Steering column JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 8 of 2490

В В В В В В В В В В В В 211‐02: В Powe rВ Steering В

В В В В В В В В В В В В В В В В Specif

ication

В

В В В В В В В В В В В В В В В В Description В and В Operation В

В В В В В В В В В В В В В В В В В В В В PowerВ SteeringВ

В В В В В В В В В В В В В В В В Diagnosis В and В Testing В

В В В В В В В В В В В В В В В В В В В В PowerВ SteeringВ

В В В В В В В В В В В В В В В В RemovalВ and В Installation В

В В В В В В В В В В В В В В В В В В В В SteeringВ Gear В (57.10.01) В

В В В В В В В В В В В В В В В В В В В В SteeringВ Gear В Bushing В (57.10.30) В

В

В В В В В В В В В В В В 211‐03: В SteeringВ LinkageВ

В В В В В В В В В В В В В В В В Specification В

В В В В В В В В В В В В В В В В Description В and В Operation В

В В В В В В В В В В В В В В В В В В В В SteeringВ Linkage В

В

В В В В В В В В В В В В 211‐04: В SteeringВ ColumnВ

В В В В В В В В В В В В В В В В Specification В

В В В В В В В В В В В В В В В В Description В and В Operati

onВ

В В В В В В В В В В В В В В В В В В В В SteeringВ Column В

В В В В В В В В В В В В В В В В RemovalВ and В Installation В

В В В В В В В В В В В В В В В В В В В В SteeringВ ColumnВ LowerВ Shaft В (57.40.05) В

В

В В В В В В В В В В В В 211‐05: В SteeringВ ColumnВ Switches В

В В В В В В В В В В В В В В В В Specification В

В В В В В В В В В В В В В В В В Description В and В Operation В

В В В В В В В В В В В В В В В В В В В В SteeringВ ColumnВ Switches В

В В В В В В В В В В В В В В В В RemovalВ and В Installation В

В В В В В В В В В В В В В В В В В В В В SteeringВ ColumnВ Multifunction В Switch В (86.65.92) В

В

В В В В 3: В PowertrainВ

В

В В В В В В В В 303: В Engine В

В

В В В В В В В В В В В В 303‐00: В Engine В System  ‐ General В Information В

В В В В В В В В В В В В В В В В

В В В В В В В В В В В В В В В В В В В В В

Page 32 of 2490

В В В В В В В В В В В В В В В В В В В В RearВ CupВ Holder В (76.25.27) В

В В В В В В В В В В В В В В В В В В В В SteeringВ Col u

mnВ

Lower В Shroud В (76.46.03) В

В В В В В В В В В В В В В В В В В В В В SteeringВ ColumnВ UpperВ Shroud В (76.46.02) В

В

В В В В В В В В В В В В 501‐14: В Handles, В Locks,В Latches В and В Entry В Systems В

В В В В В В В В В В В В В В В В Description В and В Operation В

В В В В В В В В В В В В В В В В В В В В Handles,В Locks,В Latches В and В Entry В Systems В

В В В В В В В В В В В В В В В В RemovalВ and В Installation В

В В В В В В В В В В В В В В В В В В В В ExteriorВ Driver В Door В Handle В (76.58.07) В

В В В В В В В В В В В В В В В В В В В В DriverВ DoorВ LatchВ (76.37.74) В

В В В В В В В В В В В В В В В В В В В В GloveВ CompartmentВ LidВ Ha

ndleВ (76.52.08) В

В В В В В В В В В В В В В В В В В В В В GloveВ CompartmentВ LidВ Lock В Cylinder В (76.52.23) В

В В В В В В В В В В В В В В В В В В В В LuggageВ CompartmentВ LidВ Latch В (76.19.25) В

В В В В В В В В В В В В В В В В В В В В LuggageВ CompartmentВ LidВ Latch В Actuator В (76.19.25) В

В В В В В В В В В В В В В В В В В В В В LuggageВ CompartmentВ LidВ Release В Switch В (86.25.56) В

В В В В В В В В В В В В В В В В В В В В LuggageВ CompartmentВ LidВ Warning В IndicatorВ SwitchВ (86.65.93) В

В В В В В В В В В В В В В В В В В В В В ExteriorВ Passenger В Door В Handle В (76.58.08) В

В В В В В В В В В В В В В В В В В В В В PassengerВ Door В Latch В (76.37.75) В

В В В В В В В В В В В В В В В В В В В В ExteriorВ Rear В Door В Handle В (76.58.02) В

В В В В В В В В В В В В В В В В В В В В RearВ Door В Latch В (76.37.09) В

В

В В В В В В В В В В В В 501‐16: В Wipers В and В Washers В

В В В В В В В В В В В В В В В В Descriptio

nВ and В Operation В

В В В В В В В В В В В В В В В В В В В В WipersВ andВ Washers В

В В В В В В В В В В В В В В В В RemovalВ and В Installation В

В В В В В В В В В В В В В В В В В В В В HeadlampВ WasherВ Jet В (84.20.08) В

В В В В В В В В В В В В В В В В В В В В HeadlampВ WasherВ Pump В (84.20.21) В

В В В В В В В В В В В В В В В В В В В В RainВ Sensor В (84.12.10) В (86.56.62) В

В В В В В В В В В В В В В В В В В В В В Windshield В Washer В Pump В (84.10.21) В

В В В В В В В В В В В В В В В В В В В В Windshield В Washer В Reservoir В (84.10.01) В (84.10.03) В

В В В В В В В В В В В В В В В В В В В В Windshield В Wiper В Motor В (84.15.13) В

В В В В В В В В В В В В В В В В В В В В Windshield В Wiper/

Washer В Switch В (86.65.42) В

В В В В В В В В В В В В В В В В В В В В WiperВ Pivot В Arm В (84.15.03) В

В

В В

Page 67 of 2490

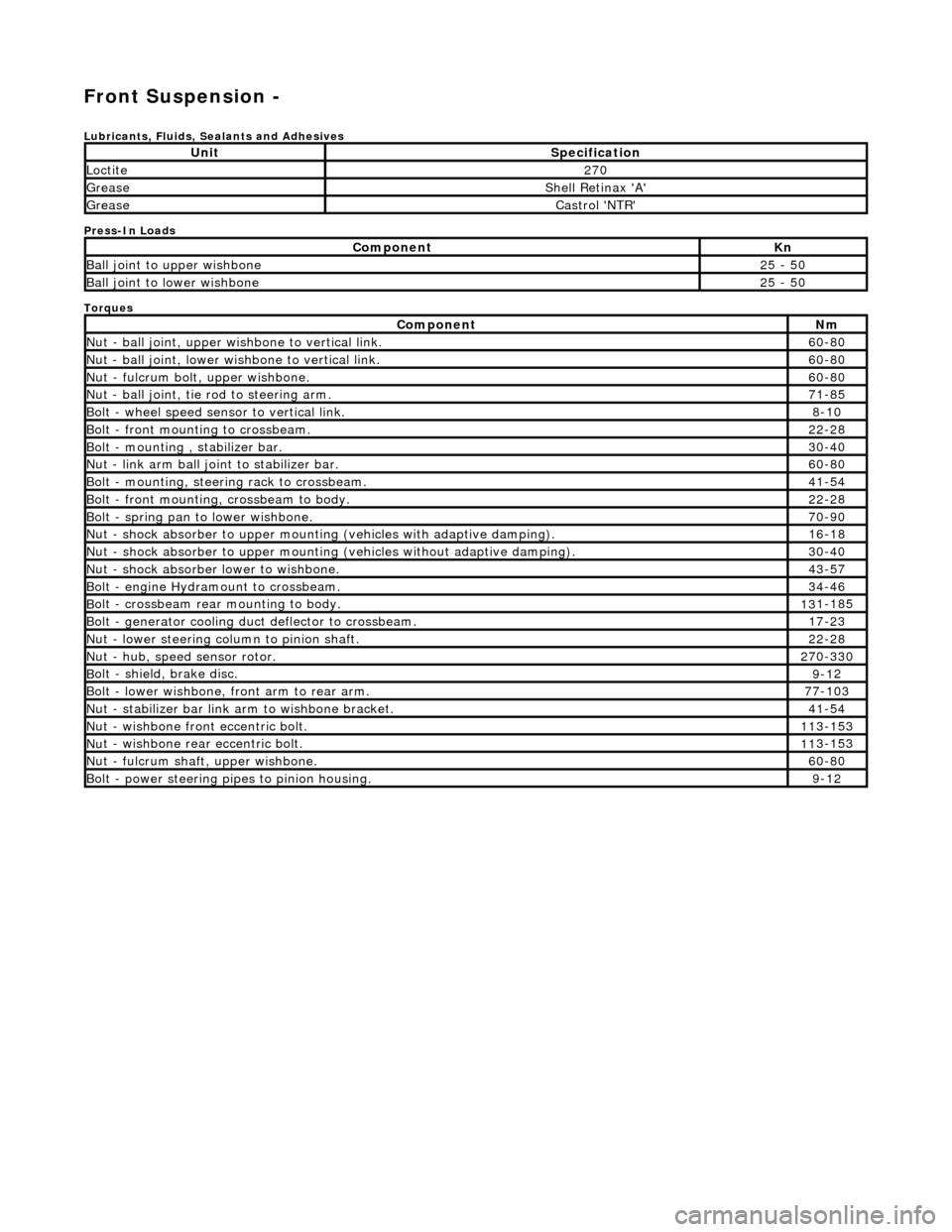

Front Suspension -

Lubri

cants, Fluids, Sealants and Adhesives

Press-In Loads

Torques

UnitS

pecification

Loctite27

0

Greas

e

Shell Retin

ax 'A'

Greas

e

Castro

l 'NTR'

Com

ponent

Kn

Ball join

t to upper wishbone

25

- 50

B

all joint to lower wishbone

25

- 50

Com

ponent

Nm

N

ut - ball joint, upper wishbone to vertical link.

60

-80

N

ut - ball joint, lower wishbone to vertical link.

60

-80

Nu

t - fulcrum bolt, upper wishbone.

60

-80

N

ut - ball joint, tie rod to steering arm.

71

-85

Bol

t - wheel speed sensor to vertical link.

8-1

0

Bol

t - front mounting to crossbeam.

22

-28

Bolt

- mounting , stabilizer bar.

30

-40

N

ut - link arm ball joint to stabilizer bar.

60

-80

Bolt

- mounting, steering rack to crossbeam.

41

-54

B

olt - front mounting, crossbeam to body.

22

-28

Bol

t - spring pan to lower wishbone.

70

-90

N

ut - shock absorber to upper mounting

(vehicles with adaptive damping).

16

-18

Nu

t - shock absorber to upper mounting (vehicles without adaptive damping).

30

-40

N

ut - shock absorber lower to wishbone.

43

-57

B

olt - engine Hydramount to crossbeam.

34

-46

B

olt - crossbeam rear mounting to body.

13

1-185

Bol

t - generator cooling du

ct deflector to crossbeam.

17

-23

N

ut - lower steering column to pinion shaft.

22

-28

N

ut - hub, speed sensor rotor.

27

0-330

B

olt - shield, brake disc.

9-1

2

Bol

t - lower wishbone, front arm to rear arm.

77

-103

Nu

t - stabilizer bar link arm to wishbone bracket.

41

-54

N

ut - wishbone front

eccentric bolt.

11

3-153

Nu

t - wishbone rear

eccentric bolt.

11

3-153

N

ut - fulcrum shaft, upper wishbone.

60

-80

Bolt -

power steering pi

pes to pinion housing.

9-1

2

Page 83 of 2490

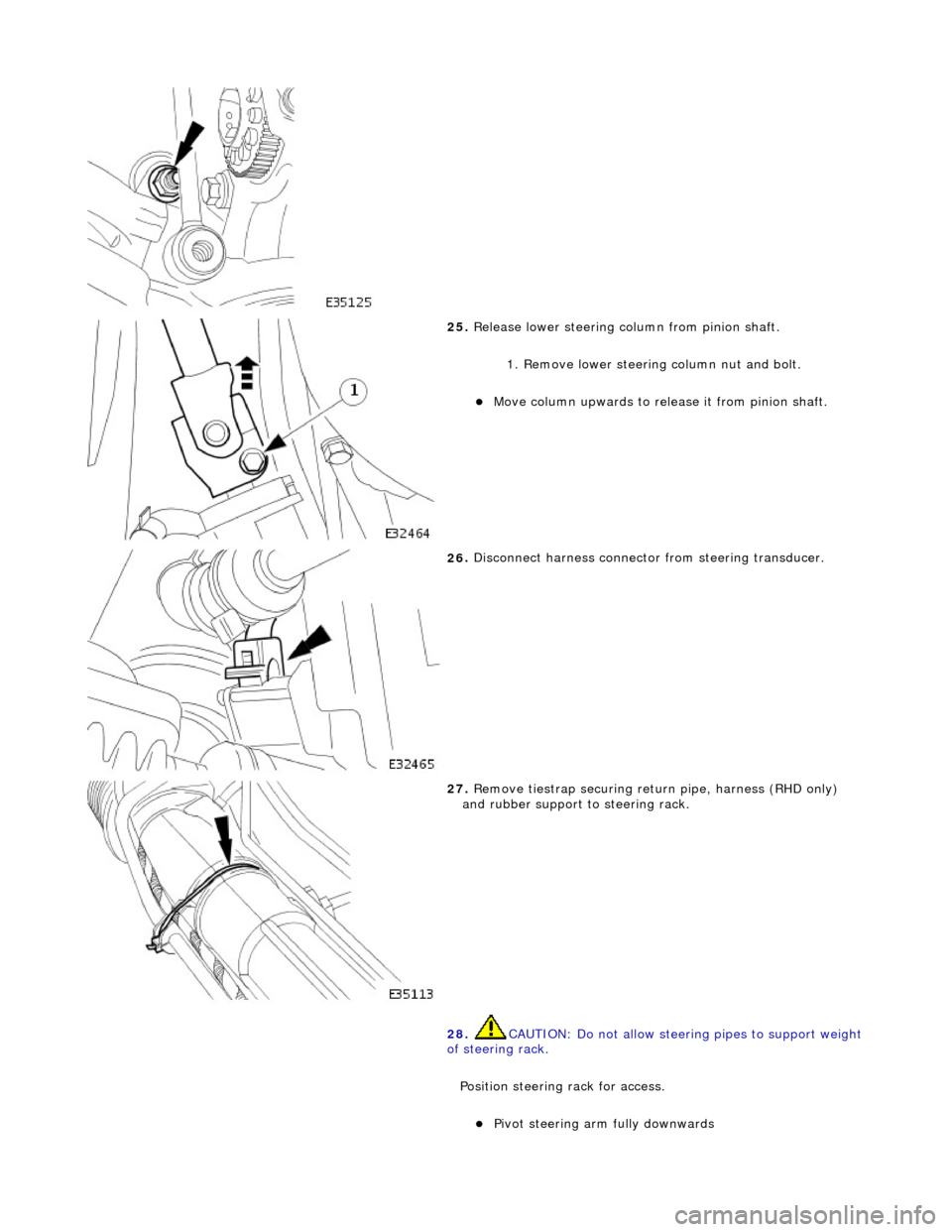

25

.

Release lower steering column from pinion shaft.

1. Remove lower steering column nut and bolt.

пЃ¬Move column up

wards to release it from pinion shaft.

26

.

Disconnect harness connector from steering transducer.

27

.

Remove tiestrap securing retu rn pipe, harness (RHD only)

and rubber support to steering rack.

28. CAUTION: Do not allow steerin g pipes to support weight

of steering rack.

Position steering rack for access.

пЃ¬Pi

vot steering arm fully downwards

Page 84 of 2490

In

stallation

пЃ¬Re

move steering rack securing bolts.

пЃ¬Carefully move steer

ing rack

downwards for access to

wishbone eccentric bolt.

29 . R

emove lower wishbone rear

arm eccentric bolt and nut.

пЃ¬Mark position of eccentri

c bo

lt large graduation mark on

crossbeam.

пЃ¬R e

move wishbone rear ec

centric bolt and nut.

30. Remove lower wishbone rear arm/ball joint assembly from

crossbeam.

1. Positi

on wishbone rear arm on crossbeam and install but do

not tighten eccentric bolt.

2. Install steeri

ng rack on crossbeam.

пЃ¬Ensure

that b

ushes are correct

ly positioned on steering

rack.

пЃ¬Posi ti

on steering rack on crossbeam.

пЃ¬Position support brac

kets over bus

hes.

пЃ¬Install mountin

g bracket bolts an

d tighten to 41-54Nm.

3. Install lower steering column on pinion shaft.

пЃ¬Move col u

mn downwards to engage coupling splines on

pinion shaft.

Page 95 of 2490

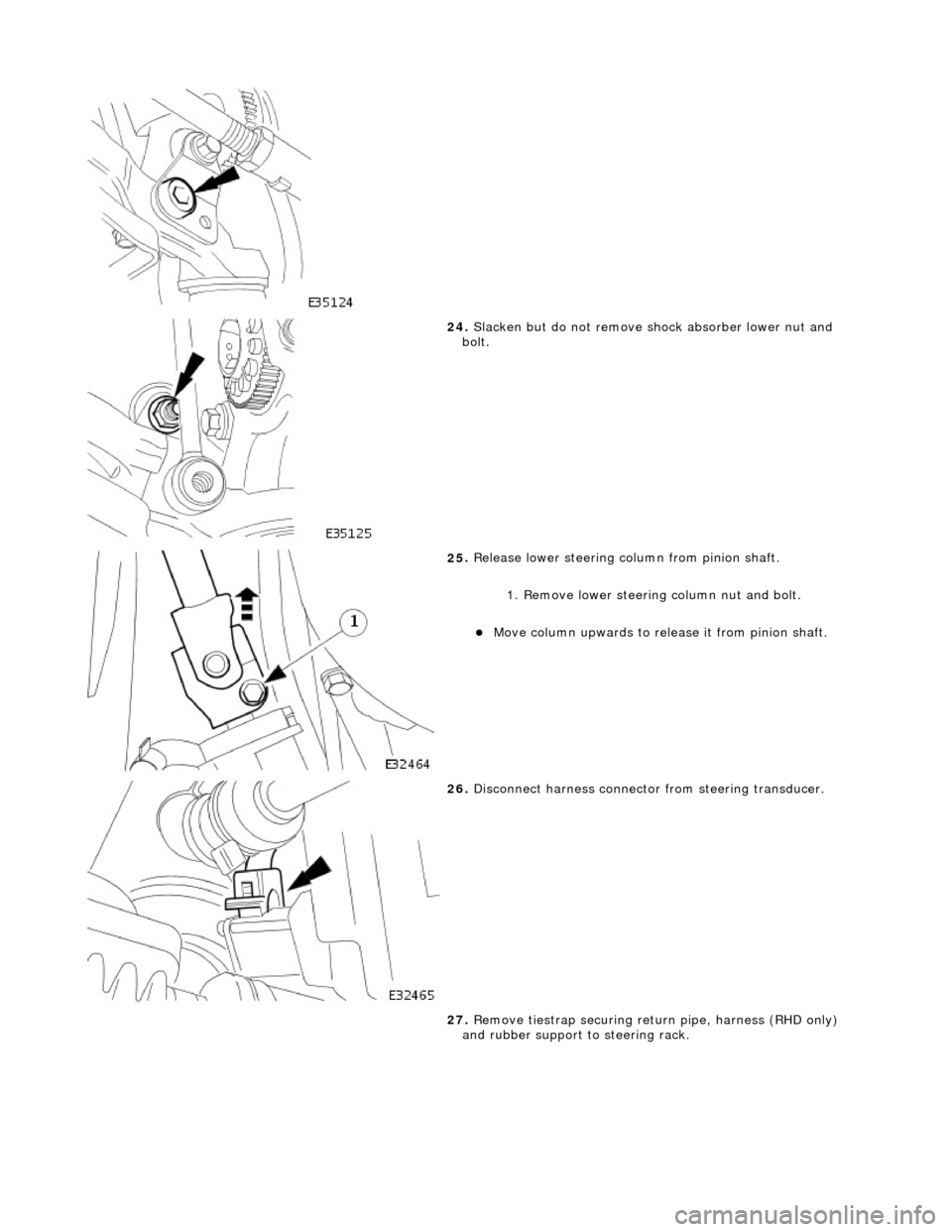

24

.

Slacken but do not remove shock absorber lower nut and

bolt.

25

.

Release lower steering column from pinion shaft.

1. Remove lower steering column nut and bolt.

пЃ¬Move column up

wards to release it from pinion shaft.

26

.

Disconnect harness connector from steering transducer.

27. Remove tiestrap securing retu rn pipe, harness (RHD only)

and rubber support to steering rack.

Page 98 of 2490

not ti

ghten eccentric bolt and nut.

4. Install steeri

ng rack on crossbeam.

пЃ¬Ensure that b

ushes are correct

ly positioned on steering

rack.

пЃ¬Posi ti

on steering rack on crossbeam.

пЃ¬Position support brac

kets over bus

hes.

пЃ¬Install mountin

g bracket bolts an

d tighten to 41-54Nm.

5. Inst al

l lower steering column on pinion shaft.

пЃ¬Move col

u

mn downwards to engage coupling splines on

pinion shaft.

1. Install nut and bolt and tighten to 22-28Nm.

6. Position an d

connect harnes

s to steering transducer.

пЃ¬RHD veh

icles. Position steeri

ng harness behind return

pipe.

пЃ¬Conne ct

harness to transducer.

7. Secure return pipe on steering rack.

1. Position pipe rubber support on steering rack.

2. Position pipe on support .

3. RHD vehicles. Position harness on pipe support rubber.

Page 455 of 2490

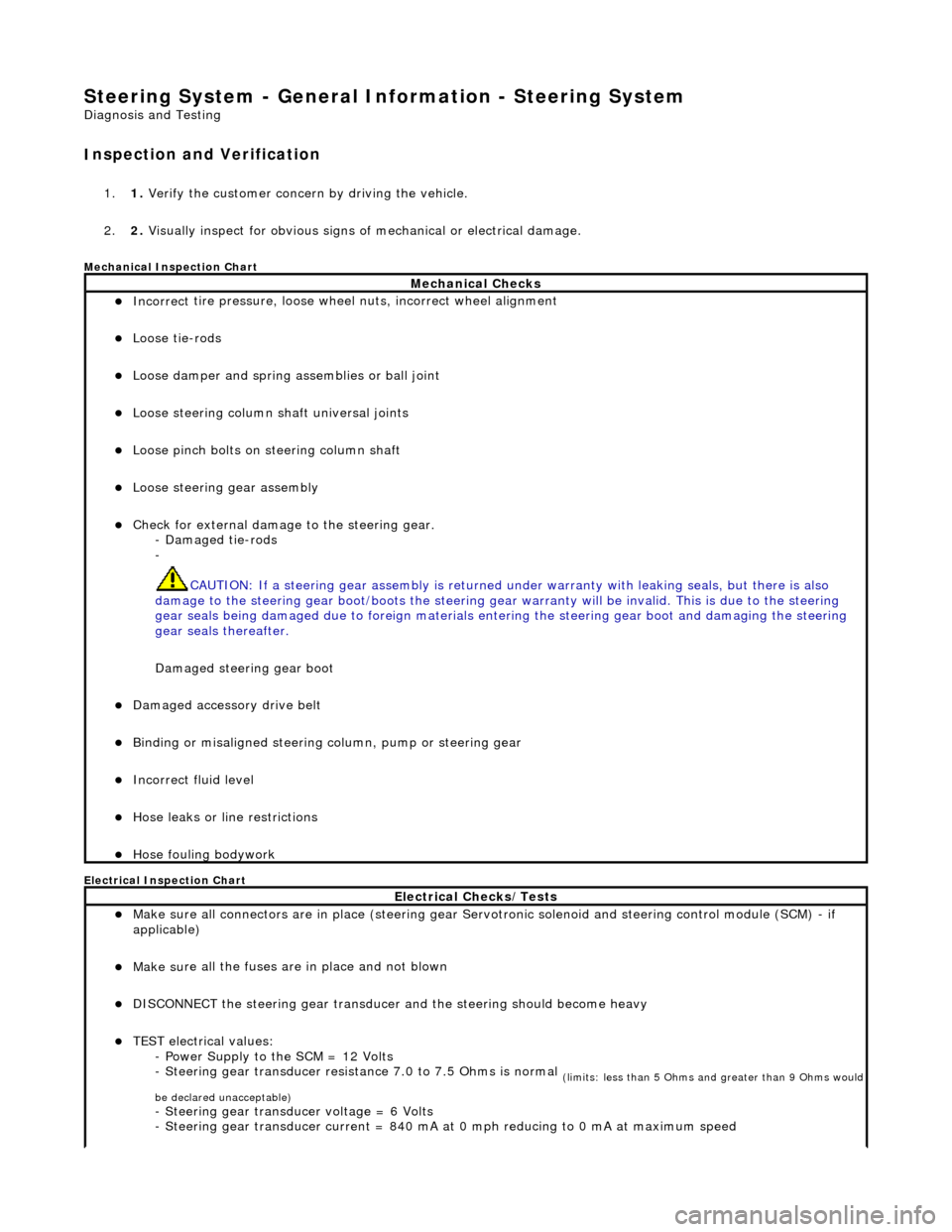

Steering System - General Inform

ation - Steering System

D

iagnosis and Testing

I

nspection and Verification

1.

1. Verify t

he customer concern by driving the vehicle.

2. 2. Visually inspect for obvious signs of mechanical or electrical damage.

Mec

hanical Inspection Chart

Electrical Inspection Chart

Mechanical Checks

пЃ¬Incorrect

tire pressure, loose whee

l nuts, incorrect wheel alignment

пЃ¬Loose ti

e-rods

пЃ¬Loose dam

per and spring assemblies or ball joint

пЃ¬Loose s

teering column shaft universal joints

пЃ¬Loose pinc

h bolts on steering column shaft

пЃ¬Loose steeri

ng gear assembly

пЃ¬Check f

or external damage to the steering gear.

- Damaged tie-rods

-

CAUTION: If a steering gear assemb ly is returned under warranty with leaking seals, but there is also

damage to the steering gear boot/boots the steering gear warranty will be invalid. This is due to the steering

gear seals being damaged due to fore ign materials entering the steering gear boot and damaging the steering

gear seals thereafter.

Damaged steering gear boot

пЃ¬Damaged accessory driv

e belt

пЃ¬Bin

ding or misaligned steering co

lumn, pump or steering gear

пЃ¬Incorrect fluid

level

пЃ¬Hose leaks o

r line restrictions

пЃ¬Hose fou

ling bodywork

El

ectrical Checks/Tests

пЃ¬Make sure all

connectors are in plac

e (steering gear Servotronic solenoid and steering control module (SCM) - if

applicable)

пЃ¬Make su

re all the fuses are in place and not blown

пЃ¬D

ISCONNECT the steering gear transducer

and the steering should become heavy

пЃ¬TEST e

lectrical values:

- Power Supply to the SCM = 12 Volts

- Steering gear transducer resist ance 7.0 to 7.5 Ohms is normal

(

limits: less than 5 Ohms and greater than 9 Ohms would

be declared unacceptable)

- Steeri

ng gear transducer voltage = 6 Volts

- Steering gear transducer cu rrent = 840 mA at 0 mph reducing to 0 mA at maximum speed

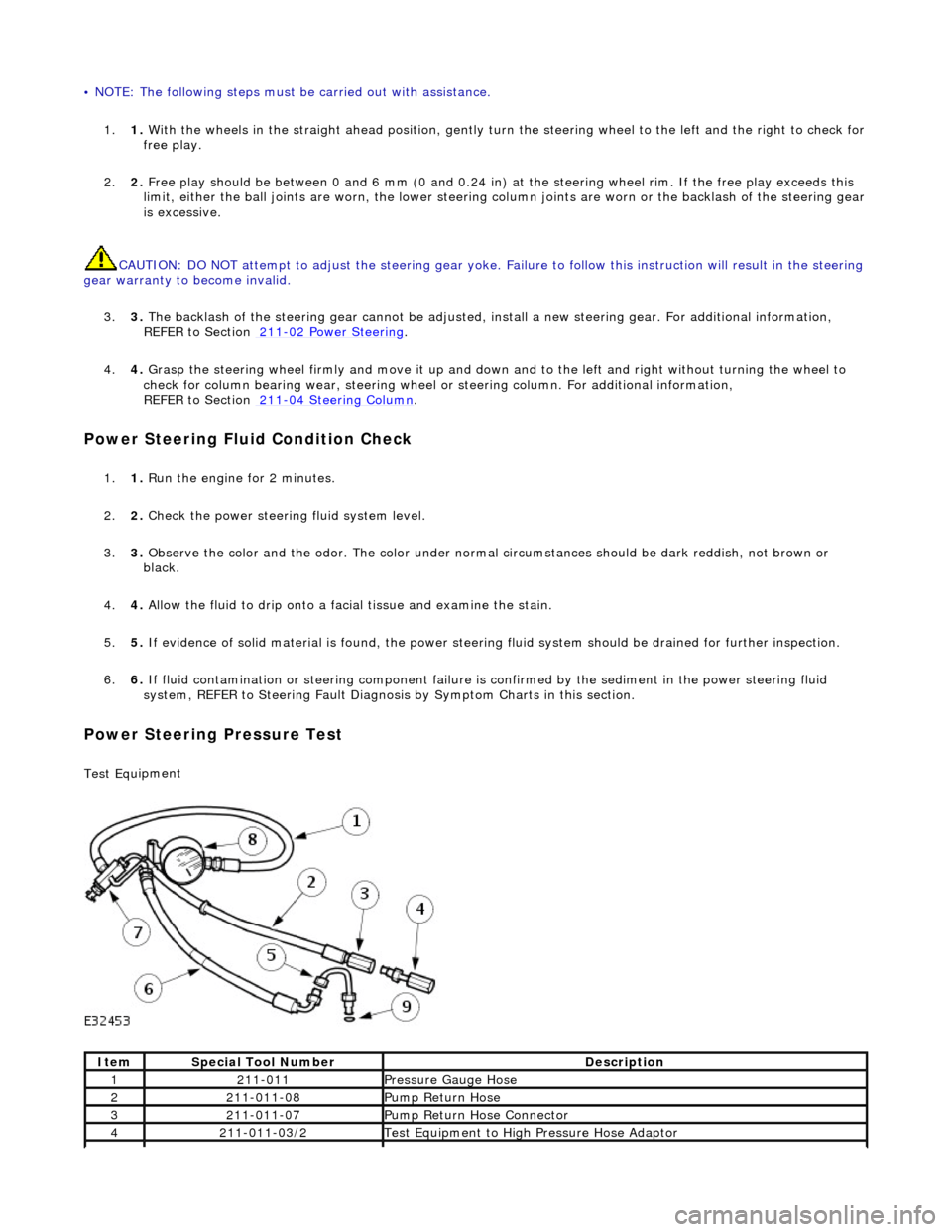

Page 457 of 2490

•

NOTE: The following steps must be carried out with assistance.

1. 1. With the wheels in the straight ahead po sition, gently turn the steering wheel to the left and the right to check for

free play.

2. 2. Free play should be between 0 and 6 mm (0 and 0.24 in) at the steering wheel rim. If the free play exceeds this

limit, either the ball joints are worn, the lower steering column joints are worn or the backlash of the steering gear

is excessive.

CAUTION: DO NOT attempt to adjust the stee ring gear yoke. Failure to follow this instruction will result in the steering

gear warranty to become invalid.

3. 3. The backlash of the steering gear cannot be adjusted, in stall a new steering gear. For additional information,

REFER to Section 211

-0

2 Power Steering

.

4. 4. Grasp the steering wheel

firm

ly and move it up and down and to the left and right without turning the wheel to

check for column bearing wear, steering wheel or steering column. For additional information,

REFER to Section 211

-0

4 Steering Column

.

Power Steering Fluid Condition Check

1.

1. R

un the engine for 2 minutes.

2. 2. Check the power steering fluid system level.

3. 3. Observe the color and the odor. The color under normal circumstances should be dark reddish, not brown or

black.

4. 4. Allow the fluid to drip onto a faci al tissue and examine the stain.

5. 5. If evidence of solid material is foun d, the power steering fluid system should be drained for further inspection.

6. 6. If fluid contamination or steering co mponent failure is confirmed by the se diment in the power steering fluid

system, REFER to Steering Fault Diagnosis by Symptom Charts in this section.

Power Steer

ing Pressure Test

Test Equ

ipment

It

em

S

pecial Tool Number

De

scription

12

11-011

Pres

sure Gauge Hose

221

1-011-08

Pump Return Hose

321

1-011-07

Pump Return Hose Connector

42

11-011-03/2

Test Equ

ipment to High

Pressure Hose Adaptor

Page 459 of 2490

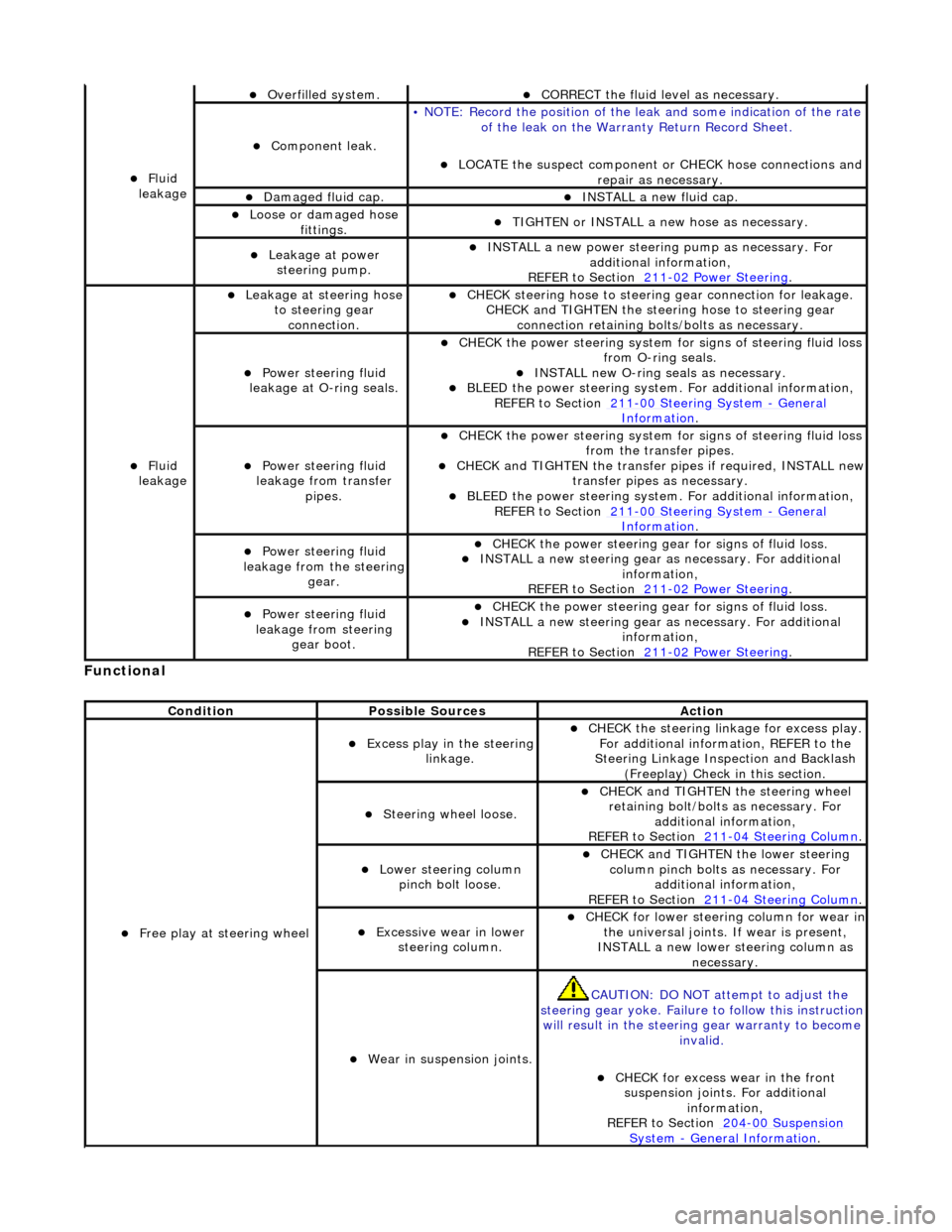

Function

al

пЃ¬Fl

uid

leakage

пЃ¬O

verfilled system.

пЃ¬CORRECT the

fluid leve

l as necessary.

пЃ¬Compon

ent leak.

•

NOTE: Record the position of the le

ak and some indication of the rate

of the leak on the Warra nty Return Record Sheet.

пЃ¬LOCATE

the suspect component or CHECK hose connections and

repair as necessary.

пЃ¬Damaged fluid cap. пЃ¬INST

ALL a new fluid cap.

пЃ¬Loose or damaged h

ose

fittings.

пЃ¬TI

GHTEN or INSTALL a new hose as necessary.

пЃ¬Leakage at

power

steering pump.

пЃ¬INST

ALL a new power steering

pump as necessary. For

additional information,

REFER to Section 211

-0

2 Power Steering

.

пЃ¬Fl

uid

leakage

пЃ¬Leakage

at steering hose

to steering gear connection.

пЃ¬CHECK

steering hose to

steering gear conn ection for leakage.

CHECK and TIGHTEN the steeri ng hose to steering gear

connection retaining bolt s/bolts as necessary.

пЃ¬Power steeri

ng fluid

leakage at O-ring seals.

пЃ¬CHECK

the power steering system fo

r signs of steering fluid loss

from O-ring seals.

пЃ¬INST

ALL new O-ring seals as necessary.

пЃ¬BLEE

D the power steering system.

For additional information,

REF

ER to Section 211

-0

0 Steering System

- Ge

neral

Informati

on

.

пЃ¬Power steeri

ng fluid

leakage from transfer pipes.

пЃ¬CHECK

the power steering system fo

r signs of steering fluid loss

from the transfer pipes.

пЃ¬CHECK

and TIGHTEN the transfer pipes if required, INSTALL new

transfer pipes as necessary.

пЃ¬BLEE

D the power steering system.

For additional information,

REF

ER to Section 211

-0

0 Steering System

- Ge

neral

Informati

on

.

пЃ¬Power steeri

ng fluid

leakage from the steering

gear.

пЃ¬CHECK

the power steering gear for signs of fluid loss.

пЃ¬INST

ALL a new steering gear as

necessary. For additional

information,

REFER to Section 211

-0

2 Power Steering

.

пЃ¬Power steeri

ng fluid

leakage from steering gear boot.

пЃ¬CHECK

the power steering gear for signs of fluid loss.

пЃ¬INST

ALL a new steering gear as

necessary. For additional

information,

REFER to Section 211

-0

2 Power Steering

.

Cond

ition

Possib

le Sources

Acti

on

пЃ¬F

ree play at steering wheel

пЃ¬Exce

ss play in the steering

linkage.

пЃ¬CHECK

the steering linkage for excess play.

For additional information, REFER to the

Steering Linkage Inspection and Backlash (Freeplay) Check in this section.

пЃ¬S

teering wheel loose.

пЃ¬CHECK

and TIGHTEN the steering wheel

retaining bolt/bolts as necessary. For additional information,

REFER to Section 211

-0

4 Steering Column

.

пЃ¬Lower steeri

ng column

pinch bolt loose.

пЃ¬CHECK

and TIGHTEN the lower steering

column pinch bolts as necessary. For additional information,

REFER to Section 211

-0

4 Steering Column

.

пЃ¬Exce

ssive wear in lower

steering column.

пЃ¬CHECK

for lower steering column for wear in

the universal joints. If wear is present,

INSTALL a new lower steering column as necessary.

пЃ¬W

ear in suspension joints.

CAU

TION: DO NOT attempt to adjust the

steering gear yoke. Failure to follow this instruction

will result in the steering gear warranty to become

invalid.

пЃ¬CHECK

for excess wear in the front

suspension joints. For additional information,

REFER to Section 204

-00

Suspension

Sy

stem

- General

Information

.