battery JAGUAR X308 1998 2.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 282 of 2490

Driveshaft - Driveshaft

Remo

val and Installation

Remov

a

l

CAUTI

O

N: To preserve 'drive line' refine

ment, individual parts, other than fixings, MUST NOT be renewed. In the event

of any balance or driveshaft component related problem, the complete assembly must be renewed. Under no circumstances

may the flexible (Jurid) coupling be remo ved from the driveshaft (or its fixings be loosened). Do not drop or subject the

driveshaft to damage.

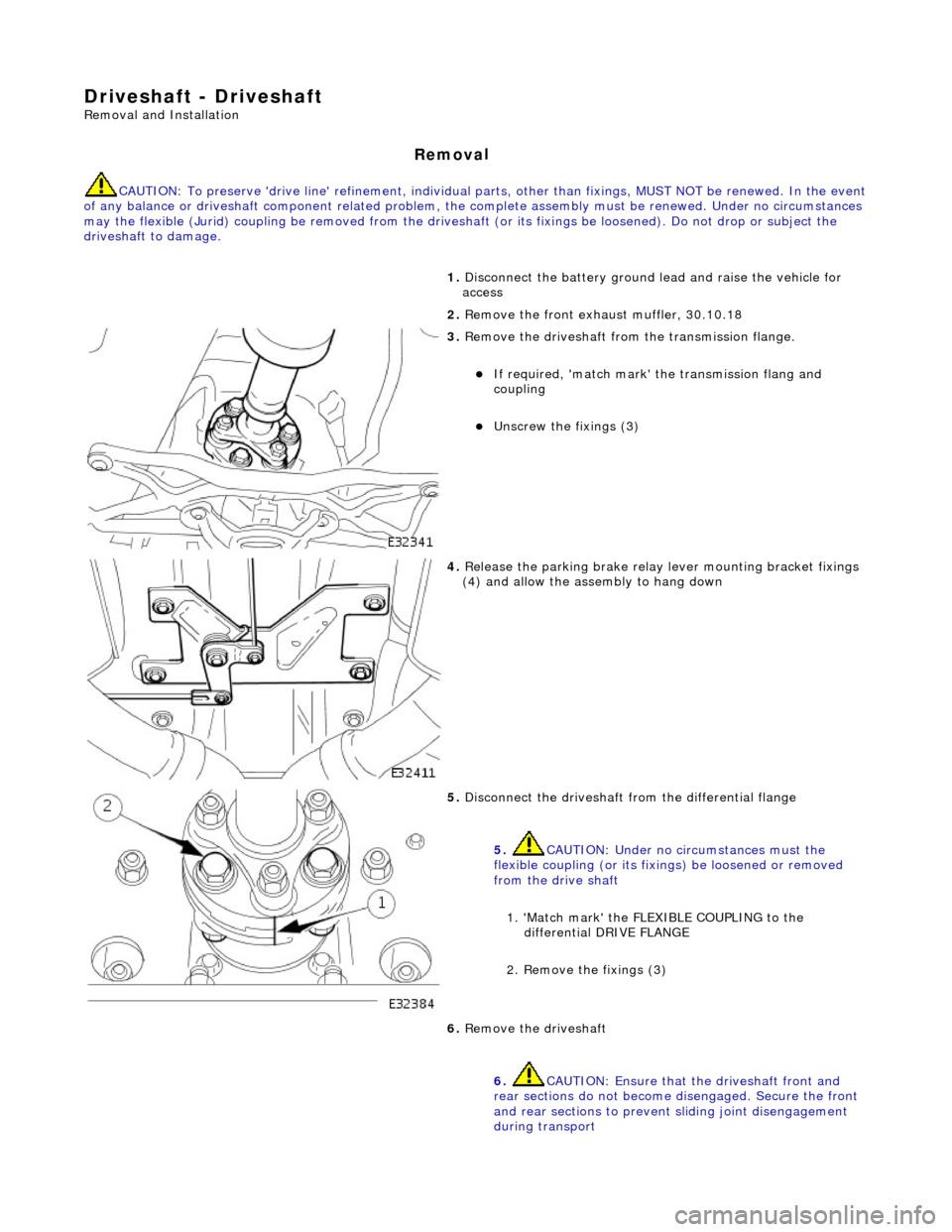

1. Disc

onnect the battery ground

lead and raise the vehicle for

access

2. Remove the front exha ust muffler, 30.10.18

3. Re

move the driveshaft from

the transmission flange.

пЃ¬If required, 'match mark'

the transmissi on flang and

coupling

пЃ¬Unscrew the fi xings (3)

4. Relea s

e the parking brake relay

lever mounting bracket fixings

(4) and allow the assembly to hang down

5. Disc onne

ct the driveshaft fr

om the differential flange

5. CAUTION: Under no circumstances must the

flexible coupling (or its fixings) be loosened or removed

from the drive shaft

1. 'Match mark' the FLEX IBLE COUPLING to the

differential DRIVE FLANGE

2. Remove the fixings (3)

6. Re

move the driveshaft

6. CAUTION: Ensure that the driveshaft front and

rear sections do not become disengaged. Secure the front

and rear sections to preven t sliding joint disengagement

during transport

Page 287 of 2490

R

ear Drive Axle/Differential - Differ

ential Output Shaft End Float Check

Gen

eral Procedures

1.

Di

sconnect the battery ground lead

2. Raise the vehicle for access

3. Mo

unt a dial test indicator (DTI

) to the differential housing with

the probe resting on the axle sh aft flange (the DTI probe must

be parallel to the output shaf t center line and NOT the axle

shaft)

4. Chec

k the end float

пЃ¬Pus

h the wheel / shaft assembly INWARDS

пЃ¬Zero the DTI

пЃ¬P

ull the wheel / shaft assembly OUTWARDS

пЃ¬N

ote the reading

5. Check the specification

пЃ¬0 t

o 0,15 mm GOOD

пЃ¬0,

15 mm + NOT GOOD; Renew the output shaft bearing

Page 288 of 2490

Re

ar Drive Axle/Differential - Axle Shaft

In-v

ehic

le Repair

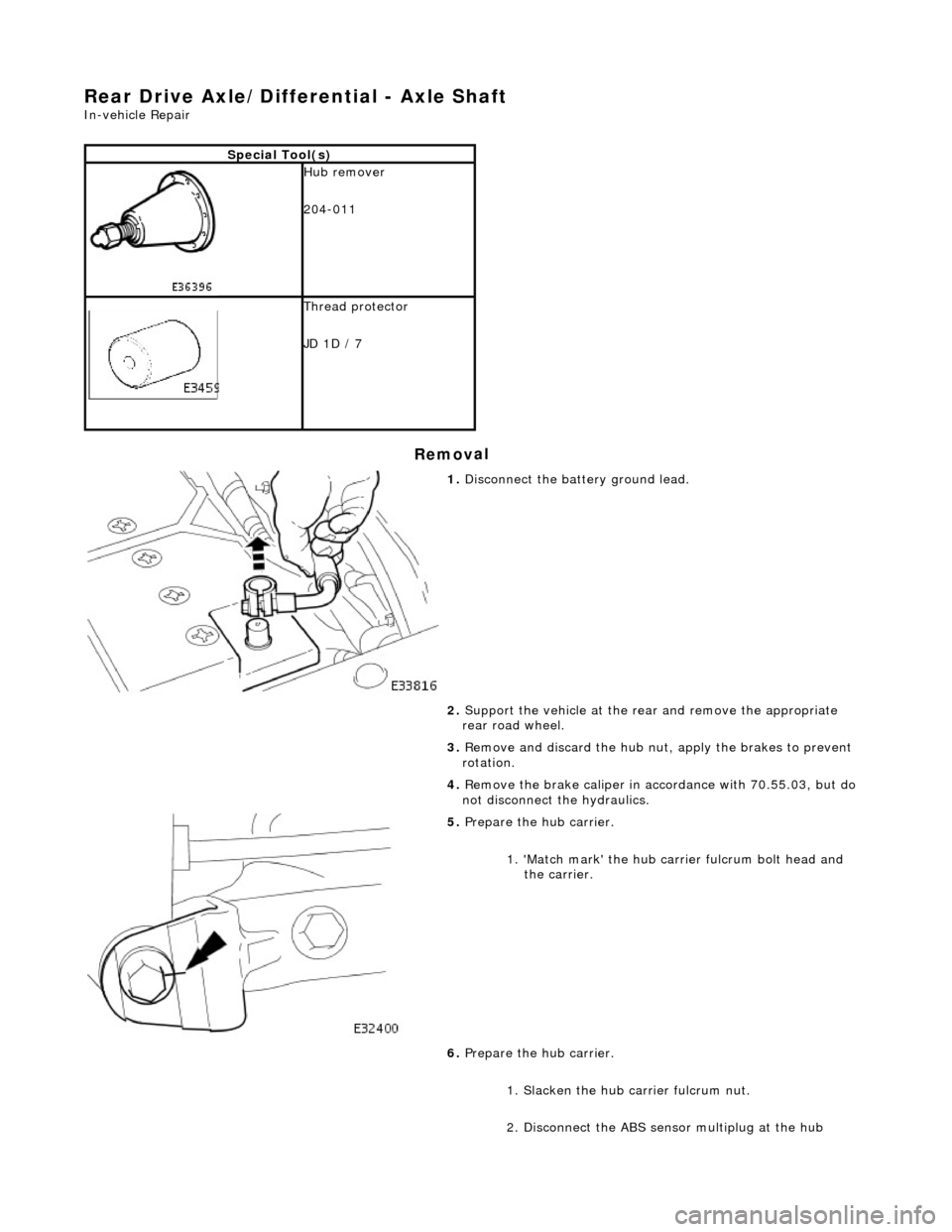

Remov

a

l

S

p

ecial Tool(s)

Hub remover

2

04-011

Thread protector

JD

1D

/ 7

1. Disc

onnect the battery ground lead.

2. Support the vehicle at the rear and remove the appropriate

rear road wheel.

3. Remove and discard the hub nut, apply the brakes to prevent

rotation.

4. Remove the brake caliper in acco rdance with 70.55.03, but do

not disconnect the hydraulics.

5. Pr

epare the hub carrier.

1. 'Match mark' the hub carr ier fulcrum bolt head and

the carrier.

6. Prepare the hub carrier.

1. Slacken the hub ca rrier fulcrum nut.

2. Disconnect the ABS sensor multiplug at the hub

Page 291 of 2490

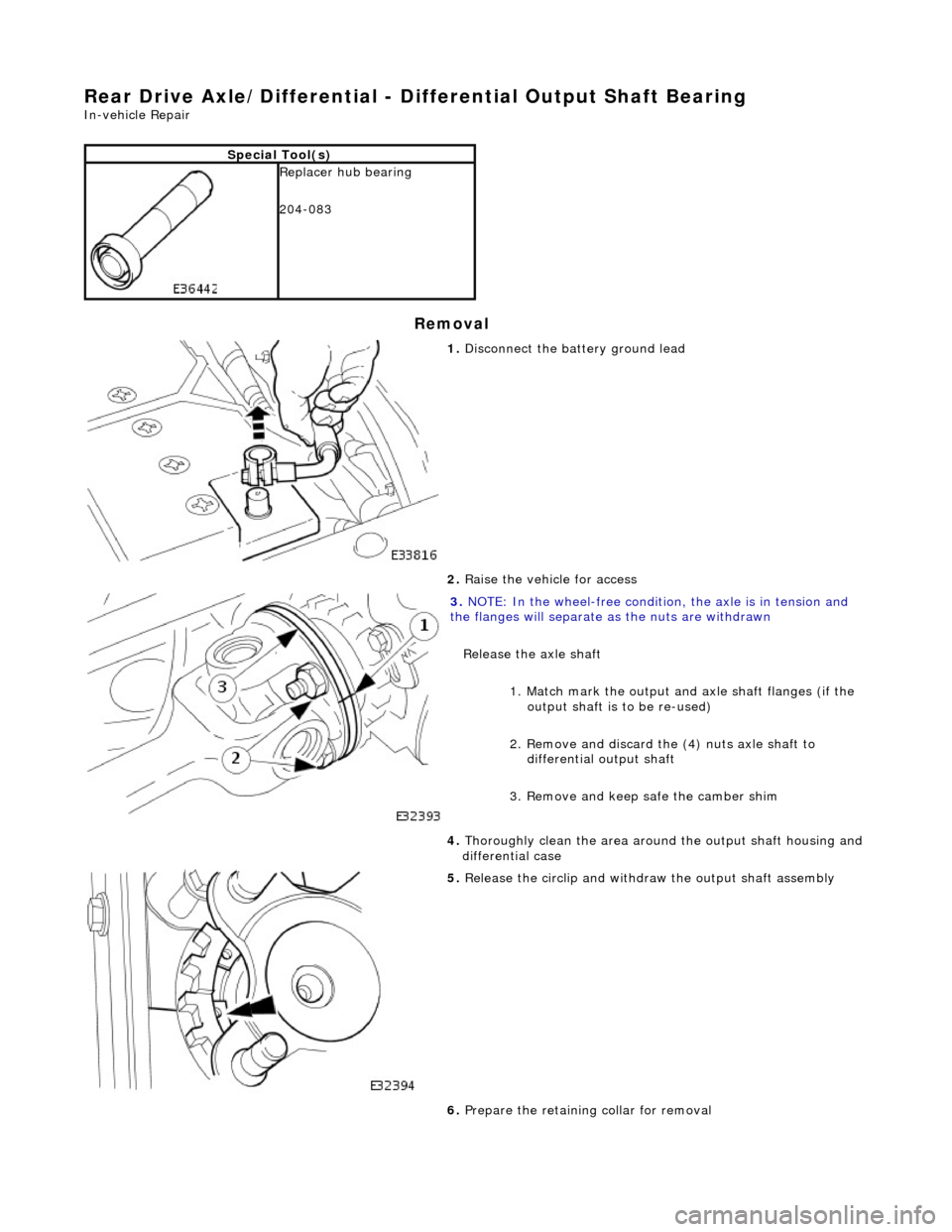

R

ear Drive Axle/Differential - Differential Output Shaft Bearing

In-v

ehicle Repair

Remov

al

S

pecial Tool(s)

Replacer hu

b bearing

204-083

1. Di

sconnect the battery ground lead

2. Raise the vehicle for access

3. NO

TE: In the wheel-free condition, the axle is in tension and

the flanges will separate as the nuts are withdrawn

Release the axle shaft

1. Match mark the output an d axle shaft flanges (if the

output shaft is to be re-used)

2. Remove and discard the (4) nuts axle shaft to differential output shaft

3. Remove and keep safe the camber shim

4. T

horoughly clean the area around the output shaft housing and

differential case

5. Relea

se the circlip and withdraw the output shaft assembly

6. Prepare the retaining collar for removal

Page 295 of 2490

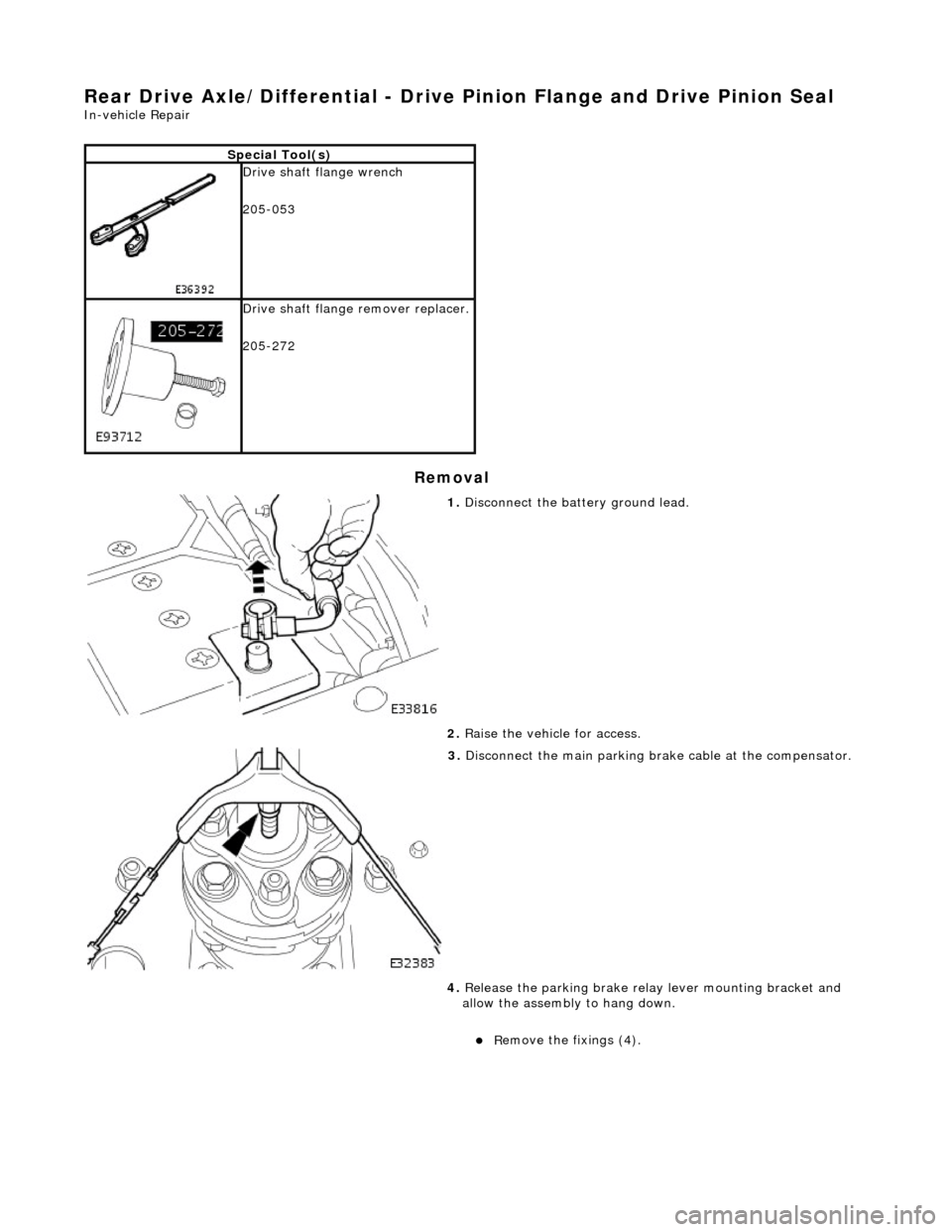

R

ear Drive Axle/Differential - Drive Pinion Flange and Drive Pinion Seal

In-v

ehicle Repair

Remov

al

S

pecial Tool(s)

Drive sh

aft flange wrench

205-053

D

rive shaft flange remover replacer.

205-272

1. Di

sconnect the battery ground lead.

2. Raise the vehicle for access.

3. Disconnect the main parking br ake c

able at the compensator.

4. Release the parking brake relay lever mounting bracket and

allow the assembly to hang down.

пЃ¬R

emove the fixings (4).

Page 300 of 2490

Rea

r Drive Axle/Differential - Axle Assembly

Re

mo

val and Installation

Remov

a

l

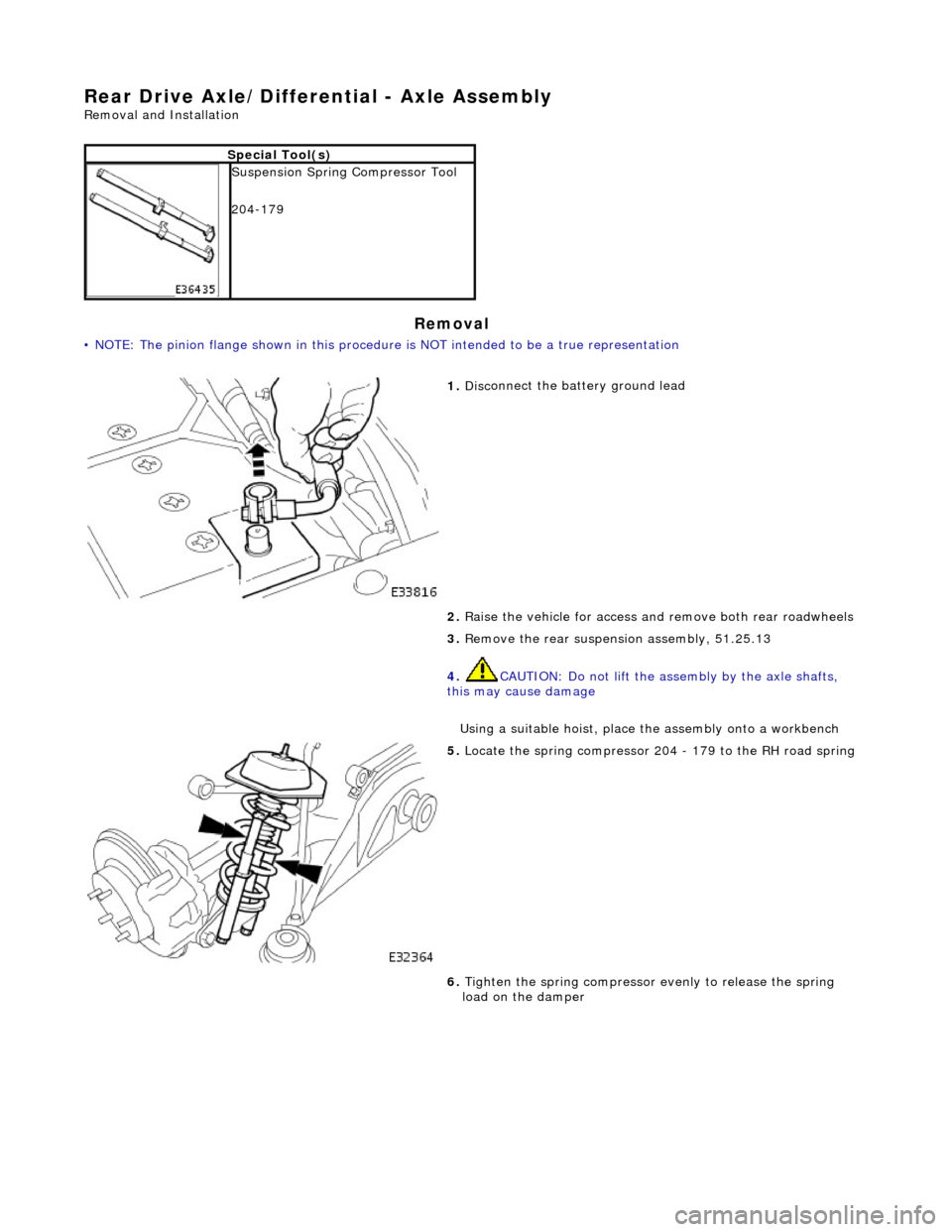

•

NOTE: The pinion flange shown in this procedure is NOT intended to be a true representation

S

p

ecial Tool(s)

Suspensi

on

Spring Compressor Tool

204-179

1. Disc

onnect the battery ground lead

2. Raise the vehicle for access and remove both rear roadwheels

3. Remove the rear suspensi on assembly, 51.25.13

4. CAUTION: Do not lift the assembly by the axle shafts,

this may cause damage

Using a suitable hoist, place the assembly onto a workbench

5. Locat e

the spring compressor 204

- 179 to the RH road spring

6. Tighten the spring compressor evenly to release the spring

load on the damper

Page 408 of 2490

Hydraulic Br

ake Actuation

- Brake Fluid Reservoir

Remo

val and Installation

Remov

a

l

• C

A

UTIONS:

Replacement of nuts and bolts: Various thread-locking de vices are used on nuts and bolts throughout the vehicle.

These devices restrict the number of times a nut or bolt can be used. See section 100-00 for information.

Remove brake fluid spilla ge immediately from paint work, with clean water.

1. Position vehicl

e on a four-post lift.

2. Open engine compartment and fit paint work protection covers

to fenders.

3. Disconnect battery ground cable (IMPORTANT, see operation

86.15.19 for further information).

4. Remove engine compartment rear cover. Refer to operation

76.11.35.

5. Remove pedal housing, brake booster and master cylinder

assembly. Refer to operation 70.35.39.

6. Remove reservoir filler cap and empty residual brake fluid into

a container. Refit cap.

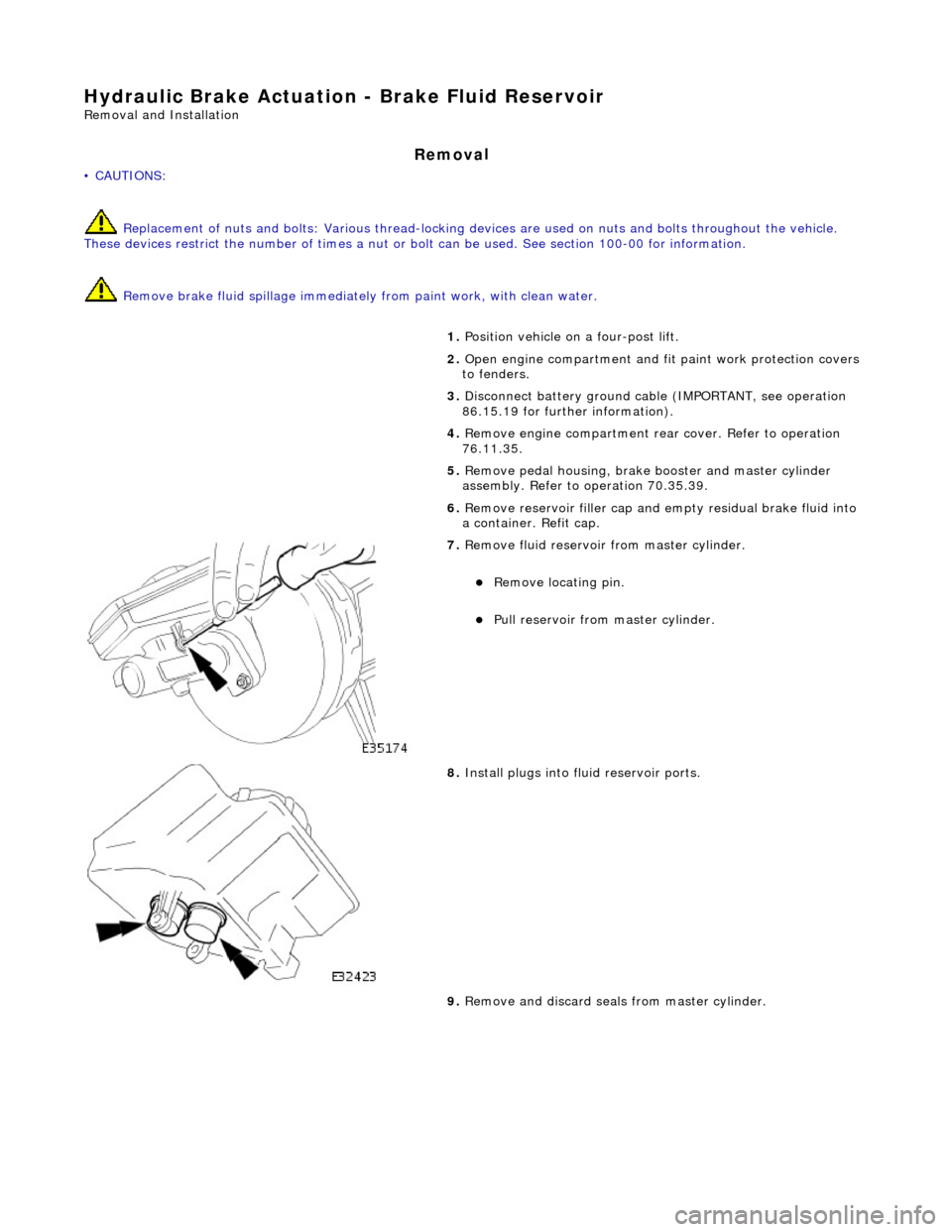

7. Re

move fluid reservoir from master cylinder.

пЃ¬R

e

move locating pin.

пЃ¬Pull reservoir

from master cylinder.

8. Install plugs into f

luid reservoir ports.

9. Remove and discard seal s from master cylinder.

Page 409 of 2490

I

nstallation

10

.

Install plugs into master cylinder ports.

11. Clean components and mating surfaces.

1. Inst

all seals into master cylinder.

пЃ¬Re

move plugs.

пЃ¬Lubricate seals with

cl

ean brake fluid.

пЃ¬Inst

all seals.

2. Install

reservoir to master cylinder.

пЃ¬Re

move plugs.

пЃ¬Install

reservoir, making sure

reservoir is fully seated.

пЃ¬Inst

all locating pin.

3. Install pedal housing, brake booster and master cylinder

assembly. Refer to operation 70.35.39.

4. Install engine compartment rear cover. Refer to operation

76.11.35.

5. Reconnect battery ground cable (IMPORTANT, see operation

Page 411 of 2490

Hydraulic B

rake Actuation

- Brake Master Cylinder

Re

moval and Installation

Remov

al

• C

AUTIONS:

Replacement of nuts and bolts: Various thread-locking de vices are used on nuts and bolts throughout the vehicle.

These devices restrict the number of times a nut or bolt can be used. See section 100-00 for information.

Remove brake fluid spilla ge immediately from paint work, with clean water.

1. Position vehi

cle on a four-post lift.

2. Open engine compartment and fit paint work protection covers

to fenders.

3. Disconnect battery ground cable (IMPORTANT, refer to

operation 86.15.19 for fu rther information).

4. Remove engine compartment rear cover. Refer to operation

76.11.35.

5. Remove pedal housing, brake booster and master cylinder

assembly. Refer to operation 70.35.39.

6. Place assembly on a work bench.

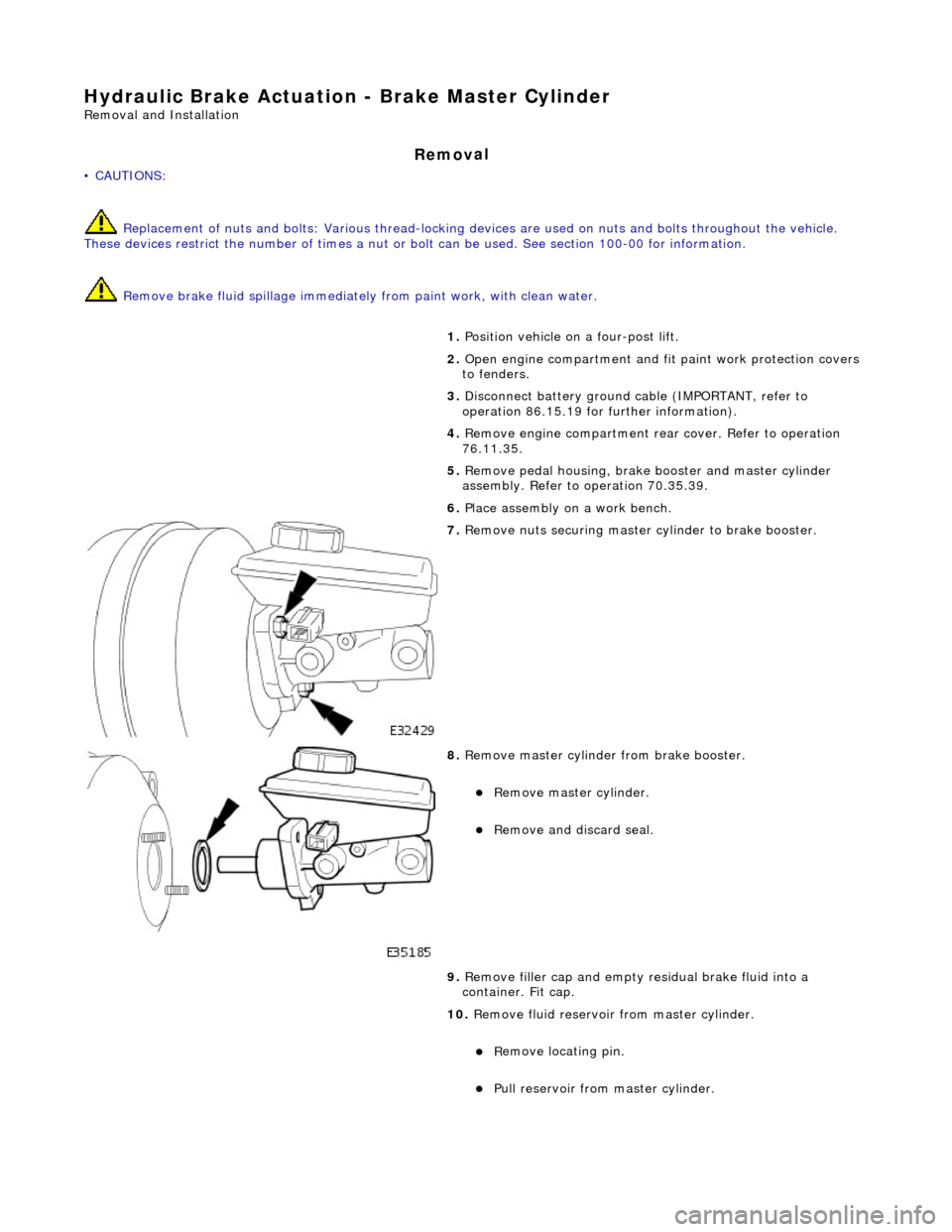

7. R

emove nuts securing master cylinder to brake booster.

8. R

emove master cylinder from brake booster.

пЃ¬Re

move master cylinder.

пЃ¬Remove an

d discard seal.

9. Remove filler cap and empty residual brake fluid into a

container. Fit cap.

10. Remove fluid reservoir from master cylinder.

пЃ¬R

emove locating pin.

пЃ¬Pull

reservoir from master cylinder.

Page 413 of 2490

пЃ¬Lubricate seals with cl

ean brake fluid.

пЃ¬Inst

all seals.

2. Install

fluid reservoir to master cylinder.

пЃ¬R

emove plugs from reservoir

пЃ¬Install

reservoir, making sure

reservoir is fully seated.

пЃ¬Inst

all locating pin.

3. Inst

all master cylinder to brake booster.

пЃ¬Inst

all seal.

пЃ¬Inst

all master cylinder, make sure master cylinder rod

locates brake booster rod.

4. Inst

all and tighten nuts to 21-29 Nm.

5. Install pedal housing, brake booster and master cylinder

assembly. Refer to operation 70.35.39.

6. Install engine compartment rear cover. Refer to operation

76.11.35.

7. Connect battery ground cable (IMPORTANT, see operation

86.15.15 for further information).

8. Bleed brake system. Refer to operation 70.25.03.

9. Remove paint-work protection covers and close engine

com

partment.