diagram JAGUAR X308 1998 2.G Owner's Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1084 of 2490

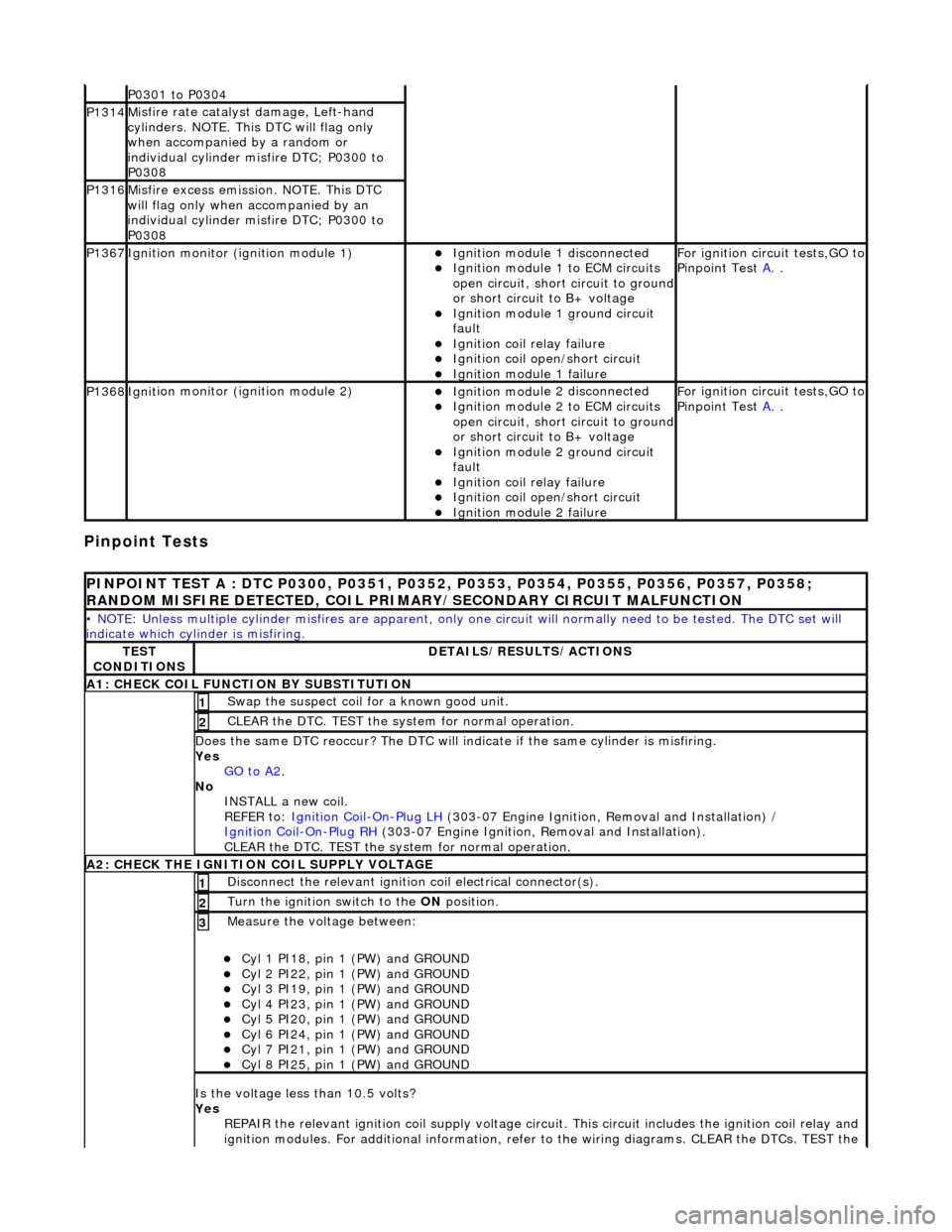

Pinpoint Tests

P0301 t

o P0304

P1314M

i

sfire rate catalyst damage, Left-hand

cylinders. NOTE. This DTC will flag only

when accompanied by a random or

individual cylinder misfire DTC; P0300 to

P0308

P1316M i

sfire excess emission. NOTE. This DTC

will flag only when accompanied by an

individual cylinder misfire DTC; P0300 to

P0308

P1367Ignit i

on monitor (ignition module 1)

Ignition modu

le

1 disconnected

Ignition modul e

1 to ECM circuits

open circuit, short circuit to ground

or short circuit to B+ voltage

Ignition modul e

1 ground circuit

fault

Ignition coil relay fai

lure

Ignition coil open/short

circuit

Ignition module

1 failure

F

o

r ignition circuit tests,GO to

Pinpoint Test A.

.

P1368Igniti

on monitor (ignition module 2)

Ignition modu

le

2 disconnected

Ignition modul e

2 to ECM circuits

open circuit, short circuit to ground

or short circuit to B+ voltage

Ignition modul e

2 ground circuit

fault

Ignition coil relay fai

lure

Ignition coil

open/short

circuit

Ignition modul

e

2 failure

F

o

r ignition circuit tests,GO to

Pinpoint Test A.

.

PINPOINT TES

T A : DTC P0300, P0351, P0352, P0353, P0354, P0355, P0356, P0357, P0358;

RANDOM MISFIRE DETECTED, COIL PRIMARY/SECONDARY CIRCUIT MALFUNCTION

• NO

TE: Unless multiple cylinder misfires are apparent, only on

e circuit will normally need to be tested. The DTC set will

indicate which cylinder is misfiring.

TE S

T

CONDITIONS

D E

TAILS/RESULTS/ACTIONS

A1

: CH

ECK COIL FUNCTI

ON BY SUBSTITUTION

Swap the suspect coi l

for a known good unit.

1

CLEAR t

h

e DTC. TEST the syst

em for normal operation.

2

Do

es the same DTC reoccur? The DTC will indicate if the same cylinder is misfiring.

Yes GO to A2

.

No

INST

ALL a new coil.

REFER to: Ignition Coil

-On-Plug

LH

(30

3-07 Engine Ignition, Removal and Installation) /

Ignition Coil

-On-Plu g

RH

(30

3-07 Engine Ignition, Removal and Installation).

CLEAR the DTC. TEST the system for normal operation.

A2: CHECK THE IGNIT

ION COIL SUPPLY VOLTAGE

Disc

onne

ct the relevant ignition

coil electrical connector(s).

1

Turn the ignition swit

ch to the ON

position.

2

Measure the voltage between:

Cyl 1 PI18, pin

1 (PW) and GROUND

Cy

l 2 PI22, pin

1 (PW) and GROUND

Cy

l 3 PI19, pin

1 (PW) and GROUND

Cy

l 4 PI23, pin

1 (PW) and GROUND

Cy

l 5 PI20, pin

1 (PW) and GROUND

Cy

l 6 PI24, pin

1 (PW) and GROUND

Cy

l 7 PI21, pin

1 (PW) and GROUND

Cy

l 8 PI25, pin

1 (PW) and GROUND

3

Is

t

he voltage less than 10.5 volts?

Yes REPAIR the relevant ignition coil su pply voltage circuit. This circuit includes the ignition coil relay and

ignition modules. For additional information, refer to the wiring diagrams. CLEAR the DTCs. TEST the

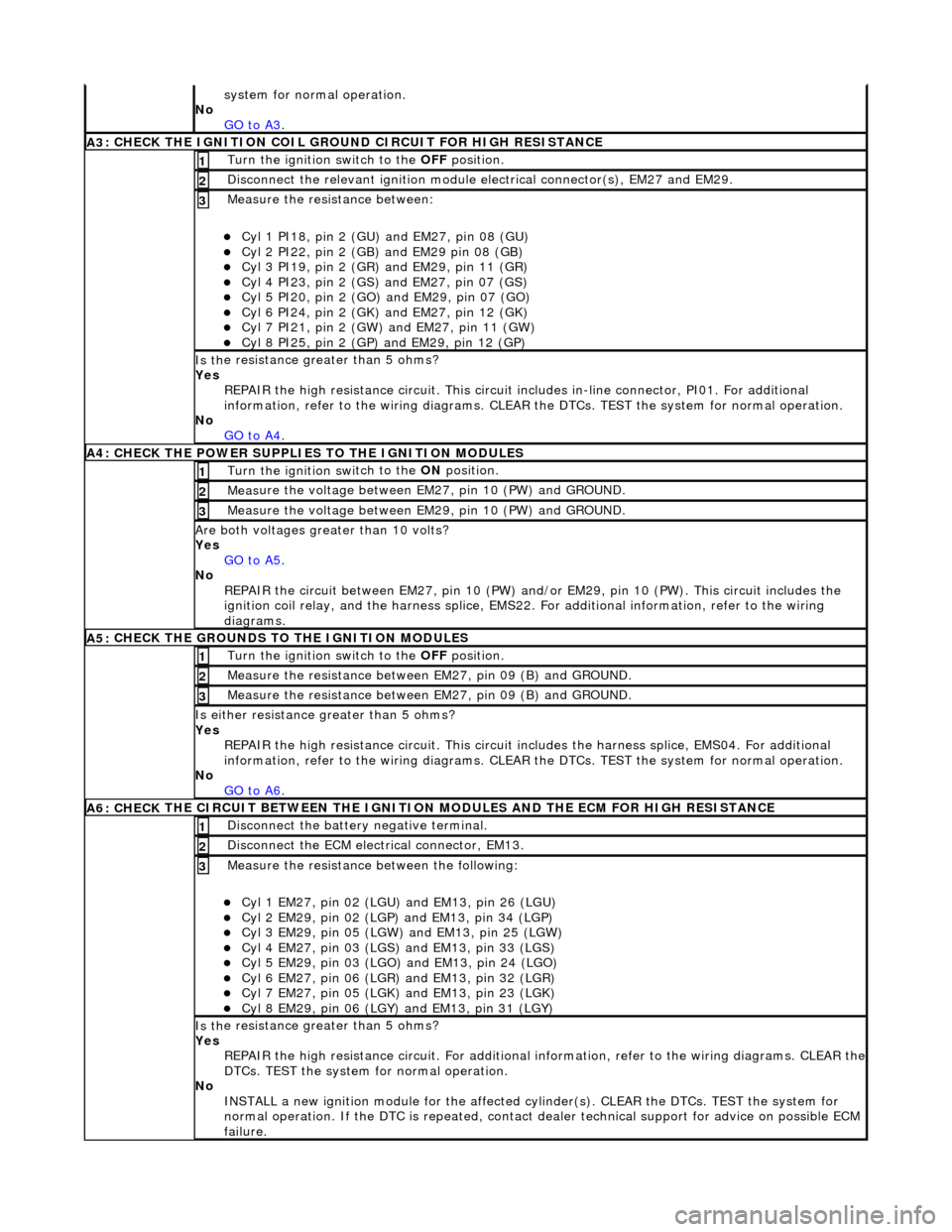

Page 1085 of 2490

system fo

r normal operation.

No GO to A3

.

A3

: CHECK THE IGNITION COIL GROUND CIRCUIT FOR HIGH RESISTANCE

Turn the ignition swi

tch to the OFF

position.

1

Disc

onnect the relevant ignition module

electrical connector(s), EM27 and EM29.

2

Meas

ure the resistance between:

Cy

l 1 PI18, pin 2 (GU) and EM27, pin 08 (GU)

Cy

l 2 PI22, pin 2 (GB) and EM29 pin 08 (GB)

Cy

l 3 PI19, pin 2 (GR) and EM29, pin 11 (GR)

Cy

l 4 PI23, pin 2 (GS)

and EM27, pin 07 (GS)

Cy

l 5 PI20, pin 2 (GO) and EM29, pin 07 (GO)

Cy

l 6 PI24, pin 2 (GK) and EM27, pin 12 (GK)

Cy

l 7 PI21, pin 2 (GW) and EM27, pin 11 (GW)

Cy

l 8 PI25, pin 2 (GP) an

d EM29, pin 12 (GP)

3

Is th

e resistance greater than 5 ohms?

Yes REPAIR the high resistance circui t. This circuit includes in-line connector, PI01. For additional

information, refer to the wiring diagrams. CLEAR the DTCs. TEST the system for normal operation.

No GO to A4

.

A4:

CHECK THE POWER SUPPLIES TO THE IGNITION MODULES

Turn the ignition swi

tch to the ON

position.

1

Meas

ure the voltage between EM27, pin 10 (PW) and GROUND.

2

Meas

ure the voltage between EM29, pin 10 (PW) and GROUND.

3

Are both

voltages greater than 10 volts?

Yes GO to A5

.

No

REPAIR the circuit between EM27, pin 10 (PW) and/or EM29, pin 10 (PW). This circuit includes the

ignition coil relay, and the harness splice, EMS22. For additional information, refer to the wiring

diagrams.

A5:

CHECK THE GROUNDS TO THE IGNITION MODULES

Turn the ignition swi

tch to the OFF

position.

1

Meas

ure the resistance between EM27, pin 09 (B) and GROUND.

2

Meas

ure the resistance between EM27, pin 09 (B) and GROUND.

3

Is either resi

stance

greater than 5 ohms?

Yes REPAIR the high resistance circui t. This circuit includes the harness splice, EMS04. For additional

information, refer to the wiring diagrams. CLEAR the DTCs. TEST the system for normal operation.

No GO to A6

.

A6: CHECK

THE CIRCUIT BETWEEN THE IGNITION

MODULES AND THE ECM FOR HIGH RESISTANCE

Di

sconnect the battery negative terminal.

1

D

isconnect the ECM electrical connector, EM13.

2

Meas

ure the resistance between the following:

Cy

l 1 EM27, pin 02 (LGU) and EM13, pin 26 (LGU)

Cy

l 2 EM29, pin 02 (LGP) and EM13, pin 34 (LGP)

Cy

l 3 EM29, pin 05 (LGW) and EM13, pin 25 (LGW)

Cy

l 4 EM27, pin 03 (LGS) and EM13, pin 33 (LGS)

Cy

l 5 EM29, pin 03 (LGO) and EM13, pin 24 (LGO)

Cy

l 6 EM27, pin 06 (LGR) and EM13, pin 32 (LGR)

Cy

l 7 EM27, pin 05 (LGK) and EM13, pin 23 (LGK)

Cy

l 8 EM29, pin 06 (LGY) and EM13, pin 31 (LGY)

3

Is th

e resistance greater than 5 ohms?

Yes REPAIR the high resistance circuit. For additional information, refer to the wiring diagrams. CLEAR the

DTCs. TEST the system for normal operation.

No INSTALL a new ignition module for the affected cy linder(s). CLEAR the DTCs. TEST the system for

normal operation. If the DTC is re peated, contact dealer technical support for advice on possible ECM

failure.

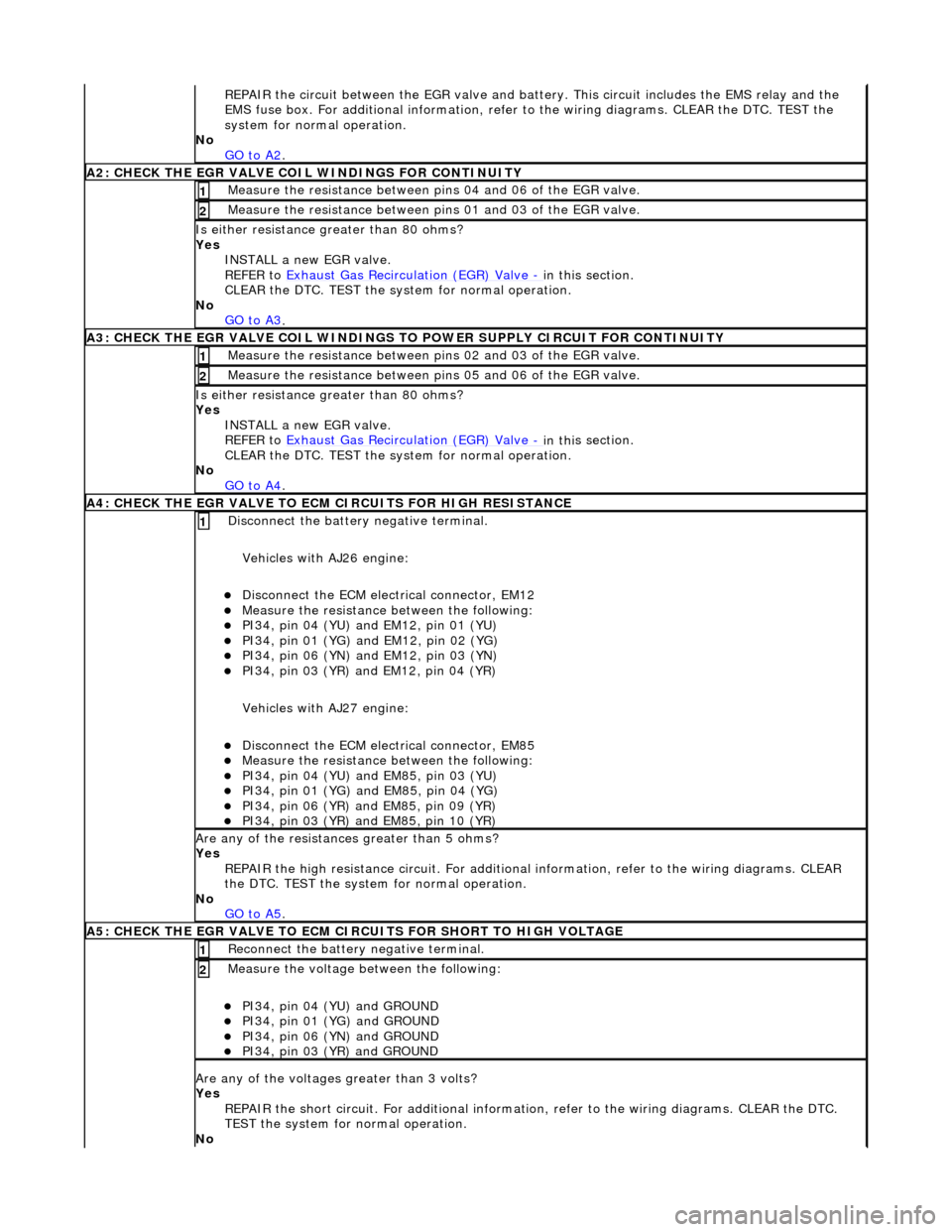

Page 1096 of 2490

RE

PAIR the circuit between the EGR valve and battery. This circuit includes the EMS relay and the

EMS fuse box. For additional info rmation, refer to the wiring diagrams. CLEAR the DTC. TEST the

system for normal operation.

No GO to A2

.

A2: CHECK THE EGR VALVE COIL WIND

INGS FOR CONTINUITY

Meas

ure t

he resistance between pins 04 and 06 of the EGR valve.

1

Meas

ure t

he resistance between pins 01 and 03 of the EGR valve.

2

Is either resi

stance

greater

than 80 ohms?

Yes INSTALL a new EGR valve.

REFER to Exhaust Gas Recirculation (EGR) Valve

- in thi

s section.

CLEAR the DTC. TEST the syst em for normal operation.

No GO to A3

.

A3: CHECK THE EGR VALVE COIL WINDINGS TO

POWER SUPPLY CIRCUIT FOR CONTINUITY

Meas

ure t

he resistance between pins 02 and 03 of the EGR valve.

1

Meas

ure t

he resistance between pins 05 and 06 of the EGR valve.

2

Is either resi

stance greater

than 80 ohms?

Yes INSTALL a new EGR valve.

REFER to Exhaust Gas Recirculation (EGR) Valve

- in thi

s section.

CLEAR the DTC. TEST the syst em for normal operation.

No GO to A4

.

A4: CHECK THE EGR VALVE T

O ECM

CIRCUITS FOR HIGH RESISTANCE

Disc

onnect the battery negative terminal.

Vehicles with AJ26 engine:

D i

sconnect the ECM electrical connector, EM12

Meas

ure t

he resistance between the following:

PI34, pin

0

4 (YU) and EM12, pin 01 (YU)

PI34,

pi

n 01 (YG) and EM12, pin 02 (YG)

PI34, pin

0

6 (YN) and EM12, pin 03 (YN)

PI34,

pi

n 03 (YR) and EM12, pin 04 (YR)

Vehicles with AJ27 engine:

D i

sconnect the ECM electrical connector, EM85

Meas

ure t

he resistance between the following:

PI34, pin

0

4 (YU) and EM85, pin 03 (YU)

PI34, pi

n 01 (YG) and EM85, pin 04 (YG)

PI34, pi

n 06 (YR) and EM85, pin 09 (YR)

PI34, pi

n 03 (YR) and EM85, pin 10 (YR)

1

Are an

y of the resistances greater than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No GO to A5

.

A5: CHECK THE EGR VALVE T

O ECM CIRCUITS FOR SHORT TO HIGH VOLTAGE

R

e

connect the battery negative terminal.

1

Meas

ure t

he voltage between the following:

PI34, pin

0

4 (YU) and GROUND

PI34, pin

0

1 (YG) and GROUND

PI34, pin

0

6 (YN) and GROUND

PI34, pin

0

3 (YR) and GROUND

2

Are any of th

e volt

ages greater than 3 volts?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No

Page 1097 of 2490

GO to A6.

A6: CHECK

THE EGR VALVE TO ECM

CIRCUITS FOR SHORT TO GROUND

Meas

ure the resistance between the following:

PI34, pin

04 (YU) and GROUND

PI34, pin

01 (YG) and GROUND

PI34, pin

06 (YN) and GROUND

PI34, pin

03 (YR) and GROUND

1

Are

any of the resistances less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No Contact dealer technical support for advice on possible ECM failure.

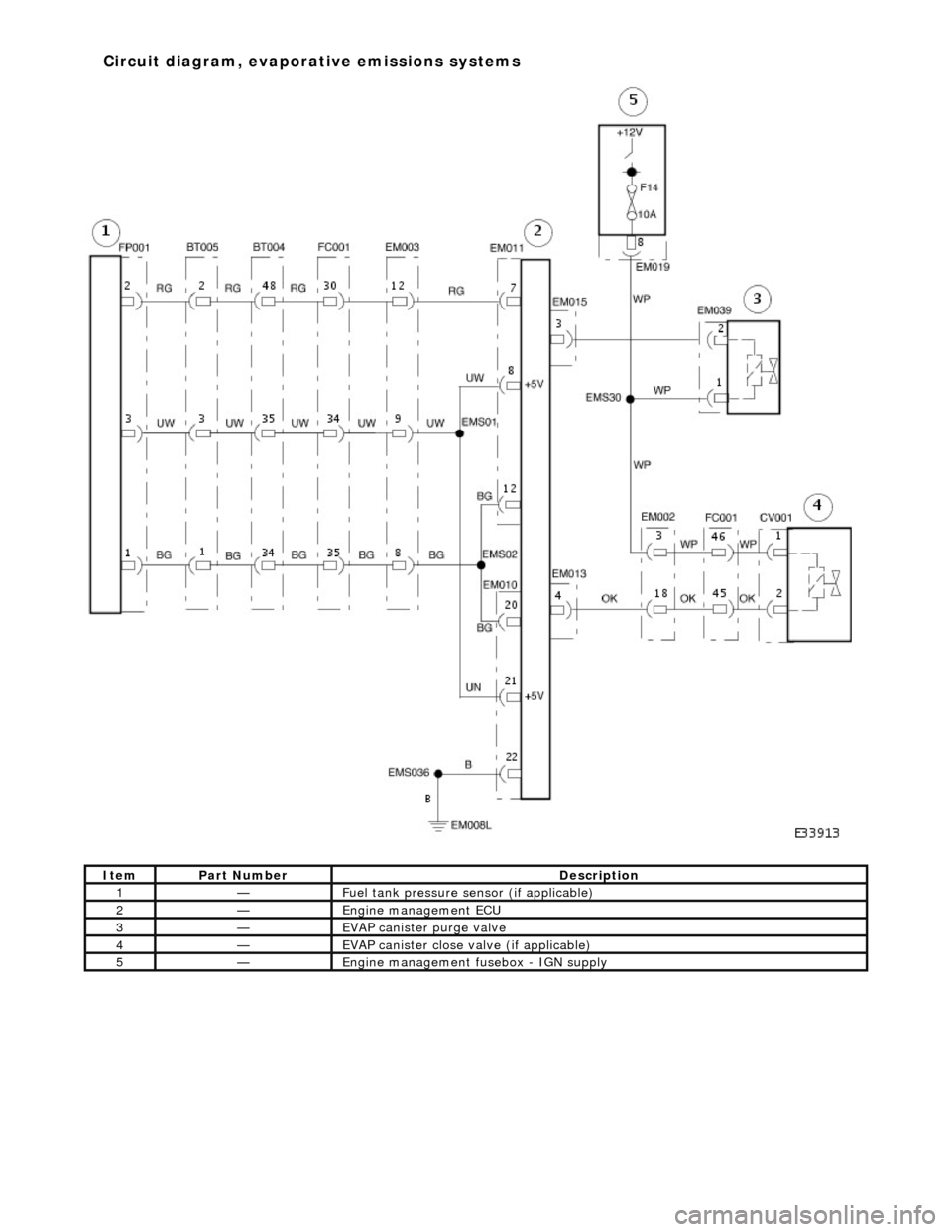

Page 1160 of 2490

Ite

m

Part

Number

Descr

iption

1—Fu

el tank pressure sensor (if applicable)

2—Engine m

anagement ECU

3—EVAP canister purge va

lve

4—EVAP ca

nister close valve (if applicable)

5—Engine

mana

gement fusebox - IGN supply

Circuit diagram

,

evaporative emissions systems

Page 1163 of 2490

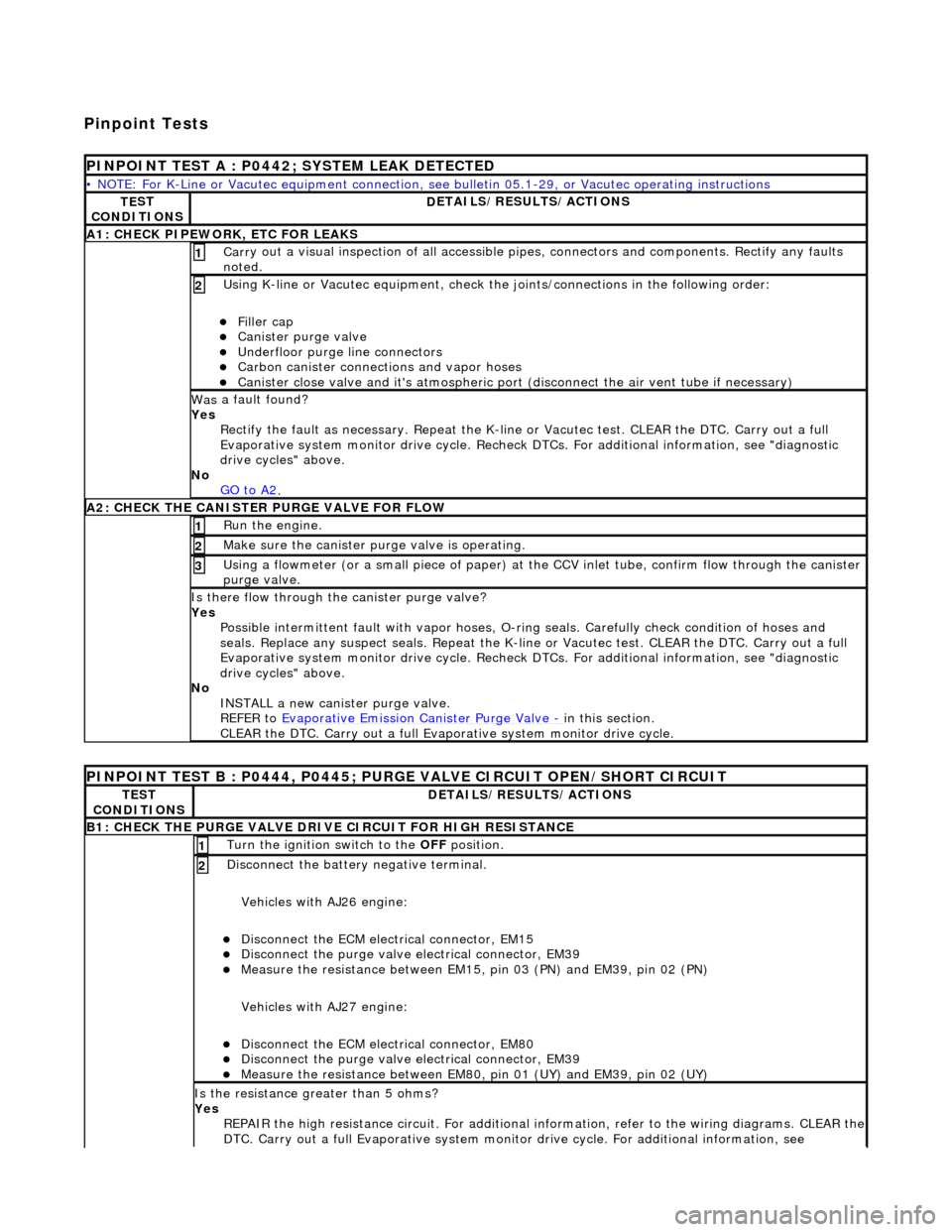

Pinpoint Tests

P

INPOINT TEST A : P0442; SYSTEM LEAK DETECTED

•

NOTE: For K-Line or Vacutec equipment connection, see bulletin 05.1-29, or Vacutec operating instructions

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

A

1: CHECK PIPEWORK, ETC FOR LEAKS

Carr

y out a visual inspection of all accessible pipes, connectors and components. Rectify any faults

noted.

1

U

sing K-line or Vacutec equipment, check the

joints/connections in the following order:

Fi

ller cap

Cani

ster purge valve

Underfl

oor purge line connectors

Carbon

canister connections and vapor hoses

Cani

ster close valve and it's atmospheric port (disconnect the air vent tube if necessary)

2

Was

a fault found?

Yes Rectify the fault as necessary. Re peat the K-line or Vacutec test. CLEAR the DTC. Carry out a full

Evaporative system monitor drive cycle. Recheck DT Cs. For additional information, see "diagnostic

drive cycles" above.

No GO to A2

.

A2: CHECK

THE CA

NISTER PURGE VALVE FOR FLOW

Ru

n the engine.

1

Make sure the canister purge

valve is operating.

2

Using a flowmeter

(or a small piece

of paper) at the CCV inlet tube, confirm flow through the canister

purge valve.

3

Is th

ere flow through the canister purge valve?

Yes Possible intermittent faul t with vapor hoses, O-ring seals. Carefully check condition of hoses and

seals. Replace any suspect seals. Repeat the K-line or Vacutec test. CLEAR the DTC. Carry out a full

Evaporative system monitor drive cycle. Recheck DT Cs. For additional information, see "diagnostic

drive cycles" above.

No INSTALL a new canister purge valve.

REFER to Evaporative Emission Canister Purge Valve

- in t

his section.

CLEAR the DTC. Carry out a full Evap orative system monitor drive cycle.

P

INPOINT TEST B : P0444, P0445; PURGE VALVE CIRCUIT OPEN/SHORT CIRCUIT

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

B1: CHECK

THE PURGE VALVE DRIV

E CIRCUIT FOR HIGH RESISTANCE

Turn the ignition swi

tch to the OFF

position.

1

Di

sconnect the battery negative terminal.

Vehicles with AJ26 engine:

Disc

onnect the ECM electrical connector, EM15

Di

sconnect the purge valve electrical connector, EM39

Meas

ure the resistance between EM15,

pin 03 (PN) and EM39, pin 02 (PN)

Vehicles with AJ27 engine:

Disc

onnect the ECM electrical connector, EM80

Di

sconnect the purge valve electrical connector, EM39

Meas

ure the resistance between EM80, pin 01 (UY) and EM39, pin 02 (UY)

2

Is th

e resistance greater than 5 ohms?

Yes REPAIR the high resistance circuit. For additional information, refer to the wiring diagrams. CLEAR the

DTC. Carry out a full Evaporative system monitor drive cycle. For additional information, see

Page 1164 of 2490

"d

iagnostic drive cycles" above.

No GO to B2

.

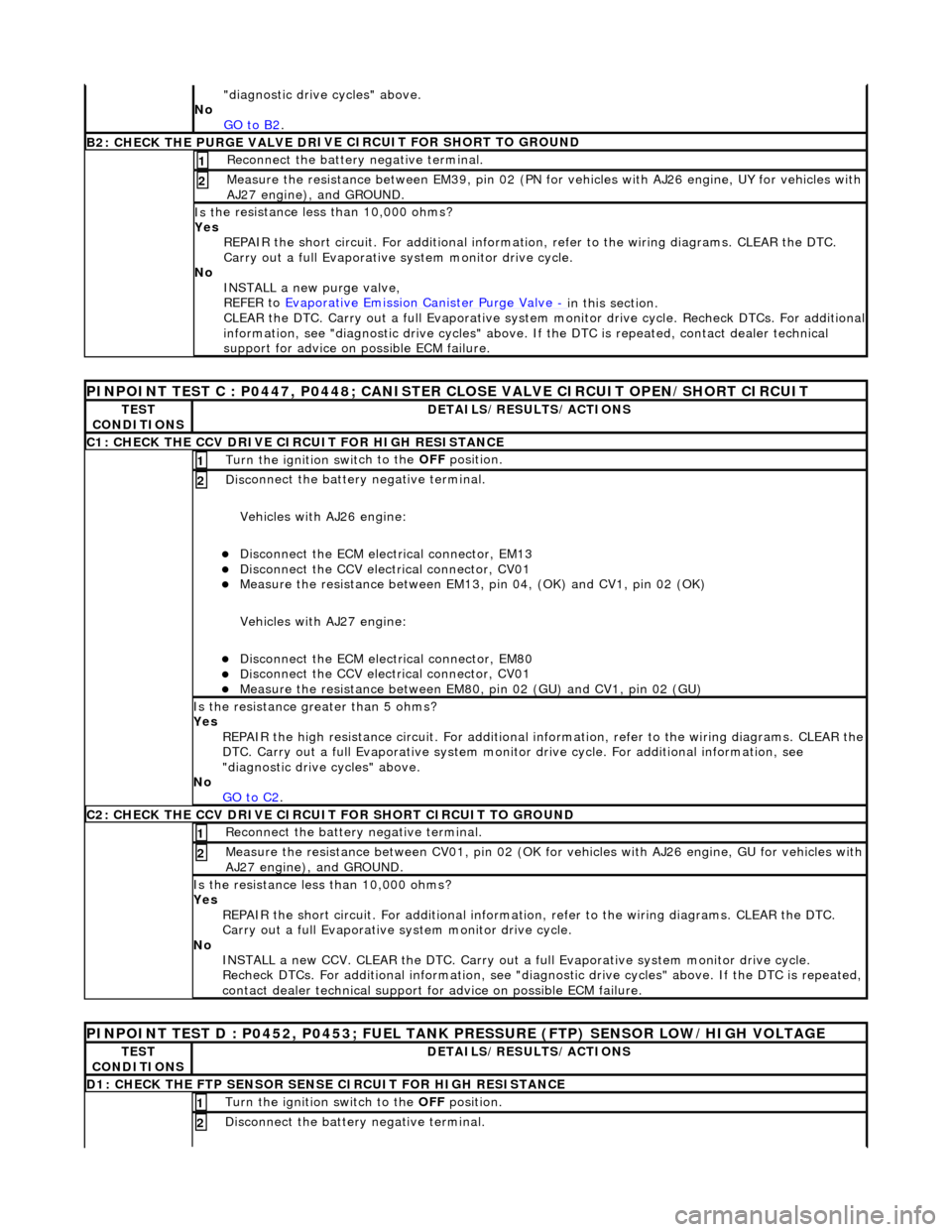

B2: CHECK THE PURGE VALVE DR

IV

E CIRCUIT FOR SHORT TO GROUND

Re

connect the battery negative terminal.

1

Meas

ure t

he resistance between EM39, pin 02 (PN for vehicles with AJ26

engine, UY for vehicles with

AJ27 engine), and GROUND.

2

Is t

he resistance less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

Carry out a full Evaporative system monitor drive cycle.

No INSTALL a new purge valve,

REFER to Evaporative Emission Canister Purge Valve

- in thi

s section.

CLEAR the DTC. Carry out a full Evaporative system monitor drive cycle. Recheck DTCs. For additional

information, see "diagnostic drive cycles" above. If the DTC is repeated, contact dealer technical

support for advice on possible ECM failure.

PI

NPOINT TEST C : P0447, P0448; CANISTER CLOSE VALVE CIRCUIT OPEN/SHORT CIRCUIT

TE

S

T

CONDITIONS

D E

TAILS/RESULTS/ACTIONS

C1

: CH

ECK THE CCV DRIVE CIRCUIT FOR HIGH RESISTANCE

Turn the ignition swi

t

ch to the

OFF position.

1

Disc

onnect the battery negative terminal.

Vehicles with AJ26 engine:

Disc onne

ct the ECM electrical connector, EM13

Di

sc

onnect the CCV electrical connector, CV01

Meas

ure t

he resistance between EM13, pi

n 04, (OK) and CV1, pin 02 (OK)

Vehicles with AJ27 engine:

Disc onne

ct the ECM electrical connector, EM80

Di

sc

onnect the CCV electrical connector, CV01

Meas

ure t

he resistance between EM80,

pin 02 (GU) and CV1, pin 02 (GU)

2

Is the res

istance greater than 5 ohms?

Yes REPAIR the high resistance circuit. For additional information, refer to the wiring diagrams. CLEAR the

DTC. Carry out a full Evaporative system monitor drive cycle. For additional information, see

"diagnostic drive cycles" above.

No GO to C2

.

C2: CH

ECK THE CCV DRIVE CIRCUI

T FOR SHORT CIRCUIT TO GROUND

Re

connect the battery negative terminal.

1

Meas

ure t

he resistance between CV01,

pin 02 (OK for vehicles with AJ26 engine, GU for vehicles with

AJ27 engine), and GROUND.

2

Is t

he resistance less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

Carry out a full Evaporative system monitor drive cycle.

No INSTALL a new CCV. CLEAR the DTC. Carry out a fu ll Evaporative system monitor drive cycle.

Recheck DTCs. For additional inform ation, see "diagnostic drive cycles" above. If the DTC is repeated,

contact dealer technical support for advice on possible ECM failure.

P INPOINT TES

T D : P0452, P0453; FUEL TANK

PRESSURE (FTP) SENSOR LOW/HIGH VOLTAGE

TES

T

CONDITIONS

DE

TAILS/RESULTS/ACTIONS

D

1:

CHECK THE FTP SENSOR SENSE CIRCUIT FOR HIGH RESISTANCE

Turn the ignition swi

t

ch to the OFF

position.

1

Disc

onnect the battery negative terminal.

2

Page 1165 of 2490

Vehicles with AJ26 en

gine:

D

isconnect the ECM electrical connector, EM11

Di

sconnect the FTP sensor electrical connector, FP01

Meas

ure the resistance between EM11,

pin 07 (RG) and FP01, pin 02 (RG)

Vehicles with AJ27 engine:

D

isconnect the ECM electrical connector, EM81

Di

sconnect the FTP sensor electrical connector, FP01

Meas

ure the resistance between EM81,

pin 16 (RG) and FP01, pin 02 (RG)

Is th

e resistance greater than 5 ohms?

Yes REPAIR the high resistance circuit. For additional information, refer to the wiring diagrams. CLEAR the

DTC. Carry out a full Evaporative system monitor drive cycle. For additional information, see

"diagnostic drive cycles" above.

No GO to D2

.

D2: CHECK

THE FTP SENSOR SENSE CI

RCUIT FOR SHORT CIRCUIT TO GROUND

R

econnect the battery negative terminal.

1

Meas

ure the resistance between

FP01, pin 07 (RG) and GROUND.

2

Is

the resistance less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

Carry out a full Evaporative system monitor drive cycle.

No GO to D4

.

D3: CHECK

THE FTP SENSOR SENSE CIRCUI

T FOR SHORT CIRCUIT TO HIGH VOLTAGE

Turn the ignition swi

tch to the ON

position.

1

Measure the

voltage between FP

01, pin 02 (RG) and GROUND.

2

Is th

e voltage greater than 3 volts?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

Carry out a full Evaporative system monitor drive cycle.

No GO to D4

.

D

4: CHECK THE FTP SENSOR SIGNAL GROUND CIRCUIT FOR HIGH RESISTANCE

Di

sconnect the battery negative terminal.

Vehicles with AJ26 engine:

D

isconnect the ECM electrical connector, EM10

Meas

ure the resistance between EM11, pin 12 (BG) and FP01, pin 01 (BG)

Meas

ure the resistance between EM10, pin 20 (BG) and FP01, pin 01 (BG)

Vehicles with AJ27 engine:

Re

connect the ECM electrical connector, EM81

D

isconnect the ECM electrical connector, EM82

D

isconnect the ECM electrical connector, EM83

Meas

ure the resistance between EM82, pin 07 (BG) and FP01, pin 01 (BG)

Meas

ure the resistance between EM83, pin 13 (BG) and FP01, pin 01 (BG)

1

Is either resi

stance

greater than 5 ohms?

Yes REPAIR the high resistance circui t. This circuit includes harness splice, EMS02. For additional

information, refer to the wiring diagrams. CLEAR the DTC. Carry out a full Evaporative system

monitor drive cycle. For additional informat ion, see "diagnostic drive cycles" above.

No GO to D5

.

D5:

CHECK THE FTP SENSOR SIGNAL GROUND

CIRCUIT FOR SHORT CIRCUIT TO GROUND

R

econnect the battery negative terminal.

1

Meas

ure the resistance between

FP01, pin 01 (BG) and GROUND.

2

Is

the resistance less than 10,000 ohms?

Page 1166 of 2490

Yes

R

EPAIR the short circuit. For addi

tional information, refer to the wiring diagrams. CLEAR the DTC.

Carry out a full Evaporative system monitor drive cycle.

No GO to D6

.

D6: CHECK

THE FTP SENSOR POWER SU

PPLY CIRCUIT FOR HIGH RESISTANCE

Disc

onnect the battery negative terminal.

Vehicles with AJ26 engine:

Measure t

he resistance between EM11,

pin 08 (UW) and FP01, pin 03 (UW)

Measure t

he resistance between EM10,

pin 21 (UW) and FP01, pin 03 (UW)

Vehicles with AJ27 engine:

Meas ure t

he resistance between EM82,

pin 01 (OY) and FP01, pin 03 (OY)

Measure t

he resistance between EM83,

pin 05 (OY) and FP01, pin 03 (OY)

1

Is either resistance greater

than 5 ohms?

Yes

REPAIR the high resistance circui t. This circuit includes harness splice, EMS01. For additional

information, refer to the wiring diagrams. CLEAR the DTC. Carry out a full Evaporative system

monitor drive cycle. For additional informat ion, see "diagnostic drive cycles" above.

No GO to D7

.

D7: CHECK

THE FTP SENSOR WIRING

FOR SHORT CIRCUIT TO EACH OTHER

Measure

the resistance between FP01, pins 01 (BG) and 02 (RG).

1

M

e

asure the resistance between FP01, pins 02 (RG) and 03 (UW).

2

Is either resi

stance le

ss than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

Carry out a full Evaporative system monitor drive cycle.

No INSTALL a new FTP sensor. CLEAR the DTC. Carry out a full Evaporative system monitor drive cycle.

For additional information, see "diagnostic drive cycles" above.

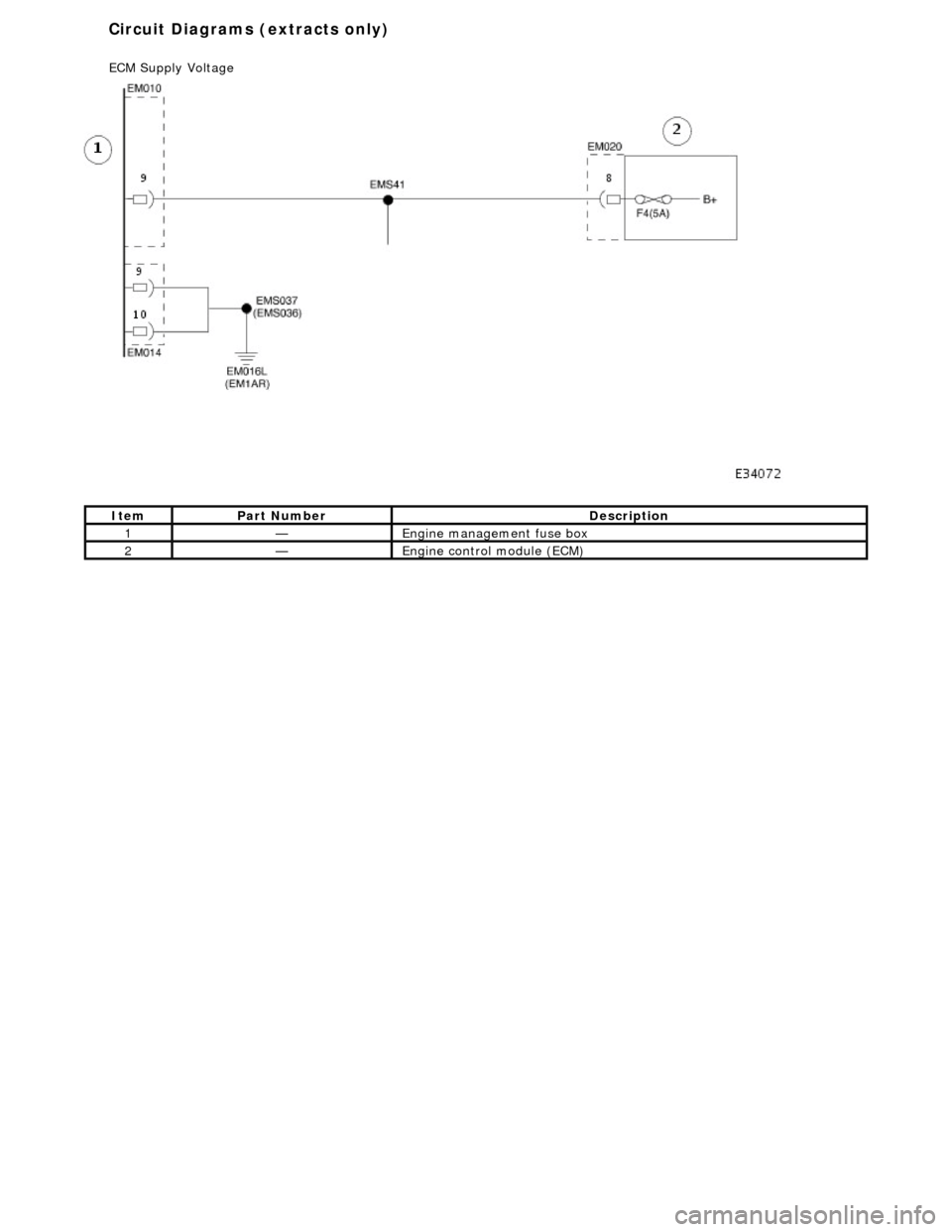

Page 1182 of 2490

Ite

m

Par

t

Number

De

scr

iption

1—Engine

management fuse box

2—Engine

control module (E

CM)

Circuit Diagrams (extracts only)

ECM Su

pply Voltage