panel JAGUAR X308 1998 2.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 432 of 2490

It is a reciprocating two

-circuit pu

mp in which one brake circuit is as signed to each pump circuit.

It supplies th

e fluid pressure and vo

lume to supply the brake circuits under ABS and Traction control.

The pump is driven by an electri

c motor, with the pump

housing incorporating two lo w pressure accumulators and

damping chambers for each brake circuit.

The ac cu

mulator stores the pressure and smooths out the output pu

lses from the pump.

ABS Warning Lamp

The sys

tem will be set in a fail-safe mode if a problem is de

tected; a warning lamp on the instrument panel will notify the

driver there is a problem.

Anti-Lock Braking Sy

stem (ABS)

The AB

S components are combined with

an hydraulic booster and a tandem master cylinder to provide a two circuit braking

system. The system comprises, four wheel speed sensor s, a brake control modulator and an ABS warning lamp.

Should a wheel start to lock-up during braking a signal tr ansmitted from the wheel speed sensor to the brake control

modulator will start the hydraulic pump. The brake control modula tor will close the input valve of the line connected to the

locked-wheel to stop any increase in fluid pressure to the br ake caliper. If this fails to prevent the wheel locking, the

pressure in the caliper will be decreased by opening the return valve until th e wheel starts accelerating again. The fluid

pressure from the return va lve is directed into the low pressure accumulator, housed in the pump.

From the low pressure accumulator, fl uid is pumped through the damping cham ber to the brake master cylinder. The

pressure to the brake caliper will then be increased in small steps to maintain maximum adhesion between the tire and road

surface. This is achieved by closing the return valve, and opening the input valve and using the hydraulic pump to increase

the pressure.

Although the system senses all four wheels independently, the rear wheels are regulated as a pair. If a sensor on a rear

wheel detects a wheel decelerating rapidly, then the fluid pressure to both wheels is reduced. The fluid pressure is then

dictated by the wheel having the lowe st adhesion with the road surface.

The ABS system will be set in a fail-safe mode if a problem is detected; a warn ing lamp on the instrument panel will notify

the driver there is a problem. The brake system will still operate conventionally and with the same standard of performance

as a vehicle not equipped with ABS.

Automa tic Stability Control (ASC)

Th

e ASC utilizes the ABS sensing arrangement to provide the maximum traction force to propel the vehicle.

The ASC is switched on when the engine is started. The system can be switched off by pressing the 'ASC OFF' (the switched

is marked 'TRAC OFF' on vehicles fitted with traction control). The switch, which is situated in the center console switchpack,

lights up to warn that the system is sw itched off. An 'ASC' amber warning light flashes on the instrument panel when the

system detects a spinning wheel.

The ASC system uses engine intervention to reduce the torque delivered to the drive wheels to prevent them spinning.

Engine torque is re duced in three ways:

The

throttle is moved towards the closed position.

The ignition is retarded. F

u

el is cut-off at the cylinder injectors.

Wheel spin is detected by the wheel sp eed sensors and communicated to the AB S/TCCM. The ABS/TCCM uses information

from the controller area network (CAN) to calculate the torque that the engine should produce to stop the wheel spinning.

Torque reductions are then requested from the engine control module (ECM ) through the CAN. The throttle is then

positioned to provide the target torque, which has been calculated to prevent wheel spin. During the transient phase of

torque reduction the fuel is cut-off and th e ignition retarded Both the fuel cut-off an d ignition retard will be restored to

normal when the throttle is set to its new position.

The ASC uses a brake control modulator with six solenoid va lves: three normally open inlet valves and three normally

Page 433 of 2490

clos

ed outlet valves.

Traction Control

Trac

tion control has the same capabilities as ASC but with th

e added ability to actuate the brakes of the spinning wheel.

This enhances ASC by improving acceleration particularly on surfaces with uneven friction , e.g. one wheel on ice the other

on tarmac.

When wheelspin occurs, brake line pressure to the slipping wheel is generated, to operate that wheel's brake. The BCM

achieves this by closing the cut-off solenoid valve and oper ating the hydraulic pump. Brake fluid is then drawn from the

reservoir through the non-actuated mast er cylinder to the brake caliper.

A 'TRAC' amber warning light flashes on the instrument panel when the system detects a spinning wheel.

The traction control system uses a brake control modulator with nine solenoid valv es: four normally open inlet valves and

four normally closed outlet valves and one special isolating va lve. The outlet valves control the brakes of each each rear

wheel individually on the traction control system.

Rear Wheel Speed Senso

rs and ABS/TCCM Circuit Diagram

Page 505 of 2490

Steering Column - Steering Column

Description an

d Operation

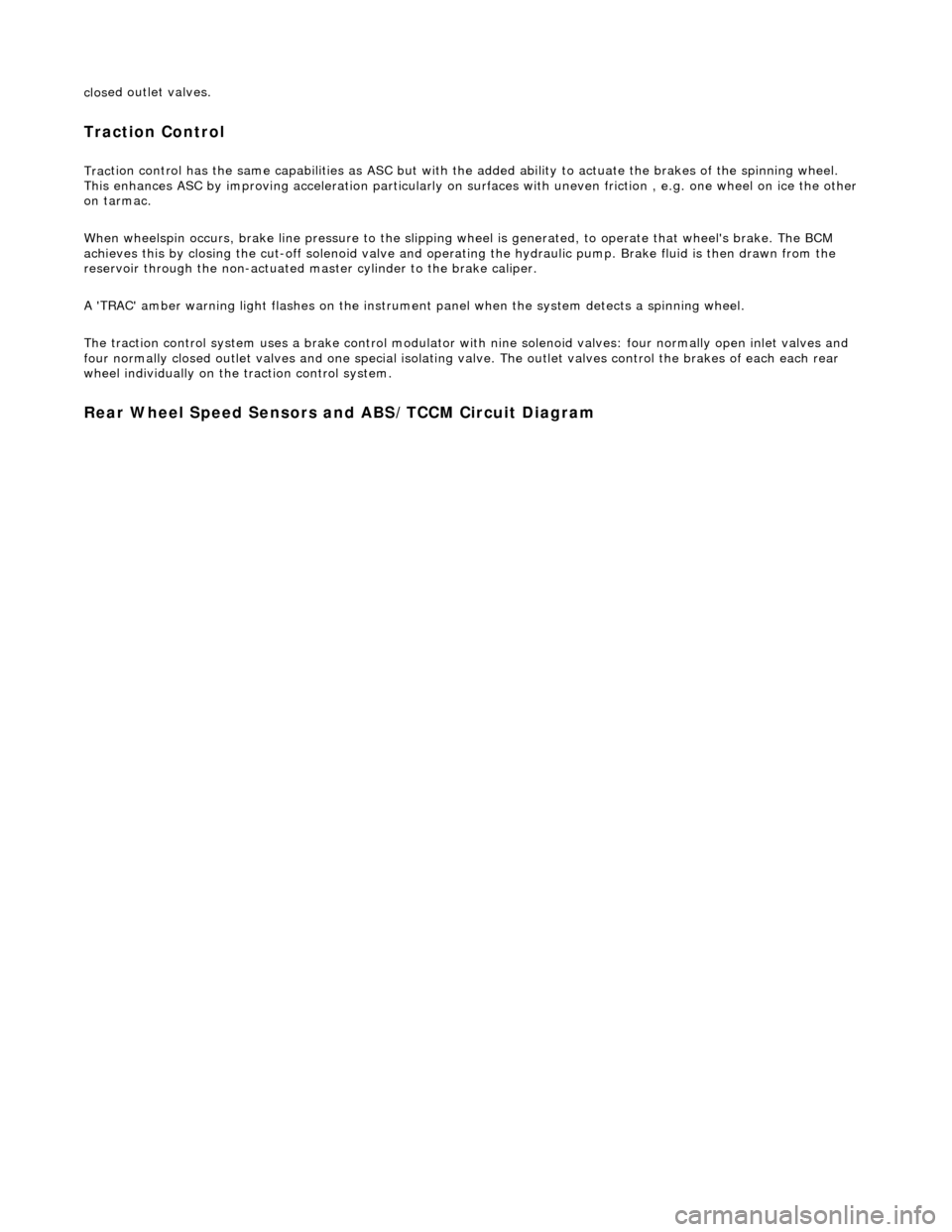

Stee

ring Wheel

T

he steering wheel assembly incorporates:

The s

peed control switchpack.

The i

n-car entertainment (ICE) switchpack.

The h

orn pad.

The driver ai

r bag module; refer to Section

501

-20A Safety Belt

System

Sectio

n

501

-2

0B Supplemental Restraint

Sy

stem

.

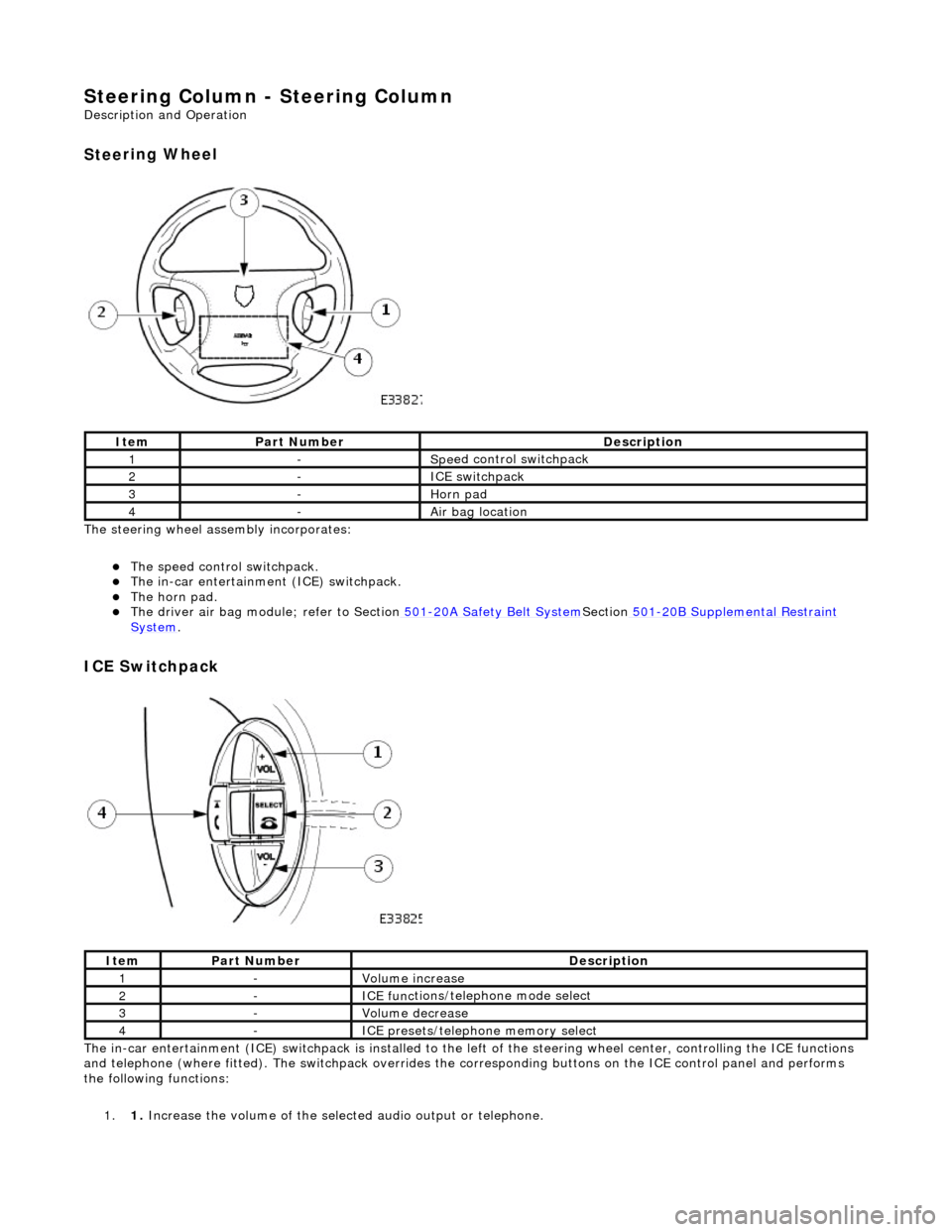

I

CE Switchpack

The

in-car entertainment (ICE) switchpack is installed to the le

ft of the steering wheel center, controlling the ICE functions

and telephone (where fitted). The switchpack overrides the corresponding bu ttons on the ICE control panel and performs

the following functions:

1. 1. Increase the volume of the select ed audio output or telephone.

It

em

Par

t Number

De

scription

1-Spe

ed control switchpack

2-I

CE switchpack

3-Horn pad

4-Air bag lo

cation

It

em

Par

t Number

De

scription

1-Vol

ume increase

2-ICE func

tions/teleph

one mode select

3-Volum

e decrease

4-ICE pres

ets/telephone memory select

Page 530 of 2490

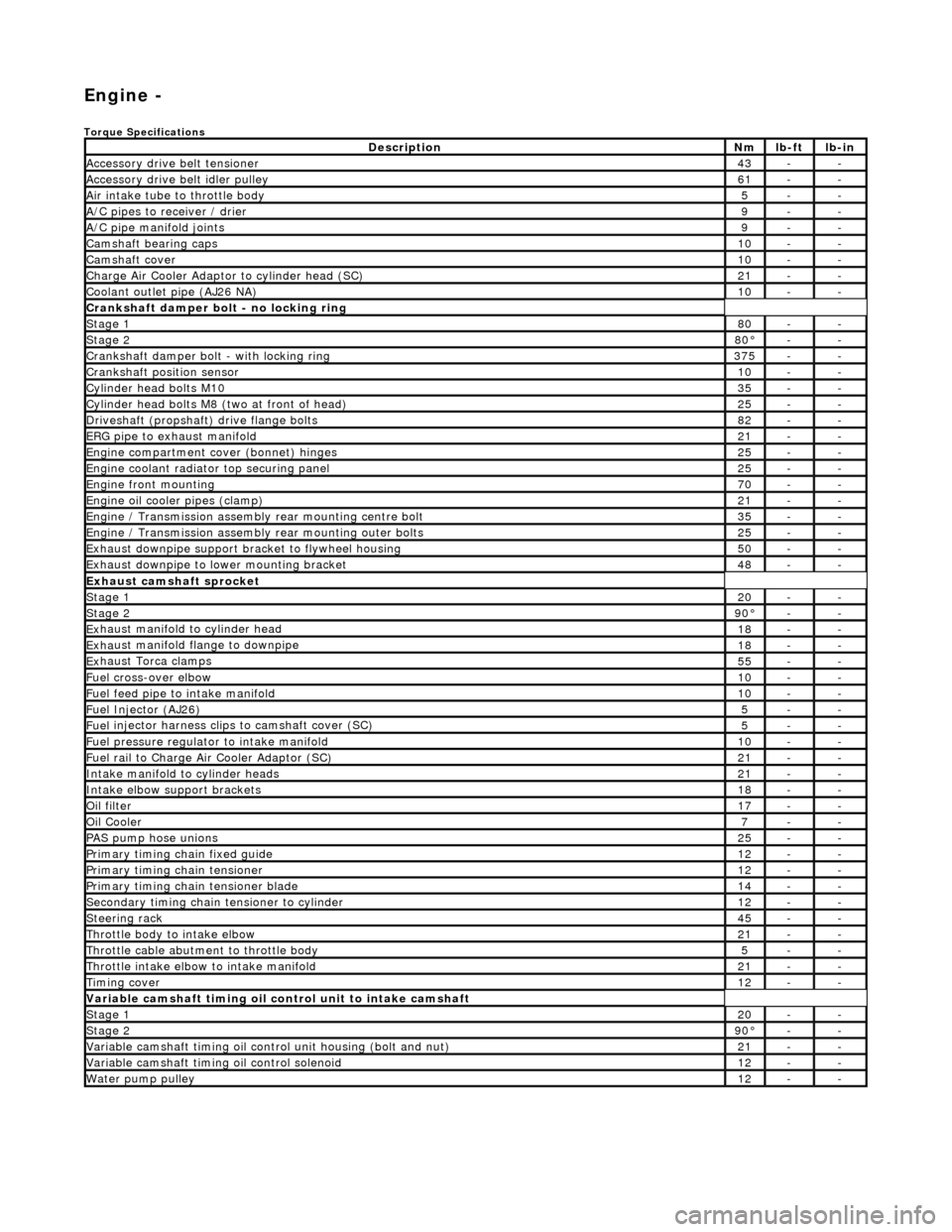

Engi

ne -

Torqu

e Specifications

De

s

cription

Nmlb

-

ft

lb

-

in

A

ccessory

drive belt tensioner

43--

A

ccessory

drive belt idler pulley

61--

Air in

ta

ke tube to throttle body

5--

A/C

pipes t

o receiver / drier

9--

A/C pipe m

anifold joints

9--

Camsh

aft bearin

g caps10--

Ca

msh

aft cove

r10--

Ch

arge Air Co

oler Adaptor to cylinder head (SC)

21--

Co

olan

t outlet pipe (AJ26 NA)

10--

Cran

kshaft damper bolt - no lockin

g ring

St

ag

e 1

80--

Stag

e 2

80°--

C

r

ankshaft damper bolt - with locking ring

37

5--

Cra

nkshaft position sensor

10--

Cy

li

nder head bolts M10

35--

Cy

lin

der head bolts M8 (two at front of head)

25--

Driv

es

haft (propshaft) drive flan

ge bo

l

ts

82--

ERG p

i

pe to exhaust manifold

21--

Engi

ne compartment cover (bonnet) hinges

25--

En

gine

coolant radiator top securing panel

25--

E

ng

ine front mounting

70--

En

gine

oil cooler pipes (clamp)

21--

En

gi

ne / Transmission assembly rear mounting centre bolt

35--

En

gi

ne / Transmission assembly rear mounting outer bolts

25--

Ex

ha

ust downpipe support bracket to flywheel housing

50--

Ex

ha

ust downpipe to lower mounting bracket

48--

E

x

haust camshaft sprocket

St

age 120--

Stage 290 °--

Ex

haust manifold to cylinder head

18--

Ex

ha

ust manifold flange to downpipe

18--

E

x

haust Torca clamps

55--

Fuel cross-over elbo

w

10--

Fu

el f

eed pipe to intake manifold

10--

Fuel

Injector (AJ

26)

5--

Fuel

injector ha

rness clips to camshaft cover (SC)

5--

Fu

el p

ressure re

gu

l

ator to intake manifold

10--

F

u

el rail to Char

ge

A

ir Cooler Adaptor (SC)

21--

In

ta

ke manifold to cylinder heads

21--

Inta

ke elbow support brackets

18--

Oil f

i

lter

17--

Oil C

o

oler

7--

P

AS pu

mp hose unions

25--

P

r

imary timing chain fixed guide

12--

P

r

imary timing chain tensioner

12--

Pr

imary timing chain tensioner blade

14--

S

e

condary timing chain tensioner to cylinder

12--

S

t

eerin

g ra

ck45--

Thro

ttle body to intake elbow

21--

Th

ro

ttle cable abutment to throttle body

5--

Th

ro

ttle intake elbow to intake manifold

21--

Ti

mi

ng cover

12--

Variable camshaft t

i

ming oil control unit to intake camshaft

St

ag

e 1

20--

St

ag

e 2

90

°--

Var

iable camshaft timing oil control unit housing (bolt and nut)

21--

Va

ria

ble camshaft timi

ng oil control solenoid

12--

Wa

ter pump pulley

12--

Page 899 of 2490

16. Disconnect the air cleaner cover.

Remove the five clips which se cure the air cleaner cover.

17. Remove the intake tube / air flow meter / air cleaner cover

assembly.

1. Remove the intake tube / air flow meter / air cleaner

cover assembly.

2. Remove and discard the ru bber seal; air intake tube

to throttle body.

18. Remove the centre trim panel from the engine compartment.

1. Remove the left hand side enclosure panel.

2. Remove the centre trim panel.

19. Release the hoses (Quick Fit connections) from the expansion

tank, using 303 - 623.

1. Release the hose, expansion tank to thermostat housing (coolant outlet pipe on supercharged

engines).

Page 901 of 2490

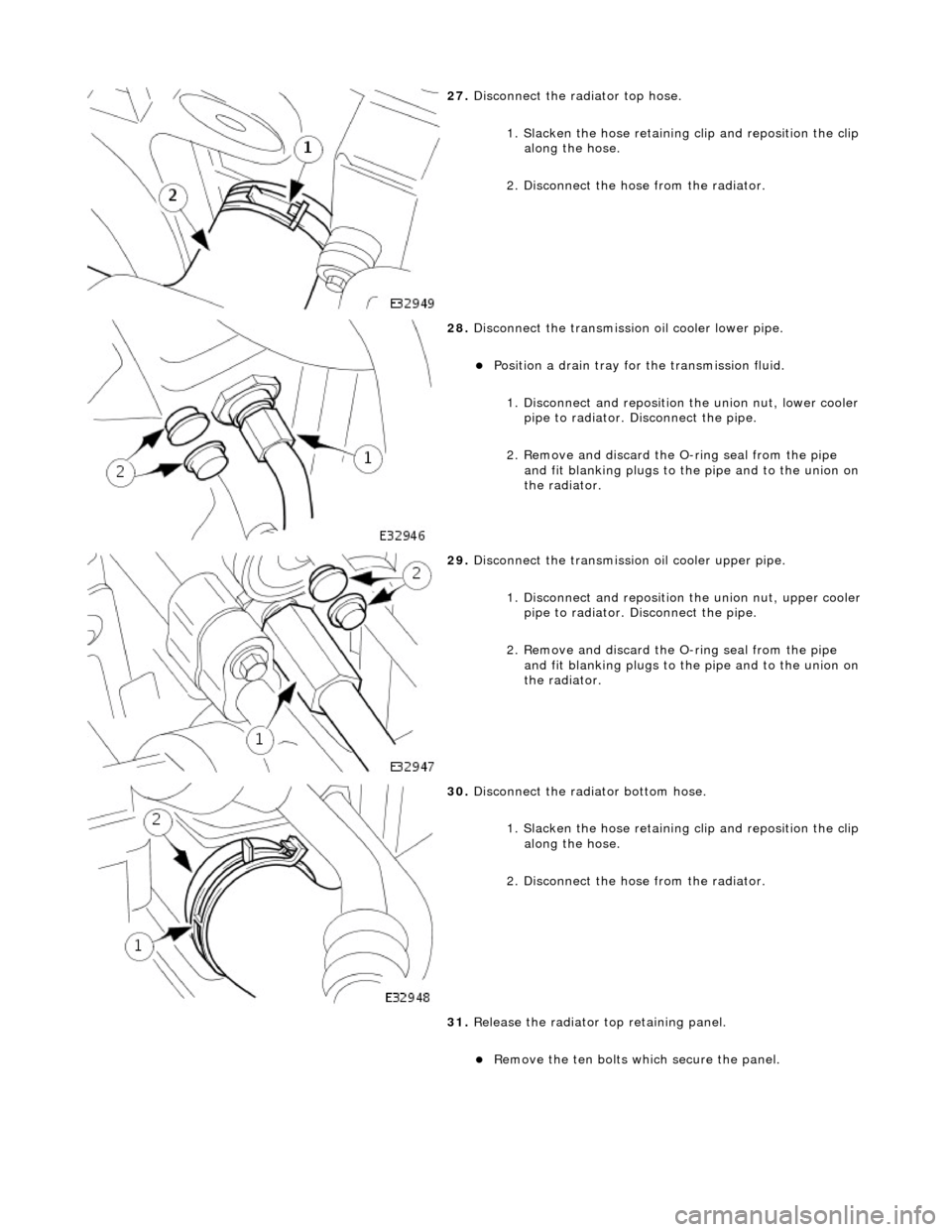

27. Disconnect the radiator top hose.

1. Slacken the hose retaining clip and reposition the clip

along the hose.

2. Disconnect the hose from the radiator.

28. Disconnect the transmission oil cooler lower pipe.

Position a drain tray for the transmission fluid.

1. Disconnect and reposition the union nut, lower cooler pipe to radiator. Di sconnect the pipe.

2. Remove and discard the O- ring seal from the pipe

and fit blanking plugs to the pipe and to the union on

the radiator.

29. Disconnect the transmission oil cooler upper pipe.

1. Disconnect and reposition the union nut, upper cooler pipe to radiator. Di sconnect the pipe.

2. Remove and discard the O- ring seal from the pipe

and fit blanking plugs to the pipe and to the union on

the radiator.

30. Disconnect the radiator bottom hose.

1. Slacken the hose retaining clip and reposition the clip

along the hose.

2. Disconnect the hose from the radiator.

31. Release the radiator top retaining panel.

Remove the ten bolts which secure the panel.

Page 902 of 2490

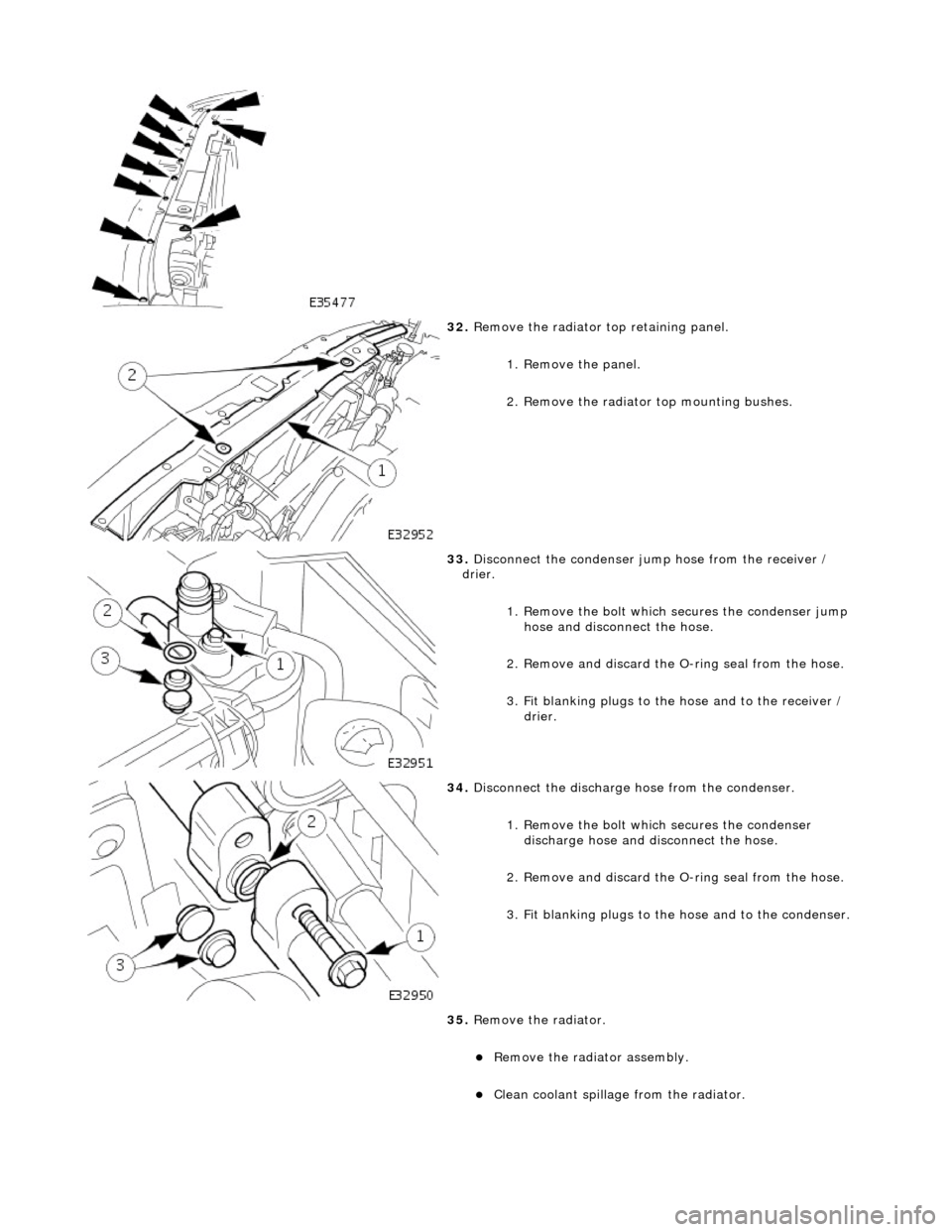

32. Remove the radiator top retaining panel.

1. Remove the panel.

2. Remove the radiator top mounting bushes.

33. Disconnect the condenser jump hose from the receiver /

drier.

1. Remove the bolt which secures the condenser jump hose and discon nect the hose.

2. Remove and discard the O-ring seal from the hose.

3. Fit blanking plugs to the hose and to the receiver / drier.

34. Disconnect the discharge hose from the condenser.

1. Remove the bolt which secures the condenser discharge hose and disconnect the hose.

2. Remove and discard the O-ring seal from the hose.

3. Fit blanking plugs to the hose and to the condenser.

35. Remove the radiator.

Remove the radiator assembly.

Clean coolant spillage from the radiator.

Page 918 of 2490

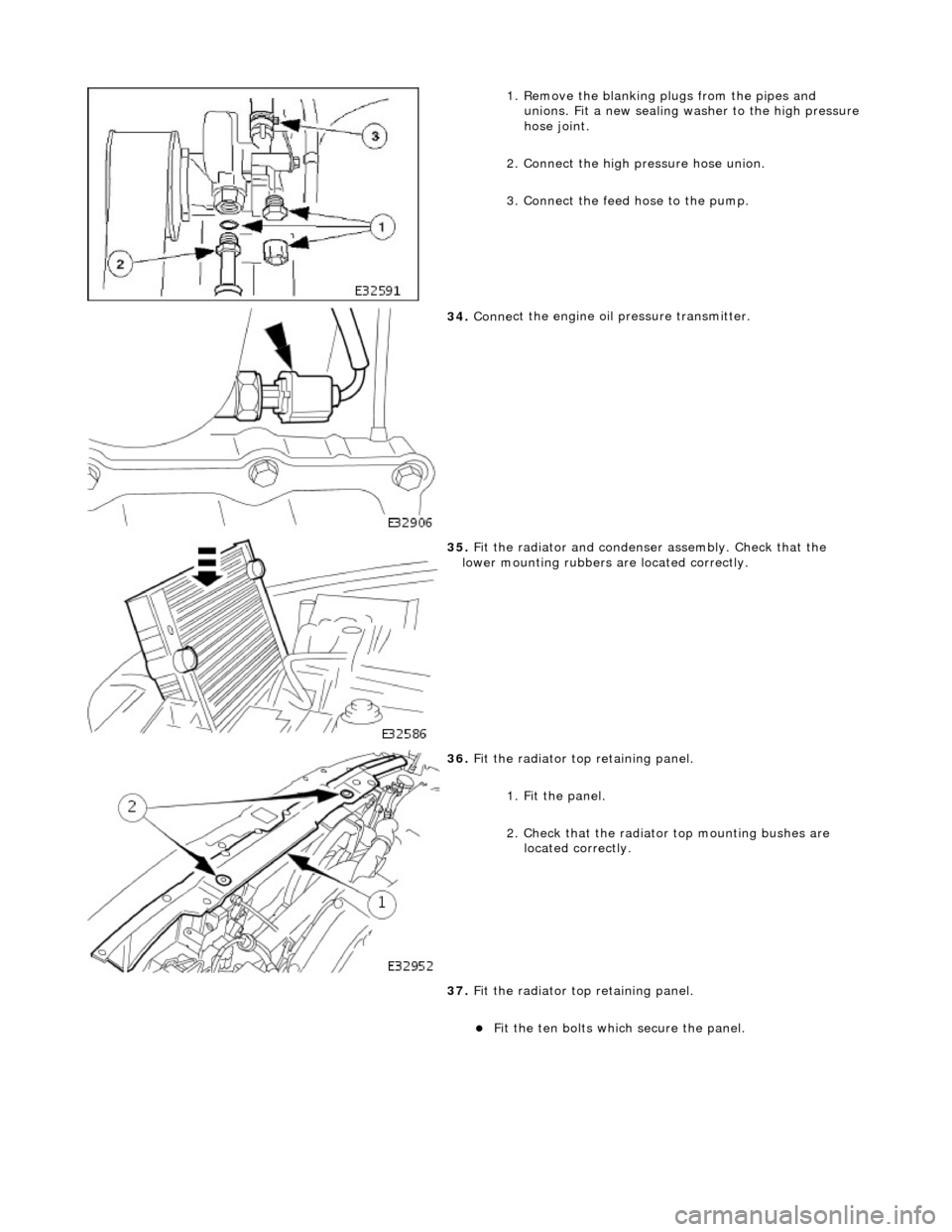

1.

Remove the blanking plugs from the pipes and

unions. Fit a new sealing washer to the high pressure

hose joint.

2. Connect the high pressure hose union.

3. Connect the feed hose to the pump.

34 . Conne

ct the engine oil

pressure transmitter.

35 .

Fit the radiator and

condense

r assembly. Check that the

lower mounting rubbers are located correctly.

36 . Fit the radiator top

retaining panel.

1. Fit the panel.

2. Check that the radiator top mounting bushes are

located correctly.

37. Fit the radiator top retaining panel.

Fit

the ten bolts which secure the panel.

Page 921 of 2490

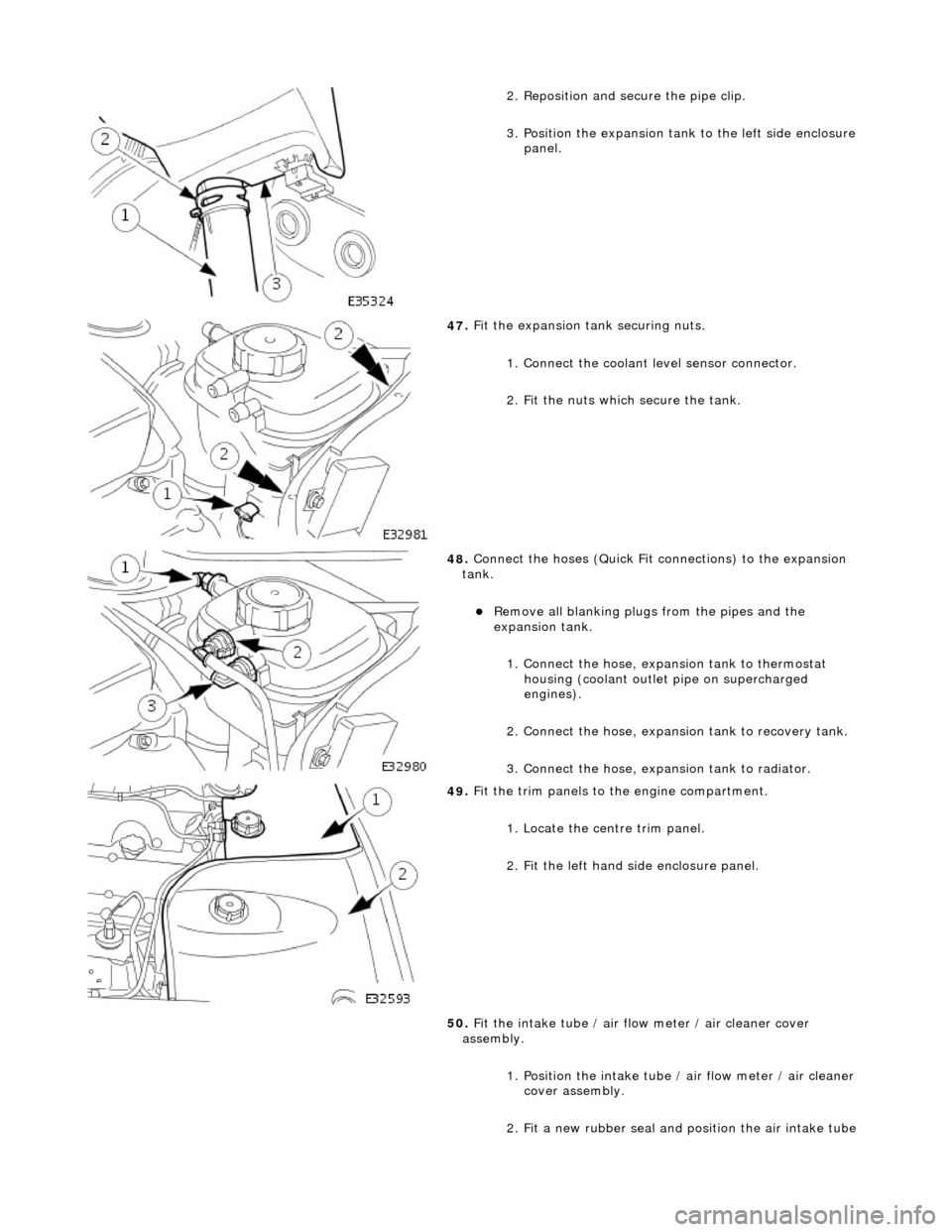

2

. Reposition and secure the pipe clip.

3. Position the expansion tank to the left side enclosure

panel.

47

.

Fit the expansion tank securing nuts.

1. Connect the coolant level sensor connector.

2. Fit the nuts which secure the tank.

48

.

Connect the hoses (Quick Fit connections) to the expansion

tank.

Remove all blanking plug s

from the pipes and the

expansion tank.

1. Connect the hose, expansion tank to thermostat housing (coolant outlet pipe on supercharged

engines).

2. Connect the hose, expansion tank to recovery tank.

3. Connect the hose, expansion tank to radiator.

49

.

Fit the trim panels to the engine compartment.

1. Locate the centre trim panel.

2. Fit the left hand side enclosure panel.

50. Fit the intake tube / air flow meter / air cleaner cover

assembly.

1. Position the intake tube / air flow meter / air cleaner

cover assembly.

2. Fit a new rubber seal and po sition the air intake tube

Page 929 of 2490

The cooling

pack incorporates the radiator a

ssembly with integral transmission oil cool er (located in the radiator outlet tank),

an air conditioning condenser, and the cooling fans and cowl assembly.

The cooling pack on supercharged vehicles is the same as described above, but with the addition of a charge air cooler

coolant radiator located in front of the condenser.

Radiator Mounti

ng/Retention

T

he radiator is mounted on four rubber mounts, one on each

end of the upper and lower horizontal face. The two lower

mountings are supported on two isolated brackets mounted on the body; the lower cradle assembly has subsequently been

deleted.

A closing panel made from polypropylene, which retains the radiat or assembly, fits over the top of the radiator and is bolted

to the vehicle top panel.

Coolant Hoses - Engine