head lamp JAGUAR X308 1998 2.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1037 of 2490

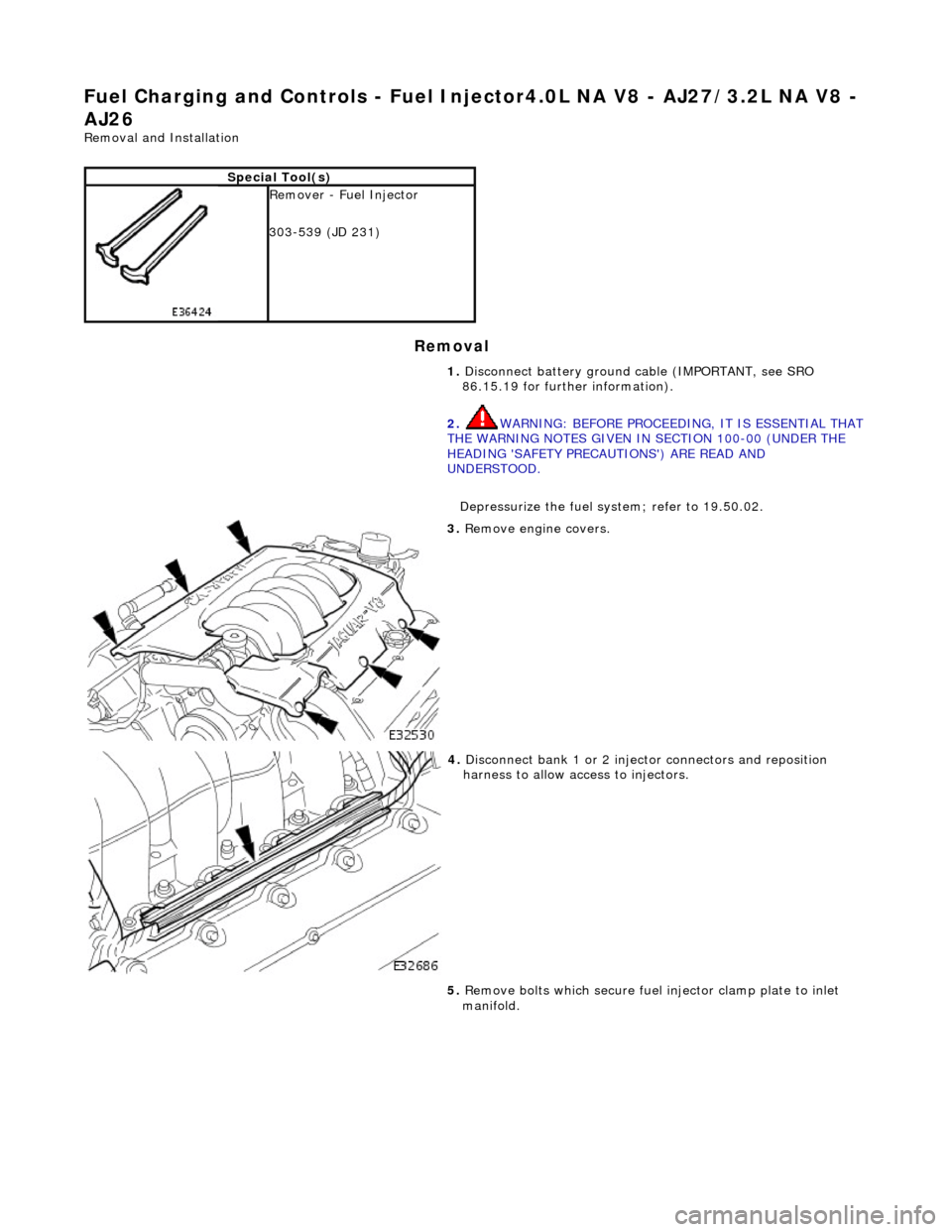

Fuel Ch

arging and Controls

- Fuel Injector4.0L NA V8 - AJ27/3.2L NA V8 -

AJ26

Re

moval and Installation

Remov

al

S

pecial Tool(s)

R

emover - Fuel Injector

303-539 (JD 231)

1. Disconnect battery ground cable (IMPORTANT, see SRO

86.15.19 for further information).

2. WARNING: BEFORE PROCEEDING, IT IS ESSENTIAL THAT

THE WARNING NOTES GIVEN IN SECTION 100-00 (UNDER THE

HEADING 'SAFETY PRECAUTIONS') ARE READ AND

UNDERSTOOD.

Depressurize the fuel sy stem; refer to 19.50.02.

3. R

emove engine covers.

4. Di

sconnect bank 1 or 2 inject

or connectors and reposition

harness to allow access to injectors.

5. Remove bolts which secure fuel injector clamp plate to inlet

manifold.

Page 1388 of 2490

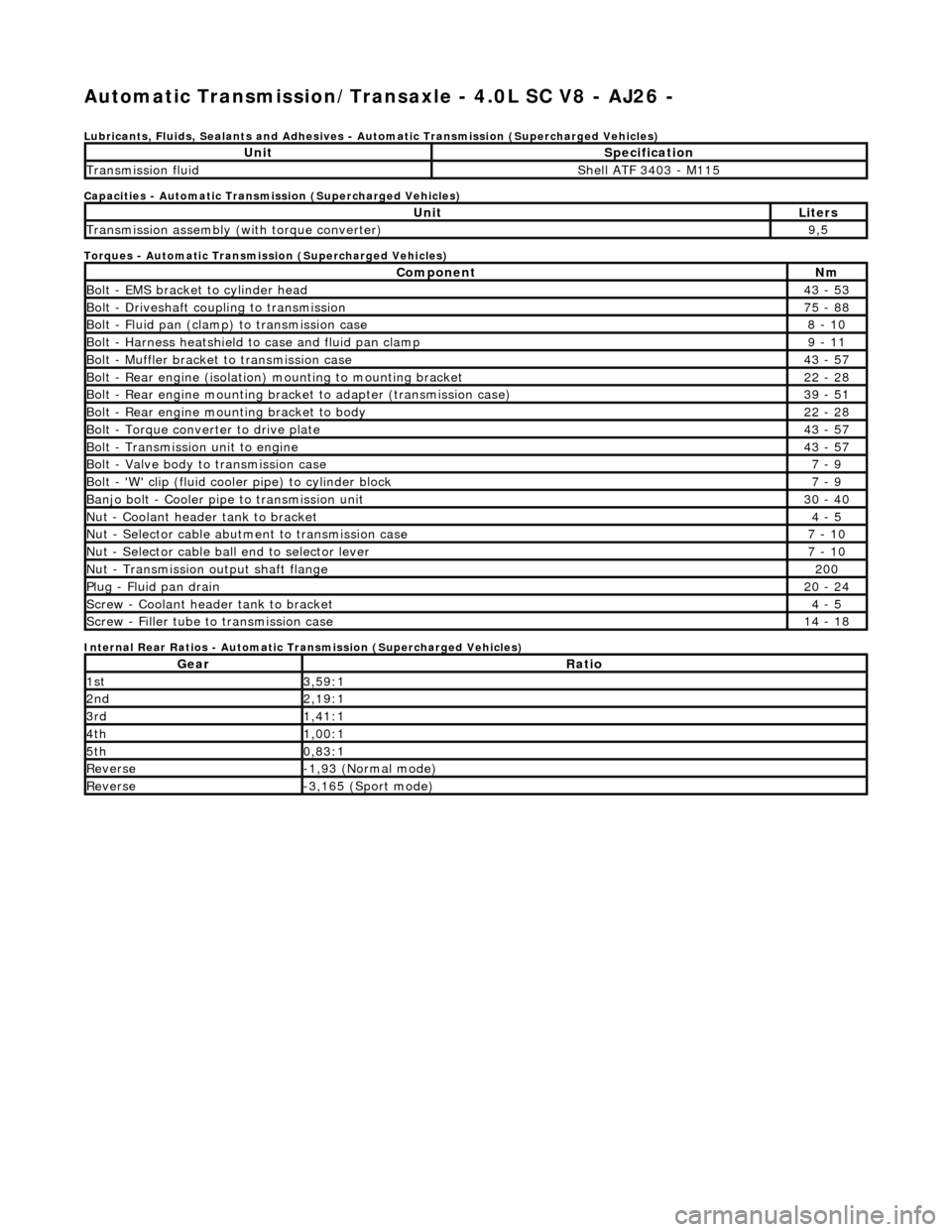

Automatic Transmission/Transaxle - 4.0L SC V8 - AJ26 -

Lubricants, Fluids, Sealants and Adhesives - Automatic Transmission (Supercharged Vehicles)

Capacities - Automatic Transmission (Supercharged Vehicles)

Torques - Automatic Transmission (Supercharged Vehicles)

Internal Rear Ratios - Automatic Transmission (Supercharged Vehicles)

UnitSpecification

Transmission fluidShell ATF 3403 - M115

UnitLiters

Transmission assembly (with torque converter)9,5

ComponentNm

Bolt - EMS bracket to cylinder head43 - 53

Bolt - Driveshaft coupling to transmission75 - 88

Bolt - Fluid pan (clamp) to transmission case8 - 10

Bolt - Harness heatshield to case and fluid pan clamp9 - 11

Bolt - Muffler bracket to transmission case43 - 57

Bolt - Rear engine (isolation) mounting to mounting bracket22 - 28

Bolt - Rear engine mounting brac ket to adapter (transmission case)39 - 51

Bolt - Rear engine mounting bracket to body22 - 28

Bolt - Torque converter to drive plate43 - 57

Bolt - Transmission unit to engine43 - 57

Bolt - Valve body to transmission case7 - 9

Bolt - 'W' clip (fluid cooler pipe) to cylinder block7 - 9

Banjo bolt - Cooler pipe to transmission unit30 - 40

Nut - Coolant header tank to bracket4 - 5

Nut - Selector cable abutment to transmission case7 - 10

Nut - Selector cable ball end to selector lever7 - 10

Nut - Transmission output shaft flange200

Plug - Fluid pan drain20 - 24

Screw - Coolant header tank to bracket4 - 5

Screw - Filler tube to transmission case14 - 18

GearRatio

1st3,59:1

2nd2,19:1

3rd1,41:1

4th1,00:1

5th0,83:1

Reverse-1,93 (Normal mode)

Reverse-3,165 (Sport mode)

Page 1692 of 2490

Fuel Tank and Lines - Fuel Tank and Li

nes

Description an

d Operation

Fuel Tank

Parts List

The steel fuel tank is located inside the trunk and mounted across the vehicle behind the passenger compartment bulkhead.

The fuel tank is held in posi tion by two retaining straps fi tted to body-mounted brackets.

The fuel tank has an integral non-adjustable fill er pipe and integral breather and vapor pipework.

A single fuel pump is mounted inside the tank on vehicles with normally aspirated engines. For vehicles with supercharged

engines, two pumps are fitted in the tank. Fuel is drawn by the pump(s) from the fuel tank and supplied via the fuel lines

and 70 micron filter to the fuel rails.

The fuel lines run from front-to-rear down the vehicle's left-hand-side.

Ite

m

Part

Number

Descr

iption

1—Fu

el filler latch box

2—Pressure reli

ef pipe, ORVR

(shown) / tank breather pipe on non-ORVR systems

3—Tank grounding

cable

4—Evaporative flan

ge assembly

(ORVR type shown)

5—Trunk elec

trical harne

ss (part of)

6—Fue

l

level sensor

flange/connector

7—Fu

el tank retaining straps

8—F

u

el tank retaining stra

ps adjustable clamps

9—Fu

el tank retaining straps lower brackets

10—Tank vapor outlet pipe to un

derflo

or pipe quick-fit connector

11—F

u

el filler latch bo

x water drain pipe

Page 1734 of 2490

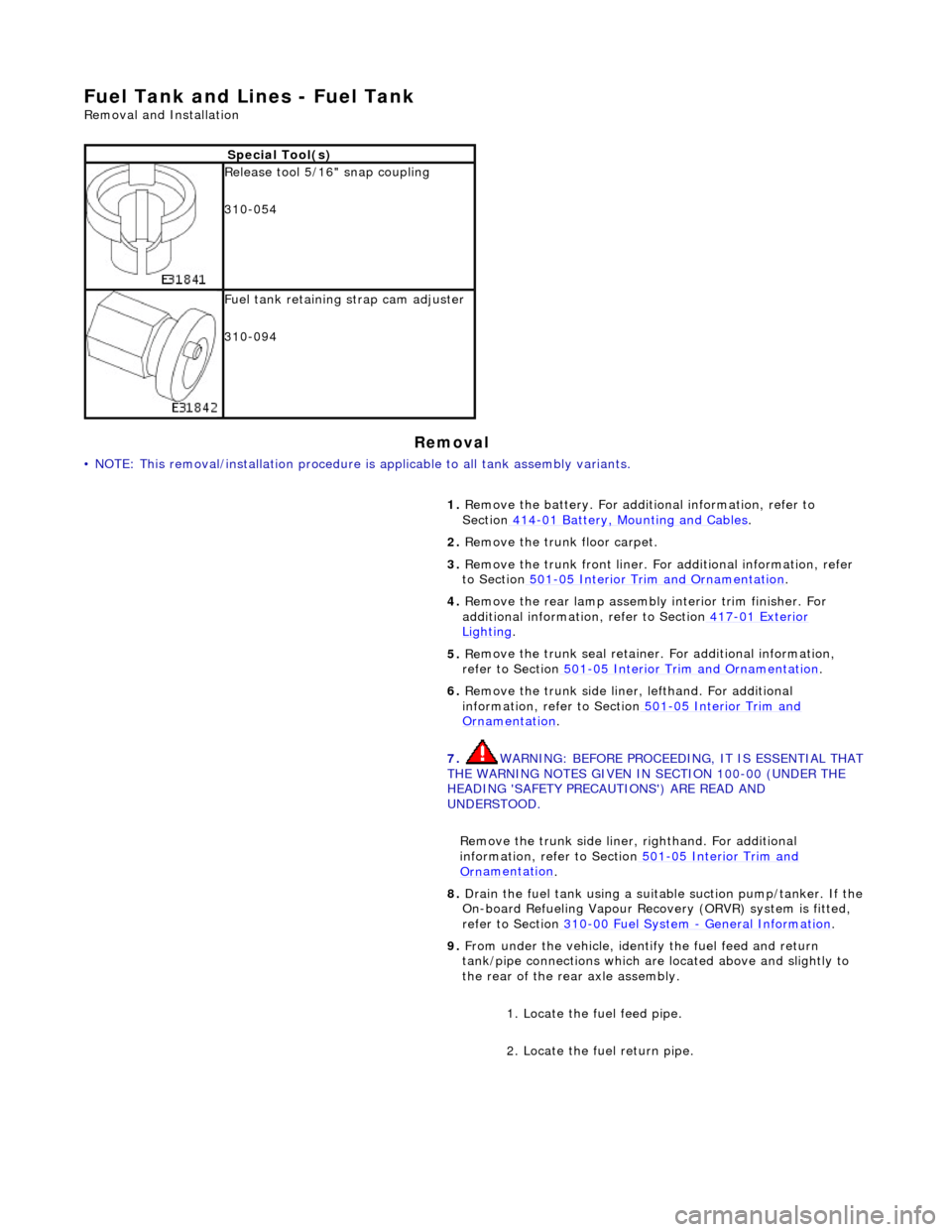

Fuel Tank and Lines - Fuel Tank

Re

mo

val and Installation

Remov

a

l

•

NO

TE: This removal/installation procedure is applicable to all tank assembly variants.

S

p

ecial Tool(s)

R

e

lease tool 5/16" snap coupling

310-054

F u

el tank retaining strap cam adjuster

310-094

1. Remove the battery. For additi onal information, refer to

Section 414

-01

Battery, Mounting and Cables

.

2. Re

move the trunk floor carpet.

3. Remove the trunk front liner. Fo r additional information, refer

to Section 501

-05

Interior Trim and Ornamentation

.

4. Re

move the rear lamp assembly interior trim finisher. For

additional information, refer to Section 417

-01

Exterior

Ligh

ting.

5. Re

move the trunk seal retainer

. For additional information,

refer to Section 501

-0 5

Interior Trim and Ornamentation

.

6. Re

move the trunk side liner, lefthand. For additional

information, refer to Section 501

-05

Interior Trim and

Or

n

amentation

.

7. WARNING: B E

FORE PROCEEDING, IT IS ESSENTIAL THAT

THE WARNING NOTES GIVEN IN SECTION 100-00 (UNDER THE

HEADING 'SAFETY PRECAUTIONS') ARE READ AND

UNDERSTOOD.

Remove the trunk side liner, righthand. For additional

information, refer to Section 501

-05

Interior Trim and

Or

n

amentation

.

8.

Drain th e fue

l tank using a suitab

le suction pump/tanker. If the

On-board Refueling Vapour Recove ry (ORVR) system is fitted,

refer to Section 310

-00 Fu

el System

- General

Information

.

9. Fr

om under the vehicle, identify the fuel feed and return

tank/pipe connections which are located above and slightly to

the rear of the rear axle assembly.

1. Locate the fuel feed pipe.

2. Locate the fuel return pipe.

Page 1785 of 2490

Engine speed (valve closed with the engine not running) Demand (set) temperature In-car temperature sensor Solar sensor

Re-heating of the refrigerated air is contro lled by the time that the water valve is open (i.e. not energised) over a six secon d

interval. The duty cycle of the water valve, the time open / time closed, is controlled by the A/CCM.

Maximum heating demand will cause the water valve to be fu lly open (not energised) to allow maximum coolant flow

through the heater matrix.

At Maximum cooling, the water va lve will be fully closed (energised) to prevent hot (engine temperature) coolant entering

the heater circuit; the pump however will continue to circulate coolant through both the heater matrix and water valve

bypass.

The water valve defaults open when the ignition is OFF.

Under engine stall conditions, when ignition is ON, the water valve will be open.

Water Pump Assembly

Located in the same area as the water valve, the water pump continually circulates coolant through the heater matrix

except when the conditions below apply:

The engine coolant is below 16°C. The ignition is OFF. Under engine stall conditions, when ignition is ON. Control panel OFF

Non return valves

The heater bypass hose has a non-return valve, located between the engine feed and return hoses. The valve prevents the

water pump from recirculating coolant fro m the heater at low engine speeds.

The flow indicator arrow embossed on the valve bo dy MUST point towards the coolant header tank.

CAUTION: Coolant flow will be compromi sed if either valve is fitted incorrectly. Observe the correct direction.

A second non-return valve is located betw een the water pump and water valve. This valve prevents hot coolant from flowing

into the heater with the engine switched off. The flow indicator arrow MUST point towards the water pump.

Heater feed and return hoses

The heater feed and return hoses are connected to the engine feed and return hoses by 'Quick-Fit' connection unions. The

feed hose has a Norma R20 connector and the return hose a Norma push and seal connector. The coolant system bleed

joints have Cobra clamps. All remaining hose connections have spring band hose clamps.

The engine feed hose is connected to the engine bypass hous ing and the engine return hose is connected to the engine

water pump.

Clamp Identification

Page 1854 of 2490

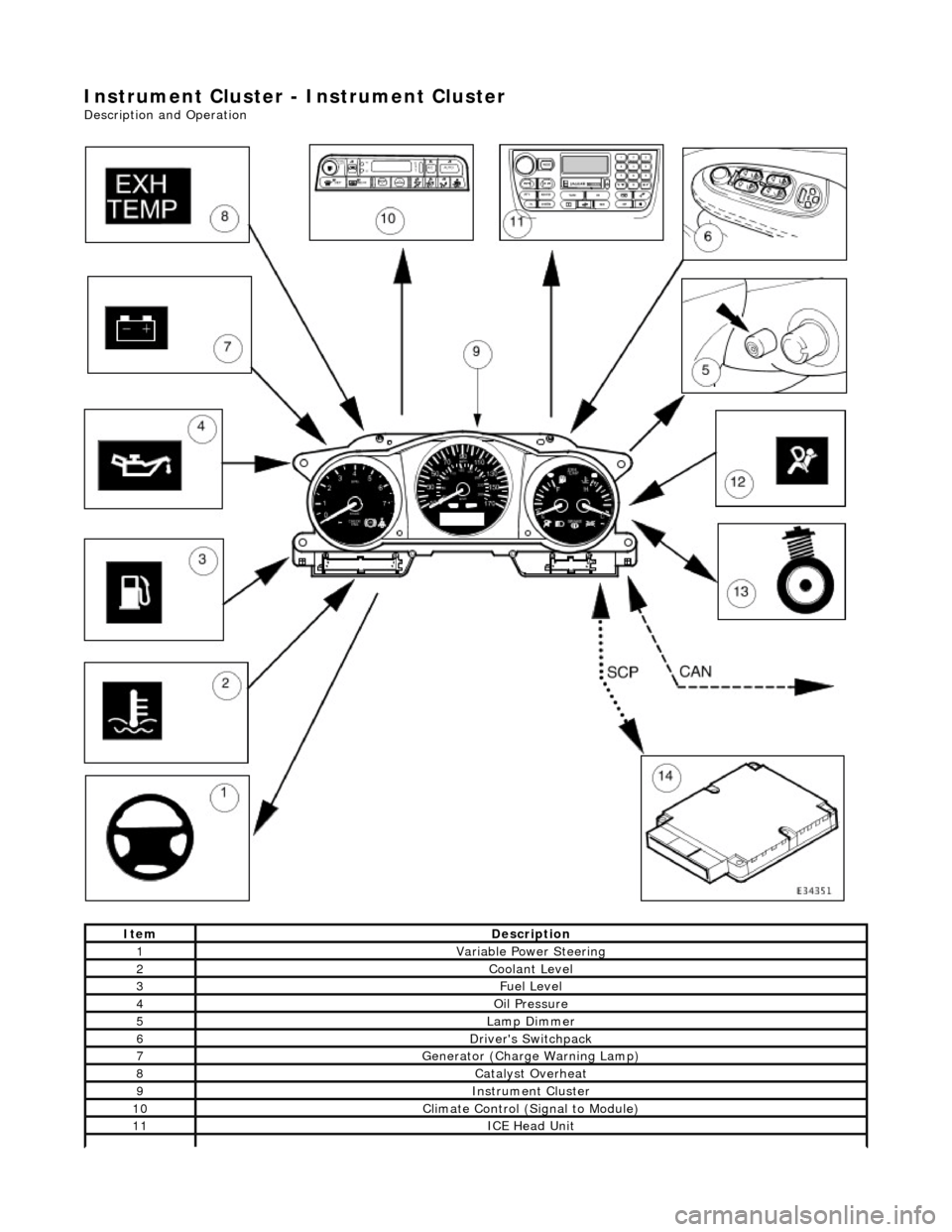

Instrument Cluster - Instrument Cluster

Description and Operation

ItemDescription

1Variable Power Steering

2Coolant Level

3Fuel Level

4Oil Pressure

5Lamp Dimmer

6Driver's Switchpack

7Generator (Charge Warning Lamp)

8Catalyst Overheat

9Instrument Cluster

10Climate Control (Signal to Module)

11ICE Head Unit

Page 1918 of 2490

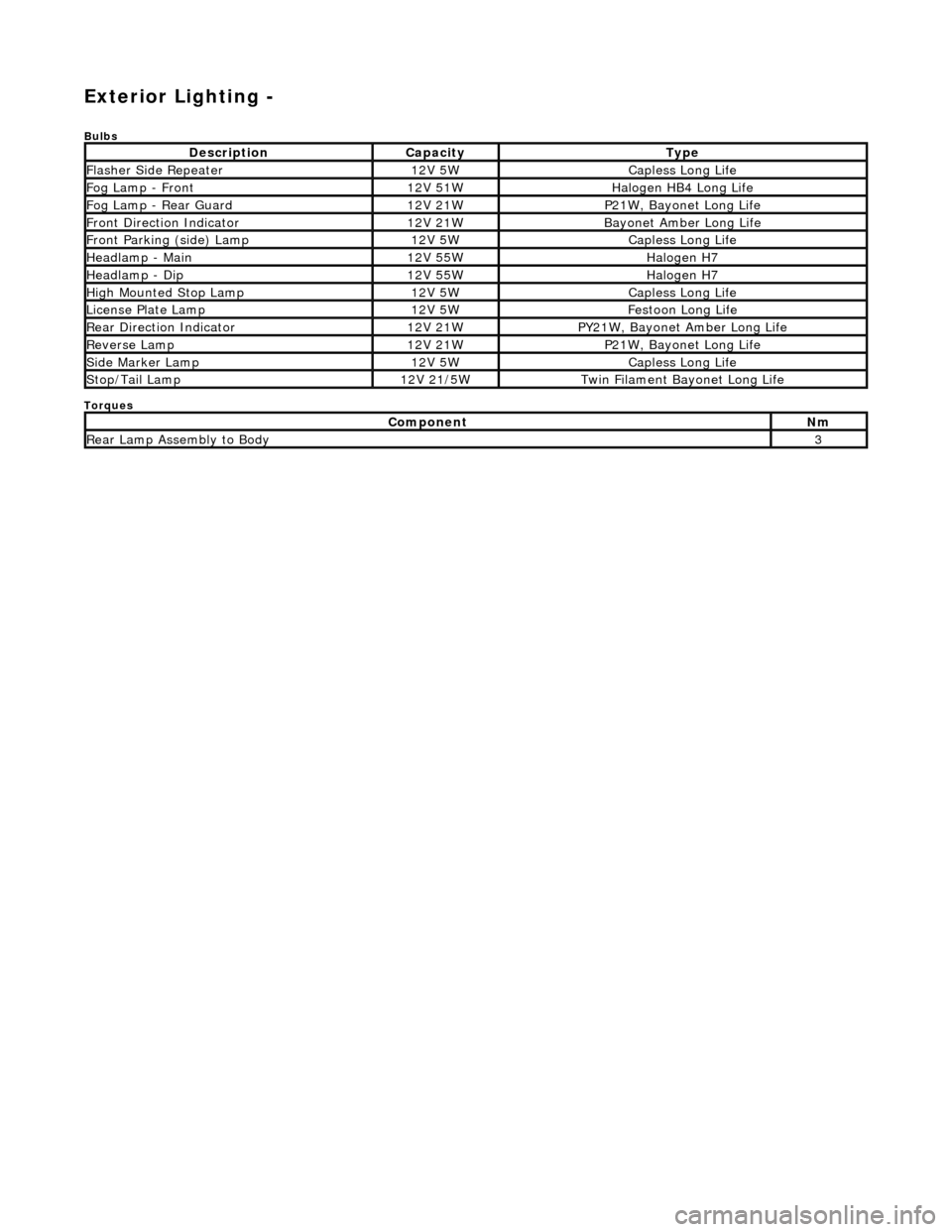

Exterior Lighting -

Bulbs

Torques

DescriptionCapacityType

Flasher Side Repeater12V 5WCapless Long Life

Fog Lamp - Front12V 51WHalogen HB4 Long Life

Fog Lamp - Rear Guard12V 21WP21W, Bayonet Long Life

Front Direction Indicator12V 21WBayonet Amber Long Life

Front Parking (side) Lamp12V 5WCapless Long Life

Headlamp - Main12V 55WHalogen H7

Headlamp - Dip12V 55WHalogen H7

High Mounted Stop Lamp12V 5WCapless Long Life

License Plate Lamp12V 5WFestoon Long Life

Rear Direction Indicator12V 21WPY21W, Bayonet Amber Long Life

Reverse Lamp12V 21WP21W, Bayonet Long Life

Side Marker Lamp12V 5WCapless Long Life

Stop/Tail Lamp12V 21/5WTwin Filament Bayonet Long Life

ComponentNm

Rear Lamp Assembly to Body3

Page 1919 of 2490

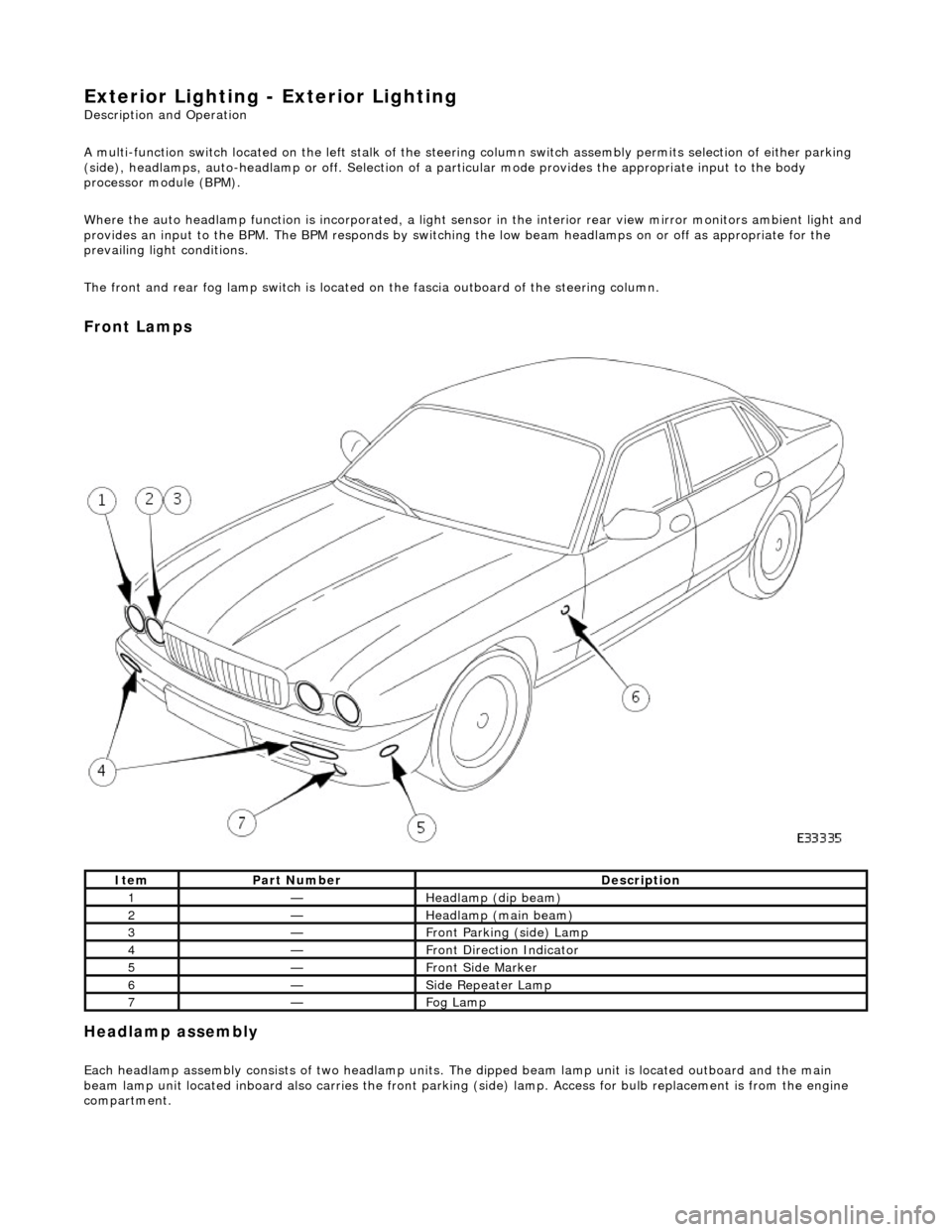

Exterior Lighting - Exterior Lighting

Description and Operation

A multi-function switch located on the left stalk of the steering column switch assembly permits selection of either parking

(side), headlamps, auto-headlamp or off. Selection of a particular mode provides the appropriate input to the body

processor module (BPM).

Where the auto headlamp function is incorporated, a light sensor in the interior rear view mirror monitors ambient light and

provides an input to the BPM. The BPM responds by switching the low beam headlamps on or off as appropriate for the

prevailing light conditions.

The front and rear fog lamp switch is located on the fascia outboard of the steering column.

Front Lamps

Headlamp assembly

Each headlamp assembly consists of tw o headlamp units. The dipped beam lamp unit is located outboard and the main

beam lamp unit located inboard also carries the front parking (side) lamp. Access for bulb replacement is from the engine

compartment.

ItemPart NumberDescription

1—Headlamp (dip beam)

2—Headlamp (main beam)

3—Front Parking (side) Lamp

4—Front Direction Indicator

5—Front Side Marker

6—Side Repeater Lamp

7—Fog Lamp

Page 1933 of 2490

Exterior Lighting - Headlamp Assembly

Removal and Installation

Removal

1. Remove radiator grill. Refer to 76.55.03.

2. Remove radiator grill surro und. Refer to 76.55.15.

3. Remove headlamp trim panel. Refer to 76.11.23.

4. Disconnect headlamp levelling actuator if fitted.

5. Disconnect headlamp assembly harness connector.

6. Remove headlamp assembly to body lower nuts.

7. Remove headlamp to body upper nuts.

Page 1934 of 2490

Installation

8. Remove headlamp assembly from vehicle.

1. Position headlamp assembly on body and install upper nuts.

2. Install headlamp to body lower nuts.

3. Connect headlamp assembly harness connector.

4. Connect headlamp levelling actuator harness connector if

fitted.