rear suspension JAGUAR X308 1998 2.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 90 of 2490

Front Suspension - Rear Lower Arm Bushing

Remo

val and Installation

Remov

a

l

CAUTI

O

N: Replacement of

nuts and bolts: Various thread-locking devices are used on nuts and bolts throughout the

vehicle. These devices restrict the number of times a nut or bolt can be used. Refer to Section 100-00 for further

information.

S p

ecial Tool(s)

R

o

ad spring compressor

204-111 (JD115)

Taper separator

2

11-098 (JD 100)

Ball

Jo

int Taper Separator

204-192 (JD 219)

Bal l

joint splitter

204-293

1. Ra

ise front of vehicle and support on stands. Refer to Section

100-02.

2. Remove appropriate road wheel. Refer to Section 100-02.

3. CAUTIO

N: Do not suspend caliper from brake hose as

this will damage the hose.

Remove brake calipers from carriers. 1. Remove caliper spring clip.

2. Remove guide pin dust caps.

3. Slacken and withdraw guide pins.

4. Remove caliper from carrier and tie to suspension mounting bracket.

4. Ra

ise vehicle further to provid

e access for Special Tool 204-

Page 117 of 2490

Front Suspension - Fro

nt Stabilizer Bar

Re

moval and Installation

Materials

S

pecification

Cas

trol NTR

Remov

al

Na

me

R

ubber Suspension Insulator Lube

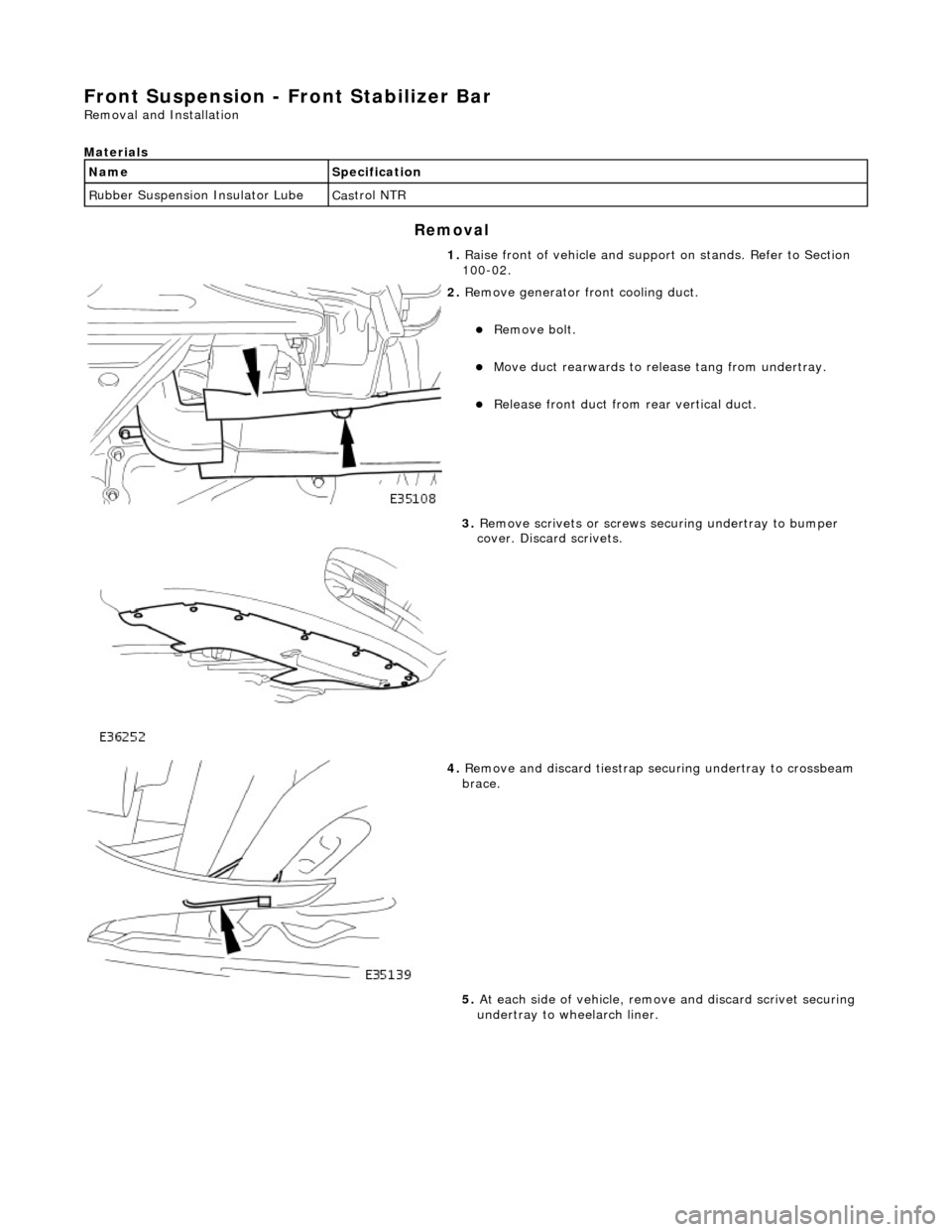

1. Raise front of vehicle and support on stands. Refer to Section

100-02.

2. R

emove generator front cooling duct.

Re

move bolt.

Move duct rea

rwards to rele

ase tang from undertray.

R

elease front duct from rear vertical duct.

3. R

emove scrivets or screws se

curing undertray to bumper

cover. Discard scrivets.

4. R

emove and discard tiestrap securing undertray to crossbeam

brace.

5. At each side of vehicle, remo ve and discard scrivet securing

undertray to wheelarch liner.

Page 122 of 2490

Front Suspension - Front Stabilizer B

ar Bushing

Re

mo

val and Installation

Materials

S p

ecification

Cas

t

rol NTR

Remov

a

l

Na

m

e

R

u

bber Suspension Insulator Lube

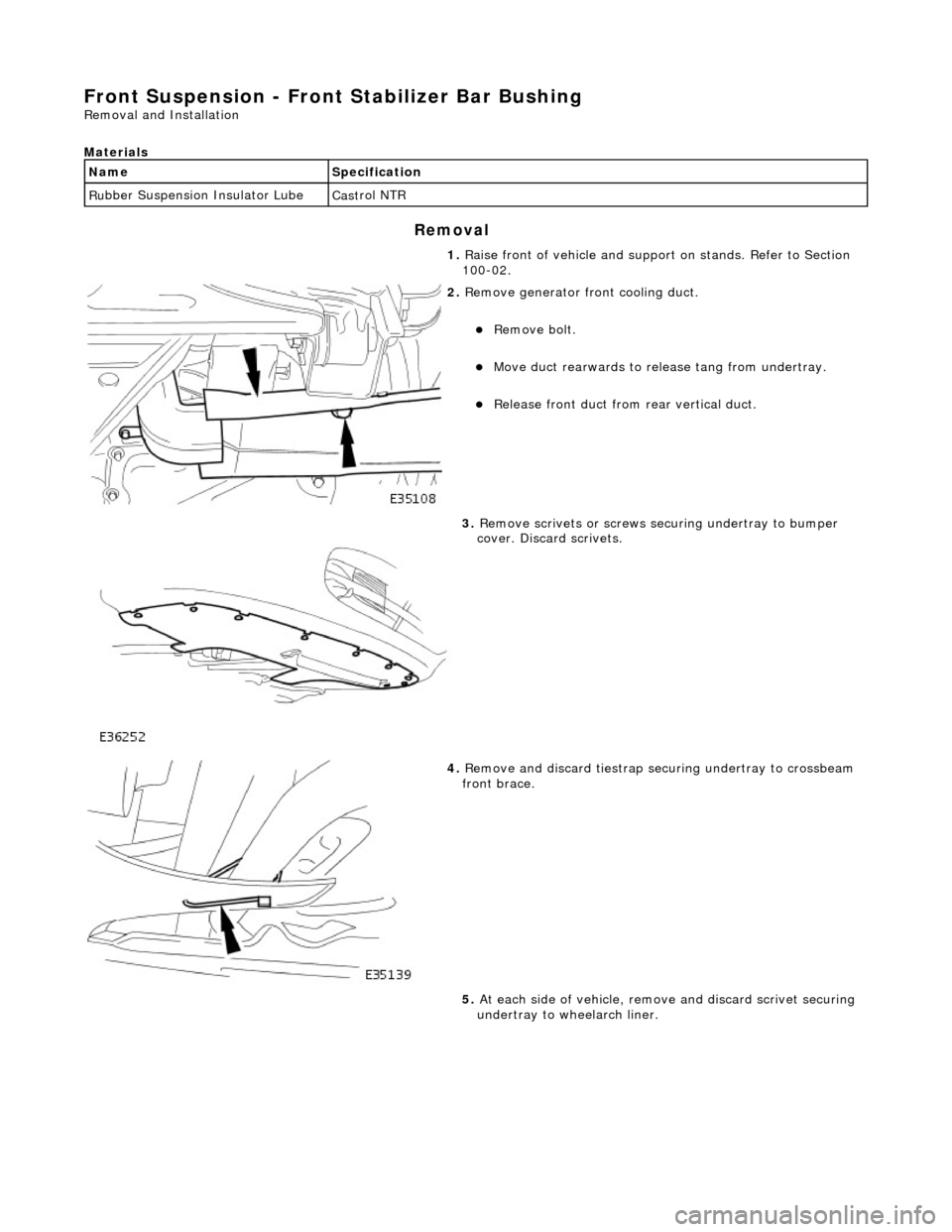

1. Raise front of vehicle and support on stands. Refer to Section

100-02.

2. Re

move generator front cooling duct.

Re

mo

ve bolt.

Move duct rea

r

wards to rele

ase tang from undertray.

Re

lease front duct from rear vertical duct.

3. Re

move scrivets or screws se

curing undertray to bumper

cover. Discard scrivets.

4. Re

move and discard tiestrap securing undertray to crossbeam

front brace.

5. At each side of vehicle, remo ve and discard scrivet securing

undertray to wheelarch liner.

Page 167 of 2490

Rear

Suspension - Rear Suspension

Description an

d Operation

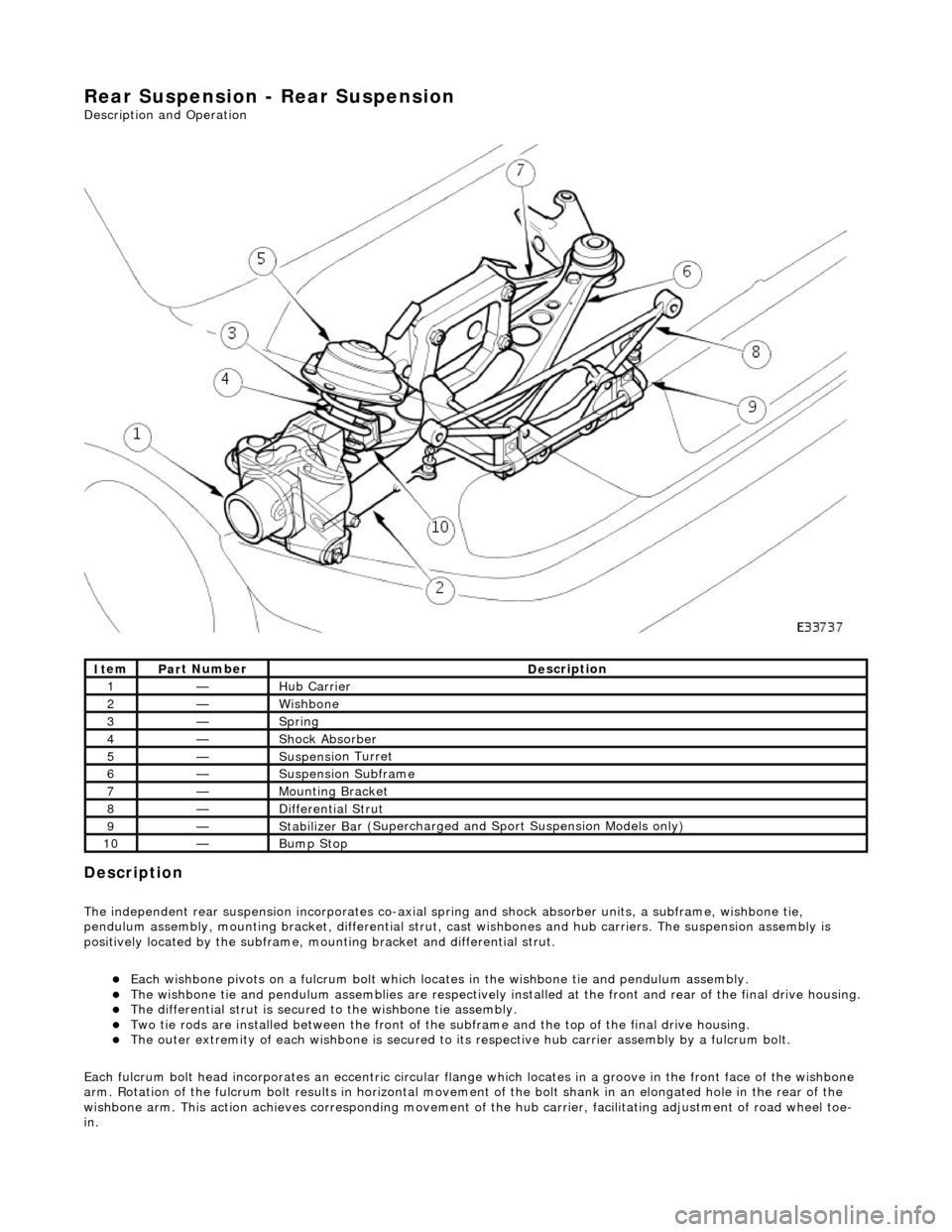

Description

The i

ndependent rear suspension incorporates co-axial sp

ring and shock absorber units, a subframe, wishbone tie,

pendulum assembly, mounting brac ket, differential strut, cast wishbones and hub carriers. The suspension assembly is

positively located by the subframe, mounting bracket and differential strut.

Each wi

shbone pivots on a fulcru

m bolt which locates in the wishbone tie and pendulum assembly.

The wish

bone tie and pendulum assemblies are respectively in

stalled at the front and rear of the final drive housing.

The differential

strut is secured to the wishbone tie assembly.

Two ti

e rods are installed between the front of the

subframe and the top of the final drive housing.

The ou

ter extremity of each wishbone

is secured to its respective hub carrier assembly by a fulcrum bolt.

Each fulcrum bolt head incorporates an ec centric circular flange which locates in a groove in the front face of the wishbone

arm. Rotation of the fulcrum bolt results in horizontal movement of the bolt shank in an elongated hole in the rear of the

wishbone arm. This acti on achieves corresponding movement of the hub carrier, facilita ting adjustment of road wheel toe-

in.

It

em

Par

t Number

De

scription

1—Hub Carrier

2—Wi

shbone

3—Sprin

g

4—Shock Absorber

5—Suspensi

on Turret

6—Suspensi

on Subframe

7—Moun

ting Bracket

8—D

ifferential Strut

9—Stabilizer Ba

r (Supercharged and

Sport Suspension Models only)

10—Bum

p Stop

Page 168 of 2490

Each r

oad spring and is located between the wishbone in

tegral spring seat and the body suspension turret.

Each shoc

k absorber unit is installed

co-axially within the road spring.

The lo

wer end of each shock absorber is secured to the

wishbone by a bolt which also functions as a pivot.

Adaptive damping is av

ailable as an option.

A

rear stabi

lizer bar is installed on

Supercharged and Sport Suspension models . Mounted at the rear of the wishbone

tie assembly, the stabilizer bar is connected to the wishbone by short links.

Op era

tion

As each road wheel r

i

ses, move

ment is transmitted through th e hub carrier assembly to the wishbone and axle shaft. The

corresponding rise of the wishbone compre sses the road spring and partially telescopes the shock absorber. During this

action, the spring absorbs result ing shocks and the shock absorber minimizes spring oscillation.

During cornering, vehicle weight is transferred to the outer road wheel with a resulting tendency for the inner wheel to lift.

On Supercharged and Sport Suspension vehicl es, a rear stabilizer bar assists in minimizing this tendency by transferring a

proportion of potential lift of the inner wheel to the outer wheel. This results in enhanced body stability with improved

cornering capabilities.

Page 169 of 2490

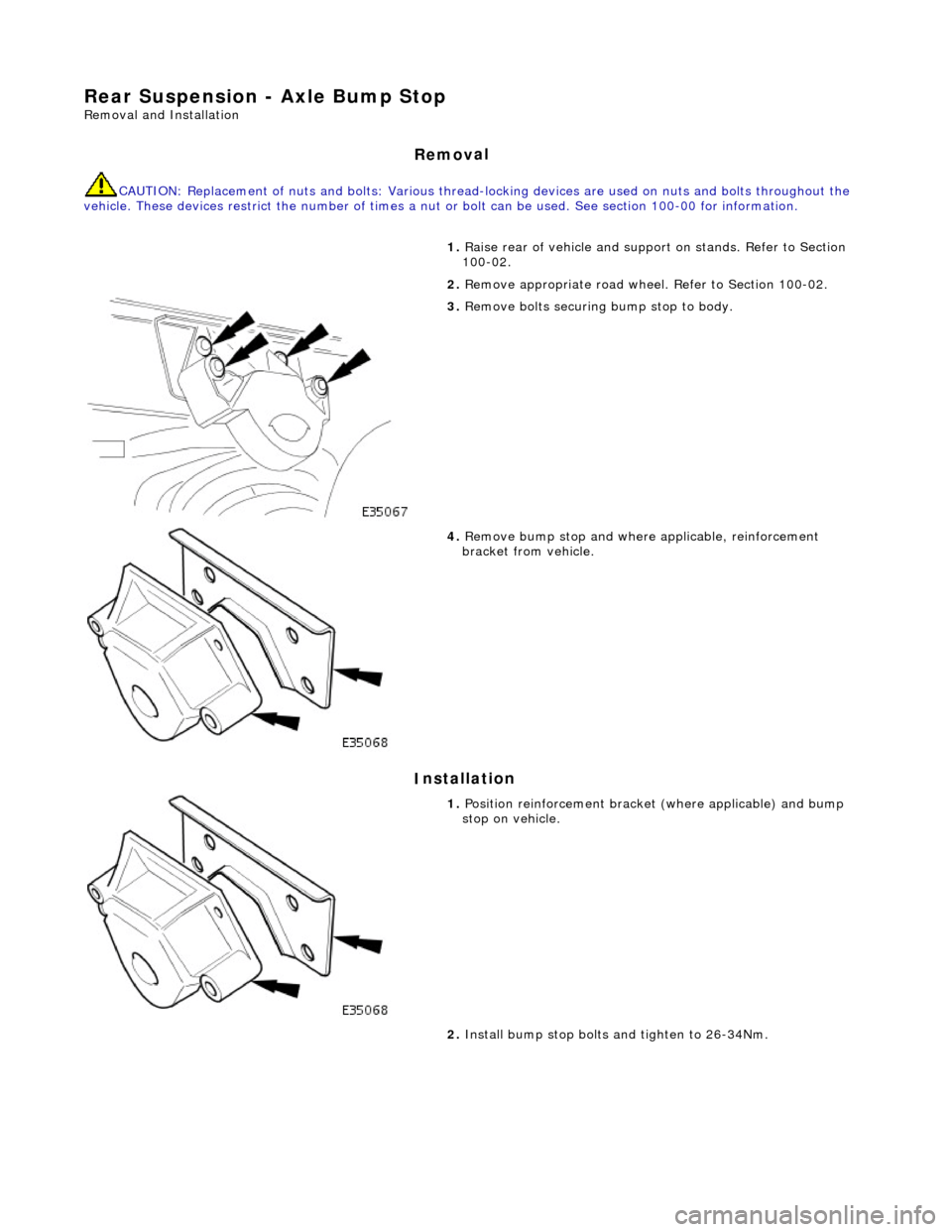

Rear Suspension - Axle B

ump Stop

Re

moval and Installation

Remov

al

CAUTI

ON: Replacement of

nuts and bolts: Various thread-locking devices are used on nuts and bolts throughout the

vehicle. These devices restrict the number of times a nut or bolt can be used. See section 100-00 for information.

I

nstallation

1.

R

aise rear of vehicle and support

on stands. Refer to Section

100-02.

2. Remove appropriate road wheel. Refer to Section 100-02.

3. Remove bolts securing bump stop to body.

4. Remove bu

mp stop and where applicable, reinforcement

bracket from vehicle.

1. Position reinforcemen t brac

ket (where a

pplicable) and bump

stop on vehicle.

2. Install bump stop bolts and tighten to 26-34Nm.

Page 171 of 2490

Rear

Suspension - Rear Susp

ension and Axle Assembly

Re

moval and Installation

Remov

al

1.

CAUTI

ON: Replacement of nuts and bolts: Various

thread-locking devices are used on nuts and bolts throughout the

vehicle. These devices restrict the number of times a nut or bolt

can be used.

For additional informat ion, refer to Section 100

-0

0 General

Informati

on

.

R

aise the rear of the vehicle

and support on axle stands.

For additional informat ion, refer to Section 100

-0

2 Jacking and

Liftin

g

.

2.

R

emove the rear wheels.

For additional informat ion, refer to Section 204

-04

Wheels and

Tire

s

.

3. CAUTI

ON: Do not suspend the caliper from the brake

hose as this will damage the hose.

• NOTE: Right-hand shown, left-hand similar

Remove the brake calipers from the carriers.

1. Remove the caliper spring clip.

2. Remove the guide pin dust caps.

3. Slacken and withdr aw the guide pins.

4. Remove the caliper from the carrier and secure to the suspension mounting bracket using a tie strap.

4. NOTE

: Right-hand shown, left-hand similar

Disconnect the wheel speed sensor electrical connectors.

5. NOTE: Right-hand shown, left-hand similar

Remove and discard th e tie straps securing the wheel speed

sensor harnesses to the brake hose clips.

Page 173 of 2490

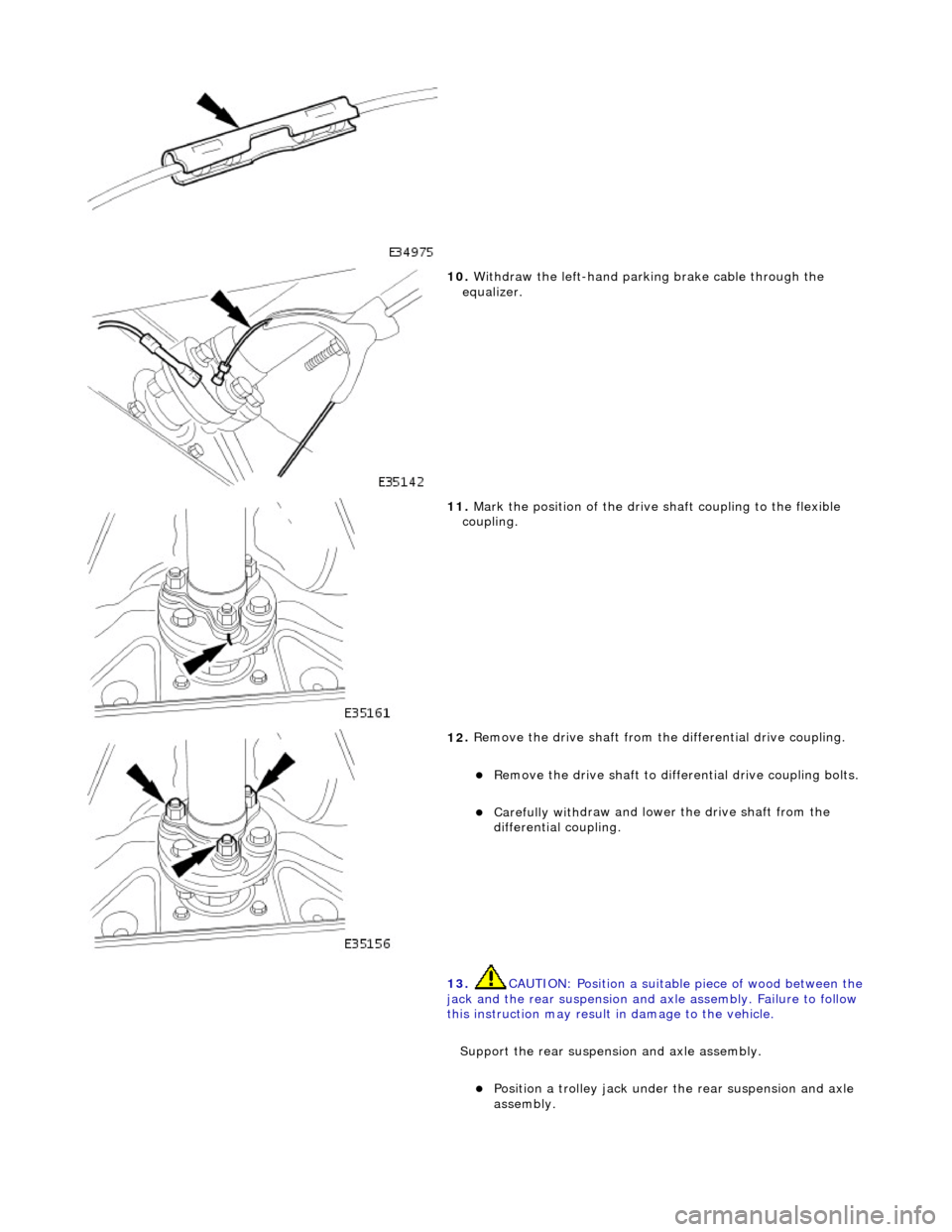

10

.

Withdraw the left-hand parking brake cable through the

equalizer.

11

.

Mark the position of the drive shaft coupling to the flexible

coupling.

12

.

Remove the drive shaft from the differential drive coupling.

R

emove the drive shaft to differential drive coupling bolts.

Carefully with

draw and lower the drive shaft from the

differential coupling.

13. CAUTION: Position a suitable piece of wood between the

jack and the rear suspension and axle assembly. Failure to follow

this instruction may result in damage to the vehicle.

Support the rear suspension and axle assembly.

Posi

tion a trolley jack under the rear suspension and axle

assembly.

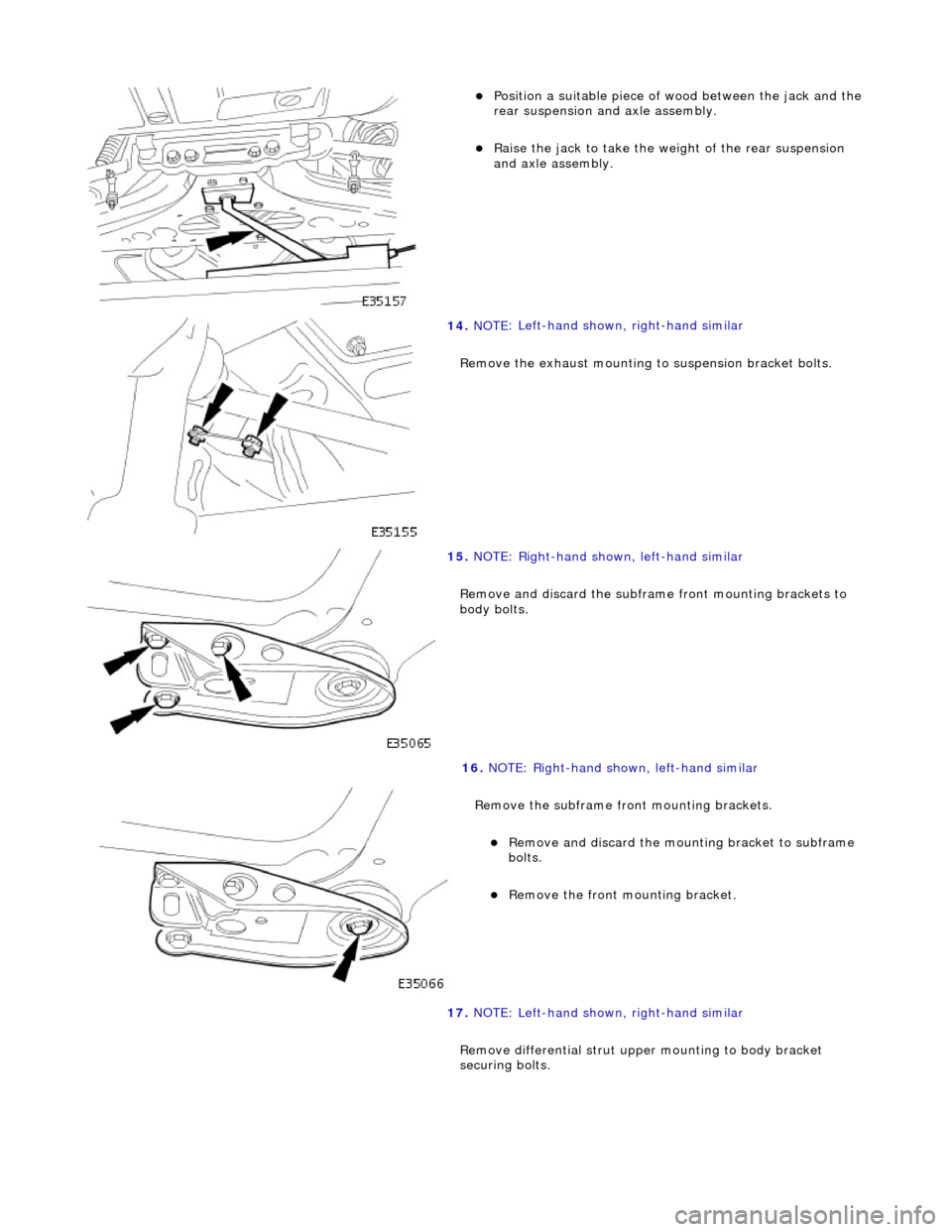

Page 174 of 2490

Position a suitable piece o

f wood between the jack and the

rear suspension and axle assembly.

Rai s

e the jack to take the weight of the rear suspension

and axle assembly.

14 . NOTE

: Left-hand shown, right-hand similar

Remove the exhaust mounting to suspension bracket bolts.

15 . NOTE

: Right-hand shown, left-hand similar

Remove and discard the subframe front mounting brackets to

body bolts.

16 . NOTE

: Right-hand shown, left-hand similar

Remove the subframe front mounting brackets.

Remove an d discard the mount

ing bracket to subframe

bolts.

R e

move the front mounting bracket.

17. NOTE: Left-hand shown, right-hand similar

Remove differential strut upper mounting to body bracket

securing bolts.

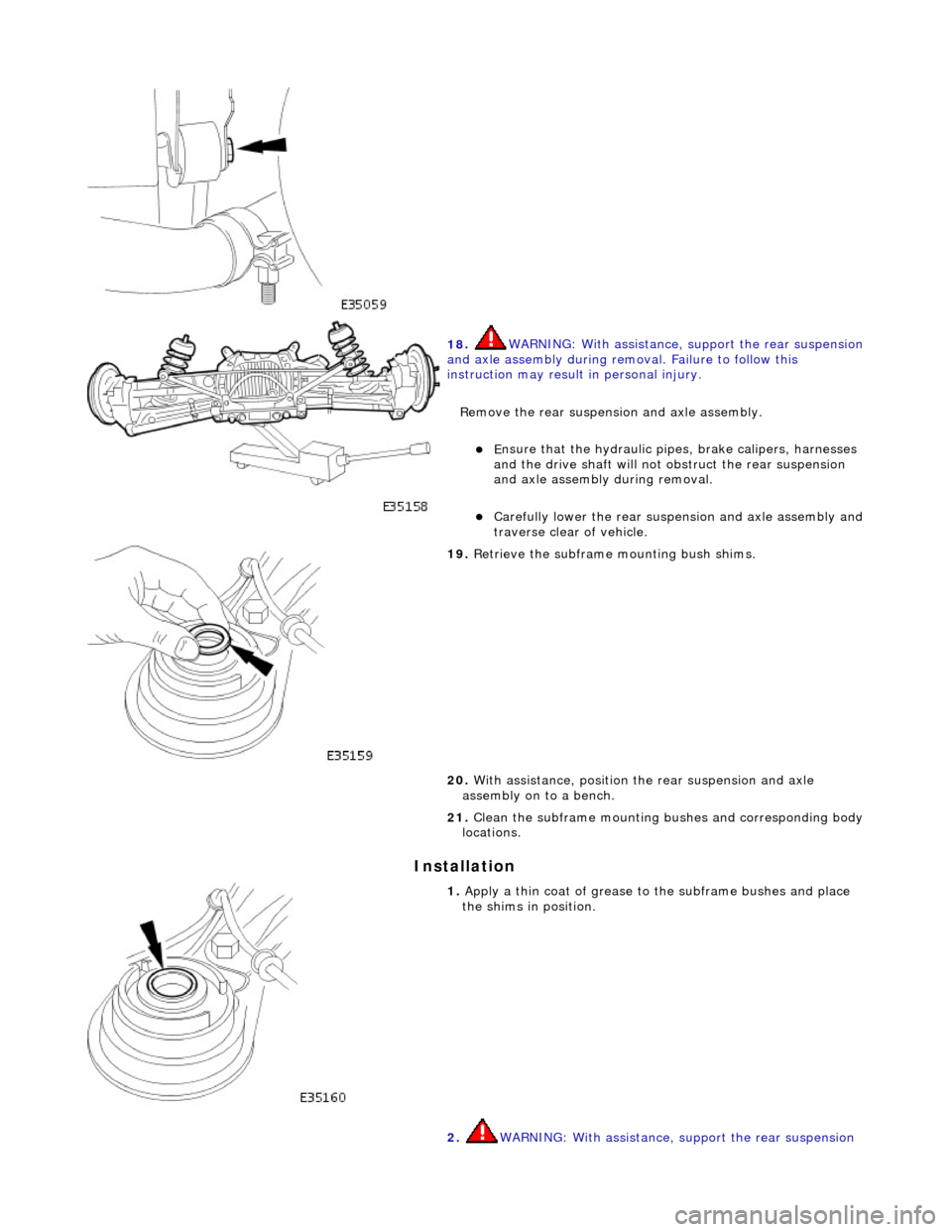

Page 175 of 2490

I

nstallation

18

.

WARNING: With assistance, support the rear suspension

and axle assembly during remo val. Failure to follow this

instruction may result in personal injury.

Remove the rear suspensi on and axle assembly.

E

nsure that the hydr

aulic pipes, brake calipers, harnesses

and the drive shaft will not obstruct the rear suspension

and axle assembly during removal.

Carefull

y lower the rear suspen

sion and axle assembly and

traverse clear of vehicle.

19

.

Retrieve the subframe mounting bush shims.

20. With assistance, position th e rear suspension and axle

assembly on to a bench.

21. Clean the subframe mounting bushes and corresponding body

locations.

1. Apply a th

in coat of grease to the subframe bushes and place

the shims in position.

2. WARNING: With assistance, support the rear suspension