rear bumper JAGUAR X308 1998 2.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1928 of 2490

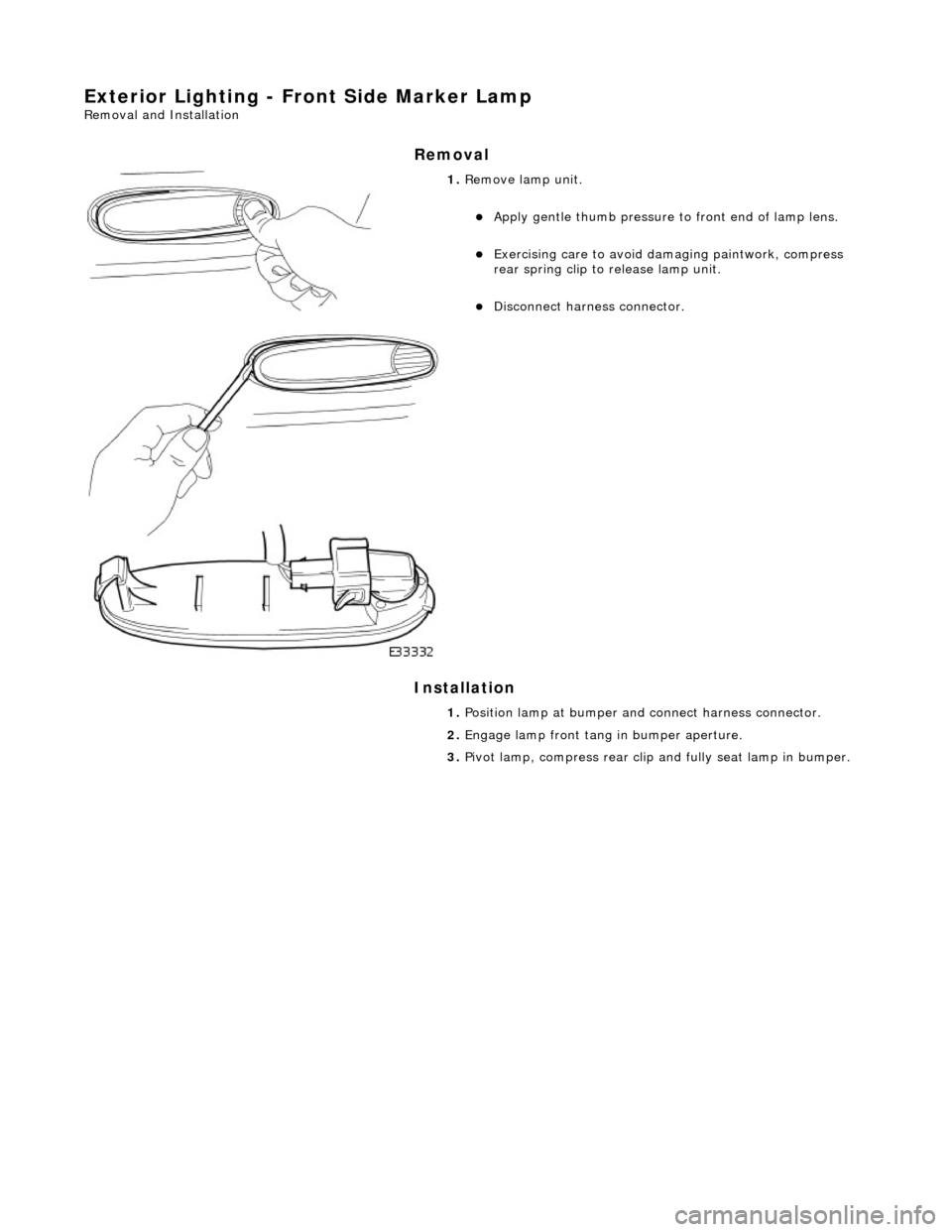

Exterior Lighting - Front Side Marker Lamp

Removal and Installation

Removal

Installation

1. Remove lamp unit.

Apply gentle thumb pressure to front end of lamp lens.

Exercising care to avoid damaging paintwork, compress

rear spring clip to release lamp unit.

Disconnect harness connector.

1. Position lamp at bumper an d connect harness connector.

2. Engage lamp front tang in bumper aperture.

3. Pivot lamp, compress rear clip and fully seat lamp in bumper.

Page 1929 of 2490

Exterior Lighting - Front Side Marker Lamp Bulb

Removal and Installation

Removal

1. Applying firm hand pressure to front end, pivot lamp assembly

for access to rear end.

2. Exercising care to avoid dama ging paintwork, use a small

screwdriver at rear end of lamp, to press and release retaining

tang.

3. Withdraw lamp from bumper for access and disconnect harness multiplug.

4. Rotate bulb holder 1/4 turn counter-clockwise to release it

from lamp assembly.

5. Withdraw bulb from holder.

Page 1930 of 2490

Installation

1. Install bulb in holder.

2. Install bulb and bulb holder in lamp assembly and rotate 1/4

turn clockwise to seat and retain.

3. Position direction lamp at bumper aperture and connect

harness multiplug.

4. Engage front end tang of lamp in bumper aperture.

5. Pivot lamp assembly and firmly seat rear retaining clip in

bumper aperture.

Page 1954 of 2490

Exterior Lighting - Rear Side Marker Lamp

Removal and Installation

Removal

Installation

1. Applying firm thumb pressure to front of lens, pivot lamp

assembly for access to rear end.

2. Exercising care to avoid dama ging paintwork, use a small

screwdriver to press and re lease rear retaining clip.

3. Withdraw lamp from bumper for access and disconnect harness connector.

1. Position lamp at bumper ap erture and connect harness

connector.

2. Engage front end tang of lamp in bumper aperture.

3. Pivot lamp assembly and firmly seat rear retaining clip in

bumper aperture.

Page 1955 of 2490

Exterior Lighting - Rear Side Marker Lamp Bulb

Removal and Installation

Removal

1. Applying firm thumb pressure to front of lens, pivot lamp

assembly for access to rear end.

2. Exercising care to avoid dama ging paintwork, use a small

screwdriver to press and re lease rear retaining clip.

3. Withdraw lamp from bumper for access and disconnect harness connector.

4. Rotate bulb holder 1/4 turn counter-clockwise to release it

from lamp assembly.

5. Withdraw bulb from holder.

Page 1956 of 2490

Installation

1. Install bulb in holder.

2. Install bulb and bulb holder in lamp assembly and rotate 1/4

turn clockwise to seat and retain.

3. Position lamp at bumper ap erture and connect harness

connector.

4. Engage front end tang in bumper aperture.

5. Pivot lamp assembly and firmly seat rear retaining clip in

bumper aperture.

Page 2021 of 2490

Body System - General Information - Body

Description and Operation

This section covers the following areas of the vehicle body:

Front end body panels

Body closures

Aperture seals

Door seals

Instrument panel, console and radio

Centre console

Handles, locks, latches and mechanisms

Wipers and washers

Glass, frames and mechanisms

Fascia

Fuel filler flap assembly

Sun visors

Seating

Interior trim and ornamentation

Exterior trim and ornamentation

Rear view mirrors

Rear parcel tray

Roof console

Bumpers

Occupant restraints

Sliding roof

Steering column cowl

Underscuttle pad

Front End Body Panels

A false bulkhead together with two insulation covers, are installed between the engine compartment and the BIW front

bulkhead to provide optimum insulation ag ainst noise and heat intrusion. Two plenum braces bolted between the BIW upper toeboards and the plenum further increase bodyshell structural integrity. The plastic ra diator grill and vane block achieve

weight reductions over steel parts and provid e high resistance to front end corrosion.

Page 2023 of 2490

sliding roof finisher and clips. Carpet covered trims line the trunk and are secured by fir tree fasteners to the sides and fro nt inner panel.

Rear View Mirrors

The.interior rear view mirror is an electrochromic unit that automatically da rkens to prevent glare from following vehicle

lights. This automatic function is selected by pressing the switch at the bottom of the mirror. Pressing the switch again

cancels this function. An LED then illuminates when automatic dipping is operative. The light sensing unit for the Night

Sentinel automatic lamp operating system is also incorporated in the mirror casing.

The door mirrors are cheater mounted, colo r-keyed units, remote electrically adjustable and heated. Adjustment of both

mirrors is carried out from the driver's door switchpack.A slider switch selects the mirror to be adjusted, and a disc switch

adjusts the selected mirror to the required position. Mirror ad justment can only be made when the ignition switch is in

position I or II or the driver's door is open, and the selector switch is moved from the central position. The door mirrors also

automatically darken under control of the electrochromic interior rear view mirror. Mirror heating elements operate on

selection of backlight heating.

Automatic dipping of passenger door mirror for kerb view when reversing, is fitted as part of the memory pack. With the

ignition switch in position II, the mirror selector switch in the left or right position and reverse gear selected, automatic

dipping is initiated by moving the mirror toggle switch rearwards and releasing. On receipt of the dip signal, the passenger

door mirror is driven downwards either 7 degrees, bottom of travel, or 4,5 to 5,5 seconds, whichever occurs first.

Subsequent rearward movement of the toggle switch achieves further dipping of the mirror in the same increments and

sequence. The mirror can be manu ally returned to the normal memorised positi on by moving the toggle switch forward with

reverse gear selected. The mirror will auto matically return to memorised position on deselection of reverse gear, or moving

ignition switch from position II.

Door mirror fold-back where fitted, to facilitate parking in conf ined spaces, can be initiated when the ignition switch is in

position I or II, the mirror selector switch is in the centra l position and vehicle speed is below 19 km/h (12 mph). Mirror

fold-back is then initiated by moving the toggle switch rear wards and releasing it. The door mirrors are returned to the

normal driving position by agai n moving toggle switch rearwards. There is no speed constraint on this operation. In the

event of a fold-back mirror becoming 'out of position' due to acci dental impact, it must only be re-positioned by initiating

the fold-back sequence.

Loss of power supplies will result in loss of mirror fold-back memory. In the event of such a memory loss with mirrors in the

normal position, fold-back will operate on second movement of the toggle swit ch. On loss of memory with mirrors in the

fold-back position, they will return to the no rmal position on next fold-back operation.

Bumpers

Each bumper comprises a beam mounted to the body via two strut assemblies, and a moulded polypropylene cover

incorporating side armatures and chrome plated blades. Each strut is secured to the BIW by three bolts and supports the

beam on a single bolt/height adjuster. The front bumper cover which is moulded to form a lo wer air intake for the cooling

pack, also incorporates left and right handed twin fog lamps, brake coolin g ducts. Side marker lamps fitted for some

markets serve only as reflectors for UK and Europe. A plastic undertray secured to the lower edge of the front bumper,

improves airflow and minimises the ingres s of road grime in that area. Standard bumpers have glass mat thermoplastic

(GMT) beams mounted on GMT struts. For certain markets, aluminium bumper beams are installed on menasco energy

absorbing struts. Whilst both types of front bumper provide a fu lly integrated 'soft front end' that satisfies bumper impact

requirements, the energy absorbing front and rear bumpers are further designed to withstand 5mph (8kph) impacts with no

visible damage sustained. Side markers/re flectors, and direction indicators are designed for ease of ac cess from the outside

of the bumper. For adjustment and bulb change, the fog lamps are accessed from th e bumper interior. The bumper covers

are body coloured and matched. Replacement covers are supplied complete with side armatures and are finished in primer

Trunk

The trunk houses the spare wheel, the battery, an electrical carrier containing electrical fuses, relays and modules and a

compact disc auto-changer attached to body bracketry. The trun k is fitted with push-fit liners to the sides and front inner

panel.The carpet covered floor is in two removable sections, one covering the spare wheel and wheel changing equipment,

the other covering the battery and electrical carrier. The front and rear edges of the floor board loca te in blocks on the fuel

tank backboard and the rear of the body , which provide two height settings to accommodate the difference in thickness

between the space saver and full sized spare wheels. A moulded finisher covering the rear of the trunk below the sill is

secured to the rear panel by tabs and fir tree fasteners. Finisher panels fitted over the rear lamp units provide for access

from the trunk. Finisher panels fitted to the rear lamp units provide trunk inte rior access to the lamps. The trunk lid

underside is fitted with a removable mo ulded liner and two trunk illumination light s. Trunk locking is based on a central

latch and striker, operated electrically through the central lo cking system by an adjacent actuator or by key in a barrel lock

Page 2099 of 2490

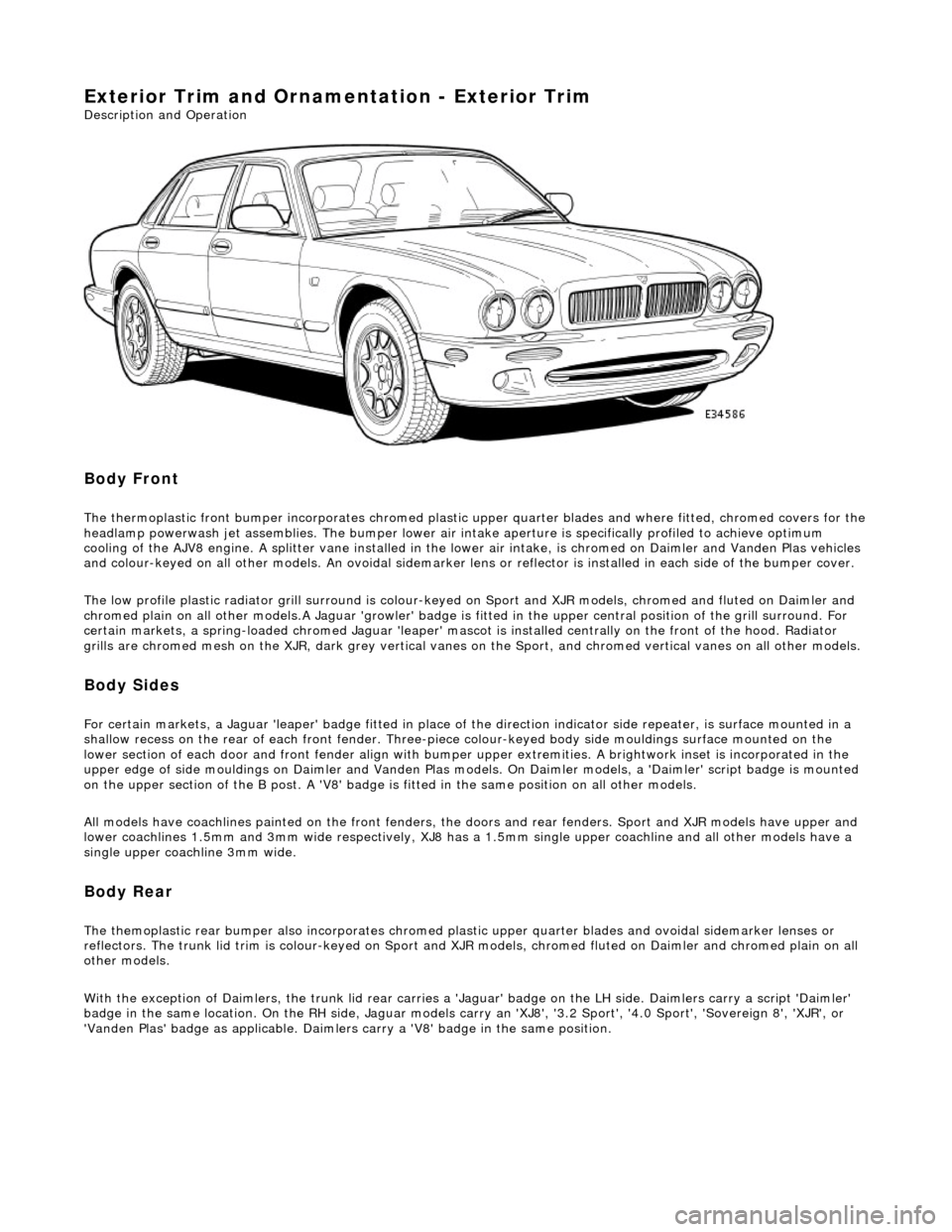

Exterior Trim and Ornamentation - Exterior Trim

Description and Operation

Body Front

The thermoplastic front bumper incorporates chromed plastic upper quarter blades and where fitted, chromed covers for the headlamp powerwash jet assemblie s. The bumper lower air intake aperture is specifically profiled to achieve optimum

cooling of the AJV8 engine. A splitter vane installed in the lowe r air intake, is chromed on Daimler and Vanden Plas vehicles

and colour-keyed on all other models. An ov oidal sidemarker lens or reflector is installed in each side of the bumper cover.

The low profile plastic radiator grill surround is colour-keyed on Sport and XJR mo dels, chromed and fluted on Daimler and

chromed plain on all other models .A Jaguar 'growler' badge is fitted in the upper central positi on of the grill surround. For

certain markets, a spring-loaded chromed Ja guar 'leaper' mascot is installed centrally on the front of the hood. Radiator

grills are chromed mesh on the XJR, dark grey vertical vanes on the Sport, and chromed ve rtical vanes on all other models.

Body Sides

For certain markets, a Jaguar 'l eaper' badge fitted in place of the direction indicator side re peater, is surface mounted in a

shallow recess on the rear of each fro nt fender. Three-piece colour-keyed body side mouldings surface mounted on the

lower section of each door and front fender align with bumper upper extremities. A brightwork inset is incorporated in the

upper edge of side mouldings on Daimler and Vanden Plas models. On Daimler models, a 'Daimler' script badge is mounted

on the upper section of the B post. A 'V8' badge is fitted in the same position on all other models.

All models have coachlines painted on th e front fenders, the doors and rear fender s. Sport and XJR models have upper and

lower coachlines 1.5mm an d 3mm wide respectively, XJ8 has a 1.5mm single upper coachline and all other models have a

single upper coachline 3mm wide.

Body Rear

The themoplastic rear bumper also inco rporates chromed plastic upper quarter blades and ovoi dal sidemarker lenses or

reflectors. The trunk lid trim is colour-keyed on Sport and XJ R models, chromed fluted on Daimler and chromed plain on all

other models.

With the exception of Daimlers, the trunk lid rear carries a 'Jaguar' badge on the LH side. Daimlers carry a script 'Daimler'

badge in the same location. On th e RH side, Jaguar models carry an 'XJ8', '3.2 Sport', '4.0 Sport', 'Sovereign 8', 'XJR', or

'Vanden Plas' badge as applic able. Daimlers carry a 'V8' badge in the same position.

Page 2307 of 2490

cooling duct.

The windshield washer is operated by pressing the button at the end of the wiper control stalk switch. Pressing and

releasing the button operates the washer for 1 to 1.4 seconds and the wiper completes three sweeps. An optional drip wipe

function adds a further sweep of the wiper after a 4 second delay, to clear residual fluid from the windshield. If the button is

held depressed, the washer and wiper will operate continuous ly for up to 20 seconds. When the button is released, the

wiper will again complete three further sweeps.

Headlamp Powerwash

The headlamp powerwash system incorporates a chromed twin nozzle assembly mounted on the chromed bumper blade

immediately in front of each pair of he adlamps. Each nozzle assembly is connected via snap fittings to a powerwash pump

mounted adjacent to the windshield wash pump on the rear face of the washer fluid reservoir.The powerwash system

operates in conjunction with the windshield washers when the ignition switch is in position II and the headlamp switch is in

the dip or main beam position. When powerwash is initially activated, a wash cycle commences, consisting of two 400 ms

pulses separated by a three second delay. If powerwash is still selected on completion of this cycle, it will continue to

operate at the same frequency for a maximum period of 20 se conds. To conserve washer fluid, headlamp powerwash will

only function on every sixth operation of the windshie ld wash switch.When the 'WASHER FLUID LOW' message is

illuminated, the windshield washer will continue to operat e for a limited period but the headlamp powerwash will not

function until the fluid level is restored.

Rain Sensing System

The rain sensing system installed form so me markets, provides automatic wiper operation when rain is detected on the

windshield. The system detects differing le vels of rainfall and varies wiper operation ranging from intermittent to maximum

continuous, to suit prevailing requirements.

The system which is brought into operation by selecting AUTO on the wiper control switch bezel, does not preclude normal

manual control of wiper operation.

The system consists of a rain sensor, an electronic control module and a dedicated wiper control switch.

The rain sensor is an optical transducer that is sensitive to changes in infra-red light penetration of the windshield created

by the refractive effects of water drople ts. The sensor elements consist of two groups of light emitting diodes which

alternately project infra-red light onto th e windshield and a photo-diode that receiv es resulting reflections from the glass. A ll

of the infra-red light is reflected back from a moisture-free windshield, resulting in a contact 5V output signal from the

sensor and no wiper activation. Rain falling on the light sensing area of the wi ndshield results in refraction and diffusion of a

proportion of the projected light with a corresponding imbalance of light received by the photodiode. This results in pulsed

outputs from the sensor, the frequency and duration of which are directly proportional to the number and size of water

droplets respectively. These pulses together with wiper switch position signals are received by the sensor control module

and processed to mimic column switch gear operation. In this recognisable form, signals are input to the body processor

module (BPM) where they are interprete d as normal wiper operation requests.