Cooling JAGUAR X308 1998 2.G Owner's Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 830 of 2490

Engine - Upper Oil Pan3.2L NA V8 - AJ26

In-vehicle Repair

Removal

Special Tool(s)

Installer/remover, Oil Filter

303-752

1. Disconnect the batt ery ground cable.

Remove the battery cover.

2. Open the engine compartment and fit paintwork protection

sheets.

3. Set the engine compartment cover to the service access

position.

4. Remove the timing cover and al l associated components, as

detailed in Operation 12.65.01.

5. Remove both front wheel and tyre assemblies. Refer to

Operation 74.20.05.

6. Remove the undertray. Re fer to Operation 76.22.90.

7. Remove the two bolts which secu re the generator cooling duct

to the oil pan body and remove the duct.

8. Remove the front cross member for access. Refer to Operation

76.10.05.

9. Drain the engine oil.

1. Position the waste oil bowser.

2. Remove the drain plug from the oil pan and drain the engine oil.

Fit a new sealing washer to the drain plug.

Page 838 of 2490

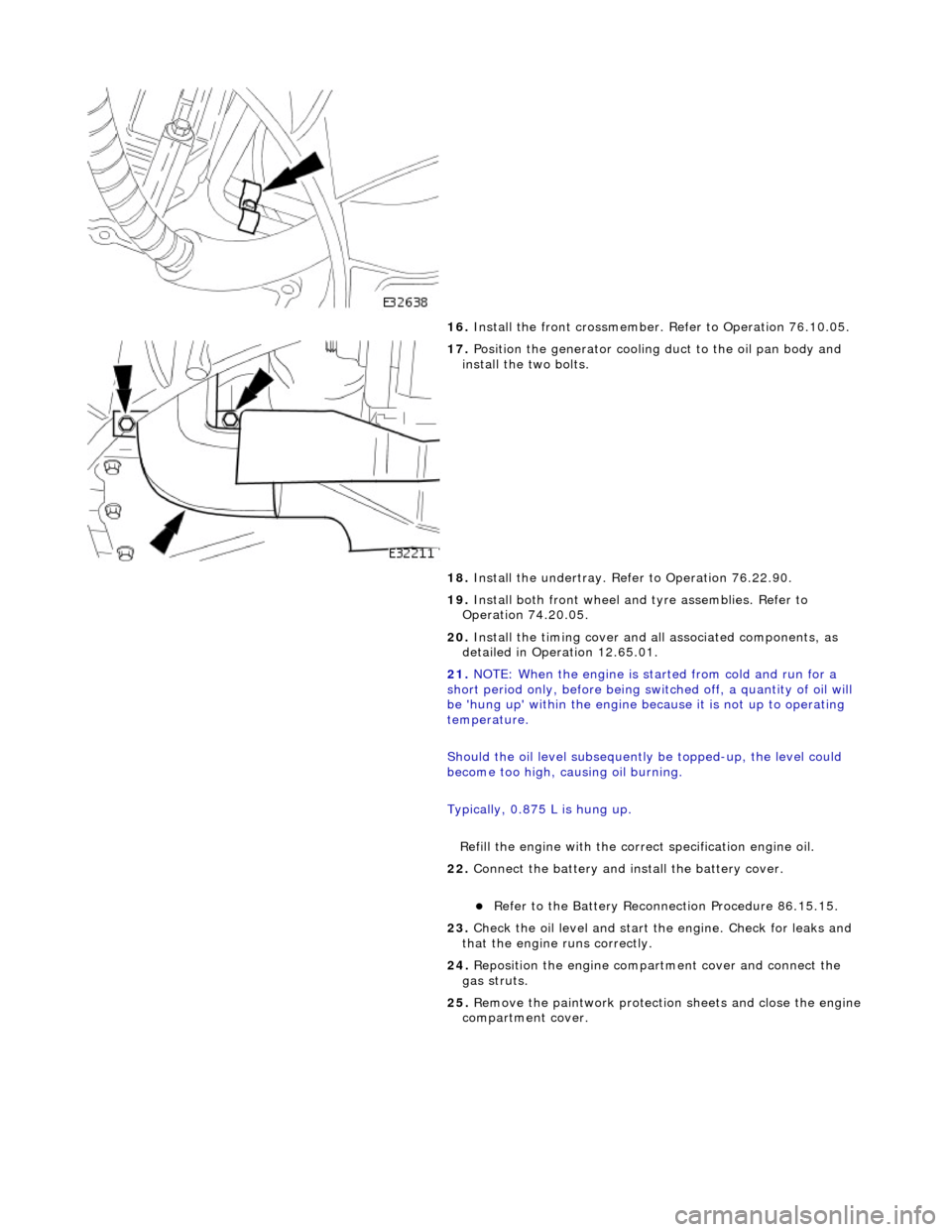

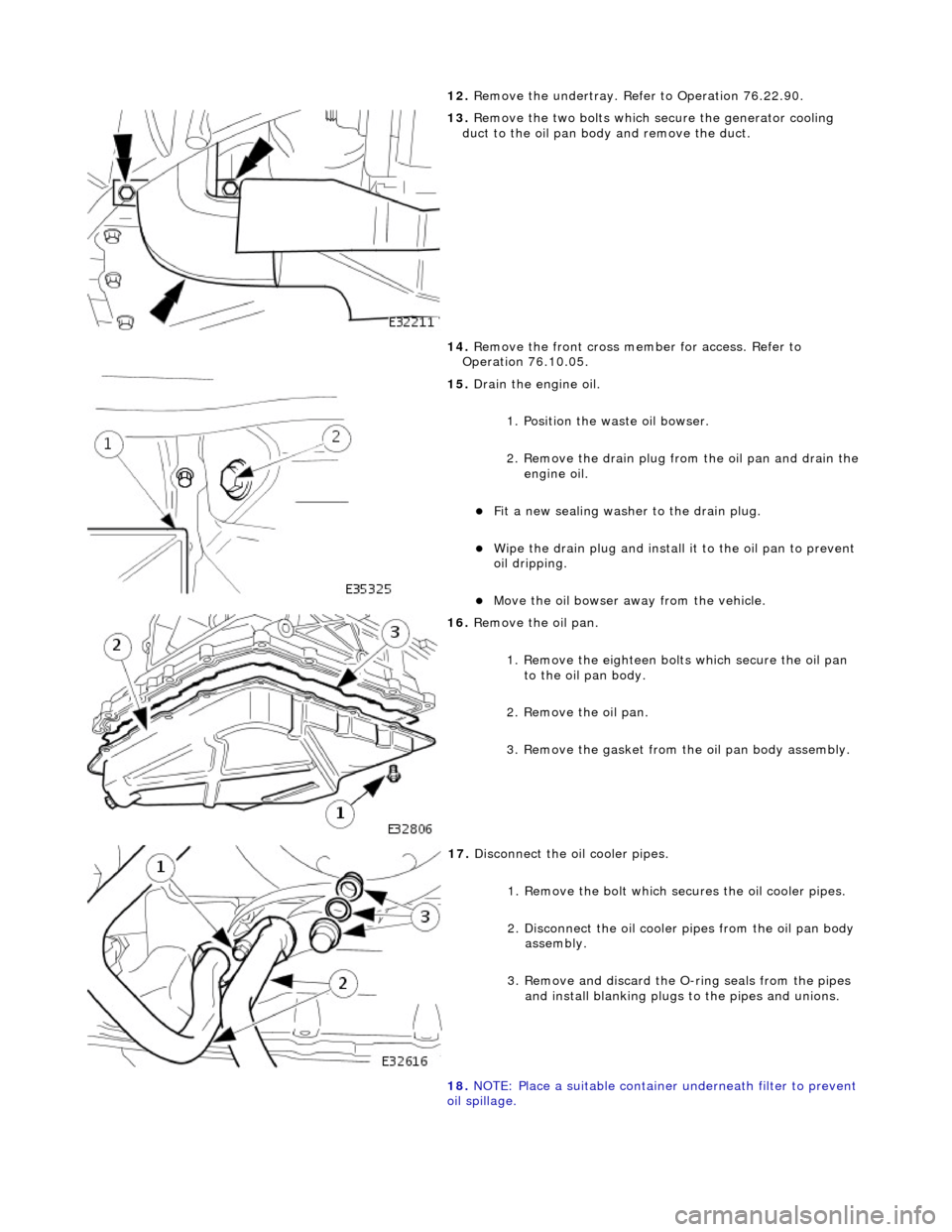

16. Install the front cr ossmember. Refer to Operation 76.10.05.

17. Position the generator cooling duct to the oil pan body and

install the two bolts.

18. Install the undert ray. Refer to Operation 76.22.90.

19. Install both front wheel and tyre assemblies. Refer to

Operation 74.20.05.

20. Install the timing cover and al l associated components, as

detailed in Operation 12.65.01.

21. NOTE: When the engine is star ted from cold and run for a

short period only, before being swit ched off, a quantity of oil will

be 'hung up' within the engine because it is not up to operating

temperature.

Should the oil level subsequently be topped-up, the level could

become too high, causing oil burning.

Typically, 0.875 L is hung up.

Refill the engine with the correct specification engine oil.

22. Connect the battery and in stall the battery cover.

Refer to the Battery Reconnection Procedure 86.15.15.

23. Check the oil level and start th e engine. Check for leaks and

that the engine runs correctly.

24. Reposition the engine compartment cover and connect the

gas struts.

25. Remove the paintwork protection sheets and close the engine

compartment cover.

Page 839 of 2490

Engine - Upper Oil Pan4.0L NA V8 - AJ27, 4.0L

In-vehicle Repair

Removal

Special Tool(s)

Installer/remover, Oil Filter

303-752

1. Disconnect the batt ery ground cable.

Remove the battery cover.

2. Open the engine compartment and fit paintwork protection

sheets.

3. Set the engine compartment cover to the service access

position.

4. Remove the timing cover and al l associated components, as

detailed in Operation 12.65.01.

5. Remove both front wheel and tyre assemblies. Refer to

Operation 74.20.05.

6. Remove the undertray. Re fer to Operation 76.22.90.

7. Remove the two bolts which secu re the generator cooling duct

to the oil pan body and remove the duct.

8. Remove the front cross member for access. Refer to Operation

76.10.05.

9. Drain the engine oil.

1. Position the waste oil bowser.

2. Remove the drain plug from the oil pan and drain the engine oil.

Fit a new sealing washer to the drain plug.

Page 847 of 2490

16. Install the front cr ossmember. Refer to Operation 76.10.05.

17. Position the generator cooling duct to the oil pan body and

install the two bolts.

18. Install the undert ray. Refer to Operation 76.22.90.

19. Install both front wheel and tyre assemblies. Refer to

Operation 74.20.05.

20. Install the timing cover and al l associated components, as

detailed in Operation 12.65.01.

21. NOTE: When the engine is star ted from cold and run for a

short period only, before being swit ched off, a quantity of oil will

be 'hung up' within the engine because it is not up to operating

temperature.

Should the oil level subsequently be topped-up, the level could

become too high, causing oil burning.

Typically, 0.875 L is hung up.

Refill the engine with the correct specification engine oil.

22. Connect the battery and in stall the battery cover.

Refer to the Battery Reconnection Procedure 86.15.15.

23. Check the oil level and start th e engine. Check for leaks and

that the engine runs correctly.

24. Reposition the engine compartment cover and connect the

gas struts.

25. Remove the paintwork protection sheets and close the engine

compartment cover.

Page 849 of 2490

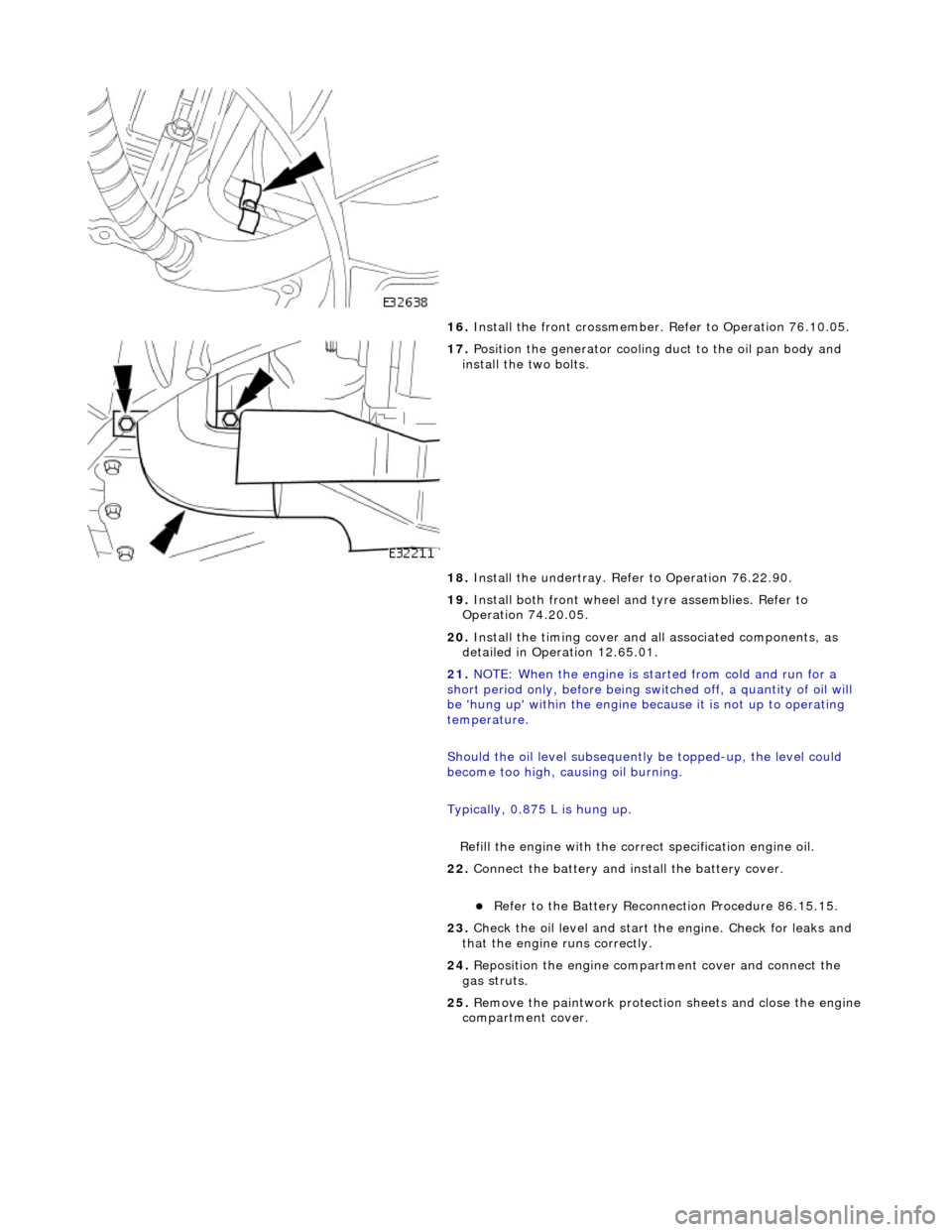

12. Remove the undertray. Re fer to Operation 76.22.90.

13. Remove the two bolts which se cure the generator cooling

duct to the oil pan body and remove the duct.

14. Remove the front cross member for access. Refer to

Operation 76.10.05.

15. Drain the engine oil.

1. Position the waste oil bowser.

2. Remove the drain plug from the oil pan and drain the engine oil.

Fit a new sealing washer to the drain plug.

Wipe the drain plug and install it to the oil pan to prevent

oil dripping.

Move the oil bowser away from the vehicle.

16. Remove the oil pan.

1. Remove the eighteen bolt s which secure the oil pan

to the oil pan body.

2. Remove the oil pan.

3. Remove the gasket from the oil pan body assembly.

17. Disconnect the oil cooler pipes.

1. Remove the bolt which secures the oil cooler pipes.

2. Disconnect the oil cooler pipes from the oil pan body

assembly.

3. Remove and discard the O-ring seals from the pipes

and install blanking plugs to the pipes and unions.

18. NOTE: Place a suitable container underneath filter to prevent

oil spillage.

Page 857 of 2490

Install and tighten the lower securing bolts to 18-24 Nm.

Tighten the upper securing bolts to 18-24 Nm.

16. Position the transmission cooler pipes and the clamping

bracket. Install the bolt to secu re the clamp and tighten to 7-9

Nm.

17. Connect the oil cooler pipes to the oil pan body assembly

(vehicles with engine oil cooler).

1. Remove the blanking plugs and install new O-ring seals.

2. Connect the oil cooler pipes.

3. Install the clamp and bolt which secures the oil cooler pipes. Tighten to 18-24 Nm.

18. Install the front cr ossmember. Refer to Operation 76.10.05.

19. Position the generator cooling duct to the oil pan body and

install the two bolts.

20. Install the undert ray. Refer to Operation 76.22.90.

21. Install both front wheel and tyre assemblies. Refer to

Operation 74.20.05.

22. Install the timing cover and al l associated components, as

detailed in Operation 12.65.01. Do not refill the cooling system

at this stage.

Page 858 of 2490

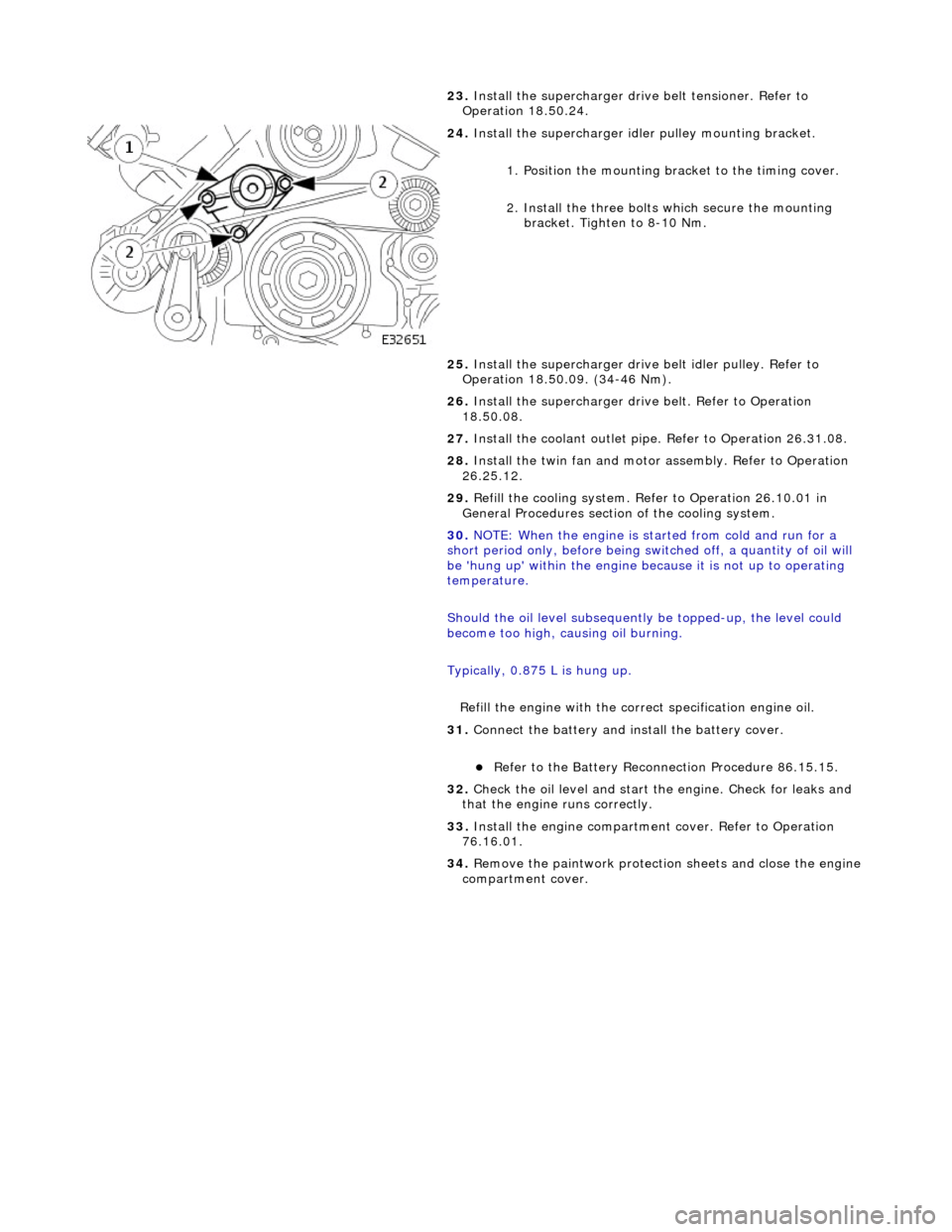

23.

Install the supercharger driv e belt tensioner. Refer to

Operation 18.50.24.

24. Install the supercharger idle r pulley mounting bracket.

1. Position the mounting bracket to the timing cover.

2. Install the three bolts which secure the mounting bracket. Tighten to 8-10 Nm.

25. Install the supercharger drive belt idler pulley. Refer to

Operation 18.50.09. (34-46 Nm).

26. Install the supercharger driv e belt. Refer to Operation

18.50.08.

27. Install the coolant outlet pipe. Refer to Operation 26.31.08.

28. Install the twin fan and motor assembly. Refer to Operation

26.25.12.

29. Refill the cooling system. Refer to Operation 26.10.01 in

General Procedures section of the cooling system.

30. NOTE: When the engine is star ted from cold and run for a

short period only, before being swit ched off, a quantity of oil will

be 'hung up' within the engine because it is not up to operating

temperature.

Should the oil level subsequently be topped-up, the level could

become too high, causing oil burning.

Typically, 0.875 L is hung up.

Refill the engine with the correct specification engine oil.

31. Connect the battery and in stall the battery cover.

Refer to the Battery Reconnection Procedure 86.15.15.

32. Check the oil level and start th e engine. Check for leaks and

that the engine runs correctly.

33. Install the engine compartmen t cover. Refer to Operation

76.16.01.

34. Remove the paintwork protection sheets and close the engine

compartment cover.

Page 897 of 2490

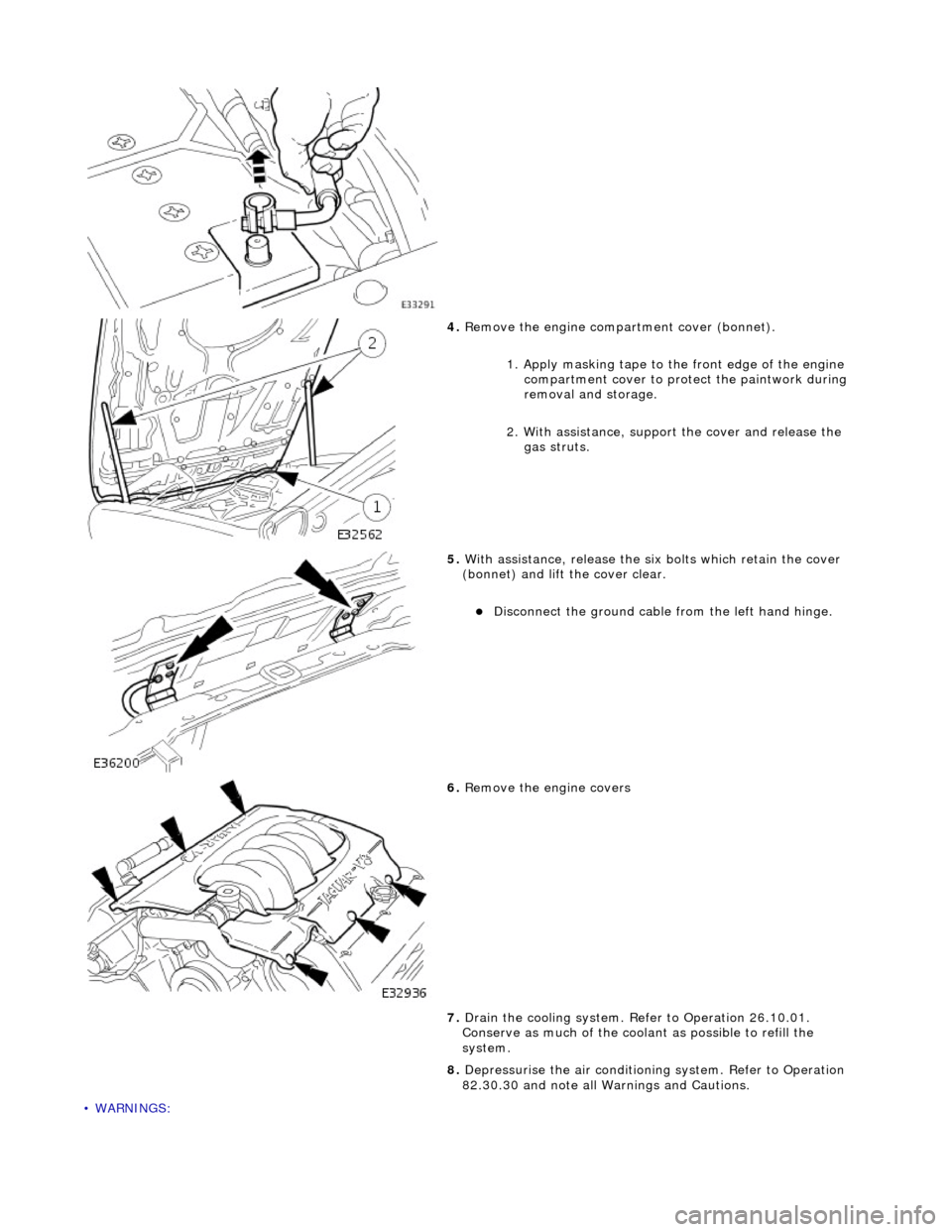

• WARNINGS:

4. Remove the engine compartment cover (bonnet).

1. Apply masking tape to th e front edge of the engine

compartment cover to protect the paintwork during

removal and storage.

2. With assistance, support the cover and release the

gas struts.

5. With assistance, release the six bolts which retain the cover

(bonnet) and lift the cover clear.

Disconnect the ground cable from the left hand hinge.

6. Remove the engine covers

7. Drain the cooling system. Refer to Operation 26.10.01.

Conserve as much of the coolant as possible to refill the

system.

8. Depressurise the air conditioni ng system. Refer to Operation

82.30.30 and note all Wa rnings and Cautions.

Page 922 of 2490

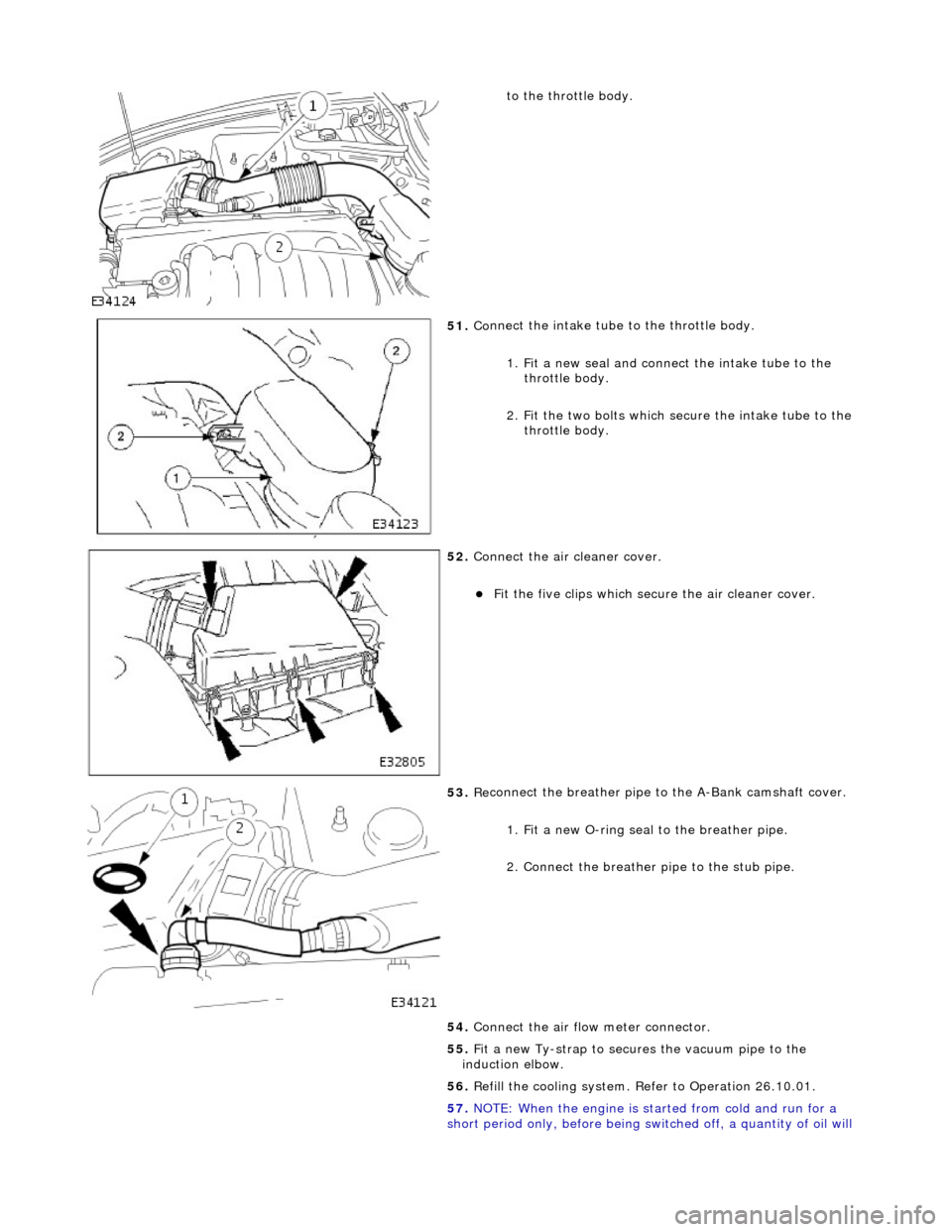

to th

e throttle body.

51 . Co

nnect the intake tube to the throttle body.

1. Fit a new seal and connect the intake tube to the throttle body.

2. Fit the two bolts which secure the intake tube to the throttle body.

52 . Conne

ct the air cleaner cover.

F

it

the five clips which secu

re the air cleaner cover.

53 . Re

connect the breather pipe to the A-Bank camshaft cover.

1. Fit a new O-ring seal to the breather pipe.

2. Connect the breather pipe to the stub pipe.

54. Connect the air flow meter connector.

55. Fit a new Ty-strap to secures the vacuum pipe to the

induction elbow.

56. Refill the cooling system. Refer to Operation 26.10.01.

57. NOTE: When the engine is star ted from cold and run for a

short period only, before being swit ched off, a quantity of oil will

Page 924 of 2490

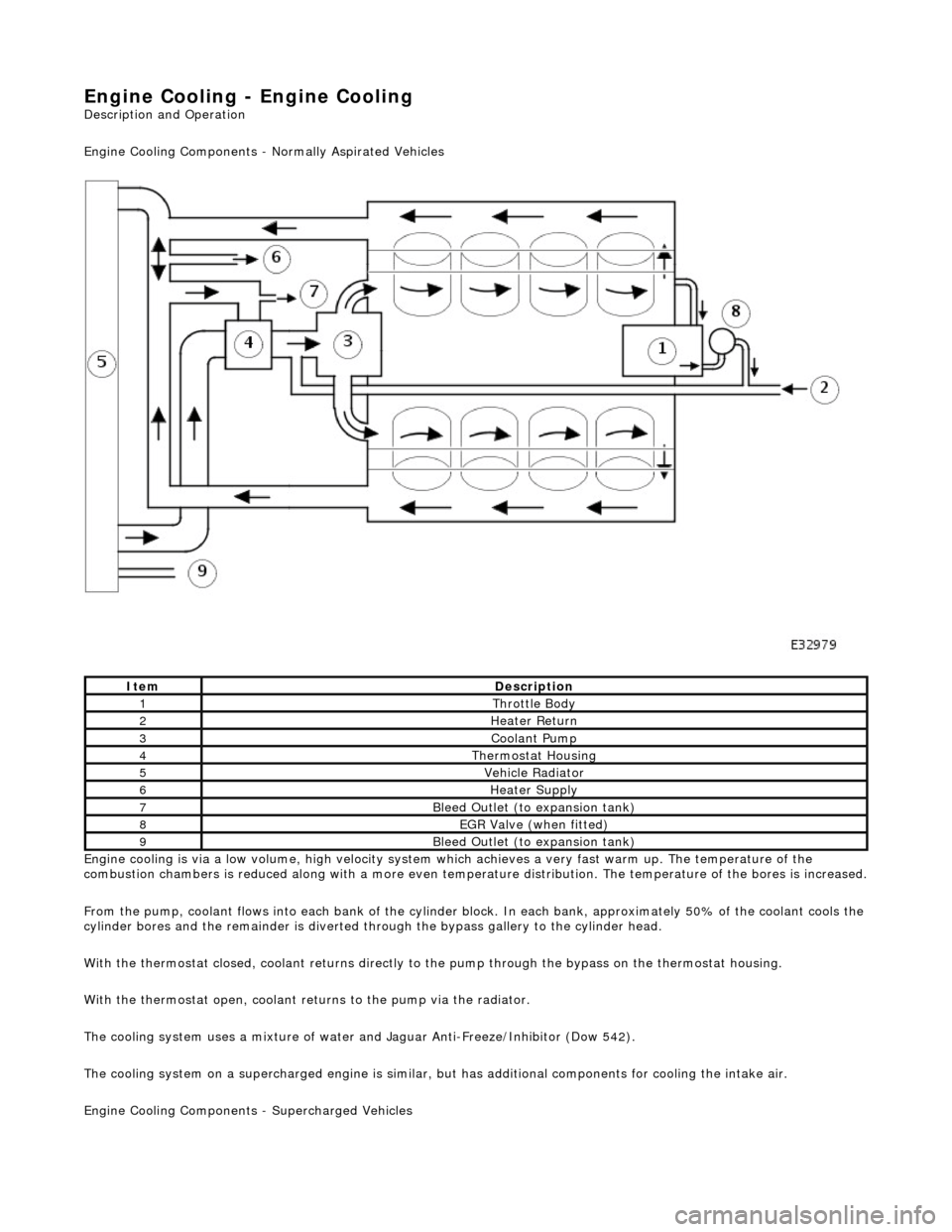

Engine Cooling

- Engine Cooling

Descr

i

ption and Operation

Engine Cooling Comp onents - Normally Aspirated Vehicles

Engine cooling is via a low volume, high velocity system which achieves a very fast warm up. The temperature of the

combustion chambers is reduced along with a more even temperature distribution. The temperature of the bores is increased.

F r

om the pump, coolant flows into each bank of the cylinder bl

ock. In each bank, approximately 50% of the coolant cools the

cylinder bores and the remainder is diverted th rough the bypass gallery to the cylinder head.

With the thermostat closed, coolant returns directly to the pump through the bypass on the thermostat housing.

With the thermostat open, coolant returns to the pump via the radiator.

The cooling system uses a mixture of water and Jaguar Anti-Freeze/Inhibitor (Dow 542).

The cooling system on a supercharged engine is similar, but has additional components for cooling the intake air.

Engine Cooling Co mponents - Supercharged Vehicles

ItemDescrip

tion

1Thr

ottle B

ody

2Hea

ter Return

3Coolant Pum p

4Ther

mostat Housing

5Vehicle Radia

t

or

6Hea

ter Su

pply

7Bleed

Outl

et (to expansion tank)

8EGR V

a

lve (when fitted)

9Bleed

Outl

et (to expansion tank)