fault codes JAGUAR X308 1998 2.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1189 of 2490

E

lectronic Engine Controls -

Electronic Engine Controls

D

iagnosis and Testing

I

nspection and Verification

1.

1. Veri

fy the customer concern.

2. 2. Confirm which, if any, warning li ghts and/or messages were displayed on the instrument cluster.

• NOTE: If any warning lights and/or me ssages were displayed when the fault occurred, refer to the Driver Information

table for DTCs associated with the display, then to the DTC index table for possible sources and actions. Some warnings will

appear to clear when the ignition is cycl ed. This is often because the warning has flagged as a resu lt of one of the vehicle's

on-board diagnostic routines having run to detect the fault. If the same routine is not run when the ignition is switched ON,

the warning will not reflag until the routine does run. See the DTC summaries for drive cycle routines.

3. 3. Visually inspect for obvious signs of mechanical or electrical damage.

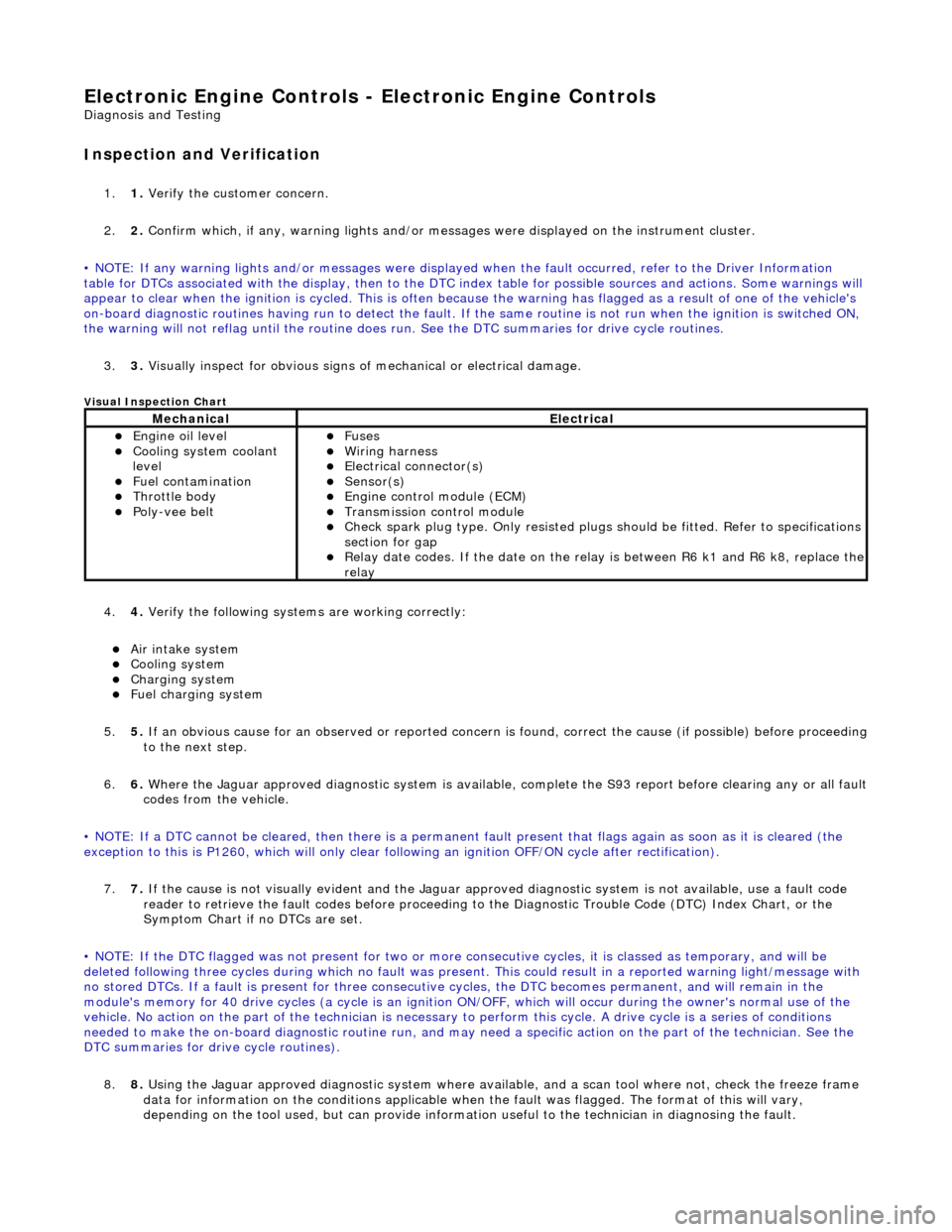

V

isual Inspection Chart

4.

4. Veri

fy the following syst

ems are working correctly:

Air in

take system

Coo

ling system

Charging system

F

uel charging system

5. 5. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding

to the next step.

6. 6. Where the Jaguar approved diagnostic sy stem is available, complete the S93 report before clearing any or all fault

codes from the vehicle.

• NOTE: If a DTC cannot be cleared, then there is a permanent fault present that flag s again as soon as it is cleared (the

exception to this is P1260, which will only clear following an ignition OFF/ON cycle after rectification).

7. 7. If the cause is not visually evident and the Jaguar approv ed diagnostic system is not available, use a fault code

reader to retrieve the fault codes be fore proceeding to the Diagnostic Trou ble Code (DTC) Index Chart, or the

Symptom Chart if no DTCs are set.

• NOTE: If the DTC flagged was not present for two or more co nsecutive cycles, it is classed as temporary, and will be

deleted following three cycl es during which no fault was present. This could result in a reported wa rning light/message with

no stored DTCs. If a fault is present for three consecutive cycles, the DTC becomes permanent, and will remain in the

module's memory for 40 drive cycles (a cy cle is an ignition ON/OFF, which will occur during the owner's normal use of the

vehicle. No action on the part of the technician is necessary to perform this cycle. A drive cycle is a series of conditions

needed to make the on-board diagnostic ro utine run, and may need a specific action on the part of the technician. See the

DTC summaries for driv e cycle routines).

8. 8. Using the Jaguar approved diagnostic system where available, and a scan tool where not, check the freeze frame

data for information on the conditions applicable when the fault was flagged. The format of this will vary,

dependin

g o

n the tool used, but can provide information useful to the technician in dia

gnos

in

g th

e fault.

MechanicalElectrical

Engi

ne oil level

Coo

ling system coolant

level

Fuel contamination

Throttle body Poly

-vee belt

F

uses

W

iring harness

E

lectrical connector(s)

Sens

or(s)

Engine

control module (ECM)

Tran

smission control module

Check spark plu

g type. Only re

sisted plugs should be fitted. Refer to specifications

section for gap

Relay date codes.

If the date on the rela

y is between R6 k1 and R6 k8, replace the

relay

Page 1275 of 2490

Automatic Transmission/Transaxle - 4.0L NA V8 - AJ27/3.2L NA V8 - AJ26

- Diagnostic Strategy

Diagnosis and Testing

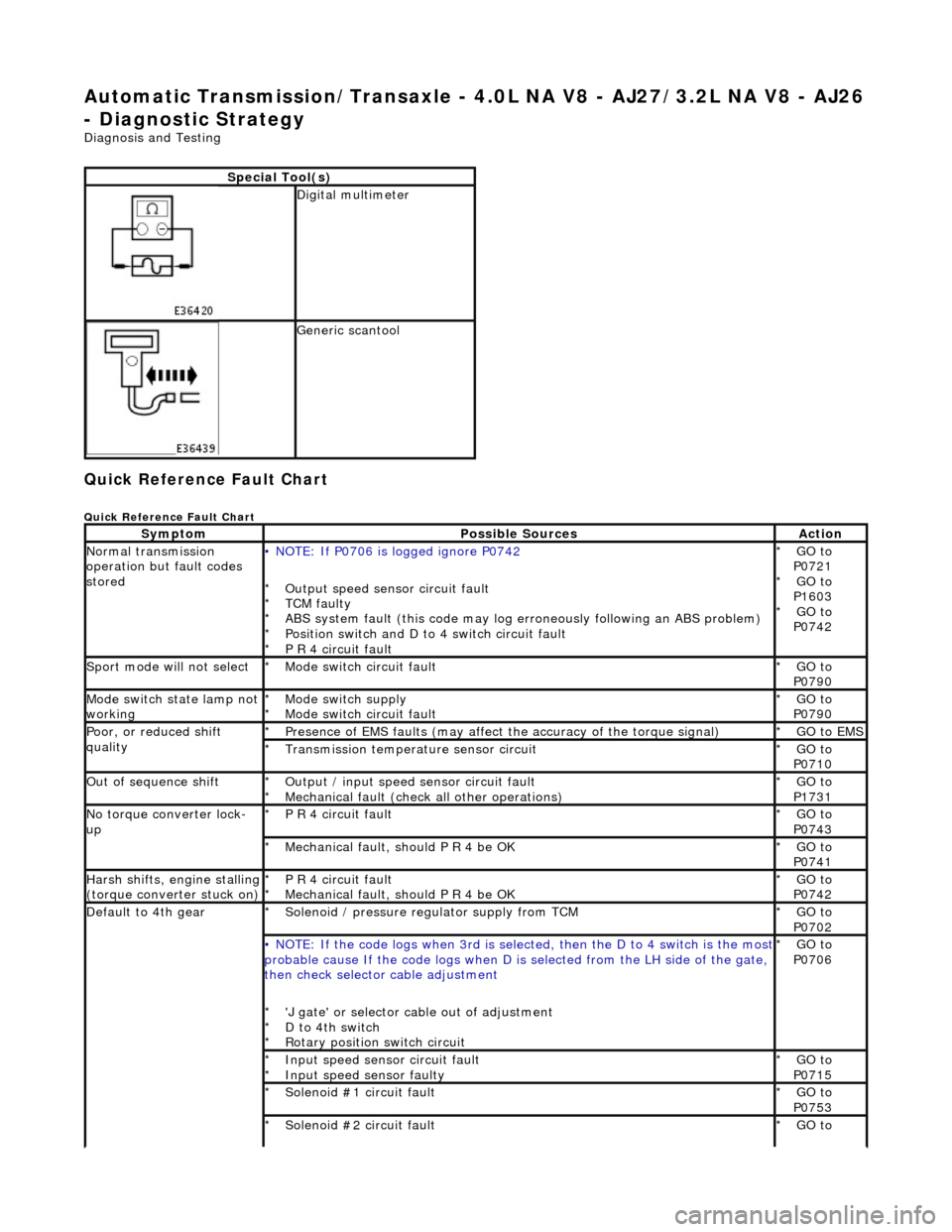

Quick Reference Fault Chart

Quick Reference Fault Chart

Special Tool(s)

Digital multimeter

Generic scantool

SymptomPossible SourcesAction

Normal transmission

operation but fault codes

stored• NOTE: If P0706 is logged ignore P0742

Output speed sensor circuit fault

TCM faulty

ABS system fault (this code may log er roneously following an ABS problem)

Position switch and D to 4 switch circuit fault

P R 4 circuit fault

*

*

*

*

*

GO to

P0721 GO to

P1603 GO to

P0742

*

*

*

Sport mode will not selectMode switch circuit fault

*GO to

P0790

*

Mode switch state lamp not

workingMode switch supply

Mode switch circuit fault

*

*GO to

P0790

*

Poor, or reduced shift

qualityPresence of EMS faults

(may affect the accuracy of the torque signal)

*GO to EMS *

Transmission temperature sensor circuit

*GO to

P0710

*

Out of sequence shiftOutput / input speed sensor circuit fault

Mechanical fault (check all other operations)

*

*GO to

P1731

*

No torque converter lock-

upP R 4 circuit fault

*GO to

P0743

*

Mechanical fault, should P R 4 be OK

*GO to

P0741

*

Harsh shifts, engine stalling (torque converter stuck on)P R 4 circuit fault

Mechanical fault, should P R 4 be OK

*

*GO to

P0742

*

Default to 4th gearSolenoid / pressure regulator supply from TCM

*GO to

P0702

*

• NOTE: If the code logs wh

en 3rd is selected, then the D to 4 switch is the most probable cause If the code logs when D is selected fro m the LH side of the gate,

then check selector cable adjustment

'J gate' or selector ca ble out of adjustment

D to 4th switch

Rotary position switch circuit

*

*

*GO to

P0706

*

Input speed sensor circuit fault

Input speed sensor faulty

*

*GO to

P0715

*

Solenoid #1 circuit fault

*GO to

P0753

*

Solenoid #2 circuit fault

*GO to

*

Page 1391 of 2490

In the event of a system fault, the TCM will adopt 'limp home' mode.

Electrical control

Refer to Section 307-01B.

Transmission Control Components

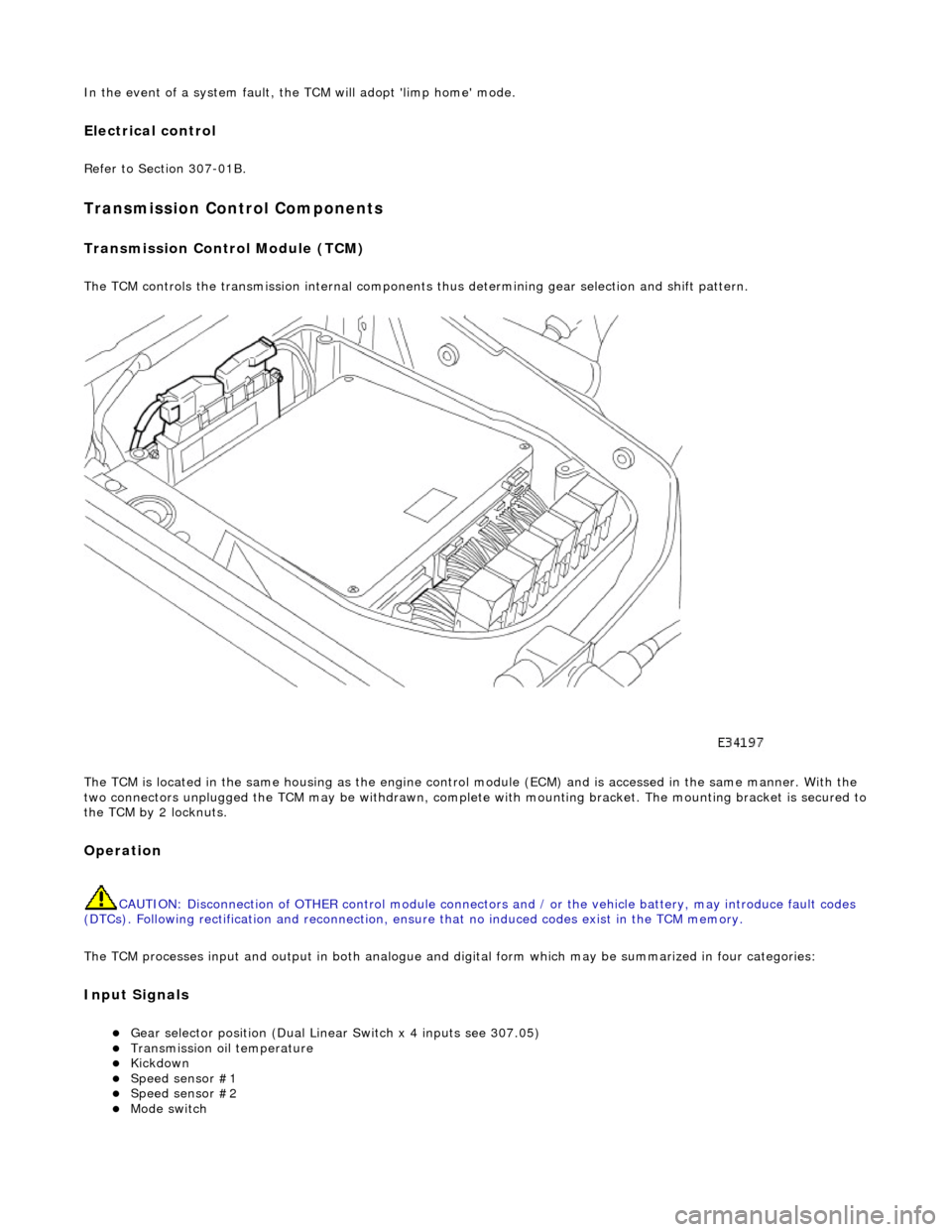

Transmission Control Module (TCM)

The TCM controls the transmission internal components thus determining gear selection and shift pattern.

The TCM is located in the same housing as the engine control module (ECM) and is accessed in the same manner. With the

two connectors unplugged the TCM may be withdrawn, complete with mounting bracket. The mounting bracket is secured to

the TCM by 2 locknuts.

Operation

CAUTION: Disconnection of OTHER contro l module connectors and / or the vehicle battery, may introduce fault codes

(DTCs). Following rectification and reconnection, ensu re that no induced codes exist in the TCM memory.

The TCM processes input and output in both analogue and di gital form which may be summarized in four categories:

Input Signals

Gear selector position (Dual Linear Switch x 4 inputs see 307.05) Transmission oil temperature Kickdown Speed sensor #1 Speed sensor #2 Mode switch

Page 1392 of 2490

CAN Input Signals

Traction status ABS malfunction ABS status Engine torque status Throttle position Accelerator pedal position Engine torque reduction confirmation Engine speed Engine coolant temperature Cruise status OBDII fault code clear request Throttle malfunction warning RED or AMBER All road wheel speeds Token for network status ECM Token for network status INST Token for network status ABS Diagnostic data in from external device (PDU)

Output Signals

Solenoid valve 1 <-> 2 and 4 <-> 5 shift Solenoid valve 2 <-> 3 shift Solenoid valve 3 <-> 4 shift Solenoid valve converter lock-up clutch Control valve - modulating pressure Control valve - shift pressure

CAN Output Signals

Engine torque reduction request MIL status (whether present DTC should operate MIL) Transmission input speed Transmission output speed Converter slip Kickdown status Gear position (actual) Gear position (selected) Gear selection fault Converter lock-up status Current selected shift map Transmission oil temperature Transmission malfunction Pecus flag (state of current TCM program) Target for next gear position Gear shift torque transfer progress at shift MIL status (response to activate the MIL relevant to a DTC) OBDII fault code clear acknowledgement Transmission DTCs (P codes) Token for network status TCM Diagnostic data out to external device (PDU)

Emergency Running (elect ronic limp-home mode)

The TCM constantly monitors the transmissi on for faults. In the event of a problem the TCM will adopt the limp-home mode, in which the gear currently held remains engaged, until P is selected. The modulati ng and shift pressures will increase to

maximum and converter lock-up will be inhibited.

Following the selection of P , the only ratios available will be 2 (irrespective of forward ratio manual selection) and R .

With the vehicle at rest, the procedure to manually select is as follows:

1. 1. Select P .

Page 1759 of 2490

Sym

ptom #2

Sy

mptom #2

Sym

ptom #3

Sy

mptom #3

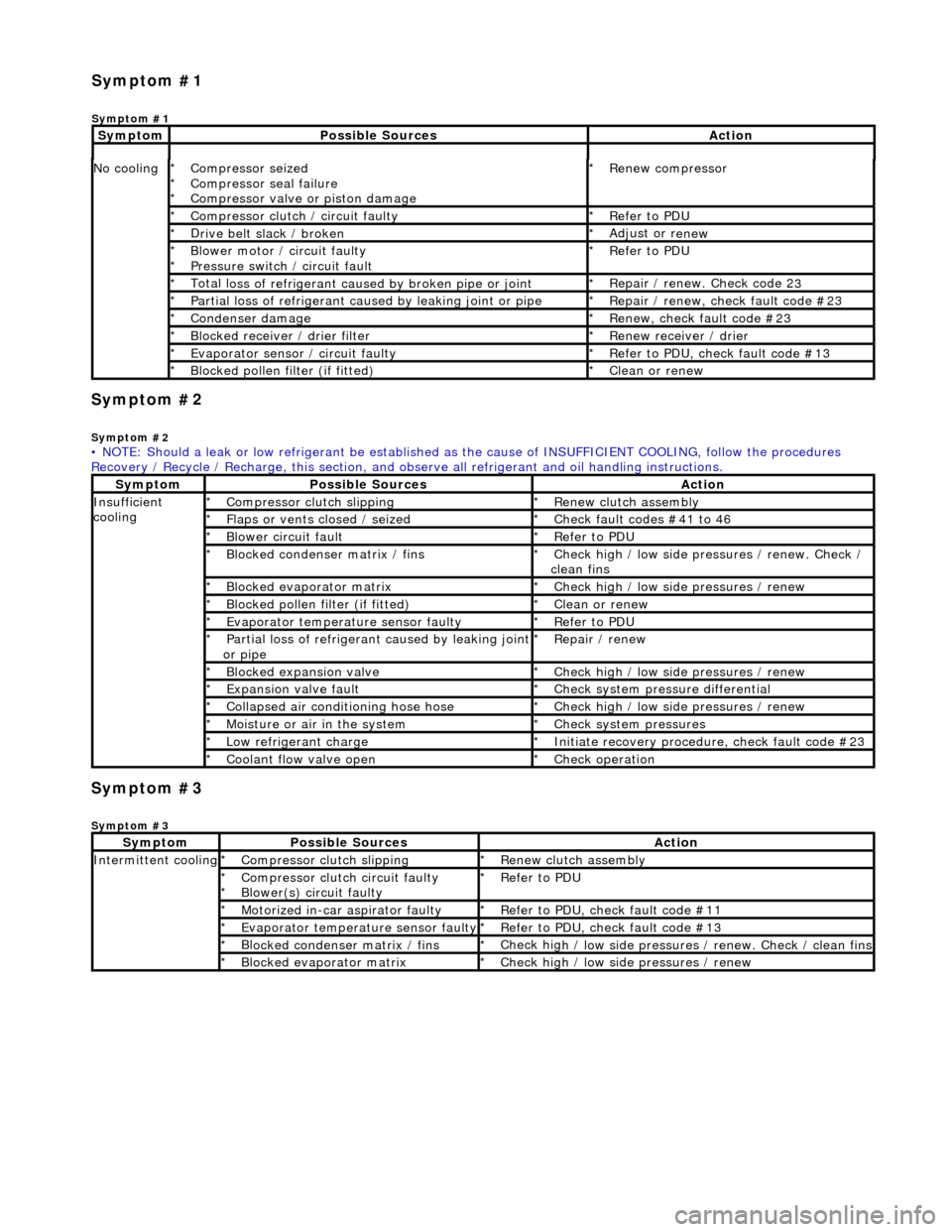

No

cooling

Compressor sei

zed

Compressor seal failure

Compressor valve or piston damage

*

*

*

R

enew compressor

*

Compressor cl

utch / circuit faulty

*

R

efer to PDU

*

D

rive belt slack / broken

*

Adjust or r

enew

*

B

lower motor / circuit faulty

Pressure switch / circuit fault

*

*

R

efer to PDU

*

Total l

oss of refrigerant caused by broken pipe or joint

*

Repair / renew. Check code 2

3

*

P

artial loss of refrigerant caused by leaking joint or pipe

*

R

epair / renew, check fault code #23

*

Conden

ser damage

*

Re

new, check fault code #23

*

Bl

ocked receiver / drier filter

*

R

enew receiver / drier

*

Evaporator senso

r / circuit faulty

*

R

efer to PDU, check fault code #13

*

Bl

ocked pollen filter (if fitted)

*

Cle

an or renew

*

• NOTE: Should a leak or low refrigerant be established as the cause of INSUFFICIENT COOL ING, follow the procedures

Recovery / Recycle / Recharge, this section, and ob serve all refrigerant and oil handling instructions.

Sy

mptom

Possib

le Sources

Acti

on

Insuffi

cient

cooling

Compre

ssor clutch slipping

*

R

enew clutch assembly

*

Fl

aps or vents closed / seized

*

Check f

ault codes #41 to 46

*

Bl

ower circuit fault

*

R

efer to PDU

*

Bl

ocked condenser matrix / fins

*

Check hig

h / low side pr

essures / renew. Check /

clean fins

*

Bl

ocked evaporator matrix

*

Check hig

h / low side

pressures / renew

*

Bl

ocked pollen filter (if fitted)

*

Cle

an or renew

*

Evaporator temp

erat

ure sensor faulty

*

R

efer to PDU

*

P

artial loss of refrigerant caused by leaking joint

or pipe

*

R

epair / renew

*

Blocked expan

sion valve

*

Check hig

h / low side

pressures / renew

*

Expans

ion valve fault

*

Chec

k system pres

sure differential

*

C

ollapsed air conditioning hose hose

*

Check hig

h / low side

pressures / renew

*

Moi

sture or air in the system

*

Chec

k system pressures

*

Low r

efrigerant charge

*

Initiate recovery

procedure, check fault code #23

*

Coo

lant flow valve open

*

Chec

k operation

*

Sy

mptom

Possib

le Sources

Acti

on

Int

ermittent cooling

Compre

ssor clutch slipping

*

R

enew clutch assembly

*

Compressor cl

utch circuit faulty

Blower(s) circuit faulty

*

*

R

efer to PDU

*

Motorized in-car aspirator faulty

*

R

efer to PDU, check fault code #11

*

Evaporator temp

erature sensor faulty

*

R

efer to PDU, check fault code #13

*

Bl

ocked condenser matrix / fins

*

Check hig

h / low side pressures / renew. Check / clean fins

*

Bl

ocked evaporator matrix

*

Check hig

h / low side

pressures / renew

*

Sym

ptom #1

Sy

mptom #1

Sy

mptom

Possib

le Sources

Acti

on

Page 1836 of 2490

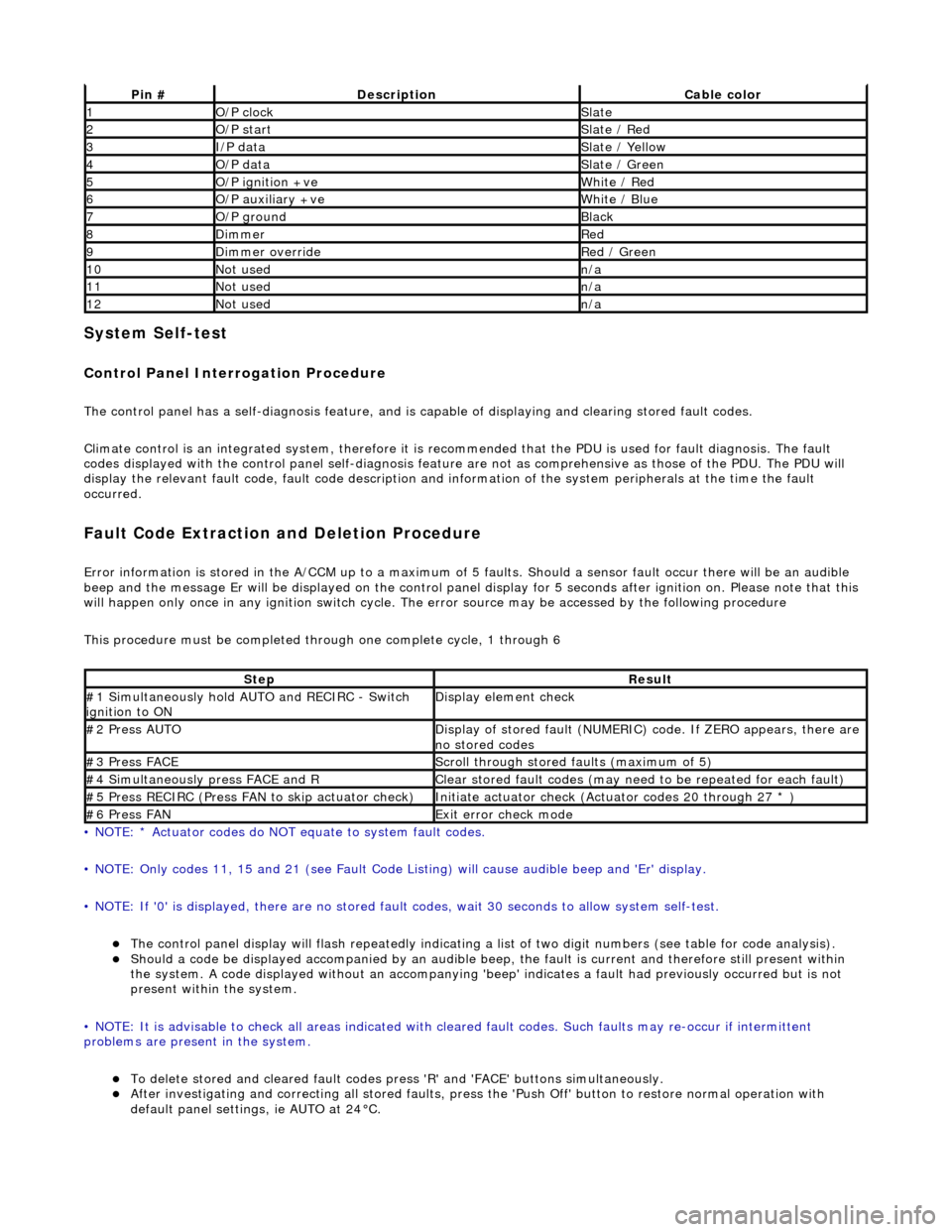

System Self-test

Control Panel Interrogation Procedure

The control panel has a self-diagnosis feature, and is capable of displaying and clearing stored fault codes.

Climate control is an integrated system, therefore it is recommended that the PDU is used for fault diagnosis. The fault

codes displayed with the control panel self -diagnosis feature are not as comprehensive as those of the PDU. The PDU will

display the relevant fault code, fault co de description and information of the system peripherals at the time the fault

occurred.

Fault Code Extraction and Deletion Procedure

Error information is stored in the A/CCM up to a maximum of 5 faults. Should a sensor fault occur there will be an audible

beep and the message Er will be displayed on the control panel display for 5 seco nds after ignition on. Please note that this

will happen only once in any ignition switch cycle. The error source may be accessed by the following procedure

This procedure must be completed through one complete cycle, 1 through 6

• NOTE: * Actuator codes do NOT equate to system fault codes.

• NOTE: Only codes 11, 15 and 21 (see Fault Code List ing) will cause audible beep and 'Er' display.

• NOTE: If '0' is displayed, there are no stored faul t codes, wait 30 seconds to allow system self-test.

The control panel display will flash repeatedly indicating a list of two digit numbers (see table for code analysis). Should a code be displayed accompanied by an audible beep, the fault is current and therefore still present within

the system. A code displayed without an accompanying 'bee p' indicates a fault had previously occurred but is not

present within the system.

• NOTE: It is advisable to check all areas indicated with cleared fault codes. Such faults may re-occur if intermittent

problems are present in the system.

To delete stored and cleared fault codes press 'R' and 'FAC E' buttons simultaneously. After investigating and correcting all stored faults, press the 'Push Off' button to restore normal operation with

default panel settings, ie AUTO at 24°C.

Pin #DescriptionCable color

1O/P clockSlate

2O/P startSlate / Red

3I/P dataSlate / Yellow

4O/P dataSlate / Green

5O/P ignition +veWhite / Red

6O/P auxiliary +veWhite / Blue

7O/P groundBlack

8DimmerRed

9Dimmer overrideRed / Green

10Not usedn/a

11Not usedn/a

12Not usedn/a

StepResult

#1 Simultaneously hold AU TO and RECIRC - Switch

ignition to ONDisplay element check

#2 Press AUTODisplay of stored fault (NUMERIC) code. If ZERO appears, there are

no stored codes

#3 Press FACEScroll through stored faults (maximum of 5)

#4 Simultaneously press FACE and RClear stored fault codes (may need to be repeated for each fault)

#5 Press RECIRC (Press FAN to skip actuator check)Initiate actuator check (Actuator codes 20 through 27 * )

#6 Press FANExit error check mode

Page 1837 of 2490

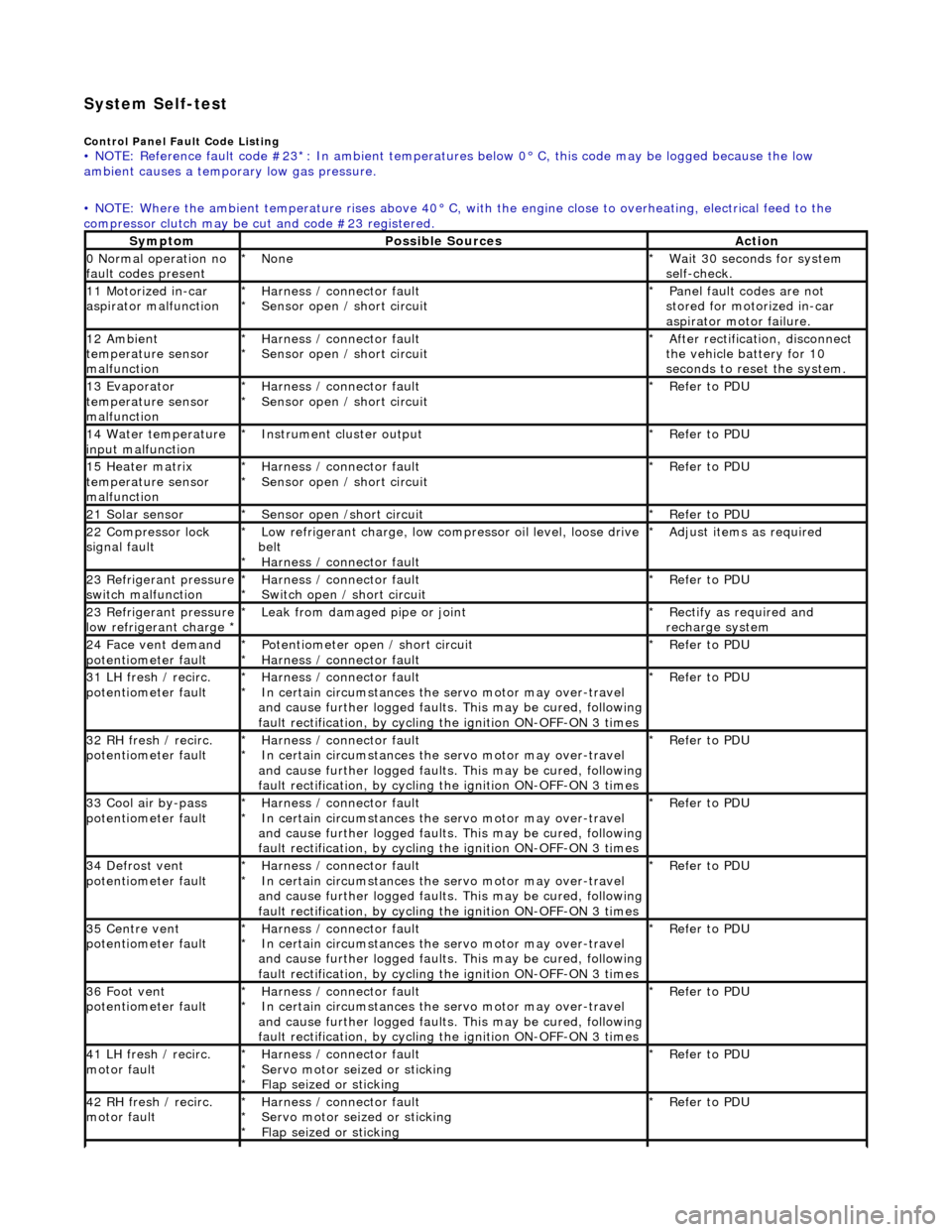

System Self-test

Control Panel Fault Code Listing • NOTE: Reference fault code #23*: In ambient temperatures below 0° C, this code may be logged because the low

ambient causes a tempor ary low gas pressure.

• NOTE: Where the ambient temperature rises above 40° C, with the engine close to overheating, electrical feed to the

compressor clutch may be cut and code #23 registered.

SymptomPossible SourcesAction

0 Normal operation no

fault codes presentNone

*Wait 30 seconds for system

self-check.

*

11 Motorized in-car

aspirator malfunctionHarness / connector fault

Sensor open / short circuit

*

*Panel fault codes are not

stored for motorized in-car

aspirator motor failure.

*

12 Ambient

temperature sensor

malfunctionHarness / connector fault

Sensor open / short circuit

*

*After rectification, disconnect

the vehicle battery for 10

seconds to reset the system.

*

13 Evaporator

temperature sensor

malfunctionHarness / connector fault

Sensor open / short circuit

*

*Refer to PDU

*

14 Water temperature

input malfunctionInstrument cl uster output

*Refer to PDU

*

15 Heater matrix

temperature sensor

malfunctionHarness / connector fault

Sensor open / short circuit

*

*Refer to PDU

*

21 Solar sensorSensor open /short circuit

*Refer to PDU

*

22 Compressor lock

signal faultLow refrigerant charge, low compressor oil level, loose drive

belt Harness / connector fault

*

*Adjust items as required

*

23 Refrigerant pressure

switch malfunctionHarness / connector fault

Switch open / short circuit

*

*Refer to PDU

*

23 Refrigerant pressure

low refrigerant charge * Leak from damaged pipe or joint

*Rectify as required and

recharge system

*

24 Face vent demand

potentiometer faultPotentiometer open / short circuit

Harness / connector fault

*

*Refer to PDU

*

31 LH fresh / recirc.

potentiometer faultHarness / connector fault

In certain circumstances the servo motor may over-travel

and cause further logged faults. This may be cured, following

fault rectification, by cycling the ignition ON-OFF-ON 3 times

*

*Refer to PDU

*

32 RH fresh / recirc.

potentiometer faultHarness / connector fault

In certain circumstances the servo motor may over-travel

and cause further logged faults. This may be cured, following

fault rectification, by cycling the ignition ON-OFF-ON 3 times

*

*Refer to PDU

*

33 Cool air by-pass

potentiometer faultHarness / connector fault

In certain circumstances the servo motor may over-travel

and cause further logged faults. This may be cured, following

fault rectification, by cycling the ignition ON-OFF-ON 3 times

*

*Refer to PDU

*

34 Defrost vent

potentiometer faultHarness / connector fault

In certain circumstances the servo motor may over-travel

and cause further logged faults. This may be cured, following

fault rectification, by cycling the ignition ON-OFF-ON 3 times

*

*Refer to PDU

*

35 Centre vent

potentiometer faultHarness / connector fault

In certain circumstances the servo motor may over-travel

and cause further logged faults. This may be cured, following

fault rectification, by cycling the ignition ON-OFF-ON 3 times

*

*Refer to PDU

*

36 Foot vent

potentiometer faultHarness / connector fault

In certain circumstances the servo motor may over-travel

and cause further logged faults. This may be cured, following

fault rectification, by cycling the ignition ON-OFF-ON 3 times

*

*Refer to PDU

*

41 LH fresh / recirc.

motor faultHarness / connector fault

Servo motor seized or sticking

Flap seized or sticking

*

*

*Refer to PDU

*

42 RH fresh / recirc.

motor faultHarness / connector fault

Servo motor seized or sticking

Flap seized or sticking

*

*

*Refer to PDU

*

Page 1838 of 2490

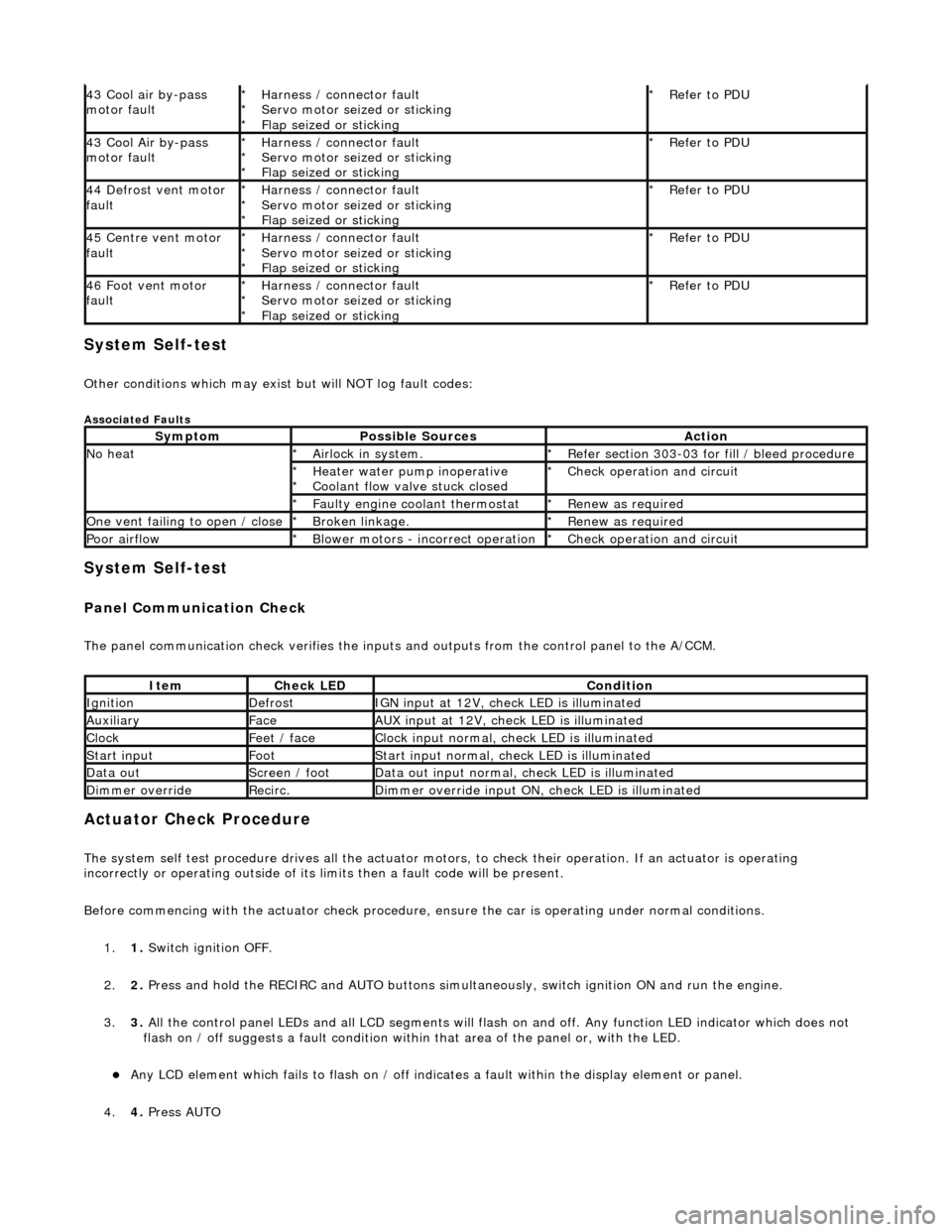

System Self-test

Other conditions which may exist but will NOT log fault codes:

Associated Faults

System Self-test

Panel Communication Check

The panel communication check veri fies the inputs and outputs from the control panel to the A/CCM.

Actuator Check Procedure

The system self test procedure drives all the actuator moto rs, to check their operation. If an actuator is operating

incorrectly or operating outside of its limi ts then a fault code will be present.

Before commencing with the actuator check procedure, ensure the ca r is operating under normal conditions.

1. 1. Switch ignition OFF.

2. 2. Press and hold the RECIRC and AUTO buttons simult aneously, switch ignition ON and run the engine.

3. 3. All the control panel LEDs and all LCD segments will flas h on and off. Any function LED indicator which does not

flash on / off suggests a fault condition within that area of the panel or, with the LED.

Any LCD element which fails to flash on / off indicates a fault within the display element or panel.

4. 4. Press AUTO

43 Cool air by-pass

motor faultHarness / connector fault

Servo motor seized or sticking

Flap seized or sticking

*

*

*Refer to PDU

*

43 Cool Air by-pass

motor faultHarness / connector fault

Servo motor seized or sticking

Flap seized or sticking

*

*

*Refer to PDU

*

44 Defrost vent motor

faultHarness / connector fault

Servo motor seized or sticking

Flap seized or sticking

*

*

*Refer to PDU

*

45 Centre vent motor

faultHarness / connector fault

Servo motor seized or sticking

Flap seized or sticking

*

*

*Refer to PDU

*

46 Foot vent motor

faultHarness / connector fault

Servo motor seized or sticking

Flap seized or sticking

*

*

*Refer to PDU

*

SymptomPossible SourcesAction

No heatAirlock in system.

*Refer section 303-03 for fill / bleed procedure

*

Heater water pump inoperative

Coolant flow valve stuck closed

*

*Check operation and circuit

*

Faulty engine coolant thermostat

*Renew as required

*

One vent failing to open / closeBroken linkage.

*Renew as required

*

Poor airflowBlower motors - incorrect operation

*Check operation and circuit

*

ItemCheck LEDCondition

IgnitionDefrostIGN input at 12V, check LED is illuminated

AuxiliaryFaceAUX input at 12V, check LED is illuminated

ClockFeet / faceClock input normal, check LED is illuminated

Start inputFootStart input normal, check LED is illuminated

Data outScreen / footData out input normal, check LED is illuminated

Dimmer overrideRecirc.Dimmer override input ON, check LED is illuminated

Page 1839 of 2490

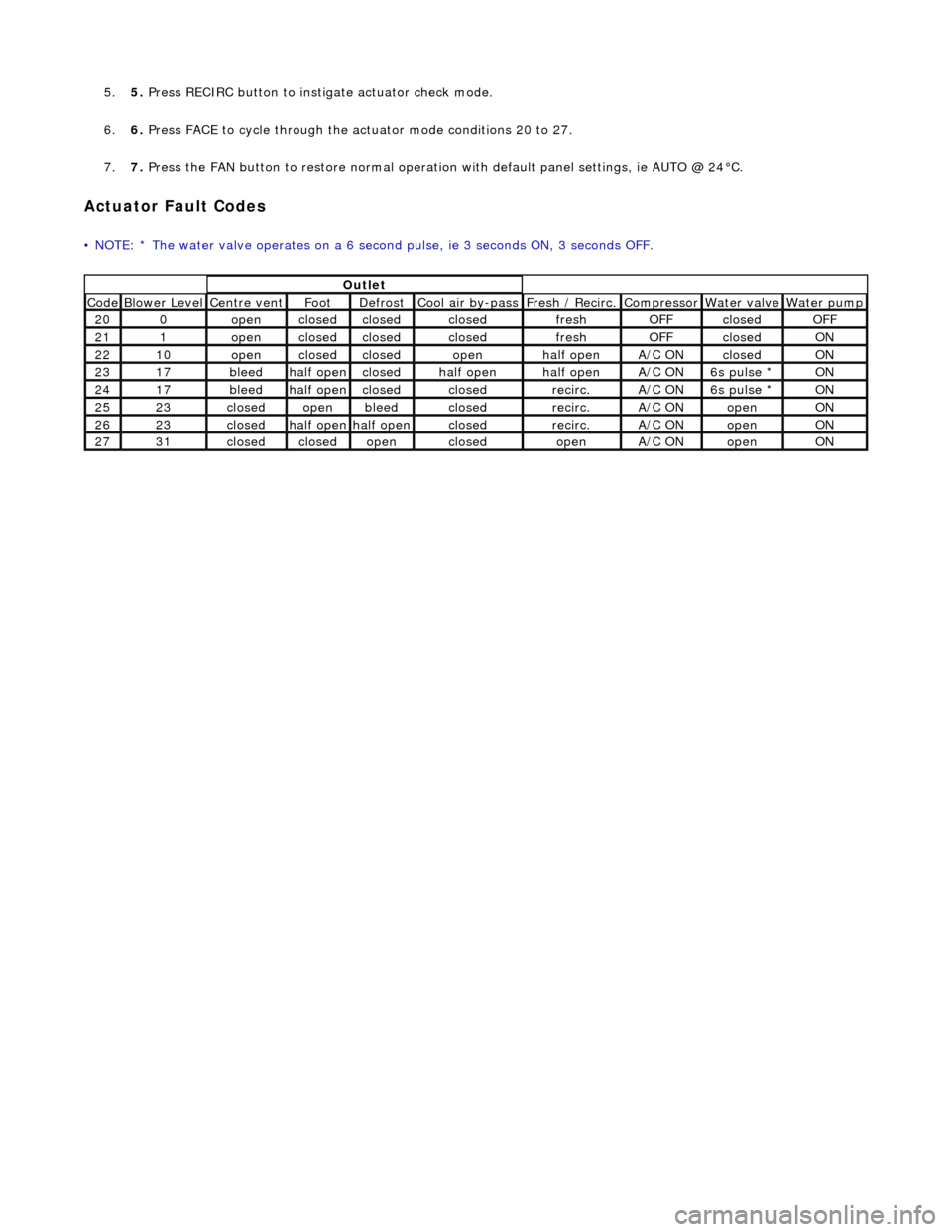

5.5. Press RECIRC button to instigate actuator check mode.

6. 6. Press FACE to cycle through the actu ator mode conditions 20 to 27.

7. 7. Press the FAN button to restore normal operation with default panel settings, ie AUTO @ 24°C.

Actuator Fault Codes

• NOTE: * The water valve operates on a 6 second pulse, ie 3 seconds ON, 3 seconds OFF.

Outlet

Code Blower Level Centre vent Foot Defrost Cool air by-pass Fresh / Recirc. Compressor Water valve Water pump

200openclosedclosedclosedfreshOFFclosedOFF

211openclosedclosedclosedfreshOFFclosedON

2210openclosedclosedopenhalf openA/C ONclosedON

2317bleedhalf openclosedhalf openhalf openA/C ON6s pulse * ON

2417bleedhalf openclosedclosedrecirc.A/C ON6s pulse * ON

2523closedopenbleedclosedrecirc.A/C ONopenON

2623closedhalf openhalf openclosedrecirc.A/C ONopenON

2731closedclosedopenclosedopenA/C ONopenON