt

age less than 10 volts?

Yes REPAIR the circuit between the rela y base, pin 01 and battery. This circuit includes the trunk fuse

box, the ignition positive relay, and the high power protection module. For additional information,

refer to the wiring diagrams. CLEAR the DTC. TEST the system for normal operation.

No GO to C2

.

Page 1031 of 2490

C2: CHECK THE FUEL

PUMP 2 RELAY TO ECM CIRCUIT

Di

sconnect the battery negative terminal.

1

D

isconnect the ECM electrical connector, EM13.

2

Meas

ure the resistance between the rela

y base, pin 02 and EM13, pin 09 (KB).

3

Is th

e resistance greater than 5 ohms?

Yes REPAIR the high resistance circuit. For additional information, refer to the wiring diagrams. CLEAR the

DTC. TEST the system for normal operation.

No INSTALL a new fuel pump 2 relay. CLEAR the DT C. TEST the system for normal operation.

P

INPOINT TEST D : CHECK THE FUEL PRESSURE REGULATOR FUNCTION

CAUTI

ON: Do not run the engine for more than

30 seconds with the vacuum hose disconnected.

T

EST CONDITIONS

D

ETAILS/RESULTS/ACTIONS

D

1: CHECK FOR FUEL PRESSURE CHANGE

WHEN THE REGULATOR IS DISCONNECTED

Connect a

fuel pressure gauge set,

REFER to Section 310

-00

Fuel System

-

General Informati

on

. 1

St

art the engine.

2

N

ote the fuel pressure readin

g with the fuel pressure regu lator vacuum hose connected.

3

Di

sconnect the fuel pressu

re regulator vacuum hose.

4

N

ote the new reading.

5

Doe

s the fuel pressure increase when the hose is disconnected?

Yes Check for DTCs. Carry out the pinpoint tests indicated.

No INSTALL a new fuel presssure regulator. TEST the system for normal operation.

P

INPOINT TEST E : DTC P1230;

FUEL PUMP RELAY MALFUNCTION

•

NOTE: This DTC applies only to the N/A system si

ngle fuel pump, and the S/C system fuel pump 1

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

E1

: CHECK THE FUEL PUMP

RELAY BATTERY SUPPLY

R

emove the fuel pump relay.

1

Meas

ure the voltage between the

relay base, pin 03 and GROUND.

2

Is th

e voltage less than 10 volts?

Yes REPAIR the circuit between the rela y base, pin 03 and the battery power bus. This circuit includes the

trunk fuse box and the high power protection module . For additional information, refer to the wiring

diagrams. CLEAR the DTC. TEST th e system for normal operation.

No GO to E2

.

E2

: CHECK THE FUEL PUMP RELAY IGNITION SWITCHED SUPPLY

Turn the ignition swi

tch to the

ON position.

1

Meas

ure the voltage between the

relay base, pin 01 and GROUND.

2

Is th

e voltage less than 10 volts?

Yes REPAIR the circuit between the rela y base, pin 01 and battery. This circuit includes the trunk fuse box,

fuse 16 of the left-hand fuse box, the ignition po

sitive relay and the high power protection module.

For additional information, refer to the wiring diagrams. CLEAR the DTC. TEST the system for normal

operation.

No GO to E3

.

E3

: CHECK THE FUEL PUMP RELAY TO

ECM CIRCUIT FOR HIGH RESISTANCE

Di

sconnect the battery negative terminal.

1

D

isconnect the ECM electrical connector, EM83.

2

Meas

ure the resistance between EM83, pi

n 04 (WR) and the relay base, pin 02.

3

Is th

e resistance greater than 5 ohms?

Yes REPAIR the high resistance circuit. For additional information, refer to the wiring diagrams. CLEAR the

DTC. TEST the system for normal operation.

No

INSTALL a new fuel pump relay. CLEAR the DTC. TEST the system for normal operation. If the DTC is

repeated, contact dealer technical support for advice on possible ECM failure.

Page 1068 of 2490

Is the res

istance greater than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No GO to B1

.

PINPOINT TES

T B : DTC P1245, P1246; ENGINE CRANK SIGNAL HIGH/LOW VOLTAGE

TE

S

T

CONDITIONS

D E

TAILS/RESULTS/ACTIONS

B1: CHECK

THE STARTER

RELAY 'ACTIV

ATE' SIGNAL AT THE RELAY BASE

Re

move the starter relay.

1

Turn the ignition swi

t

ch to the CRANK

position.

2

Measure t

he resistance between th

e relay base, pin 02 and GROUND.

3

Is the res

istance greater than 5 ohms?

Yes GO to B2

.

No Check t

he starter relay supply circui

ts and relay operation. For additi onal information, refer to the

wiring diagrams. CLEAR the DTC. TEST the system for normal operation.

B2: CHECK THE STARTER

RELAY 'A

CTIVATE' SIGNAL AT THE ECM

Disc

onnect the battery negative terminal.

1

D

i

sconnect the ECM electrical connector (EM11 for vehicles with AJ26 engine

, EM82 for vehicles with

AJ27 engine).

2

R e

connect the battery negative terminal.

Vehicles with AJ26 engine:

пЃ¬Meas ure t

he resistance between EM11, pin 06 (GO) and GROUND

Vehicles with AJ27 engine:

пЃ¬Meas ure t

he resistance between EM82, pin 02 (GO) and GROUND

3

Is th

e res

istance greater than 5 ohms?

Yes GO to B3

.

No

IN

STALL a new starter relay. TEST

the system for normal operation.

B3: CHECK THE STARTER

RELAY/ECM/BPM CIRCUIT FOR HIGH RESISTANCE

Di sc

onnect the battery negative terminal.

1

Disc

onne

ct the BPM electrical connector, FC15.

Vehicles with AJ26 engine:

пЃ¬Meas ure t

he resistance between the relay

base, pin 02 and EM11, pin 06 (GO)

пЃ¬Measure t

he resistance between the relay

base, pin 02 and FC15, pin 73 (GO)

Vehicles with AJ27 engine:

пЃ¬Meas ure t

he resistance between the relay

base, pin 02 and EM82, pin 02 (GO)

пЃ¬Measure t

he resistance between the relay

base, pin 02 and FC15, pin 73 (GO)

2

Is either resistance greater

than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No GO to B4

.

B4: CHECK THE STARTER

RE

LAY/ECM/BPM CIRCUIT FOR SHORT TO HIGH VOLTAGE

Re

connect the battery negative terminal.

1

Meas

ure t

he voltage between the

relay base, pin 02 and GROUND.

2

Is the volt

age greater than 6 volts?

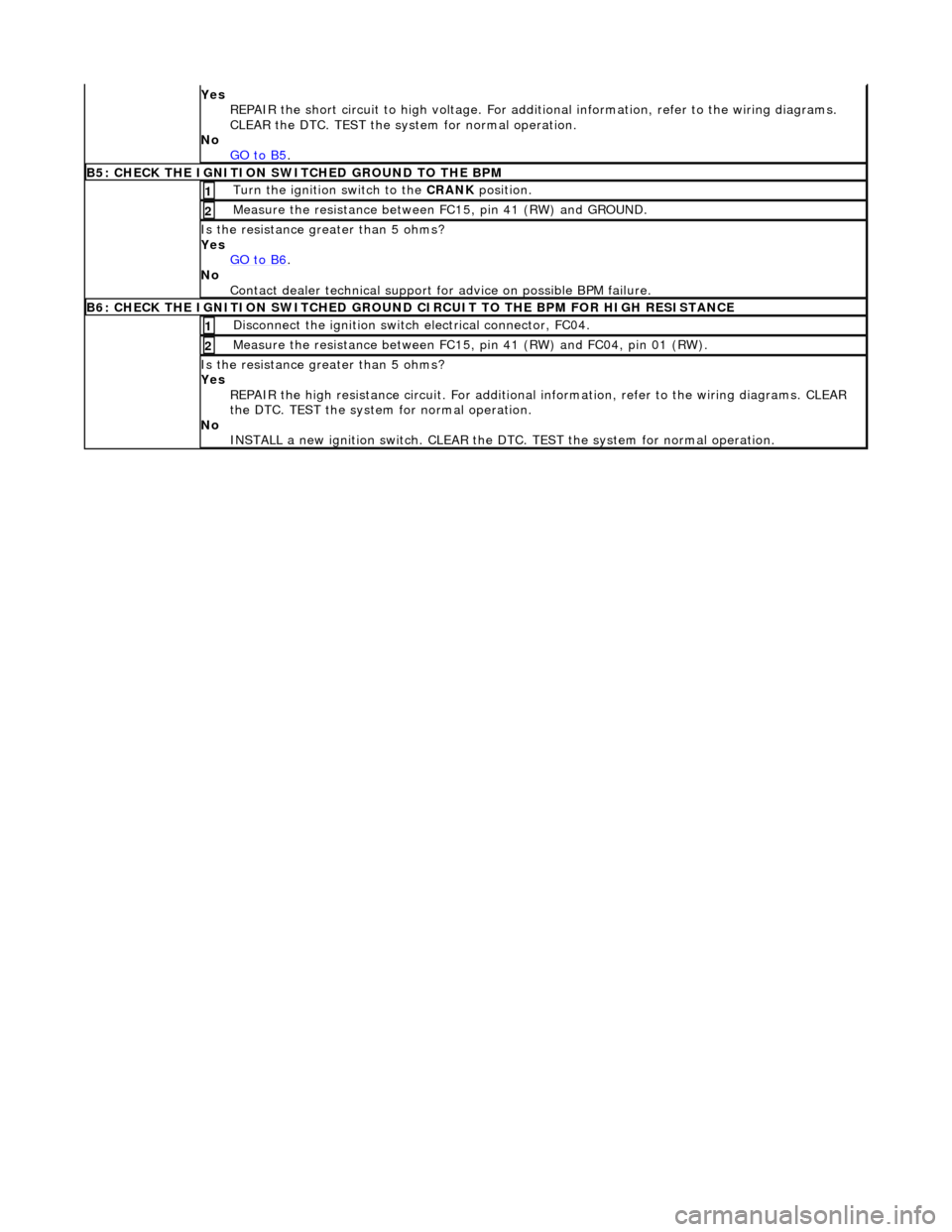

Page 1069 of 2490

Yes

REPAIR the short circuit to high voltage. For addi tional information, refer to the wiring diagrams.

CLEAR the DTC. TEST the syst em for normal operation.

No GO to B5

.

B5: CHECK

THE IGNITION SWITCHED GROUND TO THE BPM

Turn the ignition swi

tch to the CRANK

position.

1

Meas

ure the resistance between FC15, pin 41 (RW) and GROUND.

2

Is th

e resistance greater than 5 ohms?

Yes GO to B6

.

No

Contact dealer technical support fo r advice on possible BPM failure.

B6: CHECK

THE IGNITION SWIT

CHED GROUND CIRCUIT TO THE BPM FOR HIGH RESISTANCE

Di

sconnect the ignition switch electrical connector, FC04.

1

Meas

ure the resistance between FC15,

pin 41 (RW) and FC04, pin 01 (RW).

2

Is th

e resistance greater than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No INSTALL a new ignition switch. CLEAR the DTC. TEST the system for normal operation.

Page 1073 of 2490

Engine Igni

tion -

Engine Ignition

Description an

d Operation

I

gnition coil and spark plug reference

Any positional r

eferences are base

d upon the following convention:

viewing from the driving position, the right-hand cylinder bank is designated bank 1 (A on circuit diagrams) and the left-

hand cylinder bank as bank 2 (B on circuit diagrams).

The cylinder bores of each bank are number ed 1 to 4, from the front of the vehicle.

Ig

nition System

Th

e ignition system provides timing cont

rol in accordance with the engine mana gement strategy and powertrain sensor

inputs; the system consists of:

пЃ¬engine

control module

пЃ¬igni

tion coils supply relay

пЃ¬ignit

ion control modules

пЃ¬igni

tion coils

пЃ¬spark plu

gs

Engine Control Module (ECM)

пЃ¬pr

ovides triggering for the ignition control modules

to control individual firing of the spark plugs

пЃ¬supplies ground for

the igni

tion coils supply relay

I

gnition Coils Supply Relay

The

ignition coils supply relay is located

in the engine and transmission control mo dule compartment; refer to Relay Details

in Electrical Wiring and Circuit Protection, Section 418-01.

The ECM switches a ground to the coil of the ignition coils supply relay; the relay energizes and switches a 12v supply to the

ignition control modules and the ignition coils.

I

gnition Control Modules

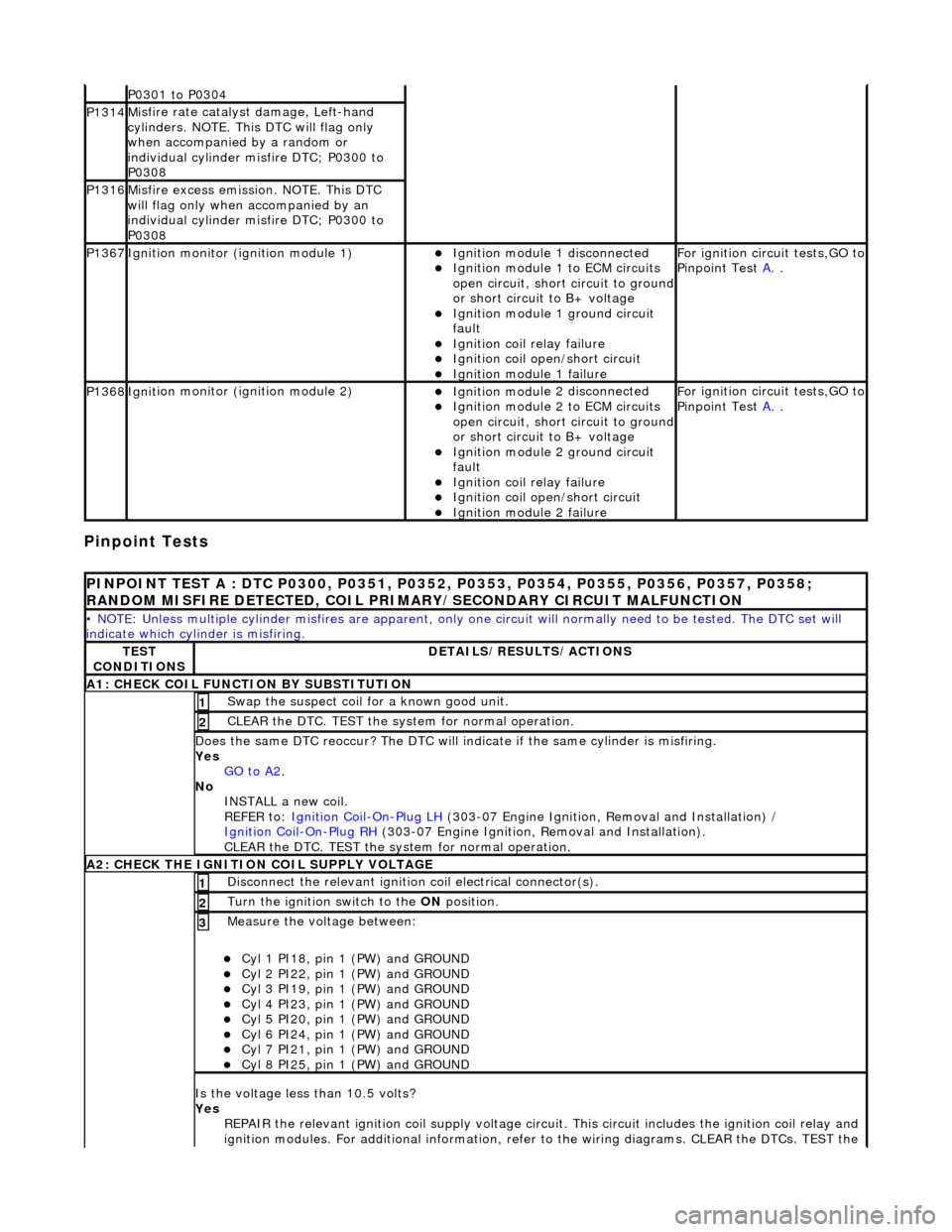

Page 1084 of 2490

Pinpoint Tests

P0301 t

o P0304

P1314M

i

sfire rate catalyst damage, Left-hand

cylinders. NOTE. This DTC will flag only

when accompanied by a random or

individual cylinder misfire DTC; P0300 to

P0308

P1316M i

sfire excess emission. NOTE. This DTC

will flag only when accompanied by an

individual cylinder misfire DTC; P0300 to

P0308

P1367Ignit i

on monitor (ignition module 1)

пЃ¬Ignition modu

le

1 disconnected

пЃ¬Ignition modul e

1 to ECM circuits

open circuit, short circuit to ground

or short circuit to B+ voltage

пЃ¬Ignition modul e

1 ground circuit

fault

пЃ¬Ignition coil relay fai

lure

пЃ¬Ignition coil open/short

circuit

пЃ¬Ignition module

1 failure

F

o

r ignition circuit tests,GO to

Pinpoint Test A.

.

P1368Igniti

on monitor (ignition module 2)

пЃ¬Ignition modu

le

2 disconnected

пЃ¬Ignition modul e

2 to ECM circuits

open circuit, short circuit to ground

or short circuit to B+ voltage

пЃ¬Ignition modul e

2 ground circuit

fault

пЃ¬Ignition coil relay fai

lure

пЃ¬Ignition coil

open/short

circuit

пЃ¬Ignition modul

e

2 failure

F

o

r ignition circuit tests,GO to

Pinpoint Test A.

.

PINPOINT TES

T A : DTC P0300, P0351, P0352, P0353, P0354, P0355, P0356, P0357, P0358;

RANDOM MISFIRE DETECTED, COIL PRIMARY/SECONDARY CIRCUIT MALFUNCTION

• NO

TE: Unless multiple cylinder misfires are apparent, only on

e circuit will normally need to be tested. The DTC set will

indicate which cylinder is misfiring.

TE S

T

CONDITIONS

D E

TAILS/RESULTS/ACTIONS

A1

: CH

ECK COIL FUNCTI

ON BY SUBSTITUTION

Swap the suspect coi l

for a known good unit.

1

CLEAR t

h

e DTC. TEST the syst

em for normal operation.

2

Do

es the same DTC reoccur? The DTC will indicate if the same cylinder is misfiring.

Yes GO to A2

.

No

INST

ALL a new coil.

REFER to: Ignition Coil

-On-Plug

LH

(30

3-07 Engine Ignition, Removal and Installation) /

Ignition Coil

-On-Plu g

RH

(30

3-07 Engine Ignition, Removal and Installation).

CLEAR the DTC. TEST the system for normal operation.

A2: CHECK THE IGNIT

ION COIL SUPPLY VOLTAGE

Disc

onne

ct the relevant ignition

coil electrical connector(s).

1

Turn the ignition swit

ch to the ON

position.

2

Measure the voltage between:

пЃ¬Cyl 1 PI18, pin

1 (PW) and GROUND

пЃ¬Cy

l 2 PI22, pin

1 (PW) and GROUND

пЃ¬Cy

l 3 PI19, pin

1 (PW) and GROUND

пЃ¬Cy

l 4 PI23, pin

1 (PW) and GROUND

пЃ¬Cy

l 5 PI20, pin

1 (PW) and GROUND

пЃ¬Cy

l 6 PI24, pin

1 (PW) and GROUND

пЃ¬Cy

l 7 PI21, pin

1 (PW) and GROUND

пЃ¬Cy

l 8 PI25, pin

1 (PW) and GROUND

3

Is

t

he voltage less than 10.5 volts?

Yes REPAIR the relevant ignition coil su pply voltage circuit. This circuit includes the ignition coil relay and

ignition modules. For additional information, refer to the wiring diagrams. CLEAR the DTCs. TEST the

Page 1085 of 2490

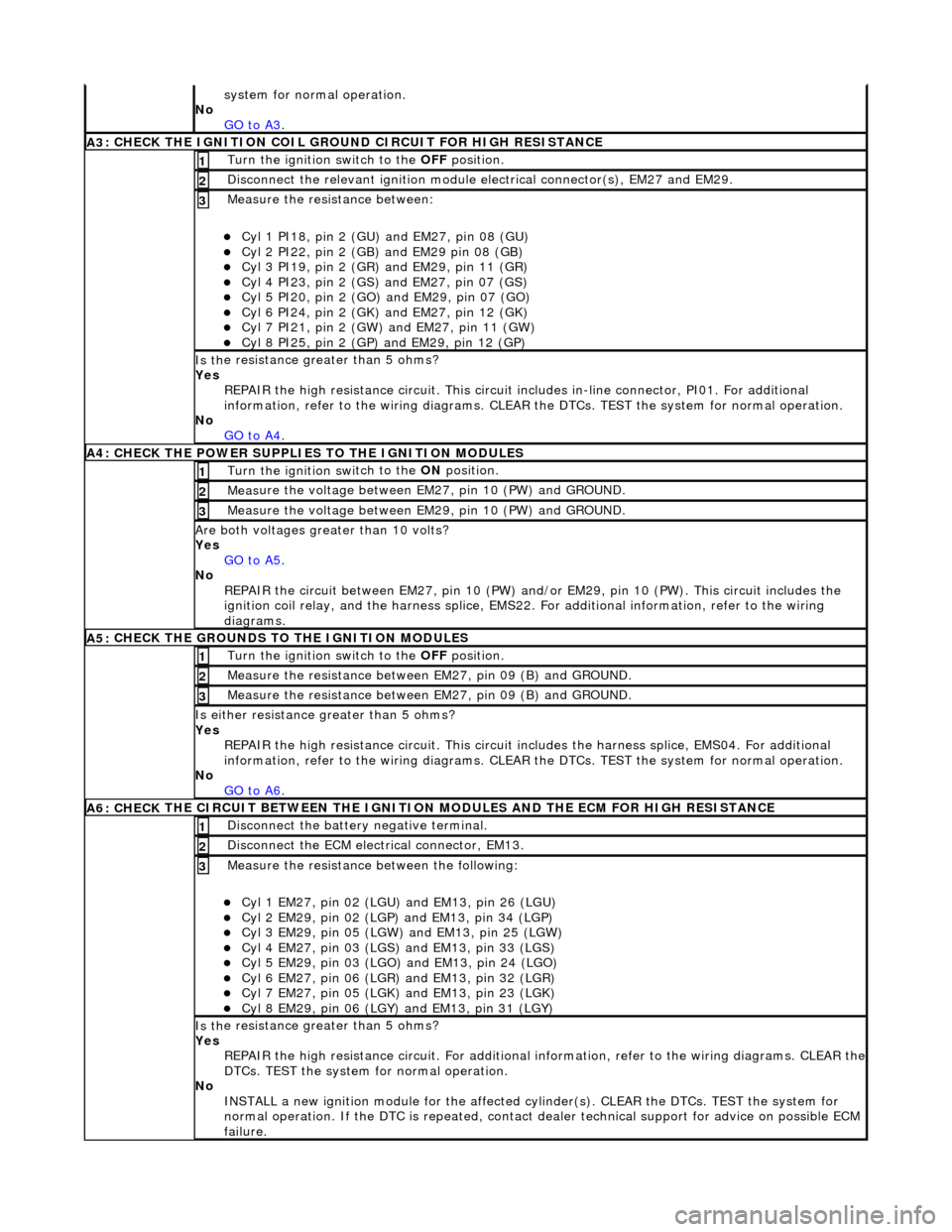

system fo

r normal operation.

No GO to A3

.

A3

: CHECK THE IGNITION COIL GROUND CIRCUIT FOR HIGH RESISTANCE

Turn the ignition swi

tch to the OFF

position.

1

Disc

onnect the relevant ignition module

electrical connector(s), EM27 and EM29.

2

Meas

ure the resistance between:

пЃ¬Cy

l 1 PI18, pin 2 (GU) and EM27, pin 08 (GU)

пЃ¬Cy

l 2 PI22, pin 2 (GB) and EM29 pin 08 (GB)

пЃ¬Cy

l 3 PI19, pin 2 (GR) and EM29, pin 11 (GR)

пЃ¬Cy

l 4 PI23, pin 2 (GS)

and EM27, pin 07 (GS)

пЃ¬Cy

l 5 PI20, pin 2 (GO) and EM29, pin 07 (GO)

пЃ¬Cy

l 6 PI24, pin 2 (GK) and EM27, pin 12 (GK)

пЃ¬Cy

l 7 PI21, pin 2 (GW) and EM27, pin 11 (GW)

пЃ¬Cy

l 8 PI25, pin 2 (GP) an

d EM29, pin 12 (GP)

3

Is th

e resistance greater than 5 ohms?

Yes REPAIR the high resistance circui t. This circuit includes in-line connector, PI01. For additional

information, refer to the wiring diagrams. CLEAR the DTCs. TEST the system for normal operation.

No GO to A4

.

A4:

CHECK THE POWER SUPPLIES TO THE IGNITION MODULES

Turn the ignition swi

tch to the ON

position.

1

Meas

ure the voltage between EM27, pin 10 (PW) and GROUND.

2

Meas

ure the voltage between EM29, pin 10 (PW) and GROUND.

3

Are both

voltages greater than 10 volts?

Yes GO to A5

.

No

REPAIR the circuit between EM27, pin 10 (PW) and/or EM29, pin 10 (PW). This circuit includes the

ignition coil relay, and the harness splice, EMS22. For additional information, refer to the wiring

diagrams.

A5:

CHECK THE GROUNDS TO THE IGNITION MODULES

Turn the ignition swi

tch to the OFF

position.

1

Meas

ure the resistance between EM27, pin 09 (B) and GROUND.

2

Meas

ure the resistance between EM27, pin 09 (B) and GROUND.

3

Is either resi

stance

greater than 5 ohms?

Yes REPAIR the high resistance circui t. This circuit includes the harness splice, EMS04. For additional

information, refer to the wiring diagrams. CLEAR the DTCs. TEST the system for normal operation.

No GO to A6

.

A6: CHECK

THE CIRCUIT BETWEEN THE IGNITION

MODULES AND THE ECM FOR HIGH RESISTANCE

Di

sconnect the battery negative terminal.

1

D

isconnect the ECM electrical connector, EM13.

2

Meas

ure the resistance between the following:

пЃ¬Cy

l 1 EM27, pin 02 (LGU) and EM13, pin 26 (LGU)

пЃ¬Cy

l 2 EM29, pin 02 (LGP) and EM13, pin 34 (LGP)

пЃ¬Cy

l 3 EM29, pin 05 (LGW) and EM13, pin 25 (LGW)

пЃ¬Cy

l 4 EM27, pin 03 (LGS) and EM13, pin 33 (LGS)

пЃ¬Cy

l 5 EM29, pin 03 (LGO) and EM13, pin 24 (LGO)

пЃ¬Cy

l 6 EM27, pin 06 (LGR) and EM13, pin 32 (LGR)

пЃ¬Cy

l 7 EM27, pin 05 (LGK) and EM13, pin 23 (LGK)

пЃ¬Cy

l 8 EM29, pin 06 (LGY) and EM13, pin 31 (LGY)

3

Is th

e resistance greater than 5 ohms?

Yes REPAIR the high resistance circuit. For additional information, refer to the wiring diagrams. CLEAR the

DTCs. TEST the system for normal operation.

No INSTALL a new ignition module for the affected cy linder(s). CLEAR the DTCs. TEST the system for

normal operation. If the DTC is re peated, contact dealer technical support for advice on possible ECM

failure.

Page 1096 of 2490

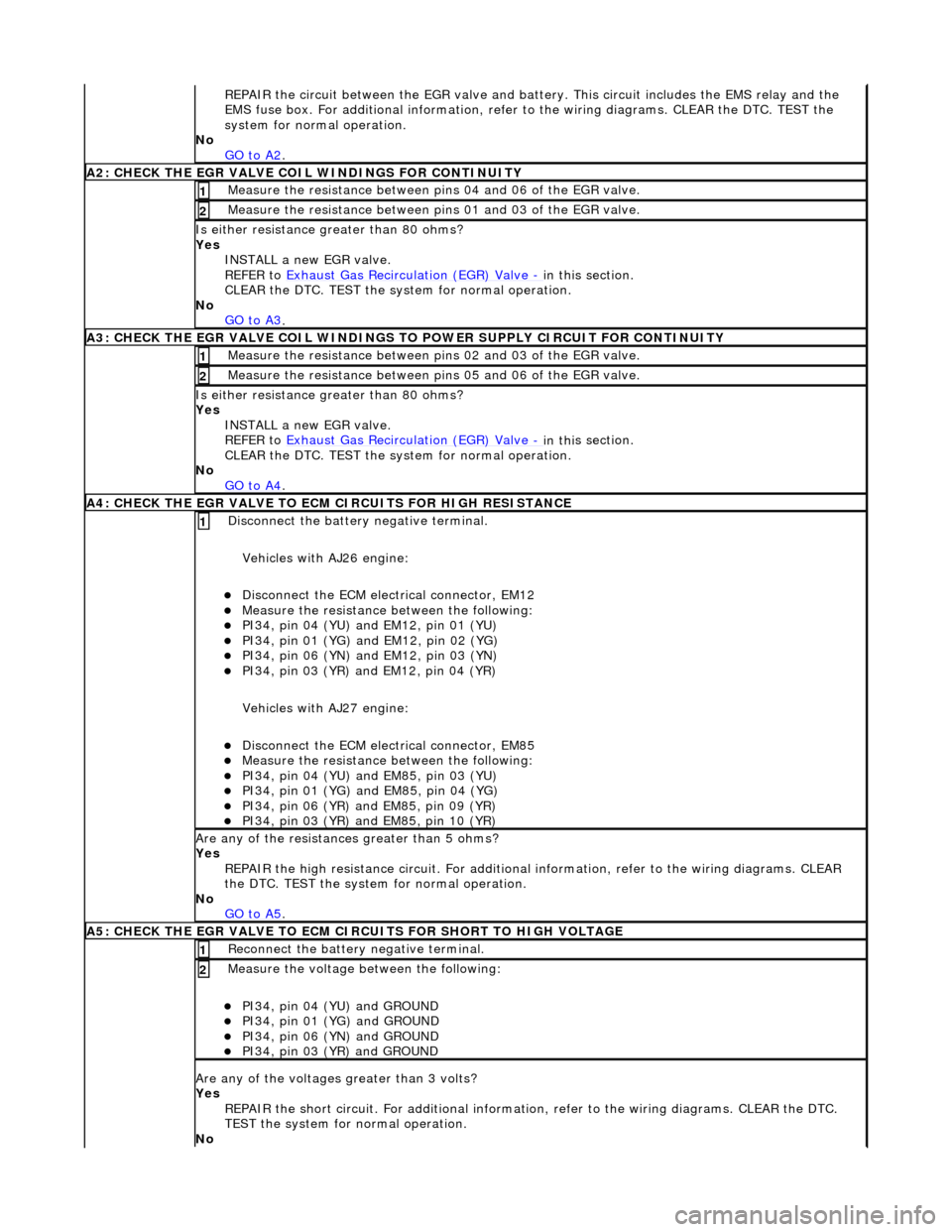

RE

PAIR the circuit between the EGR valve and battery. This circuit includes the EMS relay and the

EMS fuse box. For additional info rmation, refer to the wiring diagrams. CLEAR the DTC. TEST the

system for normal operation.

No GO to A2

.

A2: CHECK THE EGR VALVE COIL WIND

INGS FOR CONTINUITY

Meas

ure t

he resistance between pins 04 and 06 of the EGR valve.

1

Meas

ure t

he resistance between pins 01 and 03 of the EGR valve.

2

Is either resi

stance

greater

than 80 ohms?

Yes INSTALL a new EGR valve.

REFER to Exhaust Gas Recirculation (EGR) Valve

- in thi

s section.

CLEAR the DTC. TEST the syst em for normal operation.

No GO to A3

.

A3: CHECK THE EGR VALVE COIL WINDINGS TO

POWER SUPPLY CIRCUIT FOR CONTINUITY

Meas

ure t

he resistance between pins 02 and 03 of the EGR valve.

1

Meas

ure t

he resistance between pins 05 and 06 of the EGR valve.

2

Is either resi

stance greater

than 80 ohms?

Yes INSTALL a new EGR valve.

REFER to Exhaust Gas Recirculation (EGR) Valve

- in thi

s section.

CLEAR the DTC. TEST the syst em for normal operation.

No GO to A4

.

A4: CHECK THE EGR VALVE T

O ECM

CIRCUITS FOR HIGH RESISTANCE

Disc

onnect the battery negative terminal.

Vehicles with AJ26 engine:

пЃ¬D i

sconnect the ECM electrical connector, EM12

пЃ¬Meas

ure t

he resistance between the following:

пЃ¬PI34, pin

0

4 (YU) and EM12, pin 01 (YU)

пЃ¬PI34,

pi

n 01 (YG) and EM12, pin 02 (YG)

пЃ¬PI34, pin

0

6 (YN) and EM12, pin 03 (YN)

пЃ¬PI34,

pi

n 03 (YR) and EM12, pin 04 (YR)

Vehicles with AJ27 engine:

пЃ¬D i

sconnect the ECM electrical connector, EM85

пЃ¬Meas

ure t

he resistance between the following:

пЃ¬PI34, pin

0

4 (YU) and EM85, pin 03 (YU)

пЃ¬PI34, pi

n 01 (YG) and EM85, pin 04 (YG)

пЃ¬PI34, pi

n 06 (YR) and EM85, pin 09 (YR)

пЃ¬PI34, pi

n 03 (YR) and EM85, pin 10 (YR)

1

Are an

y of the resistances greater than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No GO to A5

.

A5: CHECK THE EGR VALVE T

O ECM CIRCUITS FOR SHORT TO HIGH VOLTAGE

R

e

connect the battery negative terminal.

1

Meas

ure t

he voltage between the following:

пЃ¬PI34, pin

0

4 (YU) and GROUND

пЃ¬PI34, pin

0

1 (YG) and GROUND

пЃ¬PI34, pin

0

6 (YN) and GROUND

пЃ¬PI34, pin

0

3 (YR) and GROUND

2

Are any of th

e volt

ages greater than 3 volts?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No

Page 1097 of 2490

GO to A6.

A6: CHECK

THE EGR VALVE TO ECM

CIRCUITS FOR SHORT TO GROUND

Meas

ure the resistance between the following:

пЃ¬PI34, pin

04 (YU) and GROUND

пЃ¬PI34, pin

01 (YG) and GROUND

пЃ¬PI34, pin

06 (YN) and GROUND

пЃ¬PI34, pin

03 (YR) and GROUND

1

Are

any of the resistances less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No Contact dealer technical support for advice on possible ECM failure.