heater JAGUAR X308 1998 2.G Owner's Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1197 of 2490

пЃ¬Exhaus

t leak

пЃ¬Low e

xhaust temperature

пЃ¬Cat

alyst monitor sensor failure

P0151Le

ft-hand H02S sense circuit low

voltage

пЃ¬H02

S disconnected

пЃ¬H0

2S to ECM wiring open circuit

пЃ¬H0

2S short circuit to ground

пЃ¬H0

2S failure

F

or left-hand HO2S circuit tests, GO

to Pinpoint Test H.

.

P0152Le

ft-hand H02S sense circuit high

voltage

пЃ¬H02

S sensing circuit short circuit to

high voltage

пЃ¬H0

2S ground braided shield open

circuit

пЃ¬H0

2S failure

F

or left-hand HO2S circuit tests,GO to

Pinpoint Test H.

.

P0153Le

ft-hand H02S sense circuit slow

response

пЃ¬Engine

misfire

пЃ¬H02

S disconnected

пЃ¬H0

2S mechanical damage

пЃ¬H0

2S to ECM wiring intermittent

open circuit

пЃ¬H02

S sensing circuit short circuit to

high voltage

пЃ¬H0

2S short circuit to ground

пЃ¬H0

2S ground braided shield open

circuit

пЃ¬H0

2S heater circuit fault

пЃ¬Exhaus

t leak

пЃ¬Low e

xhaust temperature

пЃ¬Injector fl

ow partially blocked

пЃ¬Catal

yst efficiency decrease

пЃ¬H0

2S failure

Chec

k for 'engine misfire detected'

DTCs. For HO2S circ uit tests, GO to

Pinpoint Test H.

. Check for exhaust

leak

s,

REFER to Section 309

-00

Exhaust

Sy

stem

.

Chec

k injectors,

REFER to Section 303

-04

Fuel

Charging and Con

trols

.

P0155Left-hand H02S heater

circuit

malfunction

пЃ¬H02

S disconnected

пЃ¬H0

2S heater power supply open

circuit

пЃ¬H0

2S heater to ECM wiring short

circuit or open circuit

пЃ¬H0

2S heater failure

F

or left-hand HO2S heater circuit

tests,GO to Pinpoint Test I.

.

P0157Le

ft-hand catalyst monitor sensor

sense circuit low voltage

пЃ¬Catal

yst monitor sensor

disconnected

пЃ¬Catal

yst monitor sensor to ECM

wiring open circuit

пЃ¬Catal

yst monitor sensor short

circuit to ground

пЃ¬Cat

alyst monitor sensor failure

F

or left-hand catalyst monitor sensor

circuit tests,GO to Pinpoint Test J.

.

P0158Le

ft-hand catalyst monitor sensor

sense circuit high voltage

пЃ¬Catal

yst monitor sensor sensing

circuit short circuit to high voltage

пЃ¬Catalyst

monitor sensor ground

braided shield open circuit

пЃ¬Cat

alyst monitor sensor failure

F

or left-hand catalyst monitor sensor

circuit tests,GO to Pinpoint Test J.

.

P0160Le

ft-hand catalyst monitor sensor

sense circuit no activity

пЃ¬Catal

yst monitor sensor

disconnected

пЃ¬Catal

yst monitor sensor

mechanical damage

пЃ¬Catal

yst monitor sensor to ECM

wiring open circuit

пЃ¬Catal

yst monitor sensor sensing

circuit short circuit to high voltage

пЃ¬Catal

yst monitor sensor short

circuit to ground

пЃ¬Catalyst

monitor sensor ground

braided shield open circuit

пЃ¬Exhaus

t leak

пЃ¬Low e

xhaust temperature

пЃ¬Cat

alyst monitor sensor failure

F

or left-hand catalyst monitor sensor

circuit tests,GO to Pinpoint Test J.

.

Check f

or exhaust leaks,

REFER to Section 309

-00

Exhaust

Sy

stem

.

P0171Right

-hand cylinders combustion

too lean

пЃ¬Air

intake leak between MAF senso

r and th

rottle

пЃ¬F

uel filter system blockage

пЃ¬F

uel injector blockage

пЃ¬F

uel pressure regulator failure (low

fuel pressure)

пЃ¬Low f

uel pump output

Check ai

r intake system for leaks,

REFER to Section 303

-1

2 Intake Air

Distribu

tion and Filtering

.

Check the fuel fi

lter,

REFER to Section 310

-01

Fuel Tank

and Lines.

Chec

k the fuel injectors and fuel

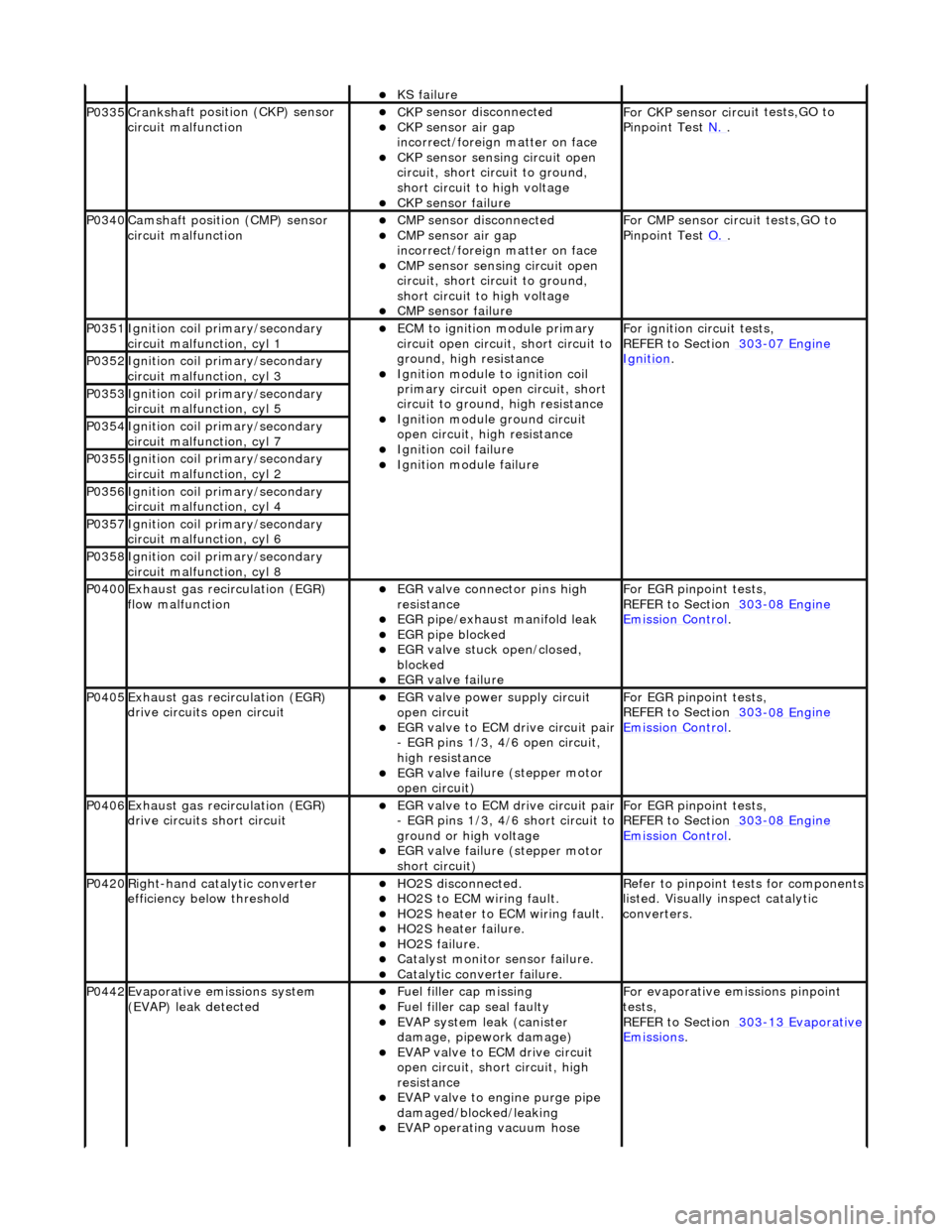

Page 1200 of 2490

пЃ¬KS fail

ure

P0335Cranksh

a

ft positi

on (CKP) sensor

circuit malfunction

пЃ¬CK P

sensor disconnected

пЃ¬CKP sensor air gap

i

n

correct/foreign matter on face

пЃ¬CKP sensor sen

s

ing circuit open

circuit, short circuit to ground,

short circuit to high voltage

пЃ¬CKP s e

nsor failure

F

or CKP sensor circ ui

t tests,GO to

Pinpoint Test N.

.

P0340Camshaft position

(CMP) sensor

circuit malfunction

пЃ¬CM P

sensor disconnected

пЃ¬CMP sensor air gap

i

n

correct/foreign matter on face

пЃ¬CMP sensor sen

s

ing circuit open

circuit, short circuit to ground,

short circuit to high voltage

пЃ¬CMP s e

nsor failure

F

or CMP sensor circ ui

t tests,GO to

Pinpoint Test O.

.

P0351Igniti

on coil primary/secondary

circuit malfunction, cyl 1

пЃ¬ECM to ignit

ion module primary

circuit open circuit, short circuit to

ground, high resistance

пЃ¬Igniti

on module to ignition coil

primary circuit open circuit, short

circuit to ground, high resistance

пЃ¬Ignition modu le

ground circuit

open circuit, hi gh resistance

пЃ¬Ignition coil fail

ure

пЃ¬Ignition modul

e

failure

F

o

r ignition circuit tests,

REFER to Section 303

-07 En

gine

Ignition. P0352Ignit

i

on coil primary/secondary

circuit malfunction, cyl 3

P0353Ignit i

on coil primary/secondary

circuit malfunction, cyl 5

P0354Ignit i

on coil primary/secondary

circuit malfunction, cyl 7

P0355Ignit i

on coil primary/secondary

circuit malfunction, cyl 2

P0356Ignit i

on coil primary/secondary

circuit malfunction, cyl 4

P0357Ignit i

on coil primary/secondary

circuit malfunction, cyl 6

P0358Ignit i

on coil primary/secondary

circuit malfunction, cyl 8

P0400Exhaus t gas

recirculation (EGR)

flow malfunction

пЃ¬EGR valve c

onnector pins high

resistance

пЃ¬EGR pipe/exhaust manifol

d leak

пЃ¬EGR pipe blocke

d

пЃ¬EGR valve st

uck open/closed,

blocked

пЃ¬EGR valve fai

lure

For EGR

pinpoint t

ests,

REFER to Section 303

-08 En

gine

Emission Control.

P0405Exhaus

t gas

recirculation (EGR)

drive circuits open circuit

пЃ¬EGR valve power supply circuit

o p

en circuit

пЃ¬EGR valve t

o

ECM drive circuit pair

- EGR pins 1/3, 4/6 open circuit,

high resistance

пЃ¬EGR val v

e failure (stepper motor

open circuit)

For EGR pinpoint t

ests,

REFER to Section 303

-08 En

gine

Emissi

on Control.

P0406Exhaus t gas

recirculation (EGR)

drive circuits short circuit

пЃ¬EGR valve t o

ECM drive circuit pair

- EGR pins 1/3, 4/6 short circuit to

ground or high voltage

пЃ¬EGR val v

e failure (stepper motor

short circuit)

For EGR pinpoint t

ests,

REFER to Section 303

-08 En

gine

Emissi

on Control.

P0420Right-

hand catalytic converter

efficiency below threshold

пЃ¬HO2S di

sconnected.

пЃ¬HO2

S

to ECM wiring fault.

пЃ¬HO2

S

heater to ECM wiring fault.

пЃ¬HO2

S

heater failure.

пЃ¬HO2

S

failure.

пЃ¬Cat

a

lyst monitor sensor failure.

пЃ¬Catal

y

tic converter failure.

R

e

fer to pinpoint tests for components

listed. Visually inspect catalytic

converters.

P0442Evaporati v

e emissions system

(EVAP) leak detected

пЃ¬Fue l

filler cap missing

пЃ¬Fu

el filler cap seal faulty

пЃ¬EVAP system

leak (can

ister

damage, pipework damage)

пЃ¬EVAP v a

lve to ECM drive circuit

open circuit, short circuit, high

resistance

пЃ¬EVAP valve to engine pu rge pipe

damaged/blocked/leaking

пЃ¬EVAP ope r

ating vacuum hose

F

or evaporati

ve emissions pinpoint

tests,

REFER to Section 303

-1 3

Evaporative

Emissi

ons

.

Page 1211 of 2490

Is

the resistance less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to E4

.

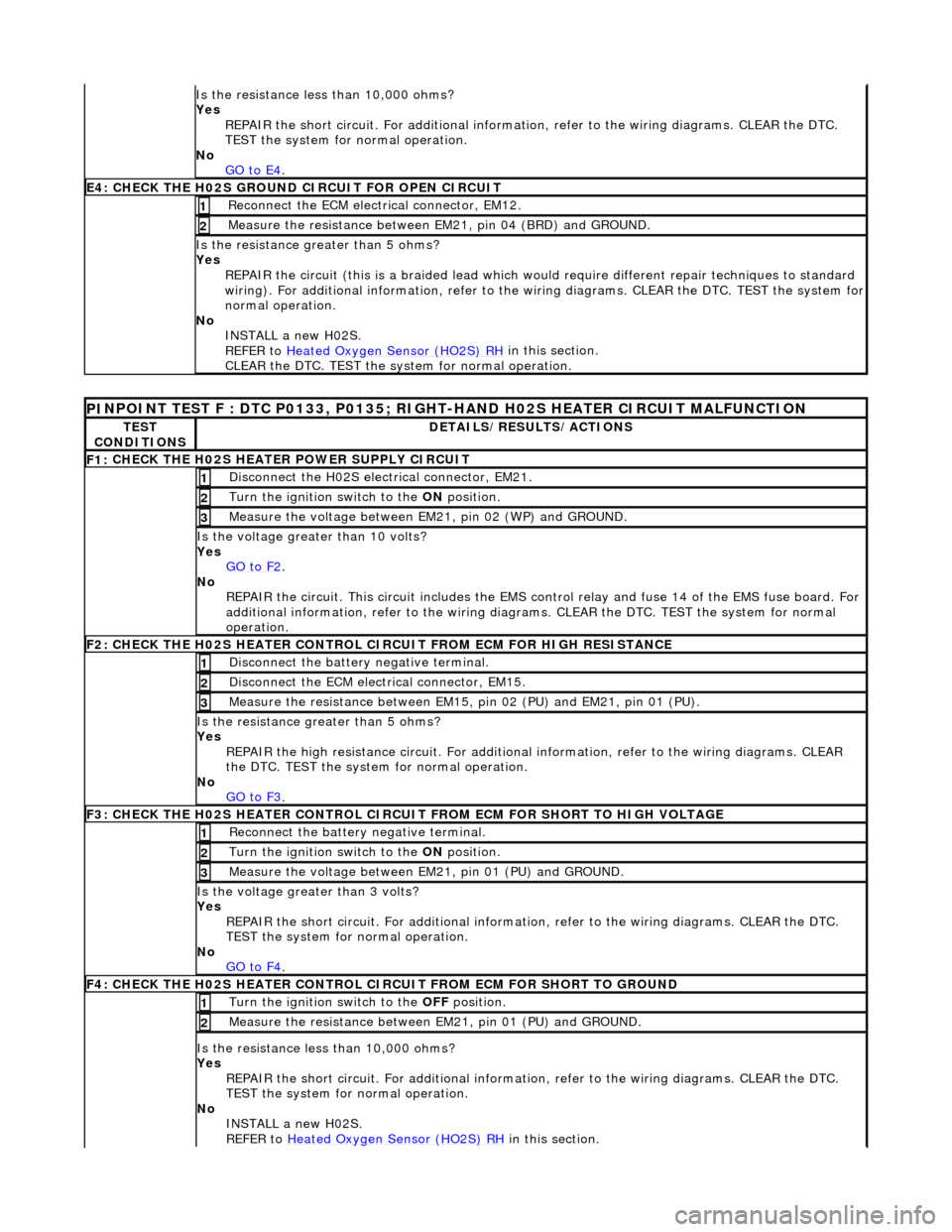

E4

: CHECK THE H02S GROUND

CIRCUIT FOR OPEN CIRCUIT

Re

connect the ECM electrical connector, EM12.

1

Meas

ure the resistance between EM21, pin 04 (BRD) and GROUND.

2

Is th

e resistance greater than 5 ohms?

Yes

REPAIR the circuit (this is a braide d lead which would require different repair techniques to standard

wiring). For additional information, refer to the wiring diagrams. CL EAR the DTC. TEST the system for

normal operation.

No INSTALL a new H02S.

REFER to Heated Oxygen Sensor (HO2S) RH

in this section.

CLEAR the DTC. TEST the syst em for normal operation.

PI

NPOINT TEST F : DTC P0133, P0135; RIGHT-HAND H02S HEATER CIRCUIT MALFUNCTION

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

F1:

CHECK THE H02S HEATER POWER SUPPLY CIRCUIT

D

isconnect the H02S electrical connector, EM21.

1

Turn the ignition swi

tch to the ON

position.

2

Meas

ure the voltage between EM21, pin 02 (WP) and GROUND.

3

Is the vol

tage greater than 10 volts?

Yes GO to F2

.

No

REPAIR the circuit. This circuit in cludes the EMS control relay and fu se 14 of the EMS fuse board. For

additional information, refer to the wiring diagrams. CLEAR the DT C. TEST the system for normal

operation.

F2: CHECK THE H02

S HEATER CONTROL CI

RCUIT FROM ECM FOR HIGH RESISTANCE

Di

sconnect the battery negative terminal.

1

D

isconnect the ECM electrical connector, EM15.

2

Me

asure the resistance between EM15, pin 02 (PU) and EM21, pin 01 (PU).

3

Is th

e resistance greater than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No GO to F3

.

F3: CHECK THE H02

S HEATER CONTROL CIRCUI

T FROM ECM FOR SHORT TO HIGH VOLTAGE

R

econnect the battery negative terminal.

1

Turn the ignition swi

tch to the ON

position.

2

Meas

ure the voltage between EM21, pin 01 (PU) and GROUND.

3

Is th

e voltage greater than 3 volts?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to F4

.

F4: CHECK THE H02

S HEATER CONTROL CI

RCUIT FROM ECM FOR SHORT TO GROUND

Turn the ignition swi

tch to the OFF

position.

1

Meas

ure the resistance between EM21, pin 01 (PU) and GROUND.

2

Is

the resistance less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No INSTALL a new H02S.

REFER to Heated Oxygen Sensor (HO2S) RH

in this section.

Page 1213 of 2490

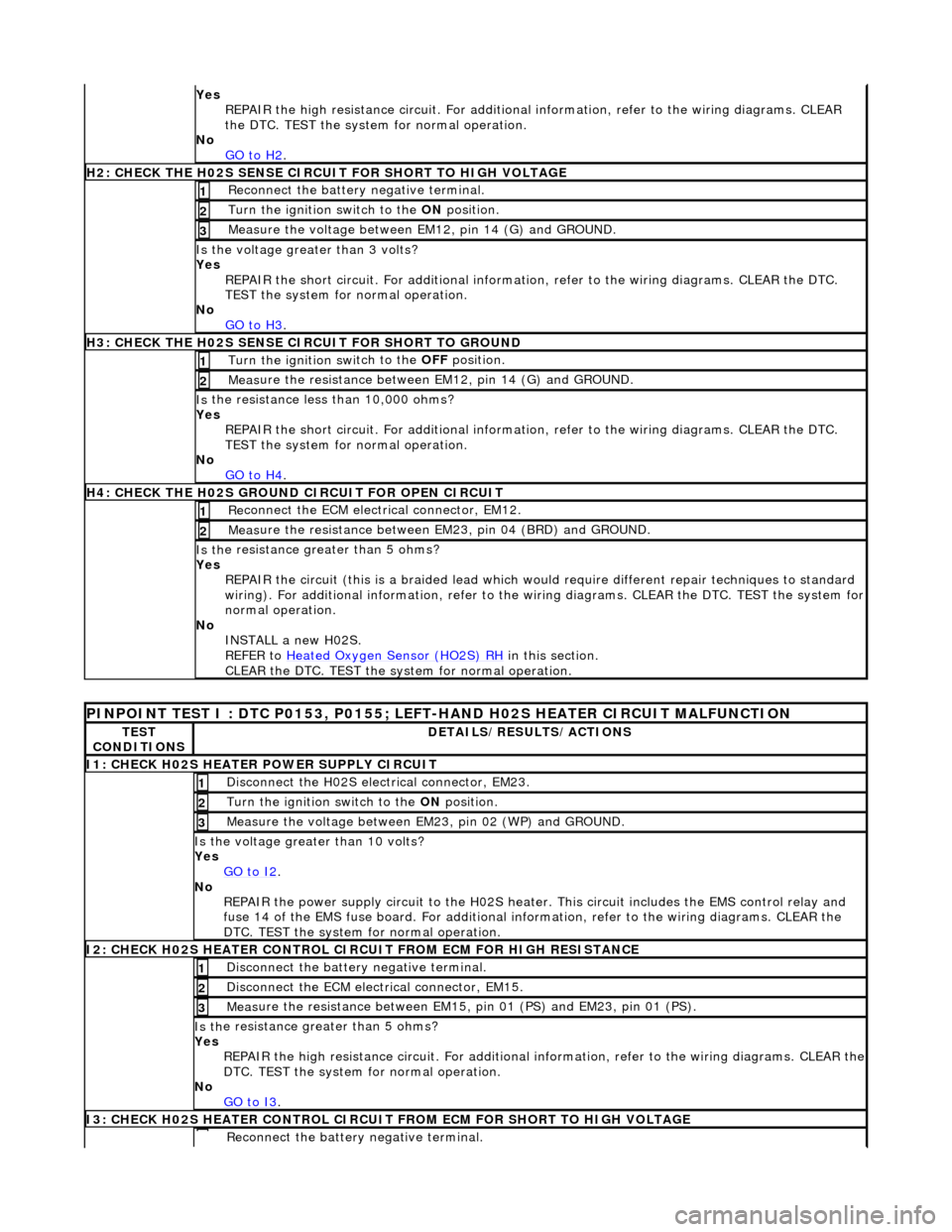

Yes

REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No GO to H2

.

H

2: CHECK THE H02S SENSE CIRCUIT FOR SHORT TO HIGH VOLTAGE

R

econnect the battery negative terminal.

1

Turn the ignition swi

tch to the ON

position.

2

M

easure the voltage between EM12, pin 14 (G) and GROUND.

3

Is th

e voltage greater than 3 volts?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to H3

.

H

3: CHECK THE H02S SENSE CIRCUIT FOR SHORT TO GROUND

Turn the ignition swi

tch to the OFF

position.

1

Meas

ure the resistance between EM12, pin 14 (G) and GROUND.

2

Is

the resistance less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to H4

.

H4:

CHECK THE H02S GROUND CIRCUIT FOR OPEN CIRCUIT

Re

connect the ECM electrical connector, EM12.

1

Meas

ure the resistance between EM23, pin 04 (BRD) and GROUND.

2

Is th

e resistance greater than 5 ohms?

Yes REPAIR the circuit (this is a braide d lead which would require different repair techniques to standard

wiring). For additional information, refer to the wiring diagrams. CL EAR the DTC. TEST the system for

normal operation.

No INSTALL a new H02S.

REFER to Heated Oxygen Sensor (HO2S) RH

in this section.

CLEAR the DTC. TEST the syst em for normal operation.

P

INPOINT TEST I : DTC P0153, P0155; LEFT-HAND H02S HEATER CIRCUIT MALFUNCTION

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

I

1: CHECK H02S HEATER POWER SUPPLY CIRCUIT

D

isconnect the H02S electrical connector, EM23.

1

Turn the ignition swi

tch to the

ON position.

2

Meas

ure the voltage between EM23, pin 02 (WP) and GROUND.

3

Is the vol

tage greater than 10 volts?

Yes GO to I2

.

No

REPAIR the power supply circuit to the H02S heater. This circuit includes the EMS control relay and

fuse 14 of the EMS fuse board. For additional info rmation, refer to the wiring diagrams. CLEAR the

DTC. TEST the system for normal operation.

I

2: CHECK H02S HEATER CONTROL CIRC

UIT FROM ECM FOR HIGH RESISTANCE

Di

sconnect the battery negative terminal.

1

D

isconnect the ECM electrical connector, EM15.

2

Meas

ure the resistance between EM15,

pin 01 (PS) and EM23, pin 01 (PS).

3

Is th

e resistance greater than 5 ohms?

Yes REPAIR the high resistance circuit. For additional information, refer to the wiring diagrams. CLEAR the

DTC. TEST the system for normal operation.

No GO to I3

.

I

3: CHECK H02S HEATER CONTROL CIRCUIT

FROM ECM FOR SHORT TO HIGH VOLTAGE

R

econnect the battery negative terminal.

Page 1214 of 2490

1

Turn the ignition swit

ch to the

ON position.

2

Meas ure t

he voltage between EM23, pin 01 (PS) and GROUND.

3

Is th

e volt

age greater than 3 volts?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to I4

.

I4

: CHECK H02S HEATER CONTROL CIRCUIT FROM ECM FOR SHORT TO GROUND

Turn the ignition swit

ch to the

OFF position.

1

Measure t

he resistance between EM23, pin 01 (PS) and GROUND.

2

Is t

he resistance less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No INSTALL a new H02S.

REFER to Heated Oxygen Sensor (HO2S) LH

in this

section.

CLEAR the DTC. TEST the system for normal operation.

P INPOINT TES

T J : DTC P0157, P0158; LEFT-H

AND CATALYST MONITOR SENSOR LOW/HIGH

VOLTAGE, NO ACTIVITY

TE S

T

CONDITIONS

D E

TAILS/RESULTS/ACTIONS

J

1

: CHECK THE CATALYST MONITOR SENSOR

SENSE CIRCUIT FOR HIGH RESISTANCE

Disc

onnect the battery negative terminal.

1

Di

sc

onnect the catalyst monitor sensor electrical connector, EM24.

2

Disc

onne

ct the ECM electrical connector, EM12.

3

Meas

ure t

he resistance between EM24, pin 02 (N) and EM12, pin 16 (N).

4

Is th

e res

istance greater than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No GO to J2

.

J2

: CHECK THE CATALYST MONITOR SENSOR SENSE CIRCUIT FOR SHORT TO HIGH VOLTAGE

R

e

connect the battery negative terminal.

1

Turn the ignition swi

t

ch to the ON

position.

2

Measure t

he voltage between EM12, pin 16 (N) and GROUND.

3

Is th

e volt

age greater than 3 volts?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to J3

.

J3

: CHECK THE CATALYST MONITOR SENSOR

SENSE CIRCUIT FOR SHORT TO GROUND

Turn the ignition swit

ch to the OFF

position.

1

Measure t

he resistance between EM12, pin 16 (N) and GROUND.

2

Is t

he resistance less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to J4

.

J4

: CHECK THE CATALYST MONITOR SENSOR

GROUND CIRCUIT FOR OPEN CIRCUIT

Reconn

ect the ECM electrical connector, EM12.

1

Meas

ure t

he resistance between EM24, pin 01 (BRD) and GROUND.

2

Is th

e res

istance greater than 5 ohms?

Yes REPAIR the circuit (this is a braide d lead which would require different repair techniques to standard

wiring). For additional information, refer to the wiring diagrams. CL EAR the DTC. TEST the system for

Page 1530 of 2490

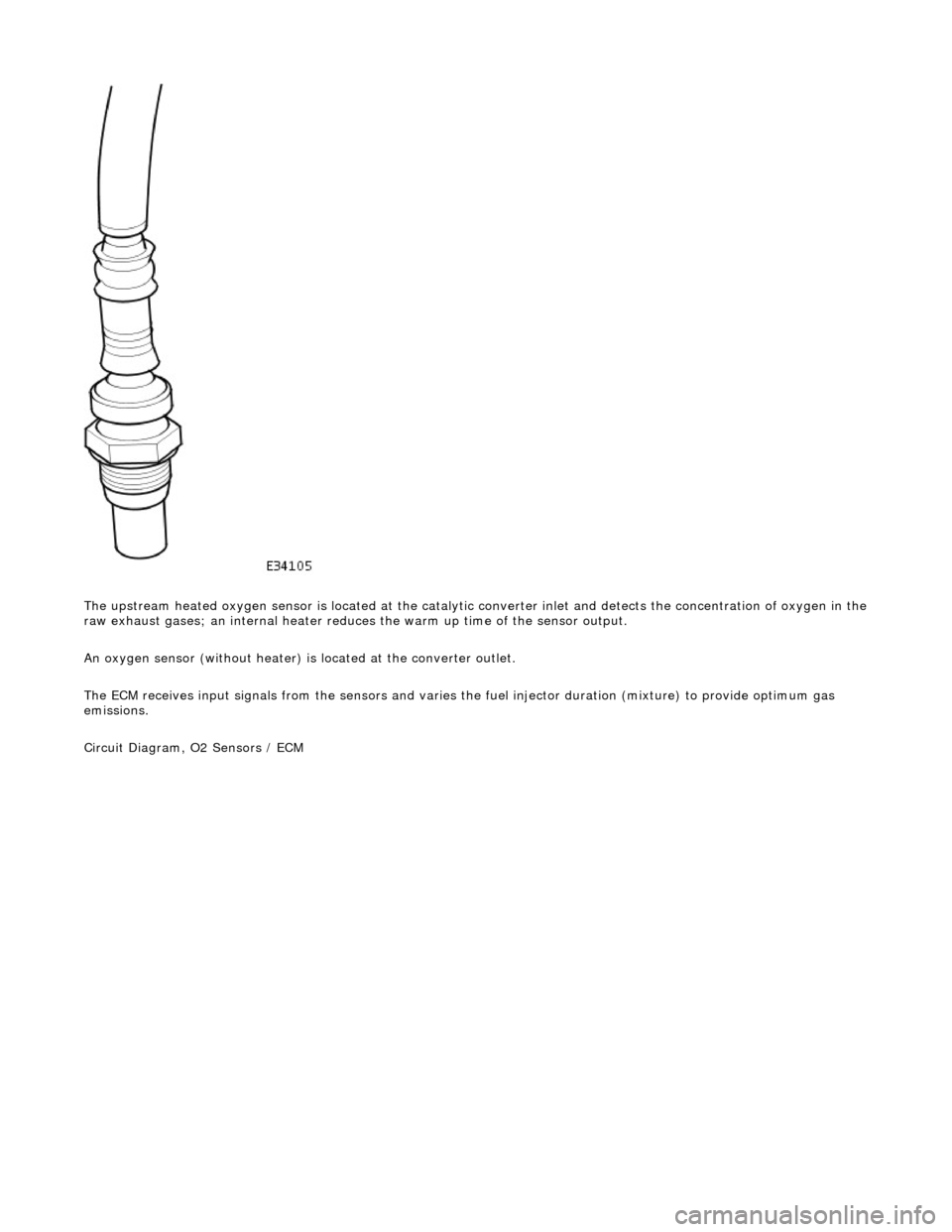

The upstream heated oxygen sensor is located at the catalytic converter inlet and detects the concentration of oxygen in the

raw exhaust gases; an internal heater reduces the warm up time of the sensor output.

An oxygen sensor (without heater) is located at the converter outlet.

The ECM receives input signals from the se nsors and varies the fuel injector duration (mixture) to provide optimum gas

emissions.

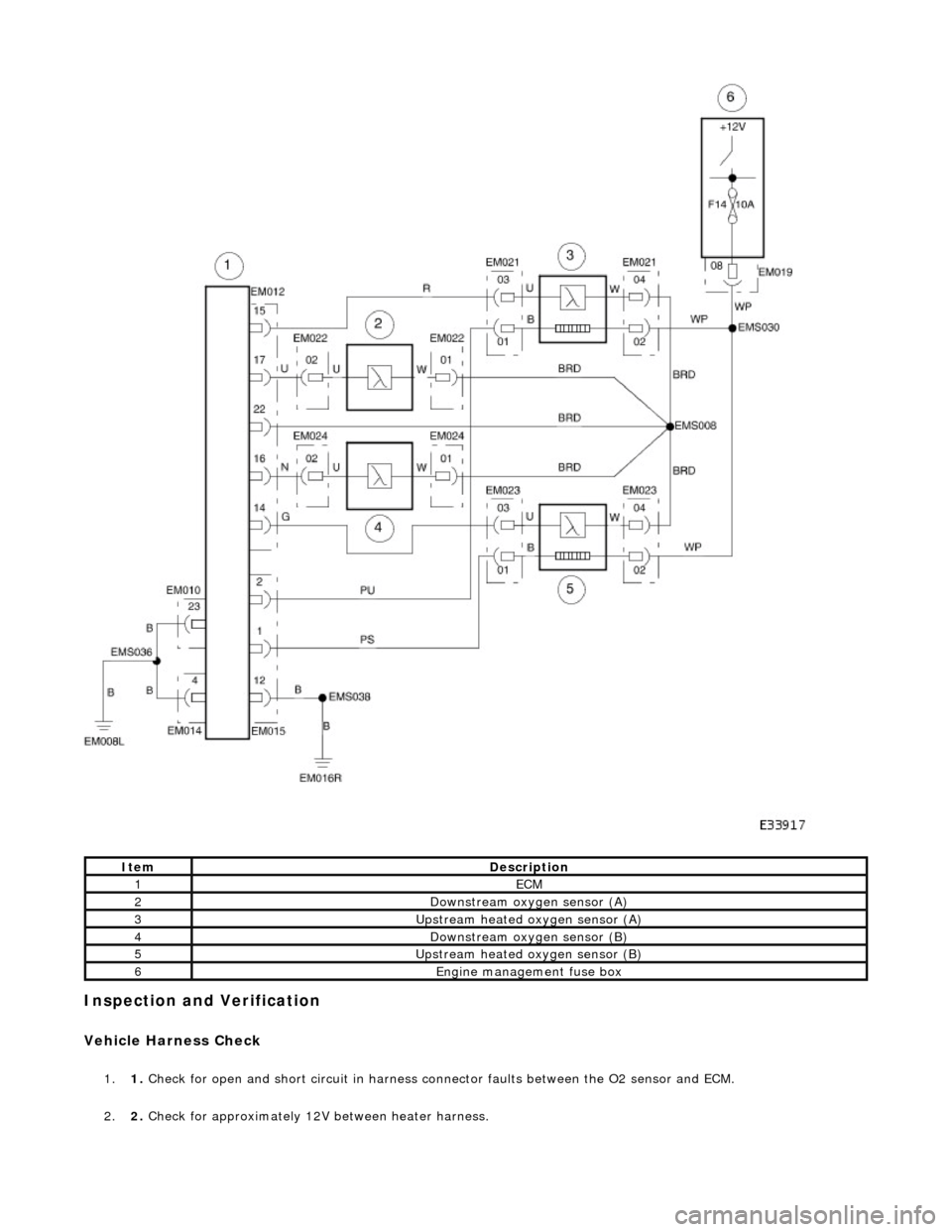

Circuit Diagram, O2 Sensors / ECM

Page 1531 of 2490

Inspection and Verification

Vehicle Harness Check

1.1. Check for open and short circuit in harness conn ector faults between the O2 sensor and ECM.

2. 2. Check for approximately 12V between heater harness.

ItemDescription

1ECM

2Downstream oxygen sensor (A)

3Upstream heated oxygen sensor (A)

4Downstream oxygen sensor (B)

5Upstream heated oxygen sensor (B)

6Engine management fuse box

Page 1532 of 2490

Heater Resistance Check

1.1. Verify that the resistance between the heater term inals is between 4OHM and 10OHM at -20В°C to 100В°C.

Performance Check

1.1. Run the engine at 2500 RPM for two minutes, to heat up the O2 sensor.

2. 2. Check the voltage of the sensor output: Alternates between less than 0.4V at feed back engine conditions and in

excess of 0.5V, see graph.

These voltages are for reference only.

3. 3. Check that cycle of the upstream se nsor output is in accordance with the appropriate pinpoint test.

4. 4. Check that cycle of the downstream sensor output is in accordance with the appropriate pinpoint test.

Page 1533 of 2490

Exhaust System - Exhaust System

Diagnosis and Testing

Symptom Chart

Symptom Chart

Special Tool(s)

Digital multimeter

Generic scantool

SymptomPossible SourcesAction

DTC P0420 Catalyst system efficiency below

threshold (Bank 1)Catalyst failure

Upstream O2 sensor failure

Downstream O2 sensor failure

O2 sensor heater failure

Associated harness / connector failure

*

*

*

*

*See DTC P0137, P0138

and P0140

*

DTC P0430 Catalyst system efficiency below

threshold (Bank 2)Catalyst failure

Upstream O2 sensor failure

Downstream O2 sensor failure

O2 sensor heater failure

Associated harness / connector failure

*

*

*

*

*See DTC P0157, P0158

and P0160

*

DTC P0131 O2 sensor circuit low voltage (Bank 1

sensor 1)O2 sensor failure

Sensor ground fault

Harness failure

Connector pin(s) bent, loose or corroded

*

*

*

*GO to Pinpoint Test A

*

DTC P0132 O2 sensor circuit high voltage (Bank

1 sensor 1)O2 sensor failure to B+

Sensor ground fault

Harness failure

Connector pin(s) bent or tracking

between connections. O2 sensor failure

*

*

*

*

*GO to Pinpoint Test A

*

DTC P0133 O2 sensor circuit slow response

(Bank 1 sensor 1)O2 sensor heater failure / out of spec

Sensor ground fault

Harness failure

Connector pin(s) bent or tracking

between connections. Low exhaust temperature

O2 sensor failure

*

*

*

*

*

*GO to Pinpoint Test B

*

DTC P0135 O2 sensor heater circuit malfunction

(Bank 1 sensor 1)O2 sensor failure

Harness failure

Connector pin(s) bent or tracking

between connections. ECM failure

*

*

*

*GO to Pinpoint Test A

*

DTC P0137 O2 sensor circuit low voltage (Bank 1

sensor 2)O2 sensor failure

Sensor ground fault

Harness failure

Connector pin(s) bent, loose or corroded

*

*

*

*GO to Pinpoint Test C

*

DTC P0138 O2 sensor circuit high voltage (Bank

1 sensor 2)O2 sensor failure to B+

Sensor ground fault

Harness failure

Connector pin(s) bent or tracking

*

*

*

*GO to Pinpoint Test C

*

Page 1534 of 2490

Pinpoint test A: P0131, P0132, P0135

between connections. ECM failure

*

DTC P0140 O2 sensor circuit no activity detected

(Bank 1 sensor 2)O2 sensor failure / out of spec

Sensor ground fault

Harness failure

Connector pin(s) bent or tracking

between connections. Low exhaust temperature

*

*

*

*

*GO to Pinpoint Test D

*

DTC P0420 Catalyst system efficiency below

threshold (bank 1)Downstream O2 sensor failure

Catalyst failure

Catalyst low temperature caused by

water splash

*

*

*GO to Pinpoint Test C

GO to Pinpoint Test D

*

*

DTC P0151 O2 sensor circuit low voltage (Bank 2

sensor 1)O2 sensor failure

Sensor ground fault

Harness failure

Connector pin(s) bent, loose or corroded

*

*

*

*GO to Pinpoint Test E

*

DTC P0152 O2 sensor circuit high voltage (Bank

2 sensor 1)O2 sensor failure to B+

Sensor ground fault

Harness failure

Connector pin(s) bent or tracking

between connections. O2 sensor failure

*

*

*

*

*GO to Pinpoint Test E

*

DTC P0153 O2 sensor circuit slow response

(Bank 2 sensor 1)O2 sensor heater failure / out of spec

Sensor ground fault

Harness failure

Connector pin(s) bent or tracking

between connections. Low exhaust temperature

O2 sensor failure

*

*

*

*

*

*GO to Pinpoint Test F

*

DTC P0155 O2 sensor heater circuit malfunction

(Bank 2 sensor 1)O2 sensor failure

Harness failure

Connector pin(s) bent or tracking

between connections. ECM failure

*

*

*

*GO to Pinpoint Test E

*

DTC P0157 O2 sensor circuit low voltage (Bank 2

sensor 2)O2 sensor failure

Sensor ground fault

Harness failure

Connector pin(s) bent, loose or corroded

*

*

*

*GO to Pinpoint Test G

*

DTC P0158 O2 sensor circuit high voltage (Bank

2 sensor 2)O2 sensor failure to B+

Sensor ground fault

Harness failure

Connector pin(s) bent or tracking

between connections. ECM failure

*

*

*

*

*GO to Pinpoint Test G

*

DTC P0160 O2 sensor circuit no activity detected

(Bank 2 sensor 2)O2 sensor failure / out of spec

Sensor ground fault

Harness failure

Connector pin(s) bent or tracking

between connections. Low exhaust temperature

*

*

*

*

*GO to Pinpoint Test H

*

DTC P0430 Catalyst system efficiency below

threshold (bank 2)Downstream O2 sensor failure

Catalyst failure

Catalyst low temperature caused by

water splash

*

*

*GO to Pinpoint Test G

GO to Pinpoint Test H

*

*

PINPOINT TEST A : P0131, P0132, P0135

TEST CONDITIONSDETAILS/RESULTS/ACTIONS

A1: RETRIEVE DTCS

• NOTE: Battery and or ECM disconnection prior to scanning wi

ll erase all data, ensure that the correct DTC is present.