WIRING JAGUAR X308 1998 2.G Owner's Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1201 of 2490

leak

/blockage

пЃ¬EVAP valve failure

P0444Evaporati

ve emissions system

(EVAP) valve circuit open circuit

пЃ¬EVAP t

o ECM drive circuit open

circuit or high resistance

пЃ¬EVAP failu

re

F

or evaporative emissions pinpoint

tests,

REFER to Section 303

-1

3 Evaporative

Emiss

ions

.

P0445Evaporati

ve emissions system

(EVAP) valve circuit short circuit

пЃ¬E

VAP to ECM drive circuit short

circuit to ground

пЃ¬EVAP failu

re

F

or evaporative emissions pinpoint

tests,

REFER to Section 303

-1

3 Evaporative

Emiss

ions

.

P0447Cani

ster close valve (CCV) circuit

open circuit

пЃ¬CCV to ECM

drive circuit open

circuit, high resi stance or short

circuit to ground

пЃ¬EVAP failu

re

F

or evaporative emissions pinpoint

tests,

REFER to Section 303

-1

3 Evaporative

Emiss

ions

.

P0448Cani

ster close valve (CCV) circuit

short circuit

пЃ¬CCV to

ECM drive circuit short

circuit to high voltage

пЃ¬CCV failure

F

or evaporative emissions pinpoint

tests,

REFER to Section 303

-1

3 Evaporative

Emiss

ions

.

P0452F

uel tank pressure (FTP) sensor

circuit low voltage

пЃ¬FTP

sensor disconnected

пЃ¬FTP

sensor to ECM sense circuit

open circuit or short circuit to

ground

пЃ¬FTP sen

sor to ECM power supply

circuit open circuit or short circuit

to ground

пЃ¬F

TP sensor failure

F

or evaporative emissions pinpoint

tests,

REFER to Section 303

-1

3 Evaporative

Emiss

ions

.

P0453F

uel tank pressure (FTP) sensor

circuit high voltage

пЃ¬FTP

sensor to ECM signal ground

circuit open circuit

пЃ¬F

TP sensor to ECM wiring (supply,

sense, signal, ground) short circuit

to each other

пЃ¬FTP

sensor to ECM sense circuit

short circuit to high voltage

пЃ¬F

TP sensor failure

F

or evaporative emissions pinpoint

tests,

REFER to Section 303

-1

3 Evaporative

Emiss

ions

.

P0460Fue

l level sense signal

performance

пЃ¬Fue

l level sensor

to instrument

cluster circuits in termittent short or

open circuit

пЃ¬F

uel level sensor failure

пЃ¬Instrument cluster

faul

t (incorrect

fuel level data)

F

or fuel level sensor

circuit tests,

REFER to Section 303

-04

Fuel

Charging and Con

trols

.

P0506Idl

e rpm lower than expected

пЃ¬Ai

r intake blockage

пЃ¬Acce

ssory drive overload

(defective/siezed component)

пЃ¬Thr

ottle valve stuck closed

пЃ¬Throttl

e assembly failure

Chec

k the air intake system.

REFER to Section 303

-1

2 Intake Air

Distribu

tion and Filtering

.

Check t

he accessory drive

components,

REFER to Section 303

-0

5 Accessory

Dr

ive

.

F

or throttle body information,

REFER to Section 303

-04

Fuel

Charging and Con

trols

.

P0507Idle rpm

higher than expected

пЃ¬Inta

ke air leak between MAF

sensor and throttle

пЃ¬Inta

ke air leak between throttle

and engine

пЃ¬Engine

breather leak

пЃ¬Cruis

e (speed) control vacuum

failure

пЃ¬Thr

ottle valve stuck open

пЃ¬Throttl

e assembly failure

Chec

k the air intake system.

REFER to Section 303

-1

2 Intake Air

Distribu

tion and Filtering

.

Chec

k the engine breather system,

REFER to Section 303

-08

Engine

Emissi

on Control

.

F

or cruise (speed) control information,

REFER to Section 310

-03

Speed

Control.

F

or throttle body information,

REFER to Section 303

-04

Fuel

Charging and Con

trols

.

P0560Vehicle voltage

malfunction

пЃ¬ECM battery

power supply open

circuit, high resistance

F

or ECM power supply circuit tests,

GO to Pinpoint Test AD.

.

P0566Cruise (speed) contr

ol

CANCEL

switch ON fault

пЃ¬Cru

ise (speed) control switches

internal steering wheel short circuit

to ground

For cru

ise (speed) control circuit tests,

REFER to Section 310

-03

Speed

Page 1207 of 2490

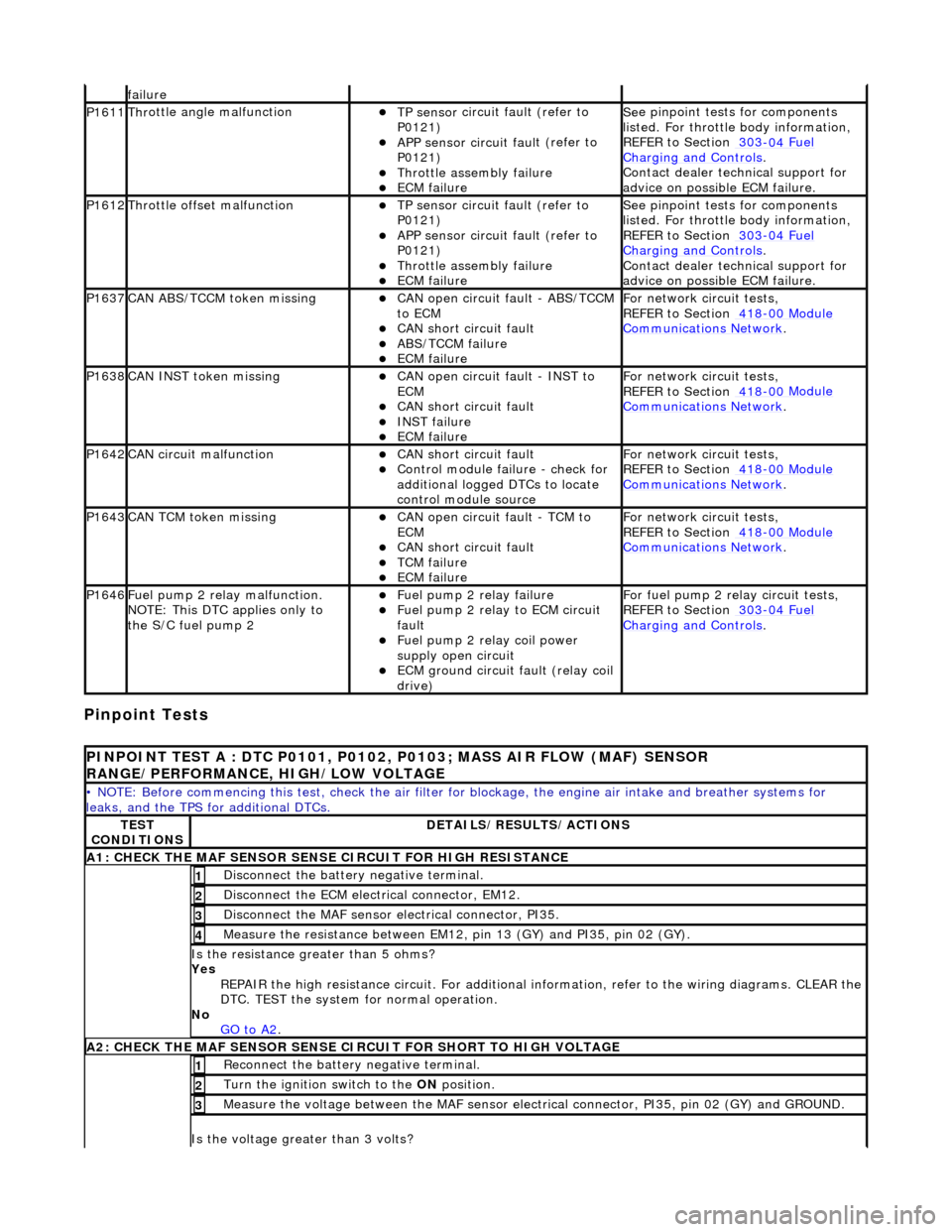

Pinpoint Tests

f

ailure

P1611Thr

ottle angle malfunction

пЃ¬TP sensor

circuit fault (refer to

P0121)

пЃ¬APP sensor circuit faul

t (refer to

P0121)

пЃ¬Throttl

e assembly failure

пЃ¬ECM failu

re

Se

e pinpoint tests for components

listed. For throttle body information,

REFER to Section 303

-04

Fuel

Charging and Con

trols

.

Contact deal

er technical support for

advice on possible ECM failure.

P1612Throttl

e offset malfunction

пЃ¬TP sensor

circuit fault (refer to

P0121)

пЃ¬APP sensor circuit faul

t (refer to

P0121)

пЃ¬Throttl

e assembly failure

пЃ¬ECM failu

re

Se

e pinpoint tests for components

listed. For throttle body information,

REFER to Section 303

-04

Fuel

Charging and Con

trols

.

Contact deal

er technical support for

advice on possible ECM failure.

P1637CAN AB

S/TCCM token missing

пЃ¬CAN

open circuit fault - ABS/TCCM

to ECM

пЃ¬CAN s

hort circuit fault

пЃ¬ABS/TCCM failu

re

пЃ¬ECM failu

re

F

or network circuit tests,

REFER to Section 418

-00

Module

Comm

unications Network

.

P1638CAN INST token missingпЃ¬CAN

open circuit fault - INST to

ECM

пЃ¬CAN s

hort circuit fault

пЃ¬INST

failure

пЃ¬ECM failu

re

F

or network circuit tests,

REFER to Section 418

-00

Module

Comm

unications Network

.

P1642CAN c

ircuit malfunction

пЃ¬CAN s

hort circuit fault

пЃ¬Control modul

e failure - check for

additional logged DTCs to locate

control module source

F

or network circuit tests,

REFER to Section 418

-00

Module

Comm

unications Network

.

P1643CAN TC

M token missing

пЃ¬CAN

open circuit fault - TCM to

ECM

пЃ¬CAN s

hort circuit fault

пЃ¬TCM failure

пЃ¬ECM failu

re

F

or network circuit tests,

REFER to Section 418

-00

Module

Comm

unications Network

.

P1646F

uel pump 2 relay malfunction.

NOTE: This DTC applies only to

the S/C fuel pump 2

пЃ¬F

uel pump 2 relay failure

пЃ¬F

uel pump 2 relay to ECM circuit

fault

пЃ¬F

uel pump 2 relay coil power

supply open circuit

пЃ¬ECM ground circuit faul

t (relay coil

drive)

F

or fuel pump 2 relay circuit tests,

REFER to Section 303

-04

Fuel

Charging and Con

trols

.

P

INPOINT TEST A : DTC P0101, P0102, P0103; MASS AIR FLOW (MAF) SENSOR

RANGE/PERFORMANCE, HIGH/LOW VOLTAGE

•

NOTE: Before commencing this

test, check the air filter for blockage, the engine air inta ke and breather systems for

leaks, and the TPS for additional DTCs.

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

A1: CHECK

THE MAF SENSOR SENS

E CIRCUIT FOR HIGH RESISTANCE

Di

sconnect the battery negative terminal.

1

D

isconnect the ECM electrical connector, EM12.

2

Di

sconnect the MAF sensor electrical connector, PI35.

3

Meas

ure the resistance between EM12, pin 13 (GY) and PI35, pin 02 (GY).

4

Is th

e resistance greater than 5 ohms?

Yes REPAIR the high resistance circuit. For additional information, refer to the wiring diagrams. CLEAR the

DTC. TEST the system for normal operation.

No GO to A2

.

A2: CHECK

THE MAF SENSOR SENSE CI

RCUIT FOR SHORT TO HIGH VOLTAGE

R

econnect the battery negative terminal.

1

Turn the ignition swi

tch to the ON

position.

2

M

easure the voltage between the MAF sensor electrical connector, PI35, pin 02 (GY) and GROUND.

3

Is th

e voltage greater than 3 volts?

Page 1208 of 2490

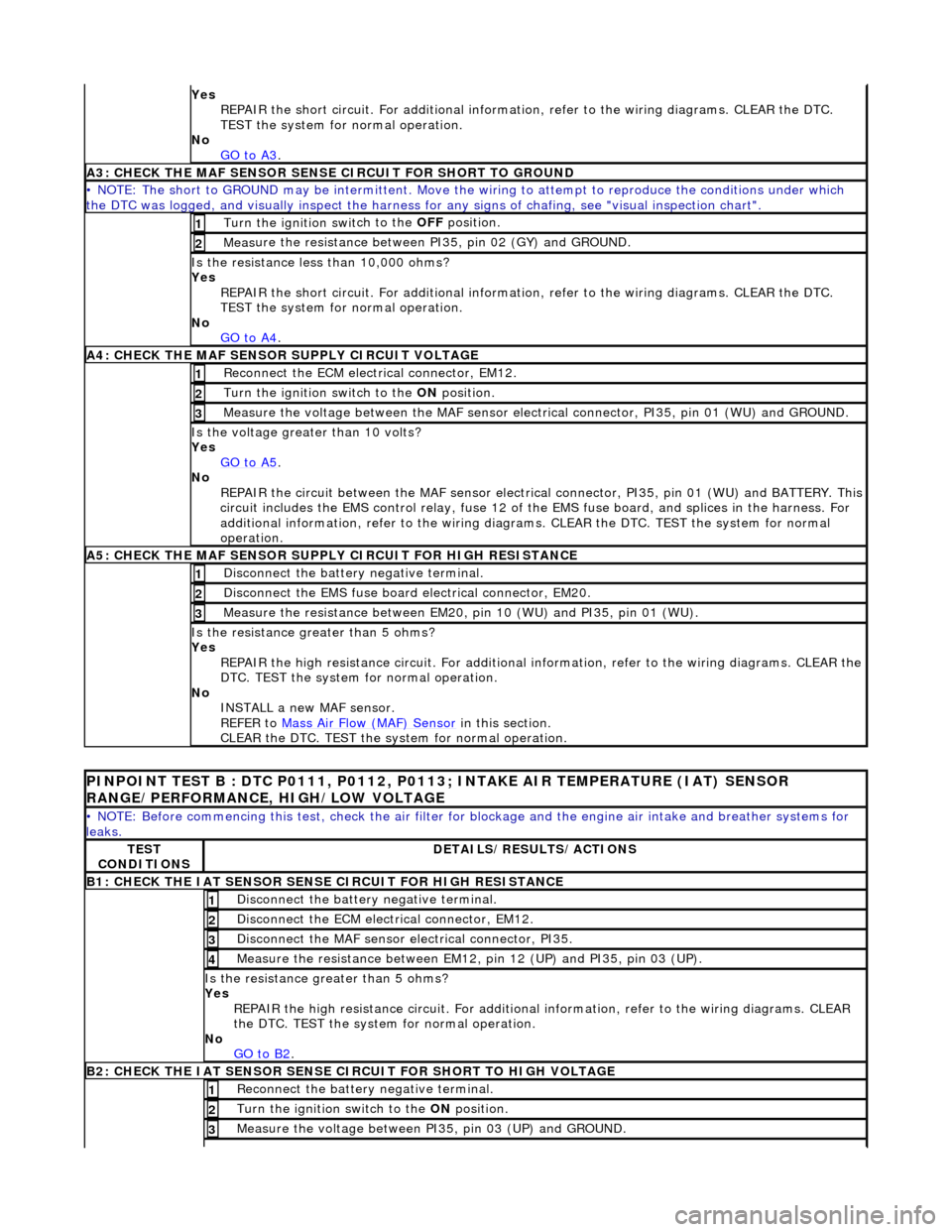

Yes

R

EPAIR the short circuit. For addi

tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to A3

.

A3: CHECK THE MAF SENSO

R SENS

E CIRCUIT FOR SHORT TO GROUND

• NO

TE: The short to GROUND may be intermittent. Move the

wiring to attempt to reproduce the conditions under which

the DTC was logged, and visually inspect the harness for any signs of chafing, see "visual inspection chart".

Turn the ignition swit

ch to the OFF

position.

1

Measure t

he resistance between PI35, pin 02 (GY) and GROUND.

2

Is t

he resistance less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to A4

.

A4: CHEC K THE MA

F SENSOR SUPPLY CIRCUIT VOLTAGE

Re

conn

ect the ECM electrical connector, EM12.

1

Turn the ignition swi

t

ch to the ON

position.

2

Me

asure the voltage between the MAF sensor electrical connector, PI35, pin 01 (WU) and GROUND.

3

Is the vol

t

age greater than 10 volts?

Yes GO to A5

.

No

REP

AIR the circuit between the MAF sensor electric

al connector, PI35, pin 01 (WU) and BATTERY. This

circuit includes the EMS control rela y, fuse 12 of the EMS fuse board, and splices in the harness. For

additional information, refer to the wiring diagrams. CLEAR the DT C. TEST the system for normal

operation.

A5: CHECK THE MAF SENSO

R SUPPLY CIRCUIT FOR HIGH RESISTANCE

Di

sc

onnect the battery negative terminal.

1

Di

sc

onnect the EMS fuse board electrical connector, EM20.

2

Meas

ure t

he resistance between EM20,

pin 10 (WU) and PI35, pin 01 (WU).

3

Is the res

istance greater than 5 ohms?

Yes REPAIR the high resistance circuit. For additional information, refer to the wiring diagrams. CLEAR the

DTC. TEST the system for normal operation.

No INSTALL a new MAF sensor.

REFER to Mass Air Flow (MAF) Sensor

in this

section.

CLEAR the DTC. TEST the system for normal operation.

P INPOINT TES

T B : DTC P0111, P0112, P0113;

INTAKE AIR TEMPERATURE (IAT) SENSOR

RANGE/PERFORMANCE, HIGH/LOW VOLTAGE

•

NOTE: Before commencing this

test, check the air filter for blockage and the engine air intake and breather systems for

leaks.

TE S

T

CONDITIONS

D E

TAILS/RESULTS/ACTIONS

B1: CHECK

THE IAT SENSOR

SENS

E CIRCUIT FOR HIGH RESISTANCE

Disc

onnect the battery negative terminal.

1

D

i

sconnect the ECM electrical connector, EM12.

2

Di

sc

onnect the MAF sensor electrical connector, PI35.

3

Me

asure

the resistance between EM12, pin 12 (UP) and PI35, pin 03 (UP).

4

Is th

e res

istance greater than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No GO to B2

.

B2: CHECK

THE IAT SENSOR SENSE CIRCUIT FOR SHORT TO HIGH VOLTAGE

R

e

connect the battery negative terminal.

1

Turn the ignition swi

t

ch to the ON

position.

2

Measure the voltage between PI 35,

pin 03 (UP) and GROUND.

3

Page 1209 of 2490

Is th

e voltage greater than 3 volts?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to B3

.

B3: CHECK

THE IAT SENSOR SENS

E CIRCUIT FOR SHORT TO GROUND

Turn the ignition swi

tch to the OFF

position.

1

Meas

ure the resistance between PI35, pin 03 (UP) and GROUND.

2

Is

the resistance less than 10,000 ohms?

Yes

REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No INSTALL a new MAF sensor.

REFER to Mass Air Flow (MAF) Sensor

in this section.

CLEAR the DTC. TEST the system for normal operation.

PI

NPOINT TEST C : DTC P0116, P0117, P0118

; ENGINE COOLANT TEMPERATURE (ECT) SENSOR

RANGE/PERFORMANCE, HIGH/LOW VOLTAGE

•

NOTE: Before commencing this

test, check the coolant level and condition, check the operation of the thermostat, rectify

as necessary.

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

C1: CHECK THE ECT SEN

SOR SENS

E CIRCUIT FOR HIGH RESISTANCE

Di

sconnect the battery negative terminal.

1

D

isconnect the ECM electrical connector, EM11.

2

D

isconnect the ECT sensor electrical connector, PI04.

3

Meas

ure the resistance between EM11, pin 09 (UY) and PI04, pin 02 (UY).

4

Is th

e resistance greater than 5 ohms?

Yes

REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No GO to C2

.

C2: CHECK THE ECT SEN

SOR SENSE CI

RCUIT FOR SHORT TO HIGH VOLTAGE

R

econnect the battery negative terminal.

1

Turn the ignition swi

tch to the ON

position.

2

Meas

ure the voltage between PI04, pin 02 (UY) and GROUND.

3

Is th

e voltage greater than 3 volts?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to C3

.

C3: CHECK THE ECT SEN

SOR SENSE CIRCUIT FOR SHORT TO GROUND

Turn the ignition swi

tch to the OFF

position.

1

Meas

ure the resistance between PI04, pin 02 (UY) and GROUND.

2

Is

the resistance less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No INSTALL a new ECT sensor. REFER to Section 303

-0

3A Engine Cooling

/

30

3

-0

3B Supercharger

Coo

ling

. CLEA

R the DTC. TEST the sy

stem for normal operation.

P

INPOINT TEST D : DTC P0121, P0122,

P0123; THROTTLE POSITION (TP) SENSOR

RANGE/PERFORMANCE, HIGH/LOW VOLTAGE

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

D1: CHECK

THE TP SENSOR SENS

E CIRCUIT FOR HIGH RESISTANCE

Di

sconnect the battery negative terminal.

1

Page 1210 of 2490

Di

sconnect the ECM electrical connector, EM11.

2

Disc

onne

ct the TP sensor electrical connector, PI06.

3

Meas

ure t

he resistance between EM11, pin 11 (U) and PI06, pin 03 (U).

4

Is th

e res

istance greater than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No GO to D2

.

D2

: CHECK THE TP SENSOR SENSE CIRCUIT FOR SHORT TO HIGH VOLTAGE

Re

connect the battery negative terminal.

1

Turn the ignition swit

ch to the ON

position.

2

Me

asure the voltage between PI06, pin 03 (U) and GROUND.

3

Is the volt

age greater than 5 volts?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to D3

.

D3: CH

ECK THE TP SENSOR SENSE CIRCUIT FOR SHORT TO GROUND

Turn the ignition swi

t

ch to the OFF

position.

1

Measure t

he resistance between PI06, pin 03 (U) and GROUND.

2

Is

t

he resistance less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No INSTALL a new TP sensor.

REFER to Throttle Position (TP) Sensor

in this

section.

CLEAR the DTC. TEST the syst em for normal operation.

PI

NPOINT TEST E : DTC P0131, P0132, P0133; RIGHT-HAND H02S LOW/HIGH VOLTAGE, SLOW

RESPONSE

•

NOTE: Before commencing this test, check the sensor connect

ions and harness, check for exhaust leaks, engine misfire,

etc. See 'visual inspection ch art' and 'possible causes'.

TES

T

CONDITIONS

D E

TAILS/RESULTS/ACTIONS

E1

: CHECK THE H02S

SENSE CI

RCUIT FOR HIGH RESISTANCE

Disc

onnect the battery negative terminal.

1

D

is

connect the H02S electrical connector, EM21.

2

Disc

onne

ct the ECM electrical connector, EM12

3

Meas

ure t

he resistance between EM21, pin 03 (R) and EM12, pin 15 (R).

4

Is th

e res

istance greater than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No GO to E2

.

E2: CHECK THE H02S

SENSE CIRCUI

T FOR SHORT TO HIGH VOLTAGE

Re

connect the battery negative terminal.

1

Turn the ignition swi

t

ch to the ON

position.

2

Measure t

he voltage between EM12, pin 15 (R) and GROUND.

3

Is th

e volt

age greater than 3 volts?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to E3

.

E3: CHECK THE H02S

SENSE CI

RCUIT FOR SHORT TO GROUND

Turn the ignition swi t

ch to the OFF

position.

1

Measure t

he resistance between EM12, pin 15 (R) and GROUND.

2

Page 1211 of 2490

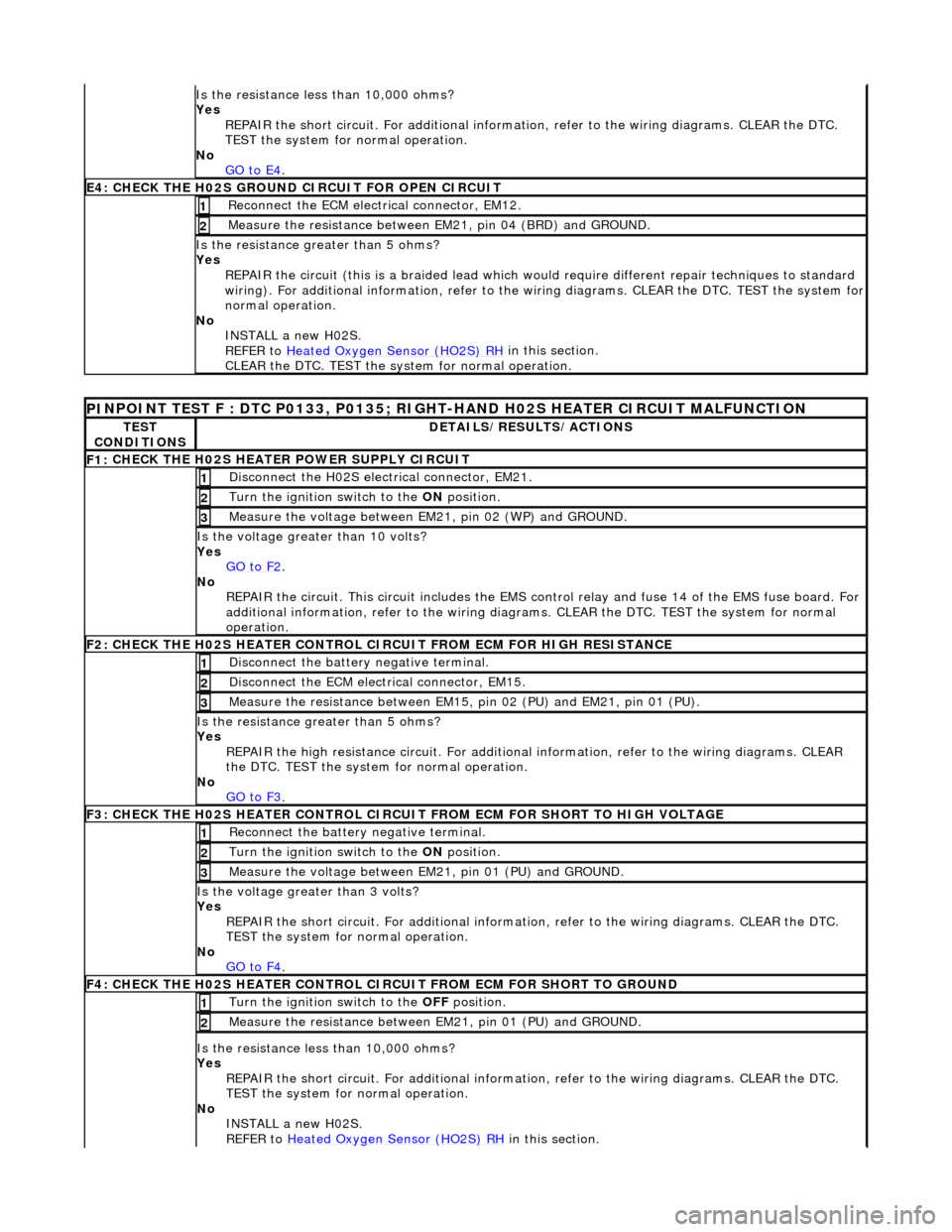

Is

the resistance less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to E4

.

E4

: CHECK THE H02S GROUND

CIRCUIT FOR OPEN CIRCUIT

Re

connect the ECM electrical connector, EM12.

1

Meas

ure the resistance between EM21, pin 04 (BRD) and GROUND.

2

Is th

e resistance greater than 5 ohms?

Yes

REPAIR the circuit (this is a braide d lead which would require different repair techniques to standard

wiring). For additional information, refer to the wiring diagrams. CL EAR the DTC. TEST the system for

normal operation.

No INSTALL a new H02S.

REFER to Heated Oxygen Sensor (HO2S) RH

in this section.

CLEAR the DTC. TEST the syst em for normal operation.

PI

NPOINT TEST F : DTC P0133, P0135; RIGHT-HAND H02S HEATER CIRCUIT MALFUNCTION

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

F1:

CHECK THE H02S HEATER POWER SUPPLY CIRCUIT

D

isconnect the H02S electrical connector, EM21.

1

Turn the ignition swi

tch to the ON

position.

2

Meas

ure the voltage between EM21, pin 02 (WP) and GROUND.

3

Is the vol

tage greater than 10 volts?

Yes GO to F2

.

No

REPAIR the circuit. This circuit in cludes the EMS control relay and fu se 14 of the EMS fuse board. For

additional information, refer to the wiring diagrams. CLEAR the DT C. TEST the system for normal

operation.

F2: CHECK THE H02

S HEATER CONTROL CI

RCUIT FROM ECM FOR HIGH RESISTANCE

Di

sconnect the battery negative terminal.

1

D

isconnect the ECM electrical connector, EM15.

2

Me

asure the resistance between EM15, pin 02 (PU) and EM21, pin 01 (PU).

3

Is th

e resistance greater than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No GO to F3

.

F3: CHECK THE H02

S HEATER CONTROL CIRCUI

T FROM ECM FOR SHORT TO HIGH VOLTAGE

R

econnect the battery negative terminal.

1

Turn the ignition swi

tch to the ON

position.

2

Meas

ure the voltage between EM21, pin 01 (PU) and GROUND.

3

Is th

e voltage greater than 3 volts?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to F4

.

F4: CHECK THE H02

S HEATER CONTROL CI

RCUIT FROM ECM FOR SHORT TO GROUND

Turn the ignition swi

tch to the OFF

position.

1

Meas

ure the resistance between EM21, pin 01 (PU) and GROUND.

2

Is

the resistance less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No INSTALL a new H02S.

REFER to Heated Oxygen Sensor (HO2S) RH

in this section.

Page 1212 of 2490

CLEAR th

e DTC. TEST the syst

em for normal operation.

PINPOINT TES

T G : DTC P0137, P0138; RIGH

T-HAND CATALYST MONITOR SENSOR LOW/HIGH

VOLTAGE, NO ACTIVITY

TE S

T

CONDITIONS

D E

TAILS/RESULTS/ACTIONS

G1

: C

HECK THE CATALYST MONITOR SENSOR SENSE CIRCUIT FOR HIGH RESISTANCE

Di

sc

onnect the battery negative terminal.

1

Di

sc

onnect the catalyst monitor sensor electrical connector, EM22.

2

Disc

onne

ct the ECM electrical connector, EM12.

3

Meas

ure t

he resistance between EM22, pin 02 (U) and EM12, pin 17 (U).

4

Is th

e res

istance greater than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No GO to G2

.

G2: CHECK

THE CATALYST MONITOR SENSOR SE

NSE CIRCUIT FOR SHORT TO HIGH VOLTAGE

Re

connect the battery negative terminal.

1

Turn the ignition swi

t

ch to the ON

position.

2

Measure t

he voltage between EM12, pin 17 (U) and GROUND.

3

Is th

e volt

age greater than 3 volts?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No

GO to G3

.

G3: CHECK

THE CATALYST MONITOR SENSOR

SENSE CIRCUIT FOR SHORT TO GROUND

Turn the ignition swit

ch to the OFF

position.

1

Measure t

he resistance between EM12, pin 17 (U) and GROUND.

2

Is t

he resistance less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to G4

.

G4: CHECK

THE CATALYST MONITOR SENSOR

GROUND CIRCUIT FOR OPEN CIRCUIT

Reconn

ect the ECM electrical connector, EM12.

1

Meas

ure t

he resistance between EM22, pin 01 (BRD) and GROUND.

2

Is th

e res

istance greater than 5 ohms?

Yes REPAIR the circuit (this is a braide d lead which would require different repair techniques to standard

wiring). For additional information, refer to the wiring diagrams. CL EAR the DTC. TEST the system for

normal operation.

No INSTALL a new catalyst monitor sensor.

REFER to Catalyst Monitor Sensor RH

in this

section.

CLEAR the DTC. TEST the syst em for normal operation.

PINPOINT TES

T H : DTC P0151, P0152, P0153;

LEFT-HAND H02S LOW/HIGH VOLTAGE, SLOW

RESPONSE

•

NOTE: Before commencing this test, check the sensor connect

ions and harness, check for exhaust leaks, engine misfire,

etc. See 'visual inspection ch art' and 'possible causes'.

TES

T

CONDITIONS

D E

TAILS/RESULTS/ACTIONS

H1:

C

HECK THE H02S SENSE CIRCUIT FOR HIGH RESISTANCE

Di

sc

onnect the battery negative terminal.

1

D

is

connect the H02S electrical connector, EM23.

2

Disc

onne

ct the ECM electrical connector, EM12.

3

Meas

ure t

he resistance between EM23, pin 03 (G) and EM12, pin 14 (G).

4

Is th

e res

istance greater than 5 ohms?

Page 1213 of 2490

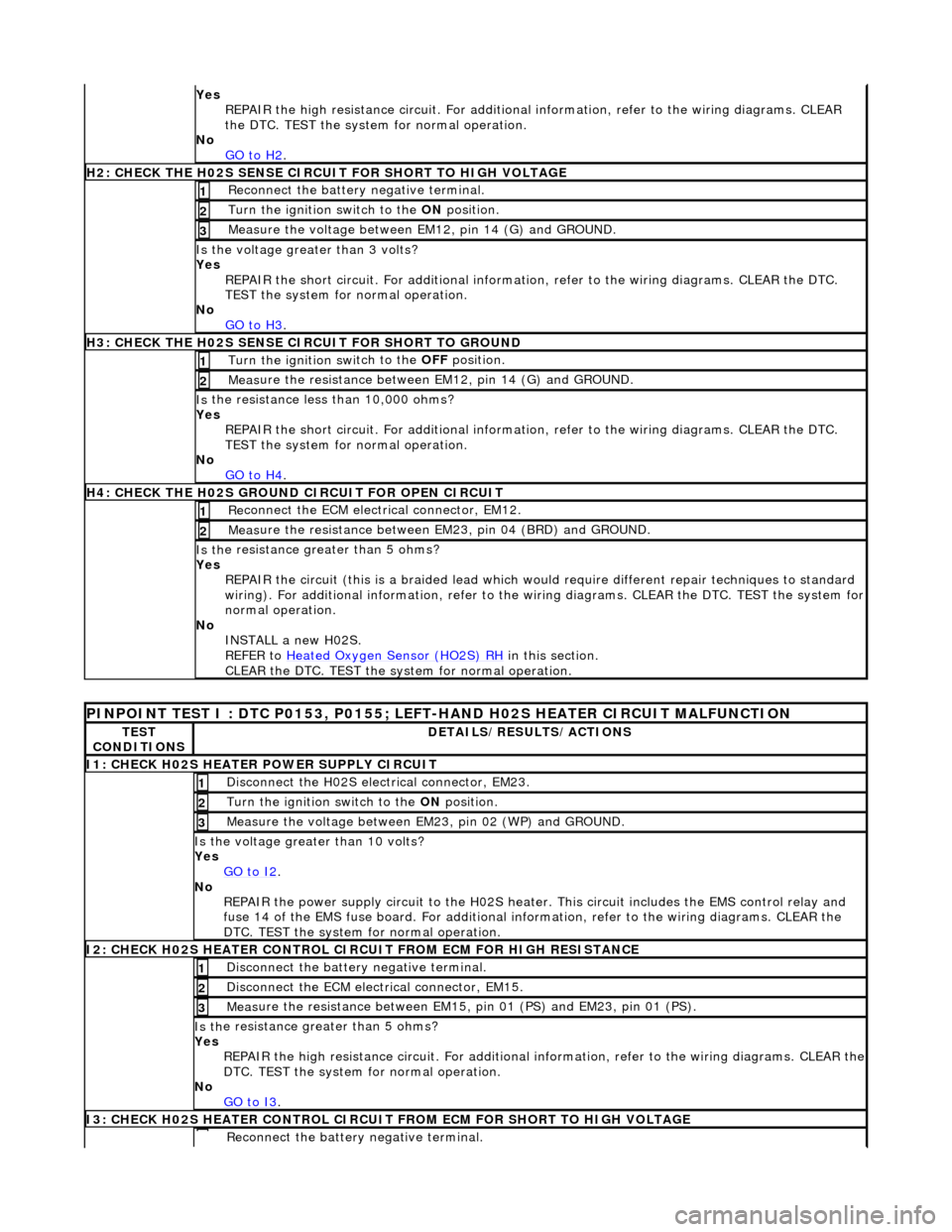

Yes

REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No GO to H2

.

H

2: CHECK THE H02S SENSE CIRCUIT FOR SHORT TO HIGH VOLTAGE

R

econnect the battery negative terminal.

1

Turn the ignition swi

tch to the ON

position.

2

M

easure the voltage between EM12, pin 14 (G) and GROUND.

3

Is th

e voltage greater than 3 volts?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to H3

.

H

3: CHECK THE H02S SENSE CIRCUIT FOR SHORT TO GROUND

Turn the ignition swi

tch to the OFF

position.

1

Meas

ure the resistance between EM12, pin 14 (G) and GROUND.

2

Is

the resistance less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to H4

.

H4:

CHECK THE H02S GROUND CIRCUIT FOR OPEN CIRCUIT

Re

connect the ECM electrical connector, EM12.

1

Meas

ure the resistance between EM23, pin 04 (BRD) and GROUND.

2

Is th

e resistance greater than 5 ohms?

Yes REPAIR the circuit (this is a braide d lead which would require different repair techniques to standard

wiring). For additional information, refer to the wiring diagrams. CL EAR the DTC. TEST the system for

normal operation.

No INSTALL a new H02S.

REFER to Heated Oxygen Sensor (HO2S) RH

in this section.

CLEAR the DTC. TEST the syst em for normal operation.

P

INPOINT TEST I : DTC P0153, P0155; LEFT-HAND H02S HEATER CIRCUIT MALFUNCTION

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

I

1: CHECK H02S HEATER POWER SUPPLY CIRCUIT

D

isconnect the H02S electrical connector, EM23.

1

Turn the ignition swi

tch to the

ON position.

2

Meas

ure the voltage between EM23, pin 02 (WP) and GROUND.

3

Is the vol

tage greater than 10 volts?

Yes GO to I2

.

No

REPAIR the power supply circuit to the H02S heater. This circuit includes the EMS control relay and

fuse 14 of the EMS fuse board. For additional info rmation, refer to the wiring diagrams. CLEAR the

DTC. TEST the system for normal operation.

I

2: CHECK H02S HEATER CONTROL CIRC

UIT FROM ECM FOR HIGH RESISTANCE

Di

sconnect the battery negative terminal.

1

D

isconnect the ECM electrical connector, EM15.

2

Meas

ure the resistance between EM15,

pin 01 (PS) and EM23, pin 01 (PS).

3

Is th

e resistance greater than 5 ohms?

Yes REPAIR the high resistance circuit. For additional information, refer to the wiring diagrams. CLEAR the

DTC. TEST the system for normal operation.

No GO to I3

.

I

3: CHECK H02S HEATER CONTROL CIRCUIT

FROM ECM FOR SHORT TO HIGH VOLTAGE

R

econnect the battery negative terminal.

Page 1214 of 2490

1

Turn the ignition swit

ch to the

ON position.

2

Meas ure t

he voltage between EM23, pin 01 (PS) and GROUND.

3

Is th

e volt

age greater than 3 volts?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to I4

.

I4

: CHECK H02S HEATER CONTROL CIRCUIT FROM ECM FOR SHORT TO GROUND

Turn the ignition swit

ch to the

OFF position.

1

Measure t

he resistance between EM23, pin 01 (PS) and GROUND.

2

Is t

he resistance less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No INSTALL a new H02S.

REFER to Heated Oxygen Sensor (HO2S) LH

in this

section.

CLEAR the DTC. TEST the system for normal operation.

P INPOINT TES

T J : DTC P0157, P0158; LEFT-H

AND CATALYST MONITOR SENSOR LOW/HIGH

VOLTAGE, NO ACTIVITY

TE S

T

CONDITIONS

D E

TAILS/RESULTS/ACTIONS

J

1

: CHECK THE CATALYST MONITOR SENSOR

SENSE CIRCUIT FOR HIGH RESISTANCE

Disc

onnect the battery negative terminal.

1

Di

sc

onnect the catalyst monitor sensor electrical connector, EM24.

2

Disc

onne

ct the ECM electrical connector, EM12.

3

Meas

ure t

he resistance between EM24, pin 02 (N) and EM12, pin 16 (N).

4

Is th

e res

istance greater than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No GO to J2

.

J2

: CHECK THE CATALYST MONITOR SENSOR SENSE CIRCUIT FOR SHORT TO HIGH VOLTAGE

R

e

connect the battery negative terminal.

1

Turn the ignition swi

t

ch to the ON

position.

2

Measure t

he voltage between EM12, pin 16 (N) and GROUND.

3

Is th

e volt

age greater than 3 volts?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to J3

.

J3

: CHECK THE CATALYST MONITOR SENSOR

SENSE CIRCUIT FOR SHORT TO GROUND

Turn the ignition swit

ch to the OFF

position.

1

Measure t

he resistance between EM12, pin 16 (N) and GROUND.

2

Is t

he resistance less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to J4

.

J4

: CHECK THE CATALYST MONITOR SENSOR

GROUND CIRCUIT FOR OPEN CIRCUIT

Reconn

ect the ECM electrical connector, EM12.

1

Meas

ure t

he resistance between EM24, pin 01 (BRD) and GROUND.

2

Is th

e res

istance greater than 5 ohms?

Yes REPAIR the circuit (this is a braide d lead which would require different repair techniques to standard

wiring). For additional information, refer to the wiring diagrams. CL EAR the DTC. TEST the system for

Page 1215 of 2490

normal operation

.

No INSTALL a new catalyst monitor sensor.

REFER to Catalyst Monitor Sensor LH

in this section.

CLEAR the DTC. TEST the syst em for normal operation.

P

INPOINT TEST K : DTC P0222, P0223; THRO

TTLE POSITION (TP) SENSOR CIRCUIT 2 LOW

VOLTAGE

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

K

1: CHECK TP SENSOR 2 SENSE CIRCUIT FOR HIGH RESISTANCE

Di

sconnect the battery negative terminal.

1

Disc

onnect the TP sensor electrical connector, PI06.

2

D

isconnect the ECM electrical connector, EM11.

3

Me

asure the resistance between PI06, pin 02 (G) and EM11, pin 10 (G).

4

Is th

e resistance greater than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No GO to K2

.

K

2: CHECK TP SENSOR 2 SENSE CIRC

UIT FOR SHORT TO HIGH VOLTAGE

R

econnect the battery negative terminal.

1

Turn the ignition swi

tch to the ON

position.

2

M

easure the voltage between PI06, pin 02 (G) and GROUND.

3

Is th

e voltage greater than 5 volts?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No INSTALL a new TP sensor.

REFER to Throttle Position (TP) Sensor

in this section.

CLEAR the DTC. TEST the system for normal operation.

PI

NPOINT TEST L : DTC P0327, P0328; RIGHT-HA

ND KNOCK SENSOR (KS) CIRCUIT OUT OF RANGE

(LOW VOLTAGE)

•

NOTE: Before commencing this

test, make sure that the sensor is making a good electrical contact with the cylinder

block. See 'possible causes'.

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

L

1: CHECK THE KS SENSE CIRCUIT FOR HIGH RESISTANCE

Di

sconnect the battery negative terminal.

1

Di

sconnect the KS electrical connector, PI26.

2

D

isconnect the ECM electrical connector, EM13.

3

Me

asure the resistance between PI26, pin 01 (S) and EM13, pin 18 (S).

4

Is th

e resistance greater than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No GO to L2

.

L

2: CHECK THE KS SENSE CIRCUIT FOR SHORT TO HIGH VOLTAGE

Turn the ignition swi

tch to the ON

position.

1

R

econnect the battery negative terminal.

2

Meas

ure the voltage between PI26, pin 01 (S) and GROUND.

3

Is th

e voltage greater than 3 volts?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to L3

.