JAGUAR X308 1998 2.G Workshop Manual

Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 2101 of 2490

Exterior Trim and Ornamentation - A-Pillar Moulding RH

Removal and Installation

Removal

Installation

1.

Remove rear grab handle. Refer to 76.58.30.

2. Remove draught welt from adjace nt section of door aperture

flange.

3. Using a trim removal tool, carefu lly ease the six trim pad fir

tree fasteners from cantrail an d upper'A' post locations.

4. If premium ICE is fitt ed, carefully withdraw trim pad for access

and disconnect tweeter connectors.

5. Remove trim pad from vehicle an d remove tweeter. Refer to

415-03.

6. Remove and discard fir tree fasteners.

1. Fit new fir tree fasten ers to the trim pad.

2. Fit tweeter to trim pad. Refer to Section 415.

3. Position trim pad for access and connect tweeter to harness.

4. Commencing at top of 'A' post and working rearwards, fully

seat three fir tree fasteners.

5. Fully seat remaining three fir tr ee fasteners in upper'A' post.

6. Fit grab handle. Refer to 76.58.30.

7. Fit draught welt to adjacent section of door aperture flange.

Page 2102 of 2490

Exterior Trim and Ornamentation - Coachlines

Removal and Installation

Removal

Installation

1.

For removal of painted coachlines , refer to Section 501-18 of

this manual.

1. For position and application of painted coachlines, refer to

Section 501-18 of this manual.

Page 2103 of 2490

Exterior Trim and Ornamentation - Door Moulding

Removal and Installation

Removal

Installation

1.

Apply suitable protecti ve tape to immediately adjacent areas of

paintwork.

2. Using a hand-held heat gun, appply heat uniformly along

moulding length.

3. Applying local heat at one end and using a suitable thin lever

to avoid damaging paintwork, progressively ease moulding

away from door panel.

4. Discard moulding and remove protective tape.

5. Remove any residual adhesive and thoroughly clean area using

white spirit.

1. NOTE: Optimum adhesion is achi eved by warming body panel

and moulding to 65deg C.

Using white spirit ensure that mounting area is clean, dry and

de-greased.

2. Remove protective backing tape from moulding.

3. NOTE: Do not allow moulding to contact the body panel until it

is correctly aligned.

Heat moulding and moun ting area to 65degC.)

4. Aligning with adjacent mouldings or to match opposite side of

vehicle, press new moulding firmly onto body panel.

5. Apply hand pressure along moulding length to ensure

satisfactory adhesion.

6. Allow moulding and door panel to cool , then thoroughly clean

both using white spirit.

7. Apply a coat of suitab le polish to moulding and body panel.

Page 2104 of 2490

Exterior Trim and Ornamentation - Front Fender Moulding

Removal and Installation

Removal

Installation

1.

Apply suitable protecti ve tape to immediately adjacent areas of

paintwork.

2. Using a hand-held heat gun, appply heat uniformly along

moulding length.

3. Applying local heat at one end and using a suitable thin lever

to avoid damaging paintwork, progressively ease moulding

away from fender.

4. Discard moulding and remove protective tape.

5. Remove any residual adhesive and thoroughly clean area using

white spirit.

1. NOTE: Optimum adhesion is achi eved by warming body panel

and moulding to 65deg C.

Using white spirit ensure that mounting area is clean, dry and

de-greased.

2. Remove protective backing tape from moulding.

3. NOTE: Do not allow moulding to contact the fender until it is

correctly aligned.

Heat moulding and mounting area to 65deg C.

4. Aligning with adjacent mouldings or to match opposite side of

vehicle, press new mouldi ng firmly onto fender.

5. Apply hand pressure along moulding length to ensure

satisfactory adhesion.

6. Allow moulding and fender to cool , then thoroughly clean both

using white spirit.

7. Apply a coat of suitable poli sh to moulding and fender.

Page 2105 of 2490

Exterior Trim and Ornamentation - Luggage Compartment Lid Badges

Removal and Installation

Removal

Installation

1.

Apply protective tape to area immediately surrounding and up

to the badge edge.

2. Using a thin plastic lever and a fulcrum of suitable material

positioned on the taped area, carefully ease the badge free.

3. Remove protective tape.

4. Using white spirit, remove any residual adhesive.

1. Ensure that contact area is clean and dry.

2. Remove backing sheet from badge.

3. Ensuring correct alig nment with trunk lid recess and where

applicable lock aperture and pr ess badge firmly into position.

4. Clean affected area and apply su itable polish to trunk lid and

badge.

Page 2106 of 2490

Exterior Trim and Ornamentation - Luggage Comp artment Lid Moulding

Removal and Installation

Removal

1. Remove battery cover and disc onnect ground cable from

battery terminal. Refer to 86.15.19.

2. Disconnect and remove trunk lamp assemblies. Refer to

86.45.16.

3. Remove covers from trunk latc h finisher securing bolts,

slacken and remove bolts and remove finisher.

4. Remove and discard trunk li d liner rear fasteners and

position liner for access.

5. Free trunk lid release button harness from retaining clip and

disconnect multiplug.

6. NOTE: The pressed steel fasteners fitted to Jaguar models

should be discarded on removal.

Slacken and remove nuts/fasteners securing trim finisher to

trunk lid.

Page 2107 of 2490

Installation

7. Position trim finisher for a ccess and withdraw and discard

release button harness grommet from trunk lid.

8. Remove trim finisher from trunk lid.

9. Carefully remove seal from trim finisher.

10. Slacken and remove screws securing release button assembly

to trim finisher and remove release button from finisher.

1. Fit and fully seat release button in trim finisher and fit and

tighten securing screws.

2. Apply suitable adhesive to contac t area of trim finisher and fit

and align seal to finisher.

3. Position trim finisher and pass release button harness through

trunk lid aperture.

Page 2108 of 2490

4.

Fit and fully seat a new harn ess grommet in trunk lid.

5. NOTE: Fit new pressed steel fasteners on Jaguar models.

Align and fully seat trim finisher on trunk lid and fit and fully

tighten securing nuts/fasteners.

6. Connect release button harness multiplug and position harness

in retaining clip.

7. Position and fully seat trunk li d trim pad and secure with new

fir tree fasteners.

8. Fit finisher over trunk latch, fi t and tighten securing bolts and

fit bolt covers..

9. Fit trunk lamp assemblies. Refer to 86.45.16.

10. Connect ground cable to batt ery terminal and fit battery

cover. Refer to 86.15.15.

Page 2109 of 2490

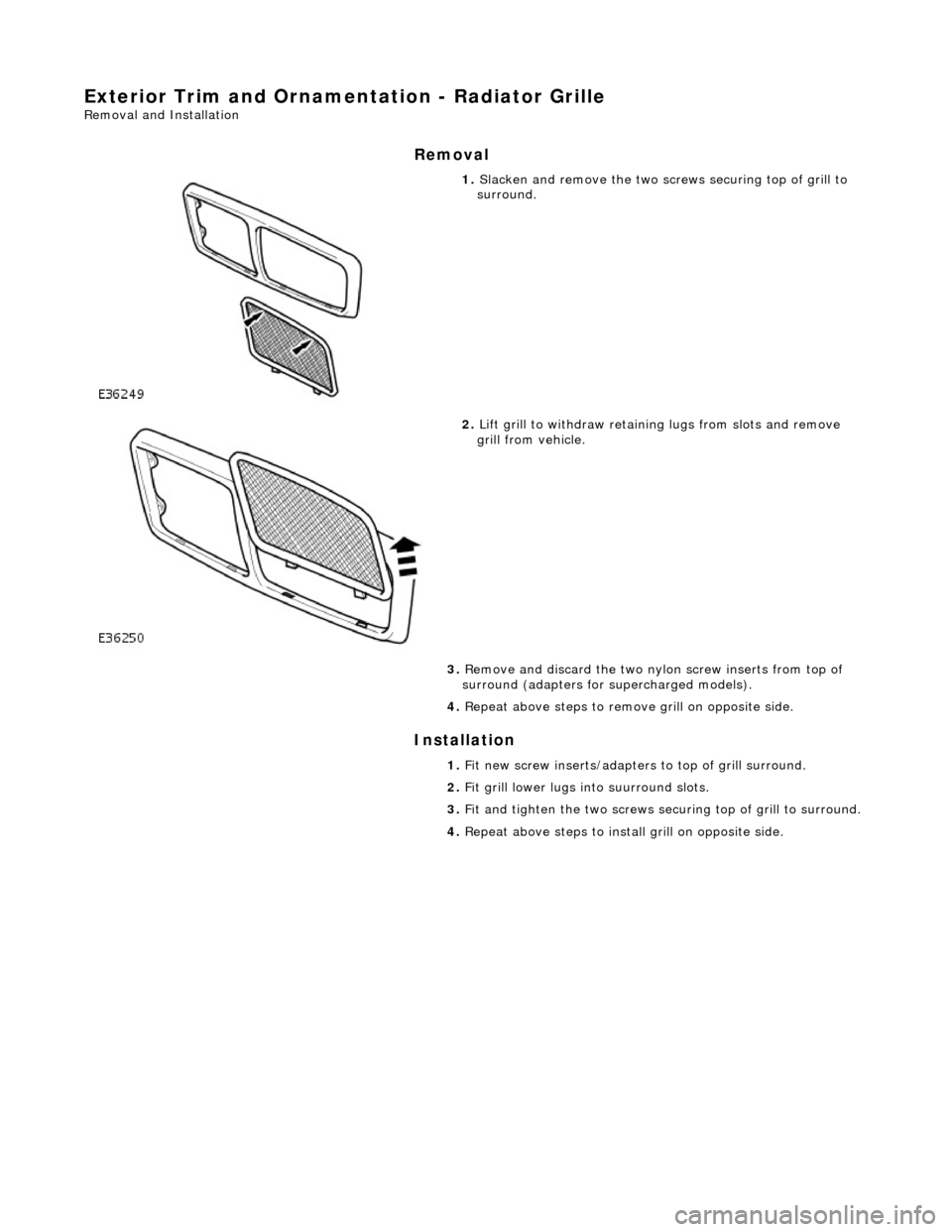

Exterior Trim and Ornamentation - Radiator Grille

Removal and Installation

Removal

Installation

1. Slacken and remove the two scre ws securing top of grill to

surround.

2. Lift grill to withdraw retainin g lugs from slots and remove

grill from vehicle.

3. Remove and discard the two ny lon screw inserts from top of

surround (adapters for su percharged models).

4. Repeat above steps to remove grill on opposite side.

1. Fit new screw inserts/adapters to top of grill surround.

2. Fit grill lower lugs into suurround slots.

3. Fit and tighten the two screws securing top of grill to surround.

4. Repeat above steps to instal l grill on opposite side.

Page 2110 of 2490

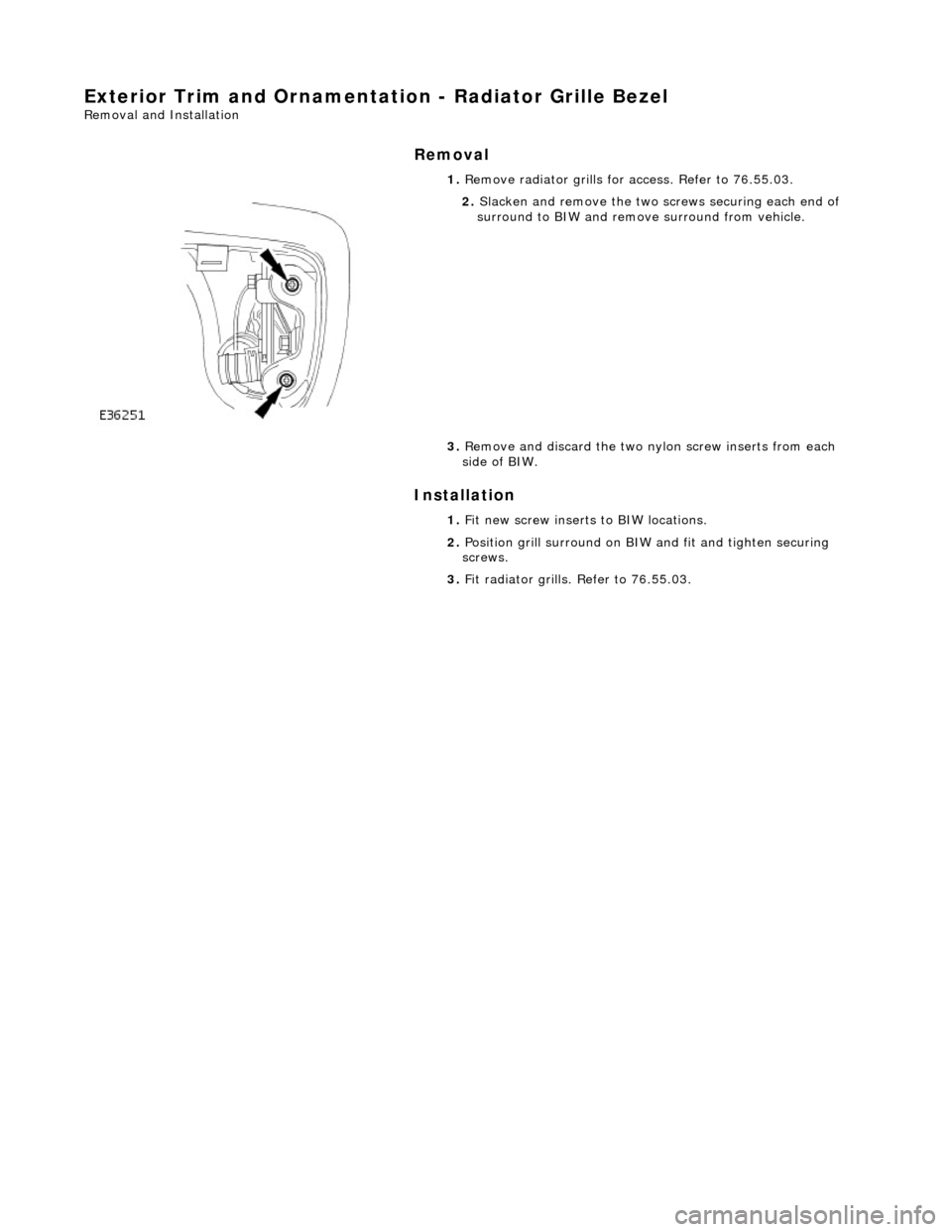

Exterior Trim and Ornamentation - Radiator Grille Bezel

Removal and Installation

Removal

Installation

1.

Remove radiator grills for access. Refer to 76.55.03.

2. Slacken and remove the two screws securing each end of

surround to BIW and remove surround from vehicle.

3. Remove and discard the two nylon screw inserts from each

side of BIW.

1. Fit new screw inserts to BIW locations.

2. Position grill surround on BIW and fit and tighten securing

screws.

3. Fit radiator grills. Refer to 76.55.03.